Lithium iron phosphate electrode material having three-dimensional hierarchical structure, and preparation method thereof

A hierarchical structure, lithium iron phosphate technology, applied in battery electrodes, structural parts, chemical instruments and methods, etc., can solve the problems of limited material application and difficult to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

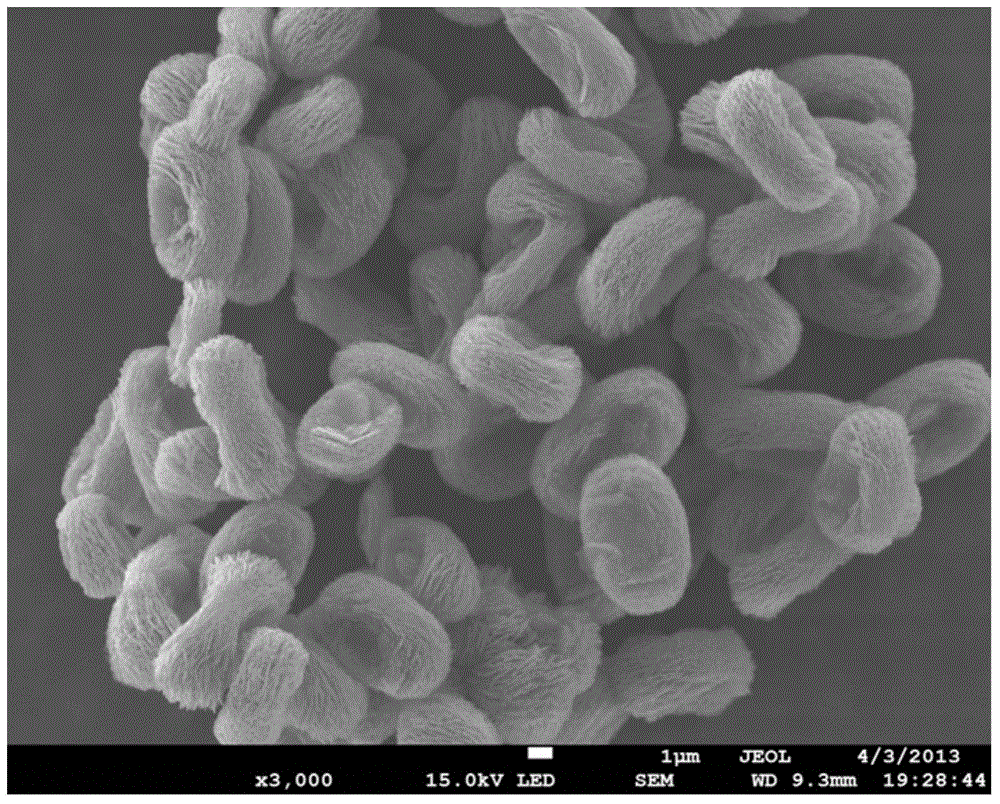

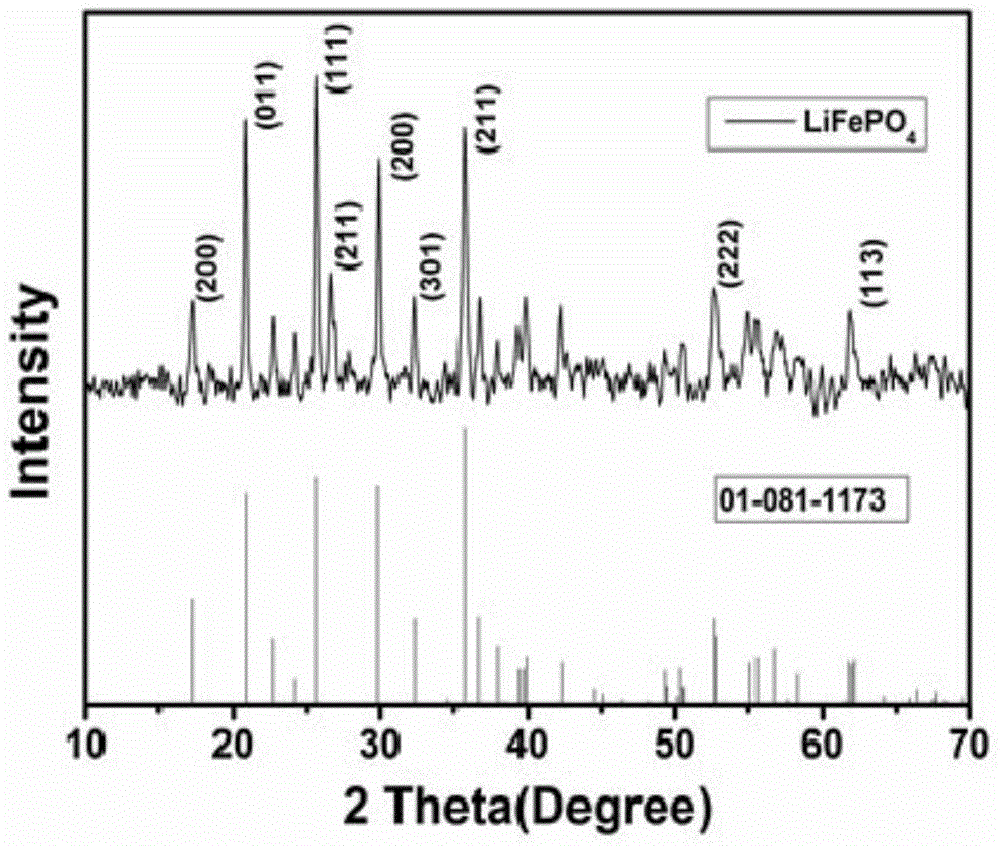

[0047] 2 g polyvinylpyrrolidone K 30 and 0.98 g H 3 PO 4 Add in 15ml ethylene glycol solvent, magnetic stirring is even; Then the Fe(NO of 4.04 grams 3 ) 3 9H 2 O and 0.64 g Li 2 SO 4 ·H 2 O is dispersed in 10ml and 15ml of ethylene glycol, and magnetically stirred evenly; finally, the three solutions are quickly mixed and stirred evenly (at this time, the ion concentrations of phosphorus source compound, iron source compound and lithium source compound are all 0.25mol / L, and the number of moles The ratio is 1:1:1) into a 100ml reactor and reacted at 180°C for 24 hours. The resulting product was washed with absolute ethanol three times and then dried in vacuum at 80°C for 12 hours. Calcined for 10 hours under ambient conditions to obtain lithium iron phosphate with hierarchical structure. A high-magnification scanning electron microscope can clearly observe that the bird's nest-shaped lithium iron phosphate grains are assembled from smaller nanosheets ( figure 1 ), f...

Embodiment 2

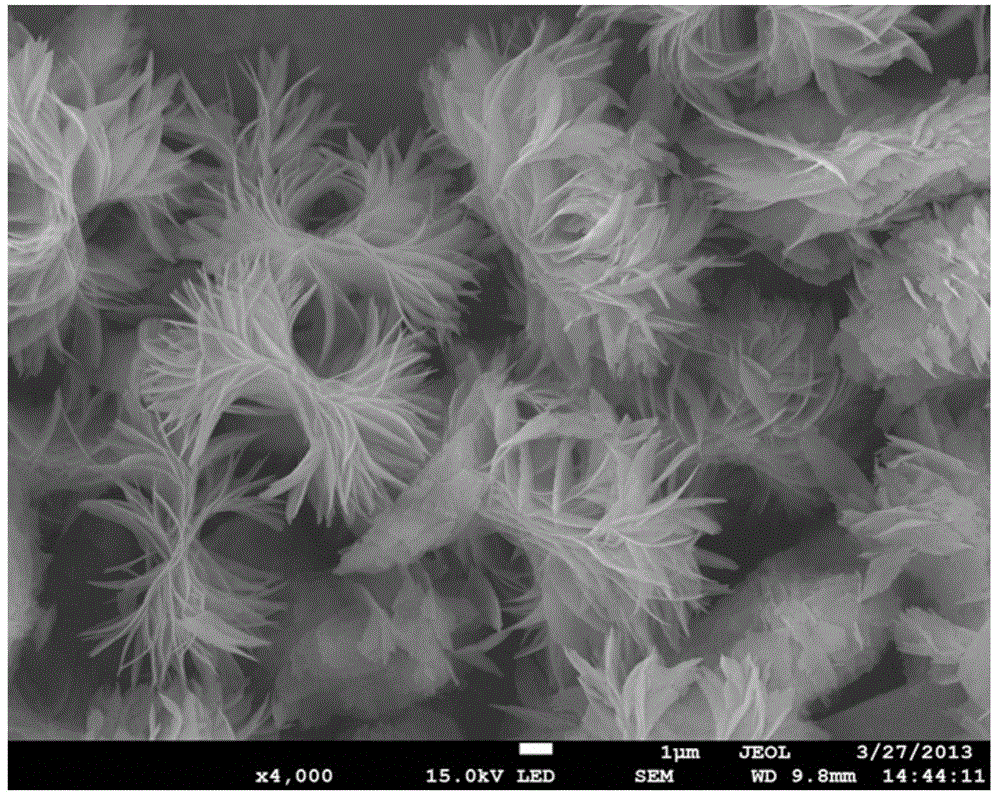

[0049] 2 g polyvinylpyrrolidone K 90 and 0.98 g H 3 PO 4 Add 15ml of ethylene glycol and ethanol mixed solvent (volume ratio is 1:1), magnetically stir evenly; then respectively add 4.04g of Fe(NO 3 ) 3 9H 2 O and 0.64 g Li 2 SO 4 ·H 2 O is dispersed in 10ml and 15ml of mixed solvents, and magnetically stirred evenly; finally, the three solutions are quickly mixed and stirred evenly (at this time, the ion concentrations of the phosphorus source compound, the iron source compound and the lithium source compound are all 0.25mol / L, and the molar ratio 1:1:1) into a 100ml reactor and reacted at 180°C for 24 hours, the resulting product was washed 3 times with absolute ethanol and then vacuum-dried at 100°C for 12 hours, and then placed in a vacuum tube furnace at 700°C under Ar gas environment Calcined for 10 hours at the bottom to obtain lithium iron phosphate with hierarchical structure. The high-magnification scanning electron microscope can clearly observe that the flo...

Embodiment 3

[0051] 1 gram of cetyltrimethylammonium bromide and 2.03 grams of (NH 4 ) 3 PO 4 ·3H 2 O was added to 25ml deionized water and ethanol mixed solvent (the volume ratio of deionized water and ethanol was 1:2), and magnetically stirred evenly; then 2.5 grams of FeAc 2 4H 2 O and 1.69 grams of LiCl were dispersed in 15ml and 20ml mixed solvents, and magnetically stirred evenly; finally, the three solutions were mixed and stirred evenly (at this time, the ion concentrations of the phosphorus source compound, the iron source compound and the lithium source compound were 0.17, 0.17, 0.67mol / L, the molar ratio is 1:1:4) into a 100ml reactor and reacted at 200°C for 36 hours. Vacuum dried for 18 hours, and then in a vacuum tube furnace at 600 °C, N 2 Calcined under air environment for 8 hours to obtain lithium iron phosphate with hierarchical structure. The resulting shuttle-like lithium iron phosphate grains are assembled from finer nanorods to form a hierarchical structure. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com