Near shape preparation method of multiphase ceramic Si3N4-SiC

A technology of complex phase ceramics and close dimensions, which is applied in the direction of ceramic forming machines and manufacturing tools, which can solve the problems of composition and morphology differences of deposition products, affect the densification process, increase the preparation cost, etc., and achieve good uniformity and no impurities , The effect of stable absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

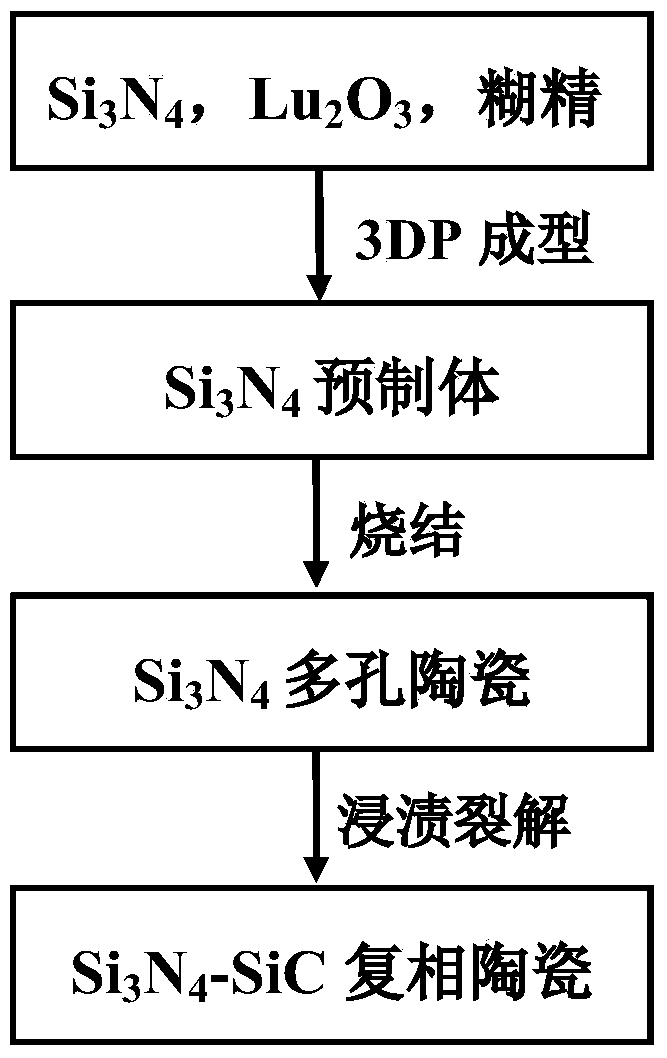

Method used

Image

Examples

Embodiment 1

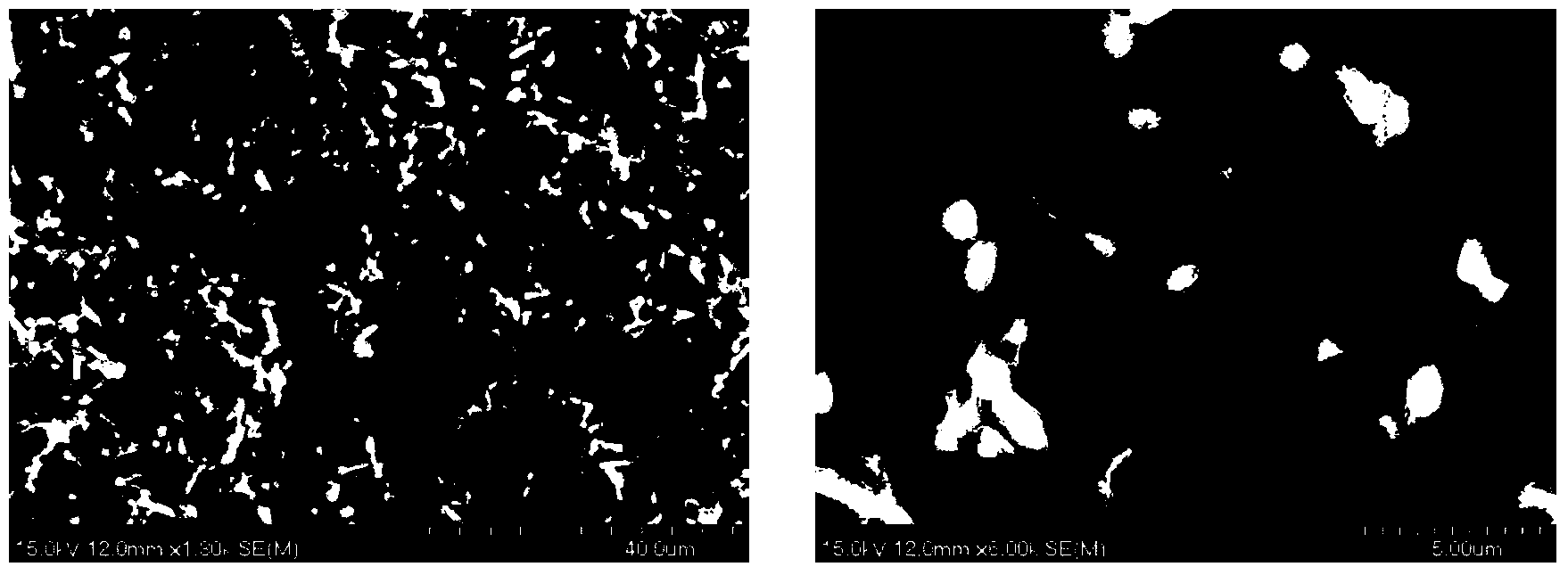

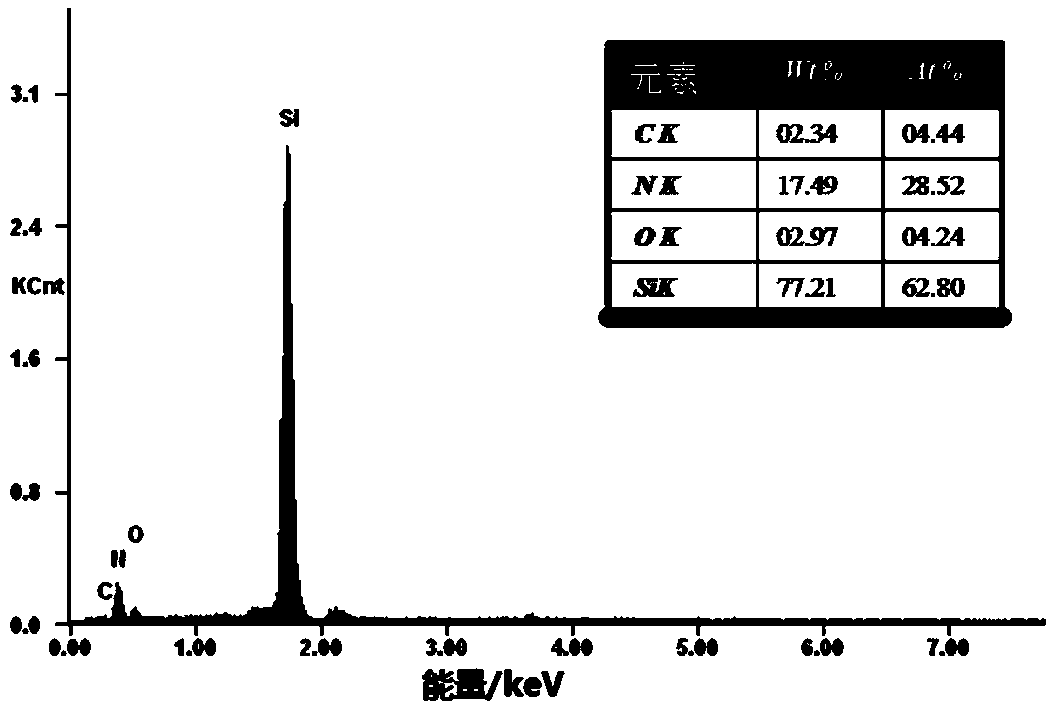

[0030] Embodiment 1: Si 3 N 4 Powder and sintering aid Lu 2 o 3 Mix at 97:3 by weight, add 5% dextrin as a binder, and use distilled water as a medium for ball milling for 96 hours to fully mix to obtain a slurry. The slurry was put into a freeze dryer to freeze for 10 hours, the freezing temperature was -80° C., and vacuum dried for 10 hours. The absolute pressure in the freeze dryer was 5 Pa, and the drying temperature was 70° C. The dried powder is sieved, and the sifted powder is put into a three-dimensional printer (Z510) to print in a size of 27mm×14mm×4mm, and the thickness of the printed layer is about 0.05mm. The printed samples were dried for more than 1 hour and taken out. The formed body was oxidized in air at 600°C for 5h, and the Si 3 N 4 The preform is sintered at 1700°C for 3 hours under a nitrogen atmosphere, and the pressure is 0.35MPa, which is Si 3 N 4 porous ceramics. The sintered Si 3 N 4 The preform was vacuum impregnated in polysiloxane for 3...

Embodiment 2

[0032] Embodiment 2: Si 3 N 4 Powder and sintering aid Lu 2 o 3 Mix by weight percentage 93:7, add 15% dextrin as a binder, and use distilled water as a medium for ball milling for 48 hours to make it fully mixed to obtain a slurry. The slurry was put into a freeze dryer to freeze for 6 hours, the freezing temperature was -60° C., and vacuum dried for 15 hours. The absolute pressure in the freeze dryer was 10 Pa, and the drying temperature was 60° C. The dried powder is sieved, and the sifted powder is put into a three-dimensional printer (Z510) to print in a size of 27mm×12mm×4mm, and the thickness of the printed layer is about 0.085mm. The printed samples were dried for more than 1 hour and taken out. The formed green body was oxidized in air at 750°C for 3h, and the Si 3 N 4 The preform is sintered at 1900°C for 1h under a nitrogen atmosphere, and the pressure is 0.3MPa, which is Si 3 N 4 porous ceramics. Add 7wt% ferrocene into polysiloxane, and mix for 15 minutes...

Embodiment 3

[0034] Embodiment 3: Si 3 N 4 Powder and sintering aid Lu 2 o 3 Mix by weight percentage 93:7, add 15% dextrin as a binder, and use distilled water as a medium for ball milling for 48 hours to make it fully mixed to obtain a slurry. The slurry was put into a freeze dryer to freeze for 6 hours, the freezing temperature was -60° C., and vacuum dried for 15 hours. The absolute pressure in the freeze dryer was 10 Pa, and the drying temperature was 60° C. The dried powder is sieved, and the sifted powder is put into a three-dimensional printer (Z510) to print in a size of 20mm×14mm×4mm, and the thickness of the printed layer is about 0.5mm. The printed samples were dried for more than 1 hour and taken out. The formed body was oxidized in air at 800°C for 2h, and the Si 3 N 4 The preform is sintered at 1900°C for 1h under a nitrogen atmosphere, and the pressure is 0.25MPa, which is Si 3 N 4 porous ceramics. Add 2wt% ferrocene into polysiloxane, and mix for 15 minutes at 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com