Rare earth Fe-based electromagnetic shielding material and preparation method thereof

An electromagnetic shielding material, rare earth technology, applied in magnetic materials, analytical materials, material analysis using microwave means, etc., can solve the problems of poor microwave absorption characteristics, high production cost, complex preparation process, etc., and achieve good anti-oxidation ability. and anti-corrosion properties, good microwave absorption properties, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

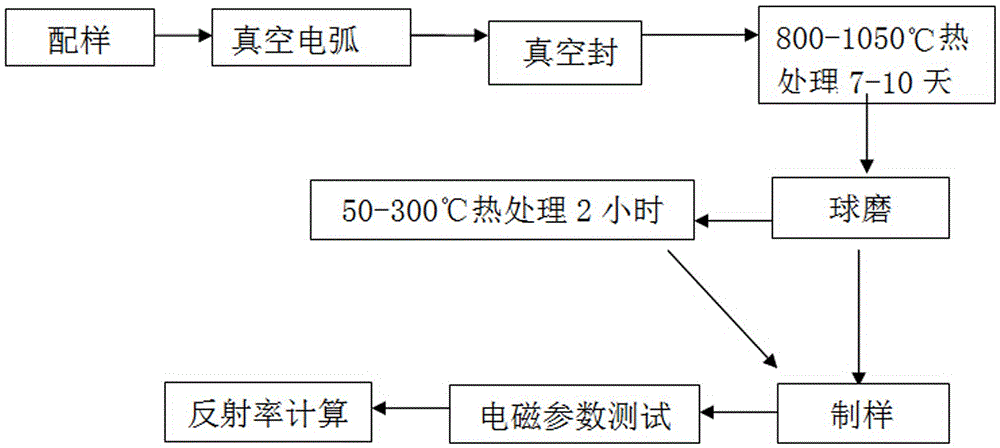

[0044] Such as figure 1 Shown:

[0045] Preparation of Nd 10.53 Fe 89.47 The specific implementation steps of (atomic percentage) are:

[0046] 1) Nd, Fe, and C materials with a purity equal to or greater than 99.90% are dosed according to a stoichiometric ratio of Nd:10.53% Fe:89.47%;

[0047]2) The ingredients in step 1) are alloyed and smelted in a non-consumable vacuum electric arc furnace. In order to ensure the uniformity of smelting, it is necessary to turn over and smelt repeatedly for 2 to 5 times;

[0048] 3) sealing the smelted alloy in a vacuum quartz tube for homogenization heat treatment at 900°C for 10 days;

[0049] 4) performing a quenching process on the homogenized heat-treated alloy in step 3) in an ice-water mixture;

[0050] 5) The quenched alloy is roughly crushed and then ball milled into powder; the mass ratio of zirconia balls and alloy powder in the ball milling process is 20:1, and the ball milling process requires absolute ethanol or gasoline ...

Embodiment 2

[0058] Preparation of Nd 10.53 Fe 84.21 C 5.26 The specific implementation steps of (atomic percentage) are:

[0059] 1) Nd, Fe, and C materials with a purity equal to or greater than 99.90% are dosed according to the stoichiometric ratio of Nd:10.53% Fe:84.21% C:5.26%;

[0060] 2) The ingredients in step 1) are alloyed and smelted in a non-consumable vacuum electric arc furnace. In order to ensure the uniformity of smelting, it is necessary to turn over and smelt repeatedly for 2 to 5 times;

[0061] 3) sealing the smelted alloy in a vacuum quartz tube for homogenization heat treatment at 800°C for 2 days;

[0062] 4) performing a quenching process on the homogenized heat-treated alloy in step 3) in an ice-water mixture;

[0063] 5) The quenched alloy is coarsely crushed and then ball milled into powder; the mass ratio of zirconia balls to alloy powder in the ball milling process is 15:1, and the ball milling process requires absolute ethanol or gasoline as a protective a...

Embodiment 3

[0071] Preparation of Nd 10.53 Fe 81.58 C 7.89 (Atomic percentage) concrete implementation steps:

[0072] 1) Nd, Fe, and C materials with a purity of ≥99.90% are mixed according to the stoichiometric ratio of Nd:10.53% Fe:81.58% C:7.89%;

[0073] 2) The ingredients in step 1) are alloyed and smelted in a non-consumable vacuum electric arc furnace. In order to ensure the uniformity of smelting, it is necessary to turn over and smelt repeatedly for 2 to 5 times;

[0074] 3) sealing the smelted alloy in a vacuum quartz tube for homogenization heat treatment at 1050°C for 15 days;

[0075] 4) performing a quenching process on the homogenized heat-treated alloy in step 3) in liquid nitrogen;

[0076] 5) The quenched alloy is roughly crushed and then ball milled into powder; the mass ratio of zirconia balls and alloy powder in the ball milling process is 20:1, and the ball milling process requires absolute ethanol or gasoline as a protective agent, and a ball mill is set The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

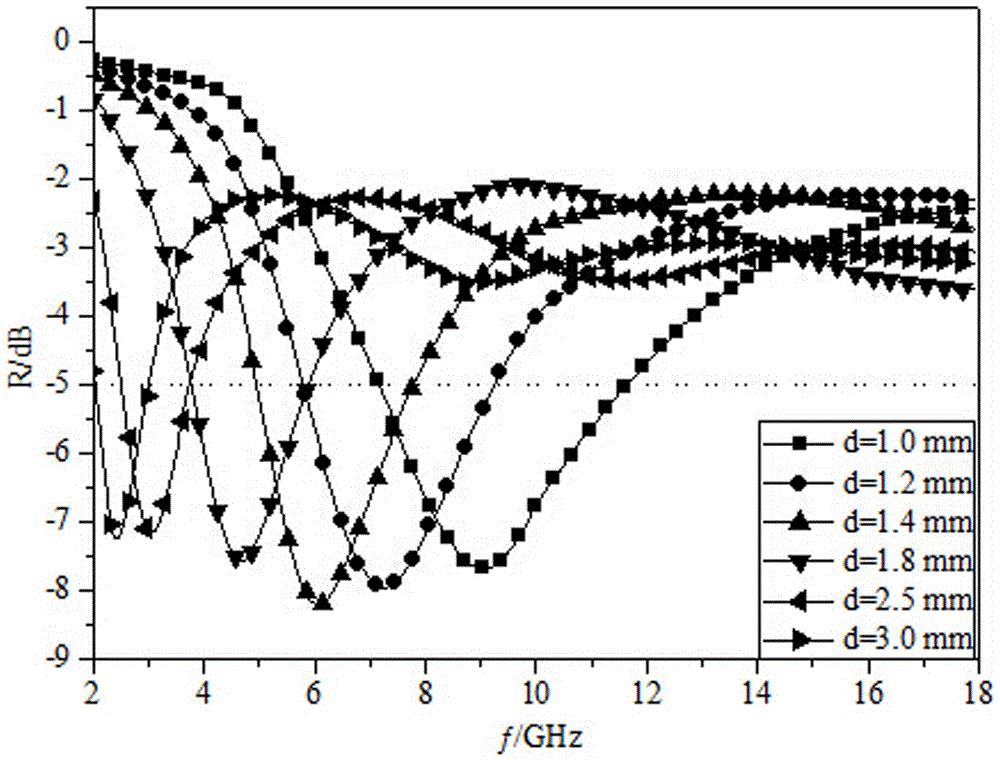

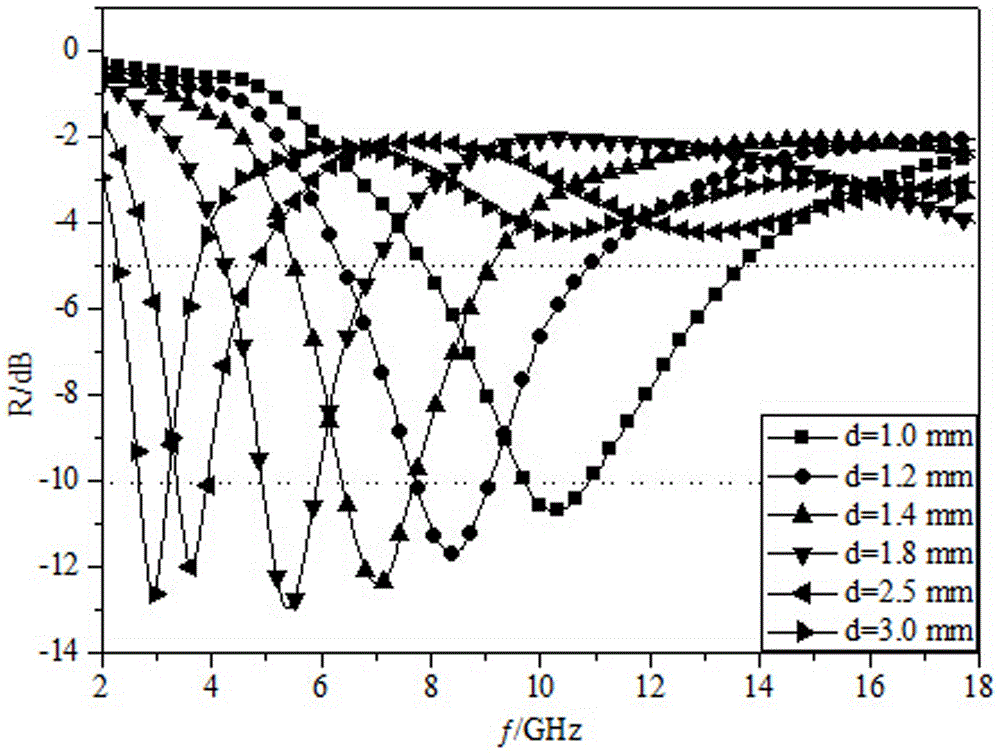

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com