Surface scratch self-repairing plastic flooring

A floor leather, self-healing technology, applied in the field of floor leather, to achieve excellent microwave absorption characteristics, increase the number of hydrogen bonds, and improve the effect of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

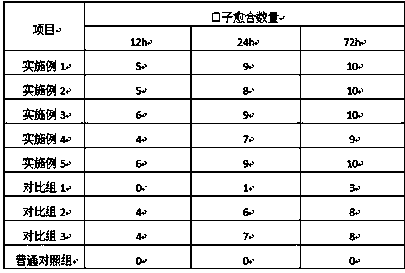

Examples

Embodiment 1

[0022] A surface scratch self-repairing floor leather, the preparation steps of which are as follows:

[0023] 1) Preparation of graphene composite powder: put lanthanum nitrate into an ethanol solution with a mass concentration of 6 times its weight and a concentration of 15%, and then add graphene with 4 times the weight of lanthanum nitrate and 0.06 times the weight of nano-silver into the ethanol solution. After stirring and mixing , and then ultrasonically treated with a frequency of 100kHz for 15min to obtain a turbid liquid, then the turbid liquid was removed by rotary evaporation and put into a ball mill, and 30% of the weight of lanthanum nitrate was added to the ball mill. 2:1, the ball milling rate of the ball mill is 1000r / min, and the graphene composite powder is obtained after ball milling for 2h, which is for use;

[0024] 2) Blending of raw materials: Take 10.5kg of thermoplastic polyurethane and put it in a small internal mixer and heat it up to 120°C, then ad...

Embodiment 2

[0028] A surface scratch self-repairing floor leather, the preparation steps of which are as follows:

[0029] 1) Preparation of graphene composite powder: put lanthanum nitrate into an ethanol solution with a mass concentration of 6 times its weight and a concentration of 15%, and then add graphene that is 3 times the weight of lanthanum nitrate and 0.05 times the weight of nano-silver into the ethanol solution. After stirring and mixing , and then ultrasonically treated with a frequency of 100kHz for 15min to obtain a turbid liquid, then the turbid liquid was removed by rotary evaporation and put into a ball mill, and 20% of the weight of lanthanum nitrate was added to the ball mill. 2:1, the ball milling rate of the ball mill is 1200 r / min, and the graphene composite powder is obtained after ball milling for 1 h, which is ready for use;

[0030]2) Blending of raw materials: Take 10.5kg of thermoplastic polyurethane and put it in a small internal mixer and heat it up to 120°...

Embodiment 3

[0034] A surface scratch self-repairing floor leather, the preparation steps of which are as follows:

[0035] 1) Preparation of graphene composite powder: put lanthanum nitrate into an ethanol solution with a mass concentration of 10 times its weight and a concentration of 30%, and then add graphene with 4 times the weight of lanthanum nitrate and 0.10 times the weight of nano-silver into the ethanol solution. After stirring and mixing Then, the turbid liquid was obtained by ultrasonic treatment with a frequency of 120 kHz for 15 min, and then the turbid liquid was removed by rotary evaporation and put into a ball mill, and 35% of the weight of lanthanum nitrate was added to the ball mill. 2:1, the ball milling rate of the ball mill is 900 r / min, and the graphene composite powder is obtained after ball milling for 2 hours, which is for standby use;

[0036] 2) Blending of raw materials: Take 10.5kg of thermoplastic polyurethane and put it in a small internal mixer and heat it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com