Chiral planar spiral PPy/Fe3O4 composite broadband microwave absorbent as well as preparation method and application thereof

A microwave absorbing agent, plane spiral technology, applied in chemical instruments and methods, climate sustainability, other chemical processes, etc., can solve the problem that the absorbing performance is difficult to meet the requirements of thin, light, wide, strong, and the shape and size are difficult to control. Problems such as poor experimental repeatability, to achieve the effect of good industrial application potential, excellent microwave absorption characteristics, and low instrument precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A planar helical polypyrrole and a preparation method thereof, specifically comprising the following steps:

[0056] 0.5465g C 19 h 42 BrN(CTAB), dissolved in 150mL deionized water, stirred magnetically at 40°C for 10min, a colorless solution was formed; then the solution was placed in an ice bath and allowed to stand for 1h to crystallize; 1.027g (NH 4 ) 2 S 2 o 8 (APS) was dissolved in 25mL deionized water, and added to the above solution at one time, after an interval of 10s, add 0.5mL C 4 h 5 N(py), stirred for 10 minutes to make the solution evenly mixed, stood at 0-3°C for 24h, washed alternately with absolute ethanol and deionized water, dried in a vacuum freeze-drying oven at -60°C, and finally obtained the plane Helical polypyrrole.

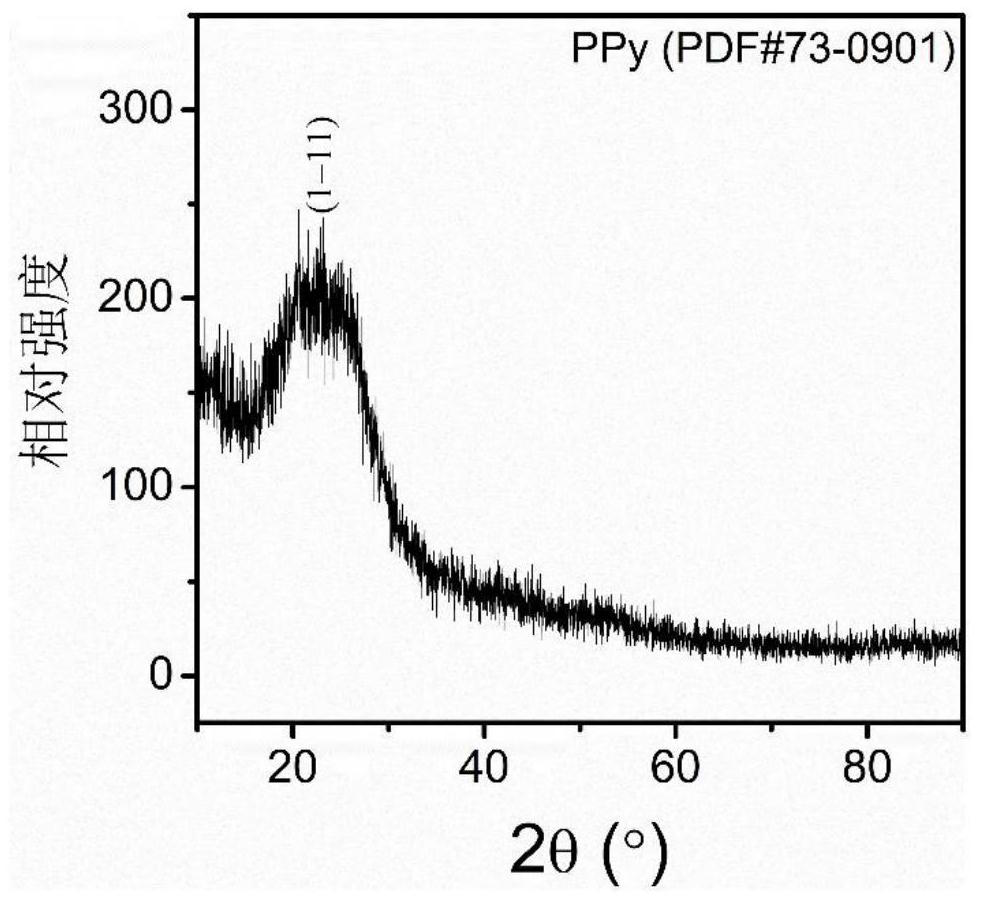

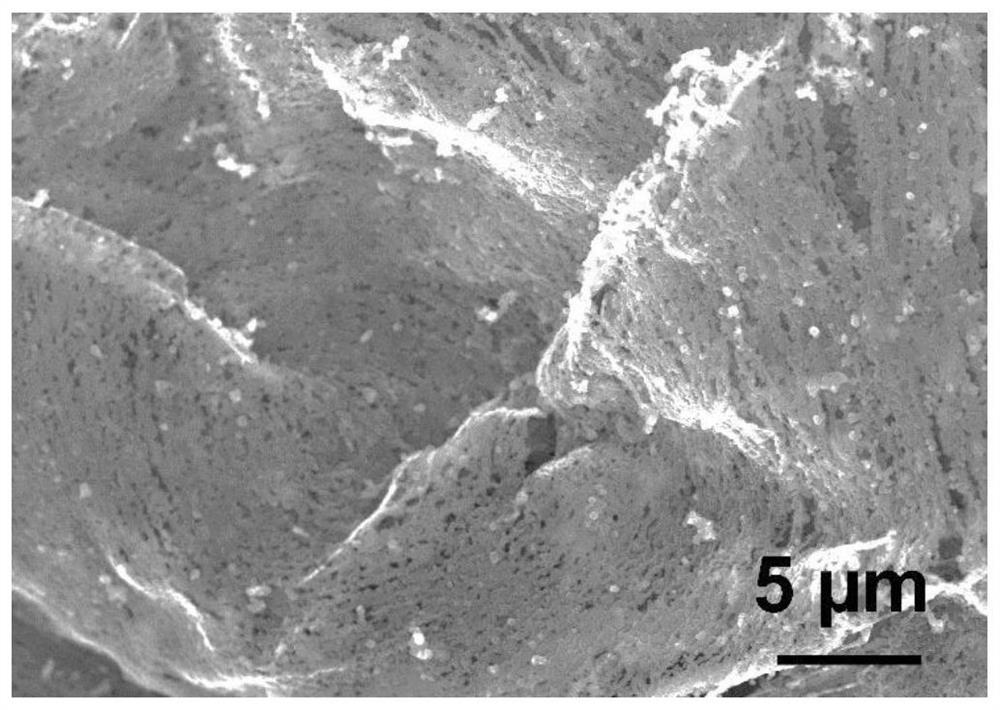

[0057] The phase and morphology of the obtained product measured under XRD and scanning electron microscope are as follows: Figure 1~2 shown. From the above analysis, it can be seen that the product is a single-chain ult...

Embodiment 2

[0060] A Chiral Planar Helical PPy / Fe 3 o 4 Composite broadband microwave absorber and preparation method thereof, composite microwave absorbing material containing same, the specific steps include:

[0061] 1.35g FeCl 3 ·6H 2 O, 12 mL of deionized water, 0.19 mL of PAA, 0.5 g of the PPy precursor prepared in Example 1 were added to 40 mL of ethylene glycol solution, after magnetic stirring for 30 min, 1.6406 g of NaAc was added and stirring continued for 2 h, and then the solution was transferred to a poly Put it in a tetrafluoroethylene liner, put it into a high-temperature oven, react at a high temperature of 200 ° C for 12 hours, cool it naturally to room temperature, wash it alternately with absolute ethanol and deionized water, and dry it in a vacuum freeze-drying oven at -60 ° C to finally obtain the described Growth of Fe on the Surface of Planar Helical Polypyrrole 3 o 4 composite of particles.

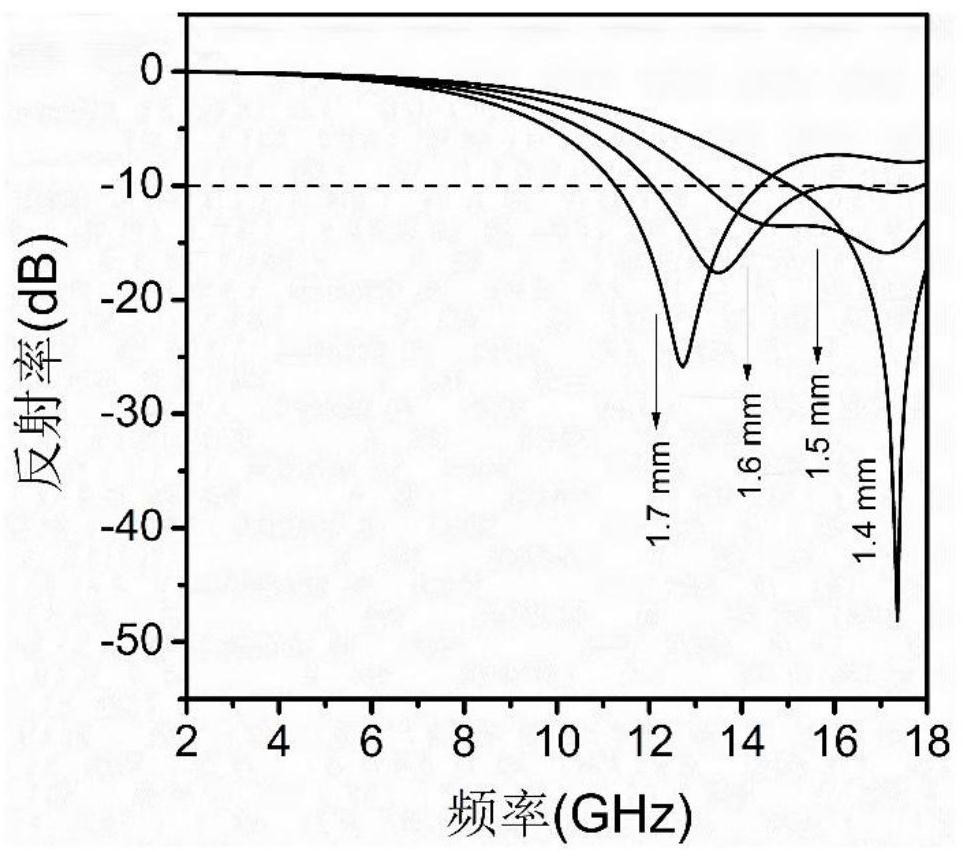

[0062] The phase, composition, electromagnetic properties and morp...

Embodiment 3

[0065] A Chiral Planar Helical PPy / Fe 3 o 4 Composite broadband microwave absorber and preparation method thereof, compared with the preparation steps disclosed in Example 2, the only difference is: Fe 3+ The concentration is 0.128M, and the rest of the preparation steps and process parameters are the same.

[0066] The phase and morphology of the obtained product measured under XRD and scanning electron microscope are as follows: Figure 10-12 shown. Among them, the atomic percentage of Fe and C is 1:6.9.

[0067] It can be seen from the analysis that the content of ferric oxide particles coated on the surface of the product is obviously more than that in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com