A core-shell heterostructure magnetic fiber and its preparation and application method

A technology of heterostructure and magnetic fibers, which is applied in the field of nanomaterials, can solve the problems of inability to obtain nanofibers, limited wide use, and thick fibers, and achieves good microwave absorption characteristics, adjustable size and composition, dispersibility and uniformity. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Prepare 20 milliliters of 50 millimoles per liter of copper acetate solution (0.2 g) and 60 milliliters of 16.7 millimoles per liter of pyrrole aqueous solution (the ratio of pyrrole to the amount of copper acetate substance is 2:1), and then the prepared pyrrole The aqueous solution and the copper acetate solution were successively transferred to the lining of a 100 ml reaction kettle, and the mixed solution was obtained after magnetic stirring for 60 minutes, and then the lining was put into the reaction kettle and sealed, and reacted in an oven at 140°C for 10 hours; at room temperature Disperse the lower precipitate in ethanol, precipitate and separate, and repeat this several times to obtain a pure precipitate, which is finally dried to obtain polypyrrole / Cu 2 O core-shell heterogeneous fibers.

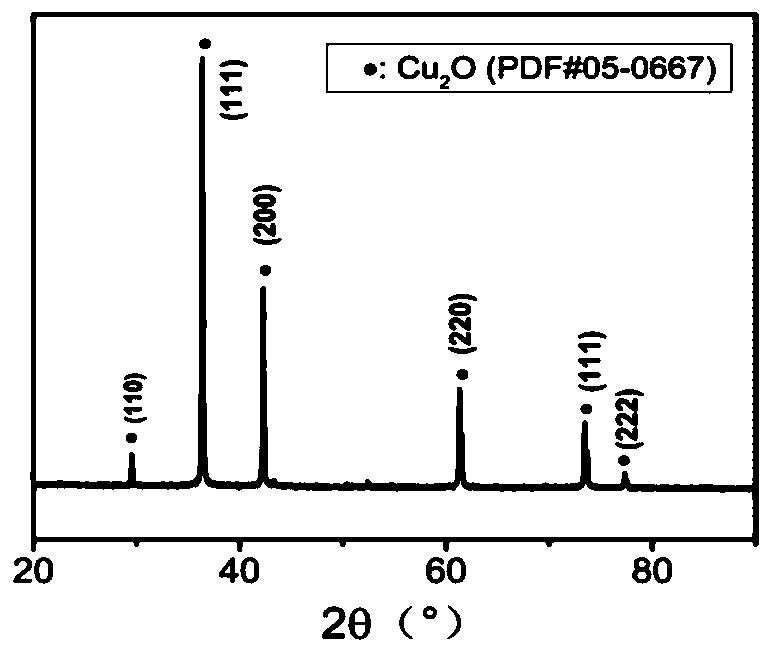

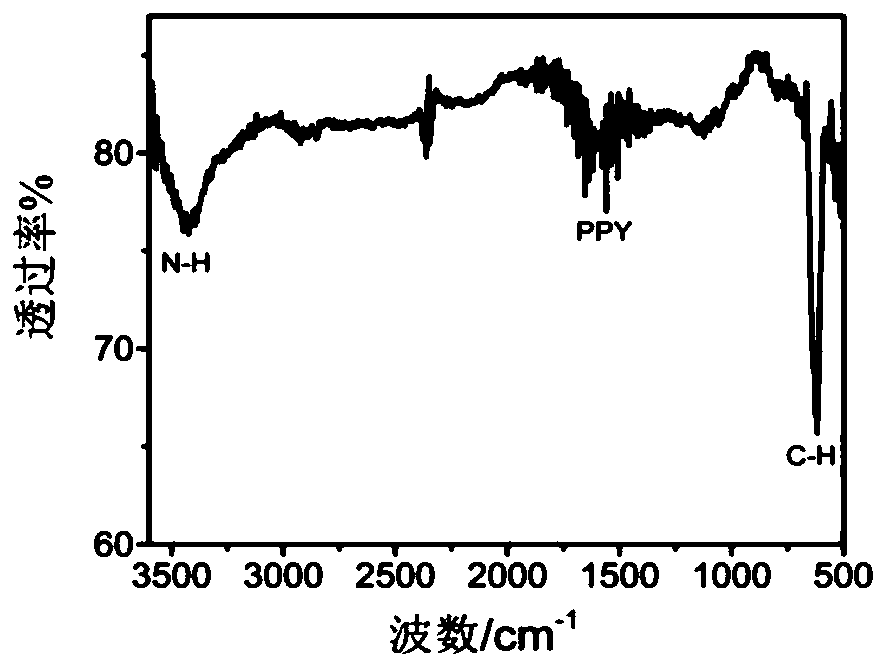

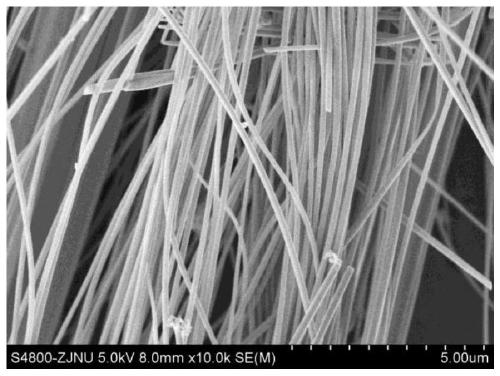

[0033] The resulting product is green, and its phase, structure, morphology, microstructure and selected area electron diffraction spectrum observed under an XRD diffractom...

Embodiment 2

[0035] The steps are the same as in Example 1, but the ratio of the amount of pyrrole to copper acetate is 0.5:1, and the concentration of pyrrole is 8.3 mmol per liter. The morphology of the obtained product observed under the scanning electron microscope is as follows: Figure 6 shown. It can be seen that the product is polypyrrole / Cu with smooth surface and uniform thickness. 2 O core-shell heterogeneous fibers, the diameter of which is 100-200nm. The reaction ratio decreases and the diameter becomes larger.

Embodiment 3

[0037] The steps are the same as in Example 1, but the ratio of pyrrole to copper acetate is 2:0.5, and the copper salt concentration is 25 millimoles per liter. The morphology of the obtained product observed under the scanning electron microscope is as follows: Figure 7 shown. It can be seen that the product is a homogeneous polypyrrole / Cu 2 O core-shell heterogeneous fibers with a diameter of 110-200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com