Magnetic hollow microsphere and preparation method and application thereof

A hollow, magnetic technology, applied in the direction of nanomagnetism, metal processing equipment, nanotechnology for materials and surface science, etc., can solve the problems of unsuitable industrial production and application, strict requirements for instrument accuracy, strong template dependence, etc. problems, to achieve the effect of novel structure and formation mechanism, low requirements for instrument precision, and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A method for preparing magnetic hollow microspheres, specifically comprising the steps of:

[0057] Dissolve 1.065g of stearic acid and 1.05g of hexadecylamine in 70mL of 1,2-propanediol, stir at 75°C for 1h, then add 0.75g of Co(OAc) 2 4H 2 O, continue stirring for 30min to form purple solution A; then 0.375g Cu(OAc) 2 ·H 2 Dissolve O in 10mL 1,2-propanediol, stir at 60°C for 30min to form a blue solution B; then add solution B to solution A, stir for 5min and transfer to a 100mL polytetrafluoroethylene-lined reactor, 200°C Heating and reacting for 15 hours, naturally cooling to room temperature, washing with absolute ethanol three times, drying in a vacuum oven at 60°C, and finally obtaining magnetic hollow microspheres.

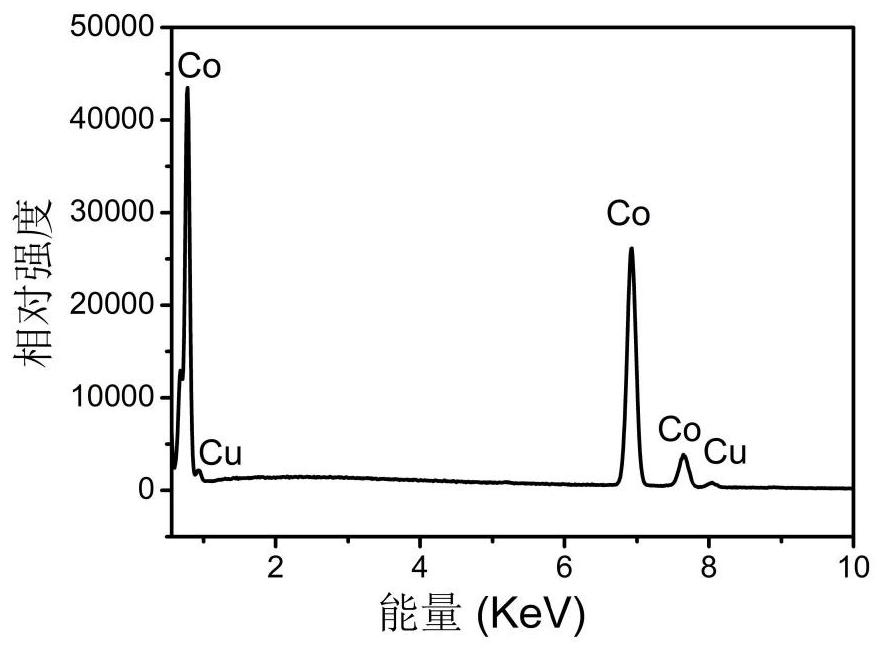

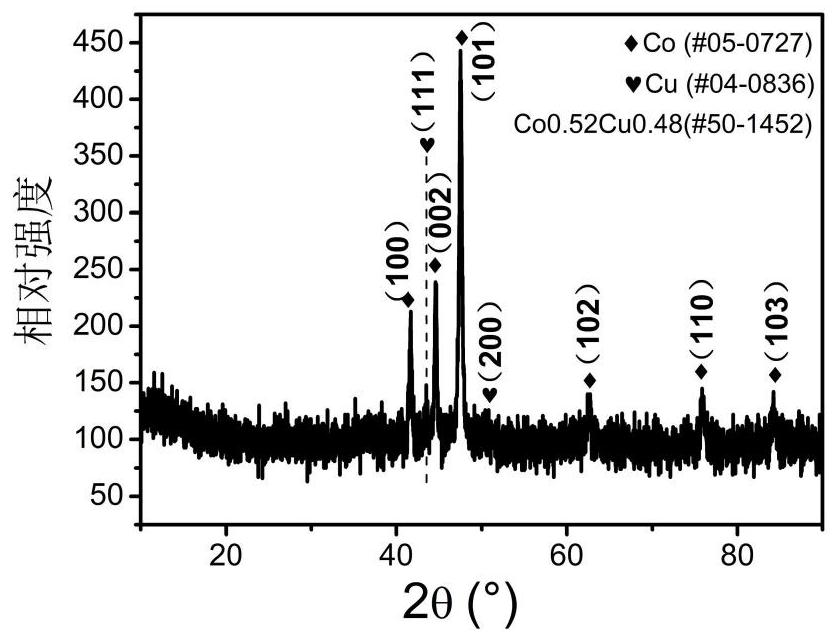

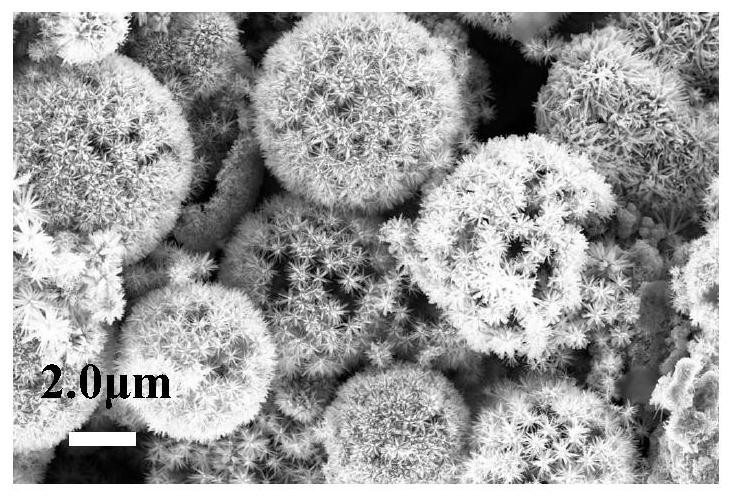

[0058] The composition, phase, morphology and static magnetic properties of the obtained product measured under energy spectrum, XRD, scanning electron microscope and VSM are as follows: Figure 1~4 shown.

[0059] From the above analysis, it c...

Embodiment 2

[0062] Compared with the preparation steps disclosed in Example 1, the only difference is that the Co(OAc) added by the reaction 2 4H 2 O, Cu(OAc) 2 ·H 2 The mass ratio of O is half of that in Example 1, and the rest of the preparation steps and process parameters are the same.

[0063] The composition, phase and morphology of the obtained product measured under energy spectrum, XRD and scanning electron microscope are as follows: Figure 6-8 shown. The analysis shows that the product is a uniform, monodisperse flower-like Co / Cu nanostructure. Wherein, the sashimi length of the flower-like Co / Cu nanostructure is about 67-238 nm, and the atomic ratio of Cu / Ni is 0.023.

Embodiment 3

[0065] Compared with the preparation steps disclosed in Example 1, the only difference is that the Co(OAc) added by the reaction 2 4H 2 O, Cu(OAc) 2 ·H 2 The mass ratio of O is 6 times that in Example 1, and the rest of the preparation steps and process parameters are the same.

[0066] The composition, phase and morphology of the obtained product measured under energy spectrum, XRD and scanning electron microscope are as follows: Figures 9 to 11 shown. Analysis shows that the product is a homogeneous, monodisperse hollow microsphere. Wherein, the diameter of the hollow microsphere is 2.2-4.1 μm, and the Cu / Ni atomic ratio is 0.030.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com