Ferrite wave-absorbing material with perovskite structure and preparation method of ferrite wave-absorbing material

A technology of perovskite structure and wave absorbing material, applied in the field of wave absorbing material, can solve the problems of performance degradation, interference with normal operation, failure, etc., to achieve less energy required, high product uniformity and purity, and low reflection loss rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

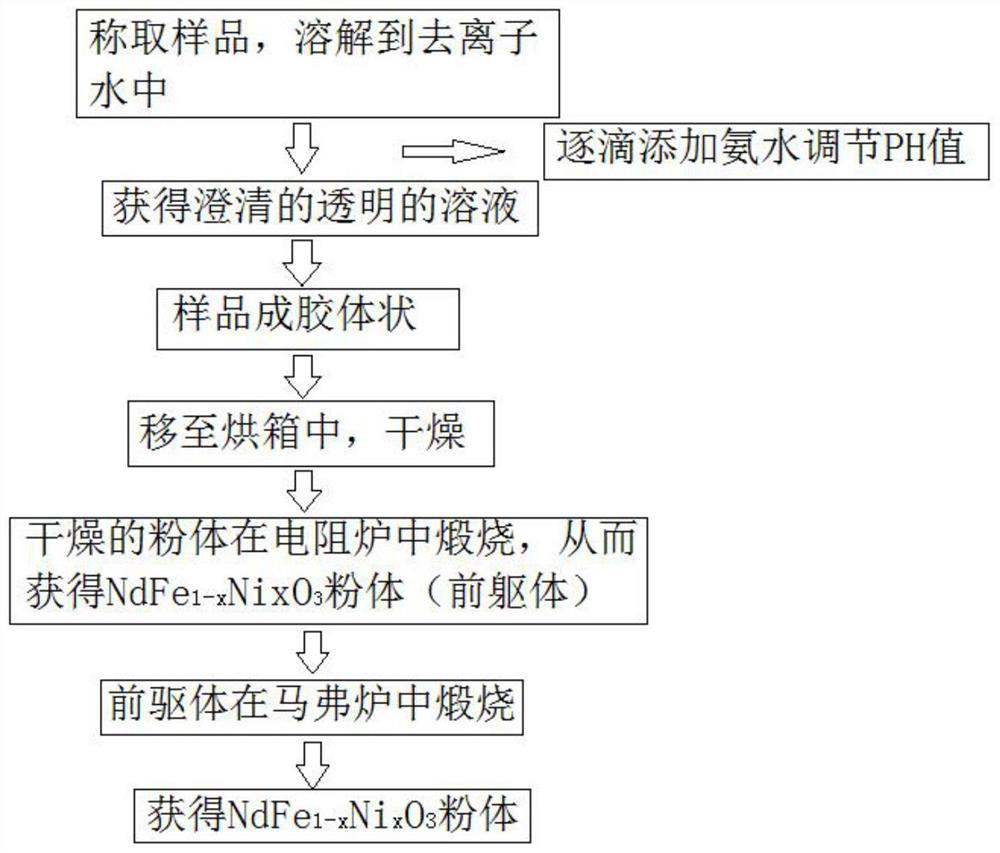

[0042] like figure 1 Shown, the preparation method of the ferrite wave-absorbing material of perovskite structure comprises the following specific steps:

[0043] (1). The analytically pure neodymium nitrate hexahydrate (Nd(NO 3 ) 3 ·6H 2 O), ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) and nickel nitrate hexahydrate (Ni(NO 3 ) 3 ·6H 2 O) as the ion source of Nd, Fe, Ni, weigh the sample according to the stoichiometric ratio of the experimental components, and utilize ultrasonic dispersion, and dissolve the weighed sample into a certain volume of deionized water to obtain a solution.

[0044] (2) Add citric acid monohydrate with a molar ratio of 1:1 to 2:1 to the metal ion in the solution, and adjust the weakly alkaline water environment with a pH of 7.3 to 9.0 by dripping ammonia water.

[0045] (3) Put the prepared solution in a 60-90°C water bath, add a clean and non-polluting magnetic rotor to the solution and stir it with a magnetic stirrer for 2.5-4 hours unt...

Embodiment 1

[0051] 1) Analyzing pure grade neodymium hexahexammonium nitrate (Nd(NO 3 ) 3 ·6H 2 O), ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) as the ion source of Nd and Fe, the 1:1 stoichiometric ratio takes the sample, and utilizes ultrasonic dispersion to dissolve the weighed sample into a certain volume of deionized water to obtain a solution;

[0052] 2) Add citric acid monohydrate with a molar ratio of 1:2 to the metal ion in the solution, and adjust the pH to 7.5 by dripping ammonia water;

[0053] 3) Put the prepared solution in a 60°C water bath, and stir it with a magnetic stirrer for 5 hours until the solution is uniform and becomes a transparent gel;

[0054] 4) placing the wet gel in a drying oven at 90°C for 36 hours to obtain a dry gel;

[0055] 5) Put the obtained xerogel into a crucible, put it in a resistance furnace and pre-fire it at 200°C for 2 hours, remove the organic matter and obtain the precursor powder;

[0056] 6) The prepared precursor powder is g...

Embodiment 2

[0065] 1) Analytical grade neodymium nitrate hexahydrate (Nd(NO 3 ) 3 ·6H 2 O), ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) and hexahydrate and nickel nitrate (Ni(NO 3 ) 3 ·6H 2 O) As the ion source of Nd, Fe, Ni, take NdFe by the stoichiometric ratio of 9:1 0.9 Ni 0.1 o 3 The sample is dispersed by ultrasonic waves, and the weighed sample is dissolved in a certain volume of deionized water to obtain a solution;

[0066] 2) Add citric acid monohydrate with a molar ratio of 1:1.25 to the metal ion in the solution, and adjust the pH to 8 by dripping ammonia water;

[0067] 3) Put the prepared solution in a 70°C water bath, and stir it with a magnetic stirrer for 4 hours until the solution is uniform and becomes a transparent gel;

[0068] 4) Drying the wet gel in a drying oven at 100°C for 32 hours to obtain a dry gel;

[0069] 5) Put the obtained xerogel into a crucible, put it in a resistance furnace and pre-fire it at 250°C for 2 hours, remove the organic matt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com