Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

183 results about "Stress-whitening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stress whitening is a white line appearing along the bend or curve when a material is stressed by bending or punching operations. The appearance of white line indicates that there is an onset of failure of the corresponding material. This phenomenon is known as "stress whitening". This is more common in amorphous materials, and also in some brittle polymers like PS, PMMA and Polycarbonate. The white colour is because of the light scattering by the crazes.

Polyester blends with improved stress whitening for film and sheet applications

Disclosed are polyester blends that provide improved stress whitening behavior. The blends may be prepared from a polyester having crystallization half-time of at least 5 minutes and a polyester elastomer. The polyesters blends may be extruded or, in the presence of a release additive, calendered to produce film or sheet. Also disclosed are processes for making a film or sheet by extrusion or calendering the above blends and the film or sheet produced therefrom. The polyester blend and the film or sheet produced therefrom also may include plasticizers and / or flame retardants to increase their flexibility and enable their use in commercial applications requiring flame resistance. The film and sheet have excellent appearance and can be used in a wide range of decorative and packaging applications.

Owner:EASTMAN CHEM CO

Stress blanching and stress crack resistant filling modified polypropylene, preparation method and application

Owner:SHANGHAI KINGFA SCI & TECH +1

A kind of stress whitening resistant polypropylene composition and its preparation method

ActiveCN102295808AImprove mechanical propertiesGood resistance to stress whiteningPolymer scienceProcedure Agents

The invention discloses a stress whitening resistant polypropylene composition and a preparation method thereof. The stress-whitening-resistant polypropylene composition comprises the following components calculated by weight percentage: 35%-82% polypropylene resin; 2%-12% compatibilizer; 5%-15% stress-whitening-resistant agent; 10%-40% filler; 0.2%-1.0% antioxidant; 0.2%-1.0% processing aid; the polypropylene resin is a mixture of homopolymerized polypropylene and random copolymerized polypropylene; The whitening agent is a mixture of polyethylene and thermoplastic elastomer; the compatibilizer is a graft polymer of polypropylene and unsaturated carboxylic acid or its anhydride. The stress-whitening-resistant polypropylene composition of the present invention has both good comprehensive mechanical properties and good stress-whitening resistance, and can be applied to the fields of household appliances, toys, auto parts, electric tools and the like.

Owner:KINGFA SCI & TECH CO LTD +2

Anti-folding stress whitening resistant polypropylene (PP) material and preparation method thereof

The invention discloses an anti-folding stress whitening resistant polypropylene (PP) material and a preparation method thereof. The material is prepared from the following raw materials in part by weight: 55 to 75 parts of co-polypropylene, 5 to 20 parts of POE Lc670, 10 to 30 parts of stress whitening resistant master batch, 0.05 to 0.15 part of white mineral oil, 0.1 to 0.3 part of hindered phenol antioxidant 1010, 0.1 to 0.3 part of phosphite ester antioxidant 1680 and 0.1 to 0.3 part of calcium stearate. The stress whitening resistant master batch comprises the following components in part by weight: 40 to 65 parts of EPDM or EPR or POE, 30 to 50 parts of nano active light CaCO3, and 0.5 to 2 parts of sodium polyethylene with low molecular weight. The polypropylene (PP) material is prepared by using a double-screw extruder with 9 temperature control areas according to the specific process conditions. The material has the advantages of good repeated bending resistance and stress whitening resistance, simple preparation process and low preparation cost.

Owner:重庆启蓝塑料有限公司

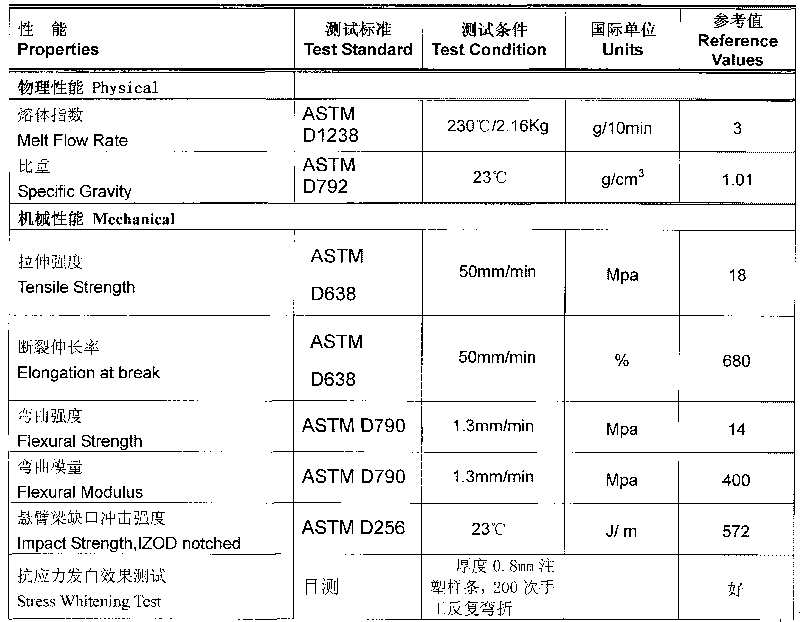

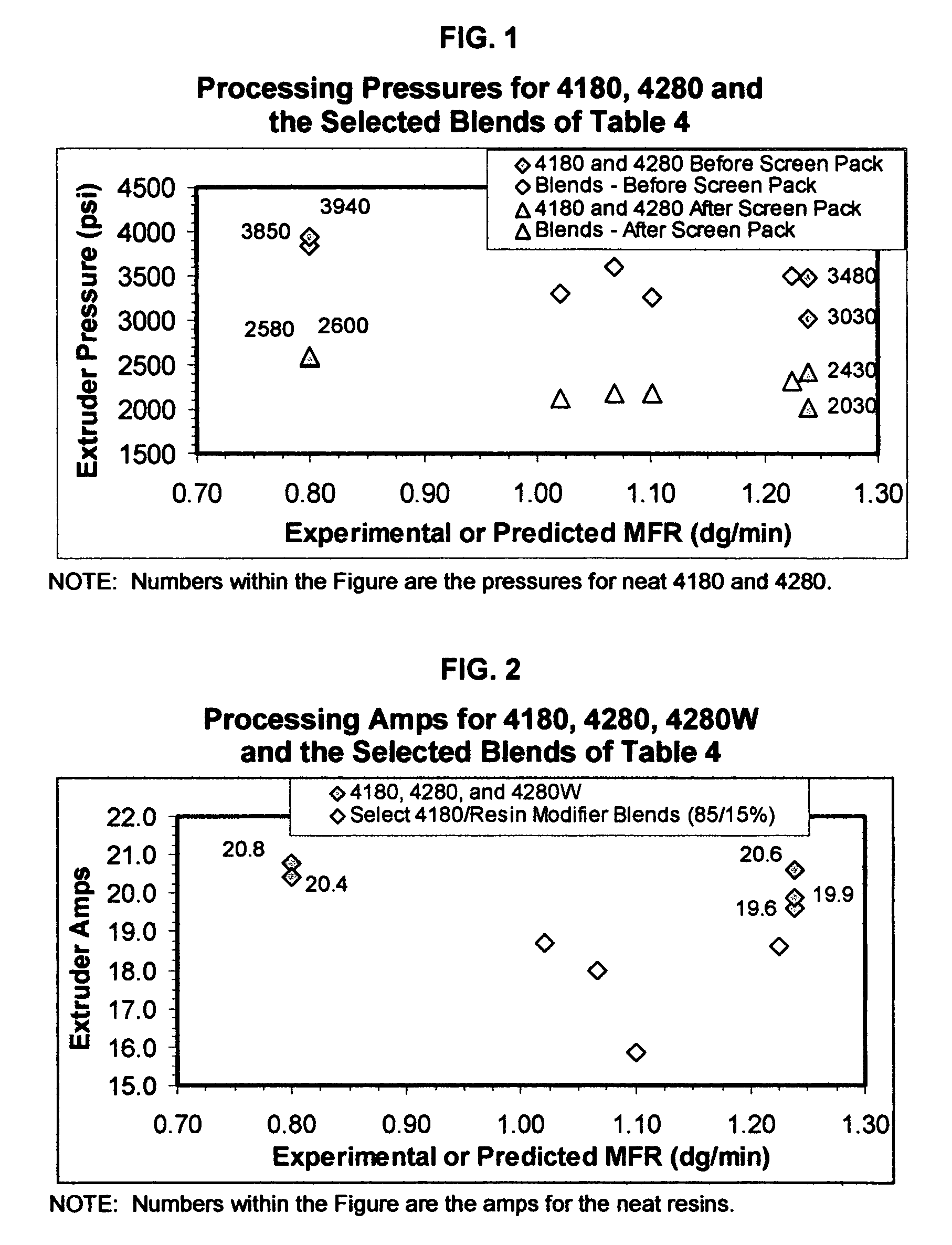

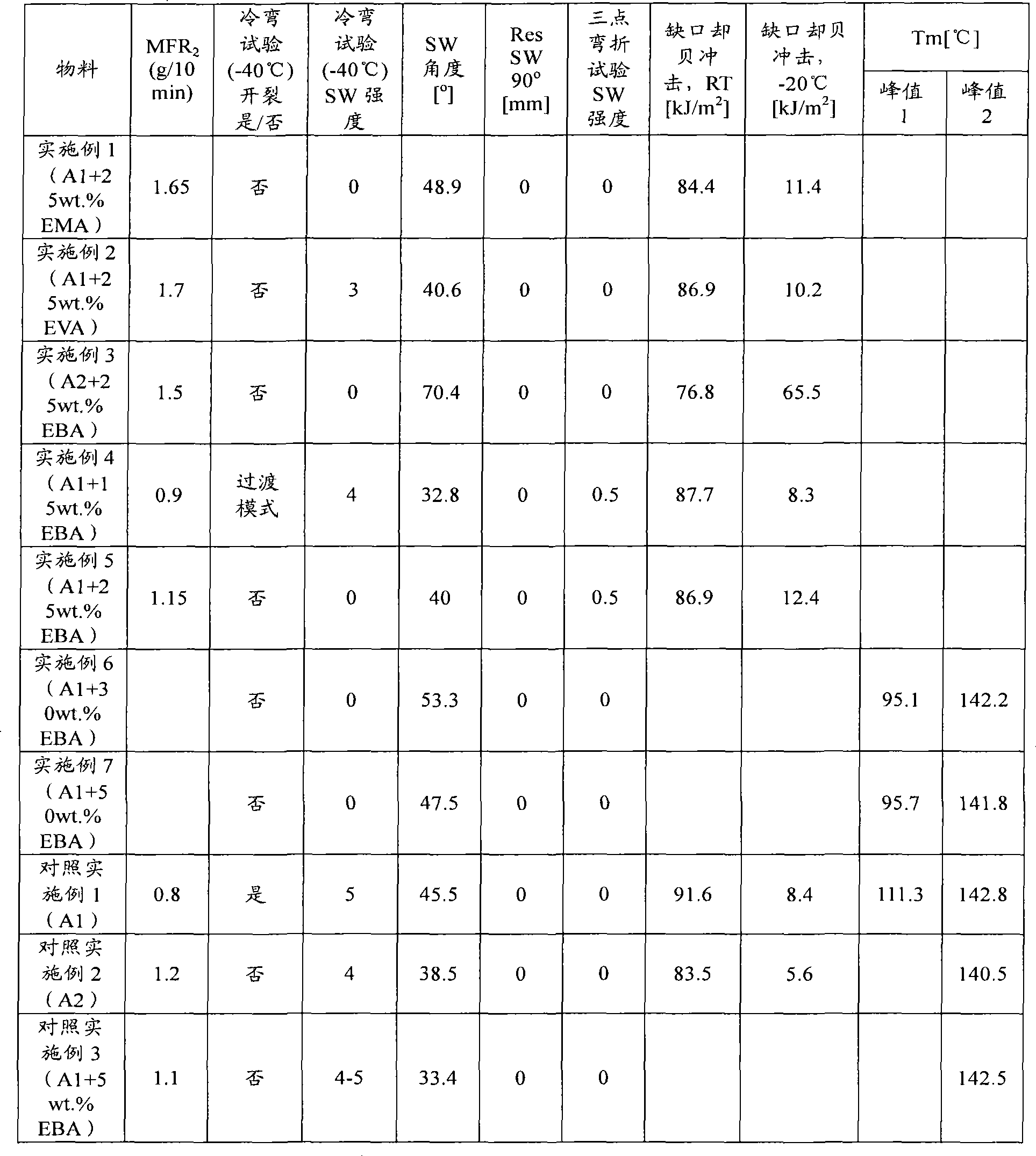

Blends of polypropylene impact copolymer with other polymers

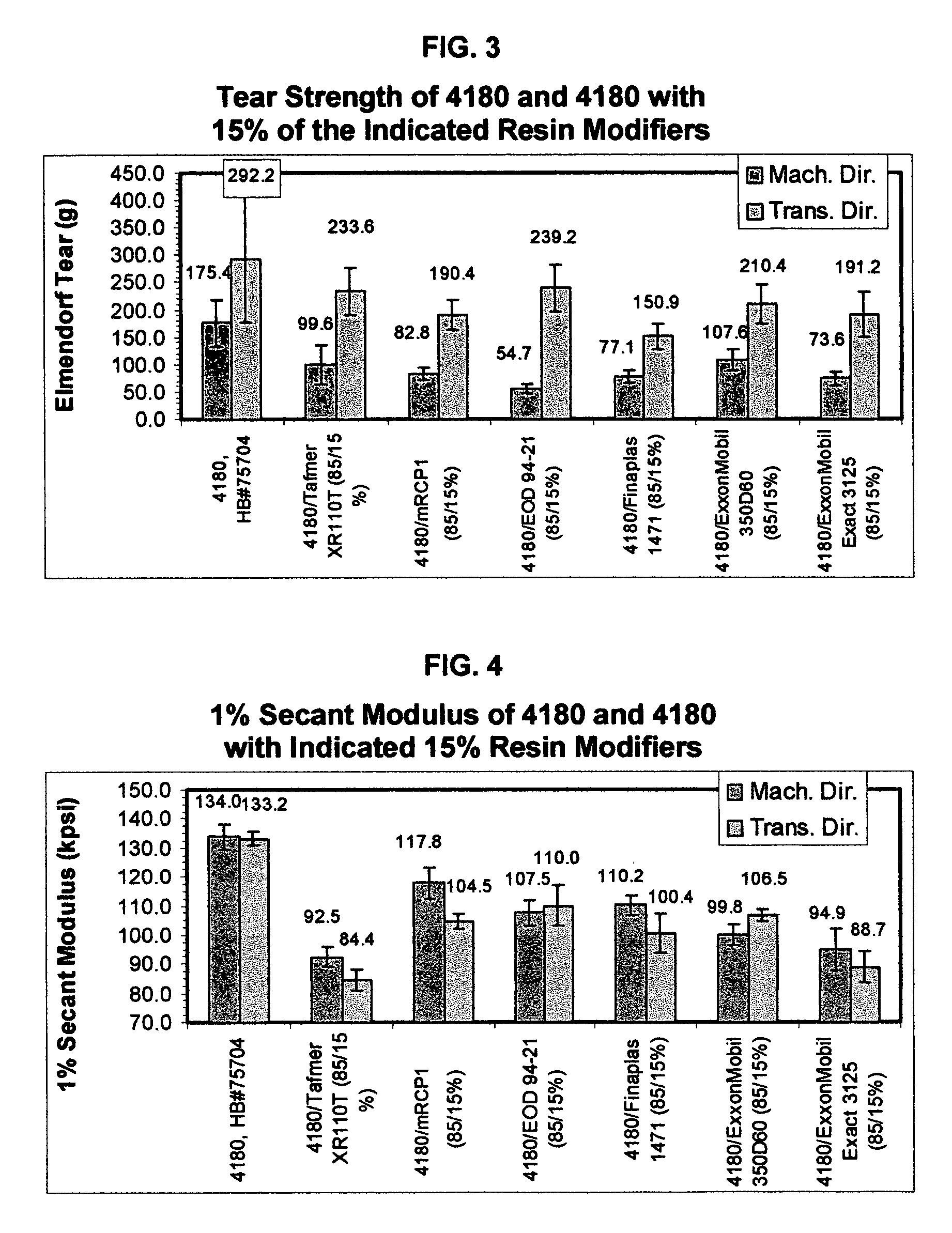

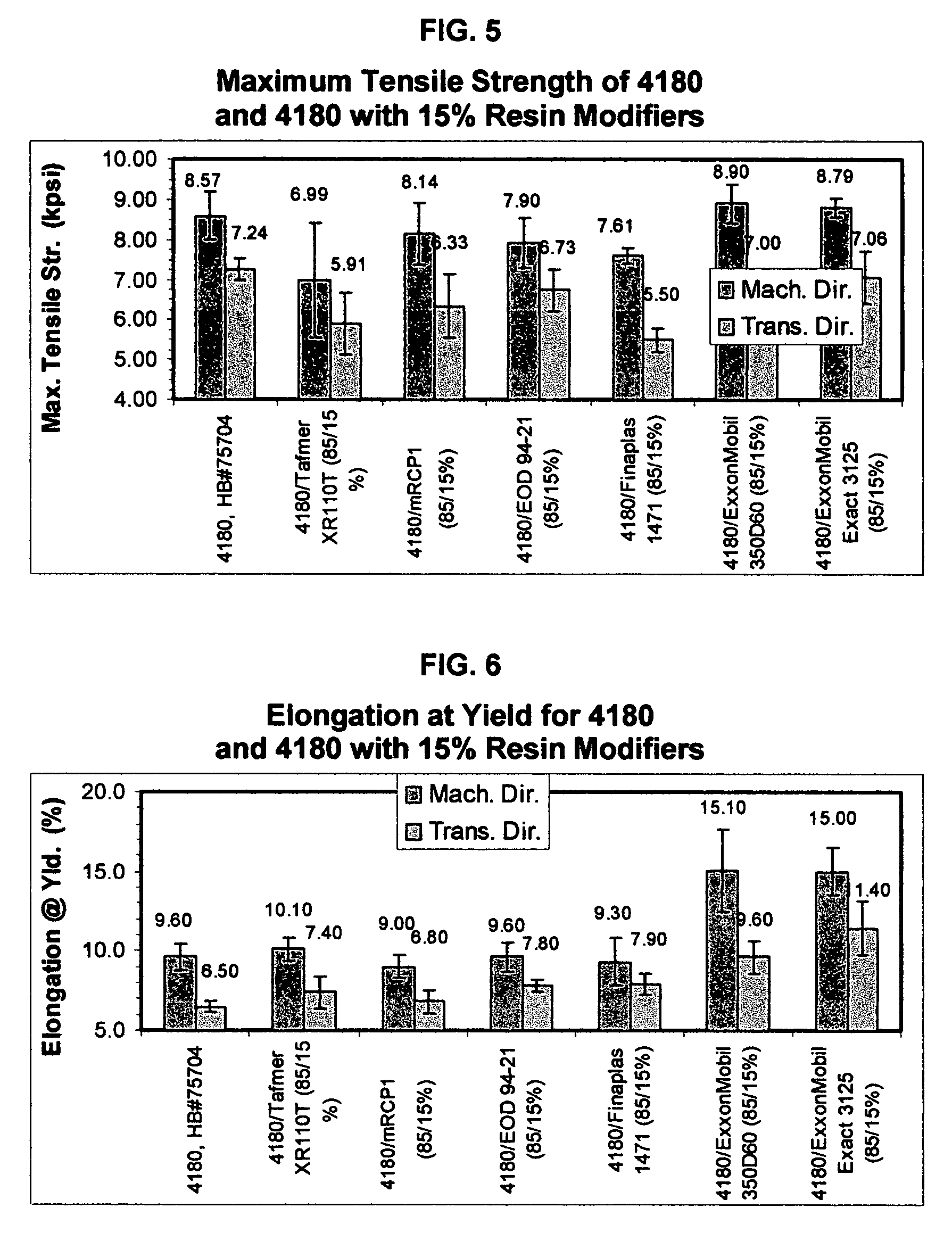

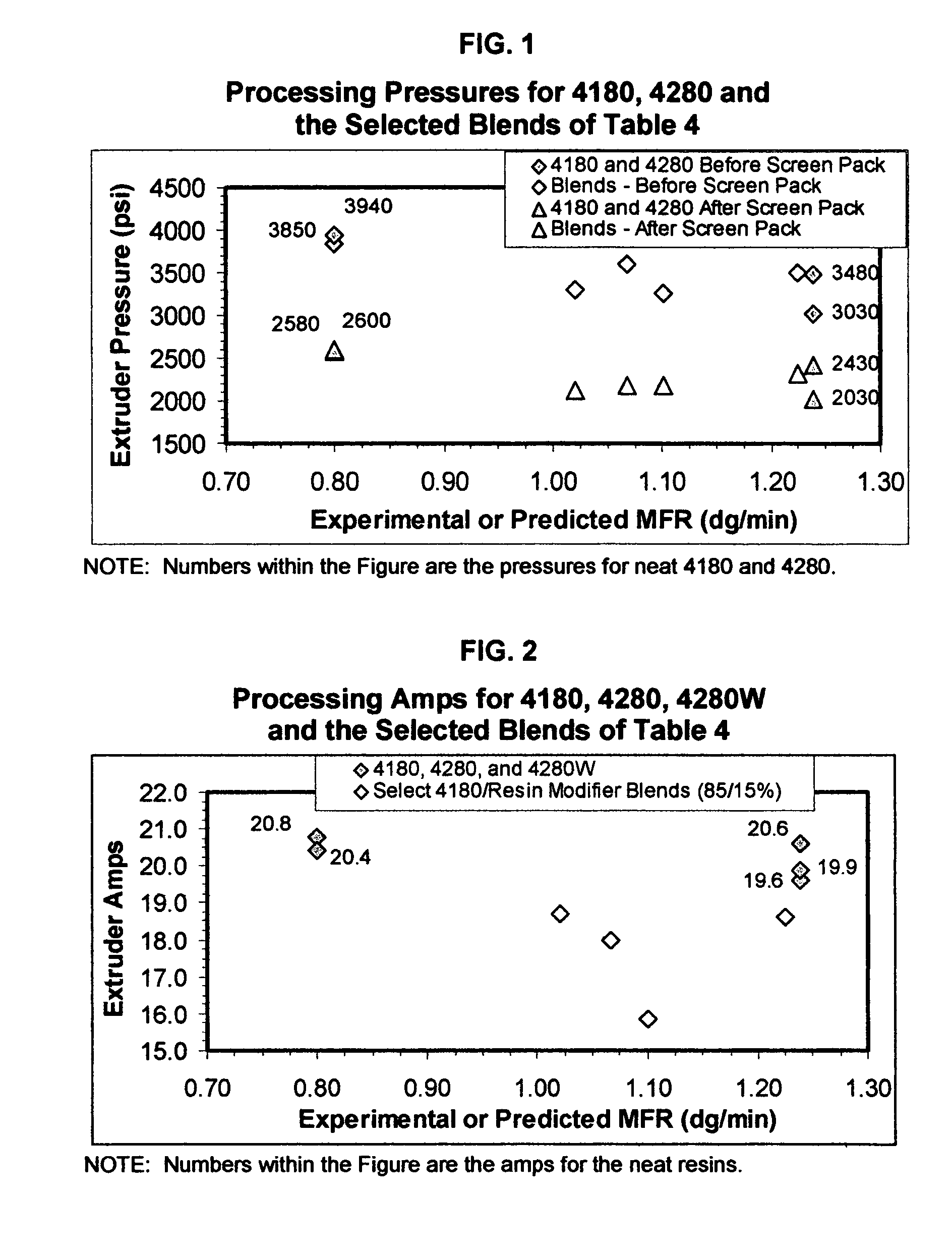

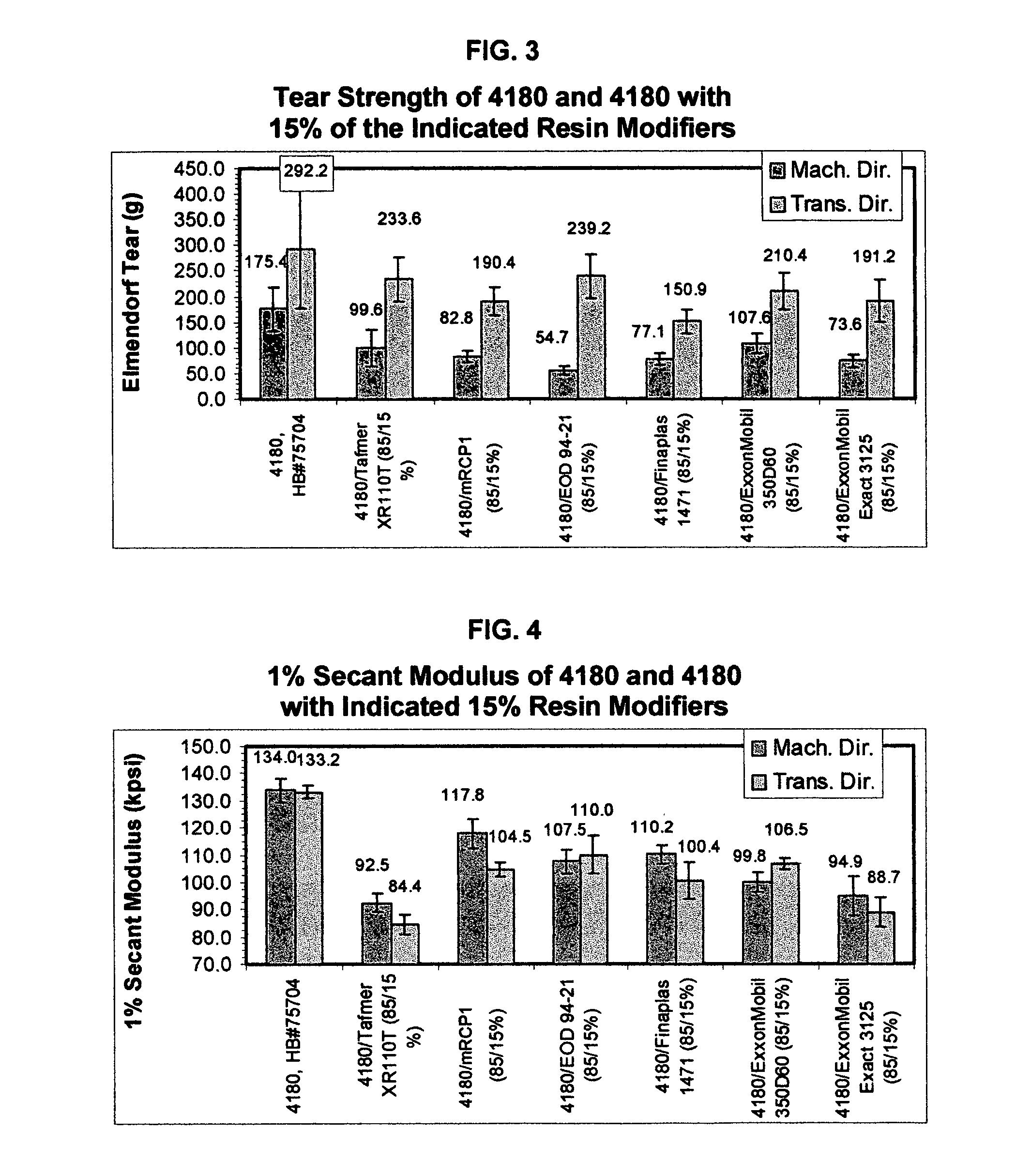

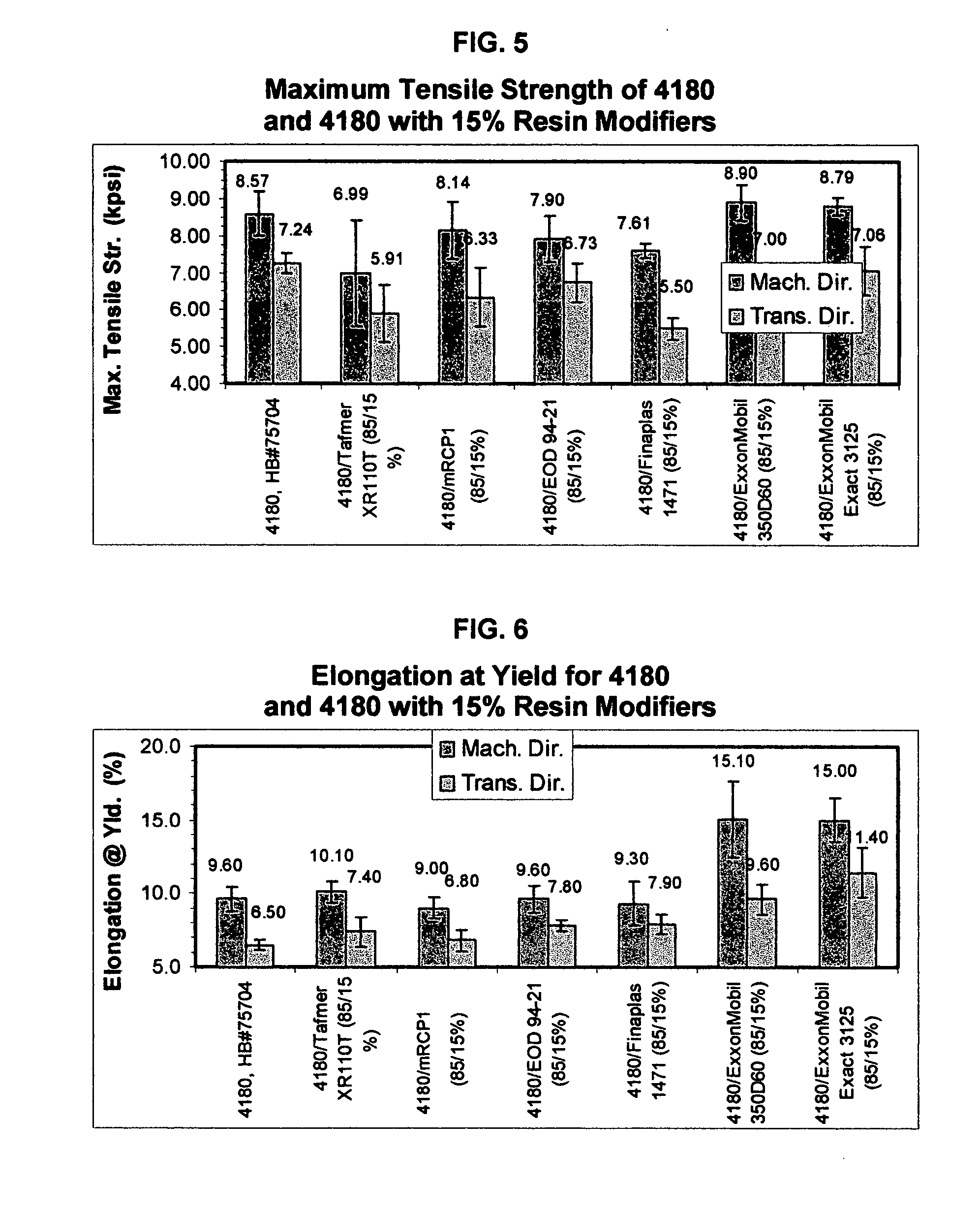

It has been discovered that the properties of sheet or film materials of broad molecular weight distribution ethylene / propylene rubber impact-modified heterophasic copolymer (ICP) can be improved by blending the ICP with a second polyolefin. The second polyolefin may be a syndiotactic polypropylene (sPP), a random copolymer (RCP) of propylene and comonomer (e.g. ethylene and / or butene) made using a Ziegler-Natta or metallocene catalyst, medium density polyethylene (MDPE), linear low density polyethylene (LLDPE), or low crystalline copolymer of propylene / α-olefin. Improvements include, but are not necessarily limited to, reduced motor amps, lower secant modulus, increased dart drop strength, increased gloss, reduced haze, increased elongation to yield, elimination of stress whitening, improved puncture resistance, and decreased seal initiation temperature. This sheet of film materials may be co-extruded with other resins or laminated with other materials after extrusion.

Owner:FINA TECH

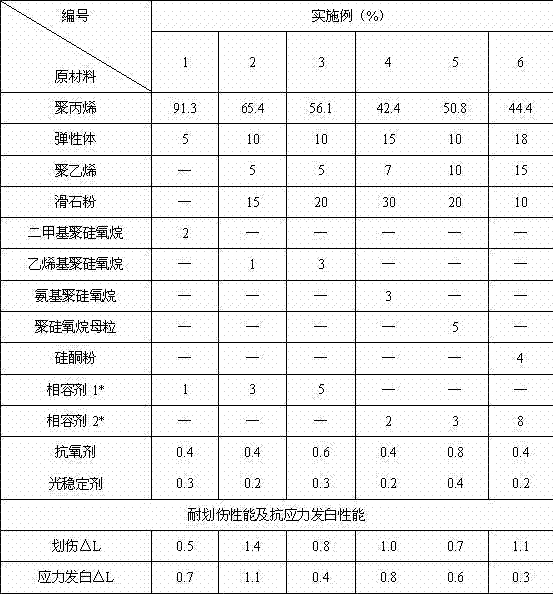

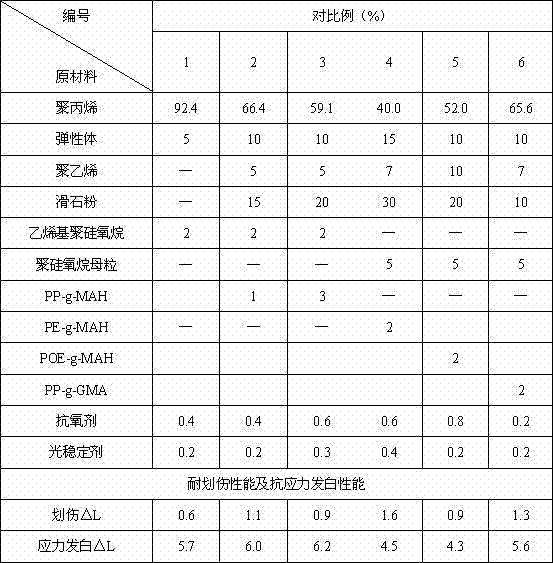

Scratching-resistant and stress-whitening prevention polypropylene compound and preparation method

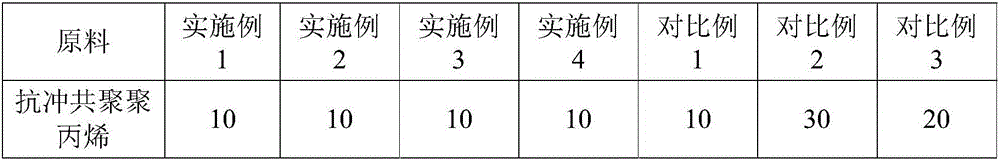

The invention discloses a scratching-resistant and stress-whitening prevention polypropylene compound, which comprises, by weight, 40% to 95% of polypropylene, 2% to 20% of elastomers, 0% to 15% of polyethylene, 0% to 30% of talcum powder, 1% to 5% of scratching-resistant agent, 0.5% to 8% of compatilizer, 0.1 % to 1% of oxidation inhibitor and 0.1% to 0.5% of light stabilizer, wherein the compatilizer is polyolefin organosilicon copolymer or alkyl modified polysiloxane. The preparation method of the scratching-resistant and stress-whitening prevention polypropylene compound includes steps offirstly, taking all components by weighing according to the percentage, mixing the polypropylene, the elastomers, the polyethylene, the scratching-resistant agent and the compatilizer in a high-mixing machine for one to three minutes, then adding the talcum powder, the oxidation inhibitor and the light stabilizer to be mixed together for one to three minutes, and obtaining pre-mixed materials; and secondly, melting and extruding the pre-mixed materials by a double-screw extruder, and pelleting in a vacuum state so as to obtain the scratching-resistant and stress-whitening prevention polypropylene, wherein the temperature of each area of screws ranges from 190 DEG C to 230 DEG C. The scratching-resistant and stress-whitening prevention polypropylene compound has the advantages that scratching resistance is improved by the aid of polysiloxane scratching-resistant agent, the problem of serious stress whitening of workpieces during injection molding, mounting and using due to introductionof the scratching-resistant agent is solved, and pass rate of products is high.

Owner:WUHAN JINFA TECH CO LTD

Blends of polypropylene impact copolymer with other polymers

It has been discovered that the properties of sheet or film materials of broad molecular weight distribution ethylene / propylene rubber impact-modified heterophasic copolymer (ICP) can be improved by blending the ICP with a second polyolefin. The second polyolefin may be a syndiotactic polypropylene (sPP), a random copolymer (RCP) of propylene and comonomer (e.g. ethylene and / or butene) made using a Ziegler-Natta or metallocene catalyst, medium density polyethylene (MDPE), linear low density polyethylene (LLDPE), or low crystalline copolymer of propylene / α-olefin. Improvements include, but are not necessarily limited to, reduced motor amps, lower secant modulus, increased dart drop strength, increased gloss, reduced haze, increased elongation to yield, elimination of stress whitening, improved puncture resistance, and decreased seal initiation temperature. This sheet of film materials may be co-extruded with other resins or laminated with other materials after extrusion.

Owner:FINA TECH

Stress whitening resistant and scratch resistant polypropylene composition, and preparation method thereof

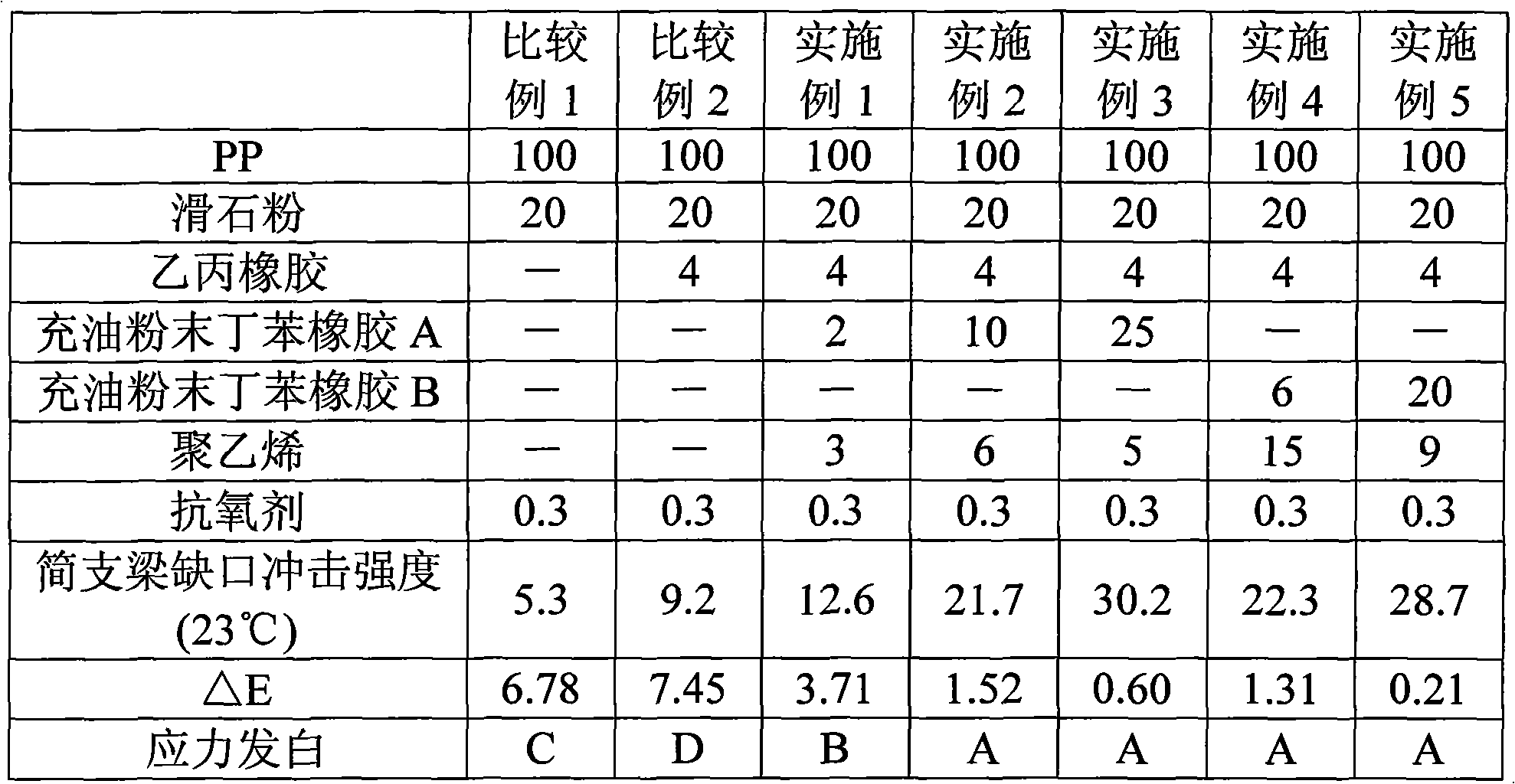

The present invention provides a stress whitening resistant and scratch resistant polypropylene composition, and a preparation method thereof. The polypropylene composition comprises the following components, wherein the components are blended, and comprise, by weight, 100 parts of a polypropylene resin, 0-50 parts of a mineral filler, 0.05-40 parts of oil-filled fully-vulcanized powdered rubber,0.01-30 parts of polyethylene and 0-30 parts of a toughening agent. The oil-filled fully-vulcanized powdered rubber is the fully-vulcanized powdered rubber filled with a polysiloxane lubricant and / orhydrocarbon lubricating oil, and the average particle size of the full-vulcanized powdered rubber is 20-2000 nm. The polypropylene composition of the present invention has characteristics of good mechanical property, scratch resistance and stress whitening resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polypropylene composition with low VOC (volatile organic compounds), scratch resistance and stress whitening resistance and preparation method of polypropylene composition

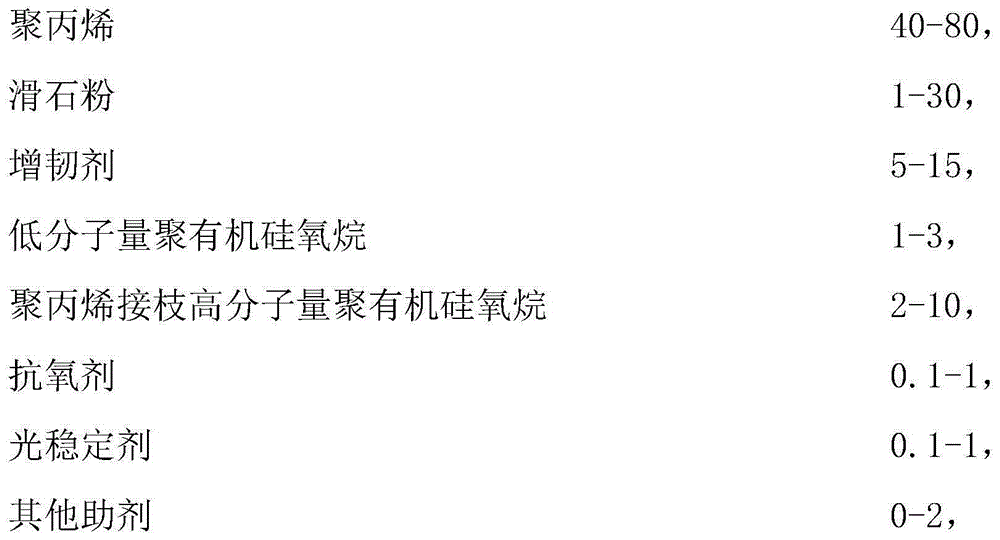

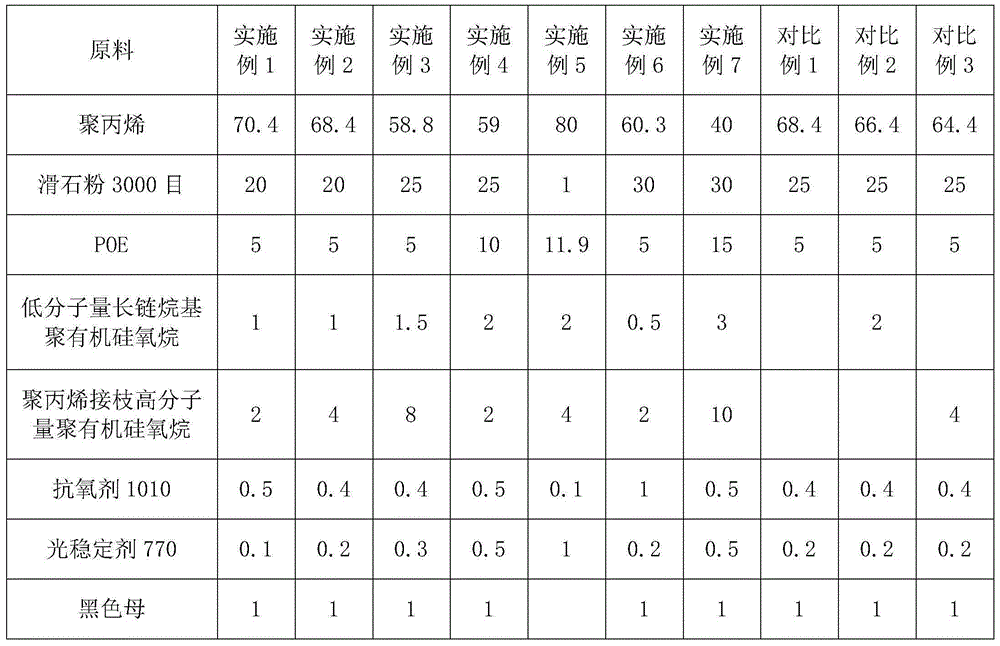

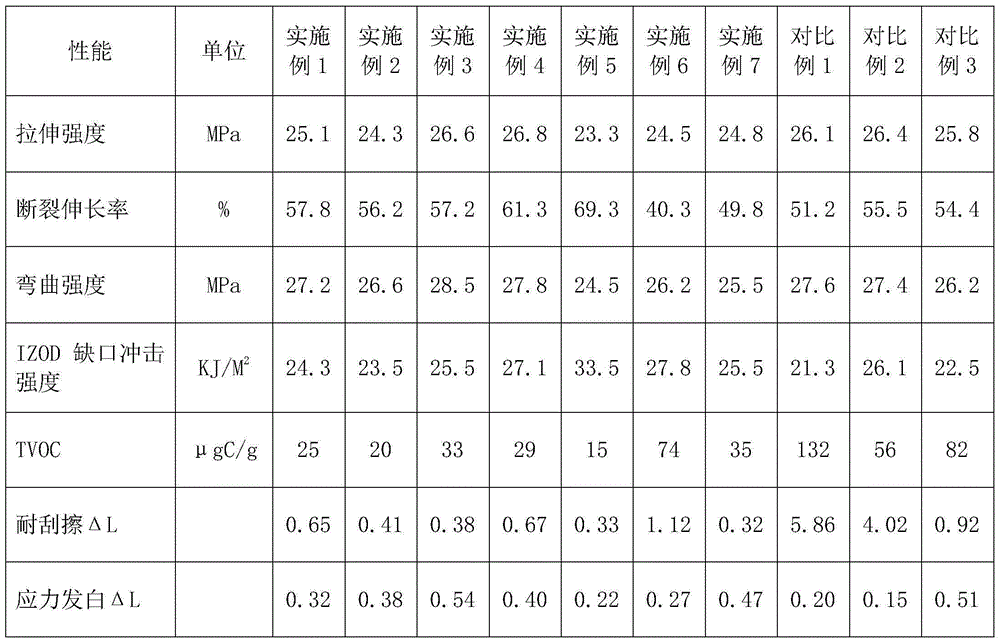

The invention provides a polypropylene composition with low VOC (volatile organic compounds), scratch resistance and stress whitening resistance. The polypropylene composition consists of the following components by weight percent: 40 to 80 percent of polypropylene, 1 to 30 percent of talcum powder, 5 to 15 percent of flexibilizer, 1 to 3 percent of low-molecular-weight polysiloxane, 2 to 10 percent of polypropylene grafted macromolecular-weight polysiloxane, 0.1 to 1 percent of antioxidant, 0.1 to 1 percent of light stabilizer and 0 to 2 percent of other additives, wherein the sum of weight percent of all components is 100. The invention also provides a preparation method of the polypropylene composition with low VOC, scratch resistance and stress whitening resistance. The polypropylene composition has characteristics of low VOC and also has good scratch resistance and stress whitening resistance.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

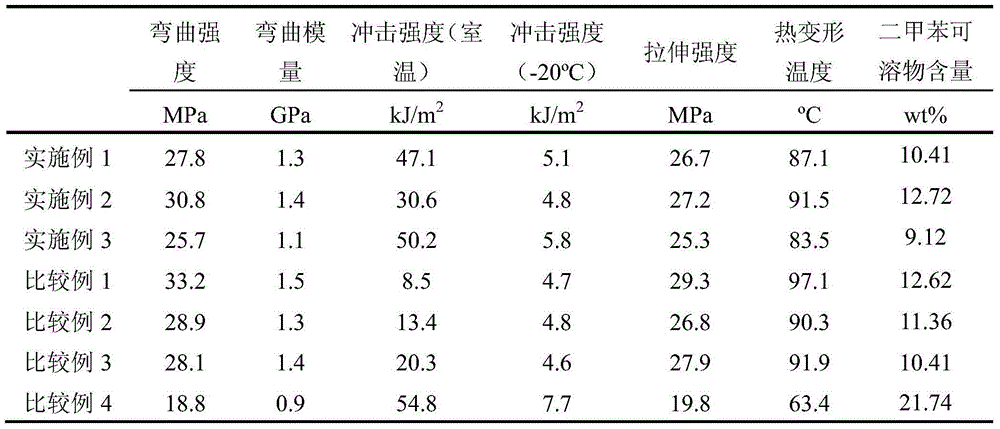

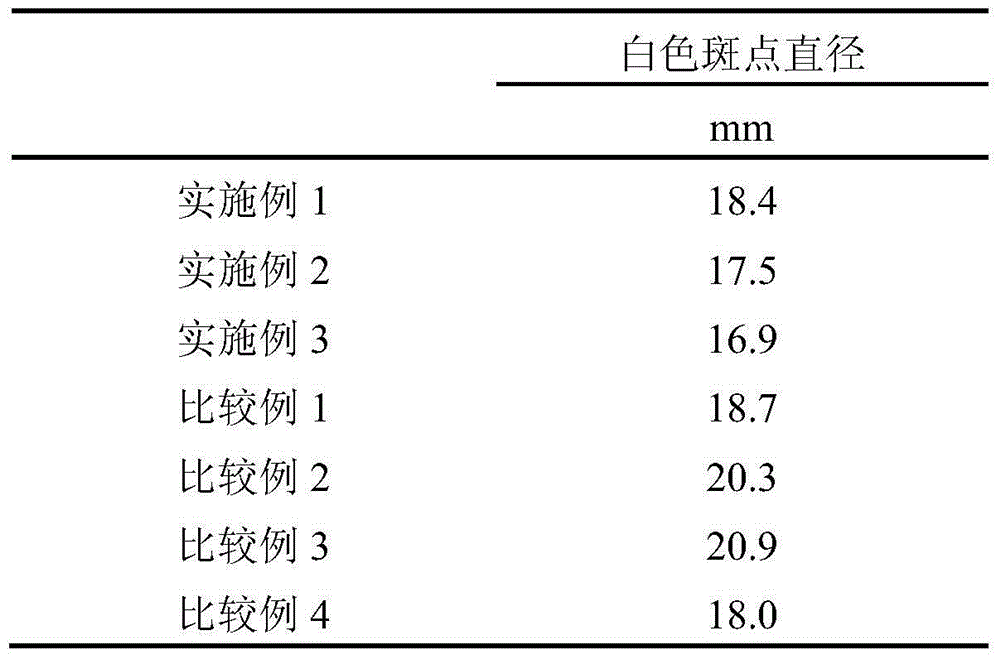

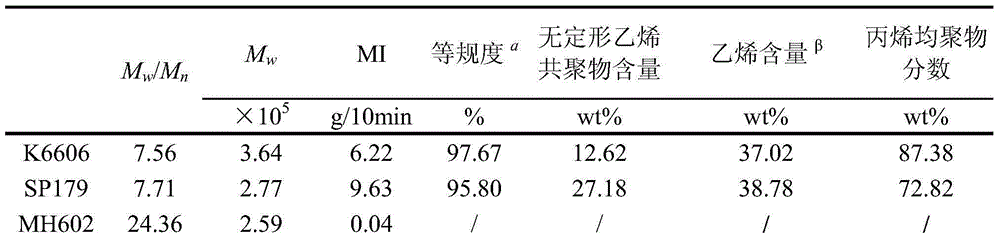

Stress whitening resistant low-temperature impact resistant polypropylene material and preparation method thereof

InactiveCN106832599AImprovement of bending stress whitening performanceImprove low temperature impact resistanceAntioxidantPolypropylene

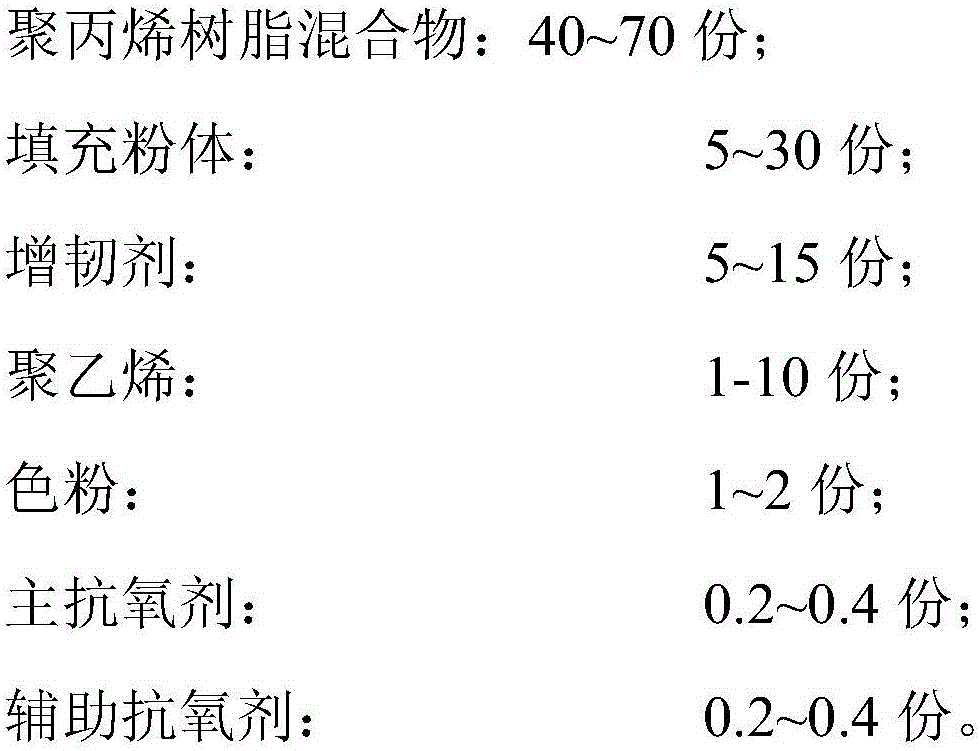

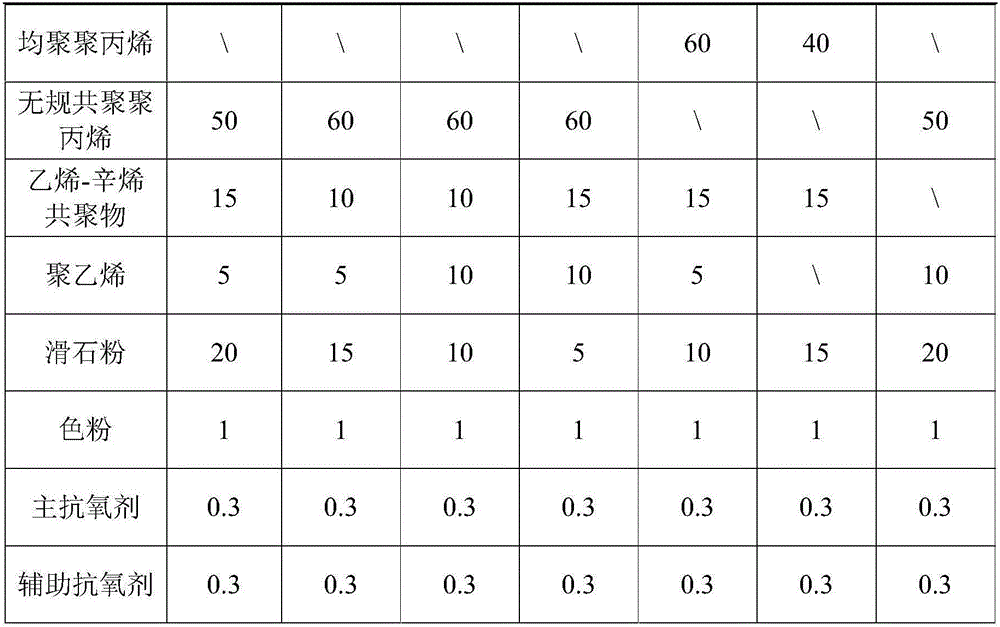

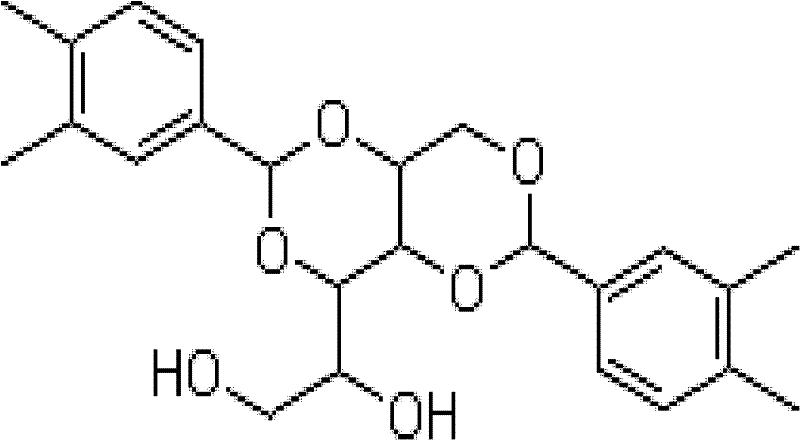

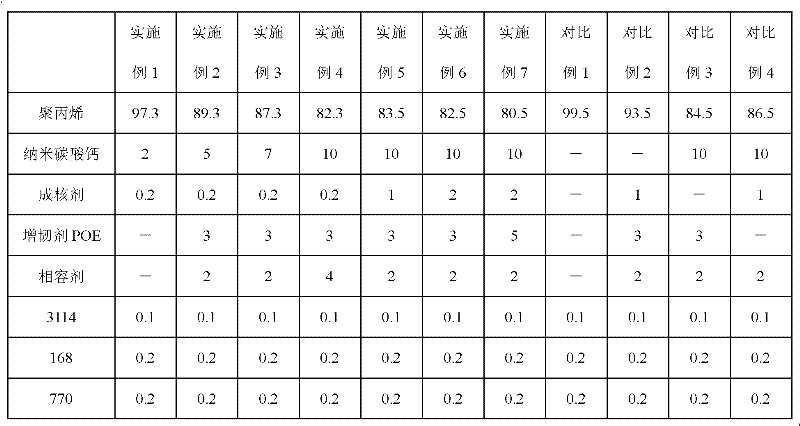

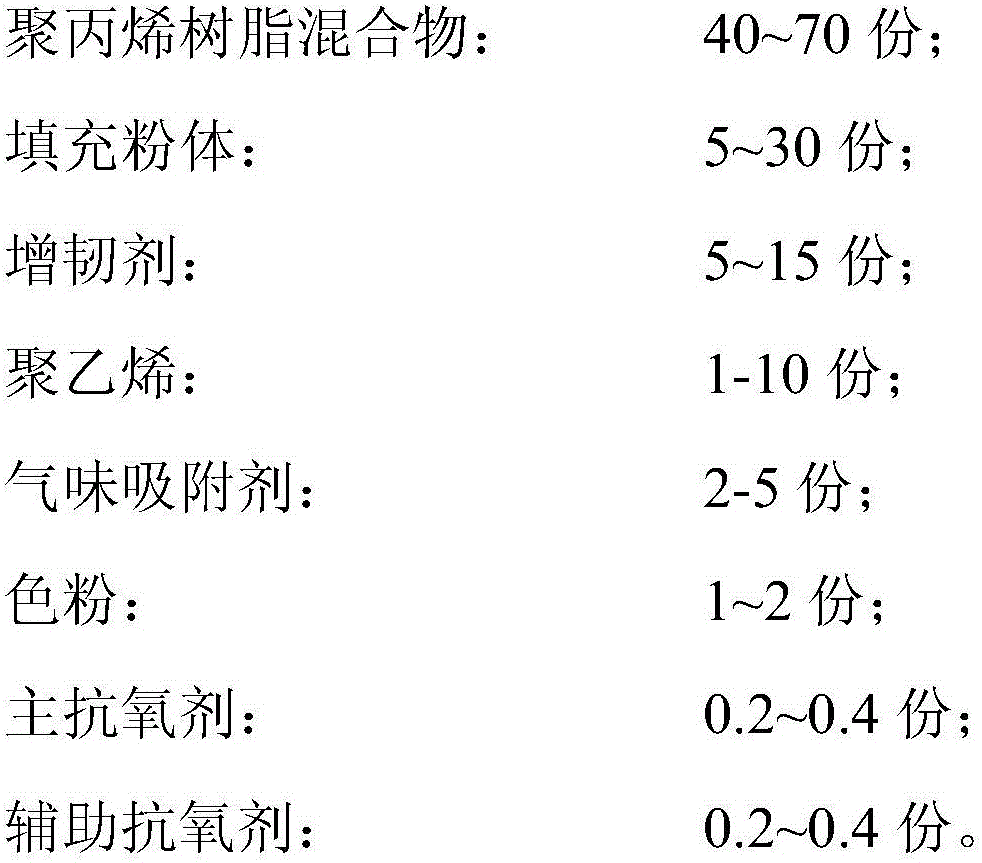

The invention provides a stress whitening resistant low-temperature impact resistant polypropylene material and a preparation method thereof. The stress whitening resistant low-temperature impact resistant polypropylene material is prepared from the following components in parts by weight: 40 to 70 parts of polypropylene resin mixture, 5 to 30 parts of filling powder, 5 to 15 parts of toughening agent, 1 to 10 parts of polypropylene, 1 to 2 parts of toner, 0.2 to 0.4 part of primary antioxidant and 0.2 to 0.4 part of auxiliary antioxidant. In the stress whitening resistant low-temperature impact resistant polypropylene material and the preparation method thereof, random copolymerization polypropylene is taken as a substrate, so that the anti-bending stress whitening performance of the material is enhanced remarkably; the toughening agent and the polyethylene are added, so that the stress whitening resistance is enhanced, and the low-temperature impact resistance of the material is improved on the basis of keeping other physical properties; meanwhile, a small quantity of auxiliary components are added, so that the color matching capability of the material is not influenced; moreover, the preparation method is easy to implement, and has wide applicability.

Owner:TIANJIN KINGFA NEW MATERIAL

Silicone master batch with long-lasting scratch resistance, and preparation method thereof

The invention discloses a silicone master batch with long-lasting scratch resistance, and a preparation method thereof. The raw materials of the master batch contain modified silicone, the modified silicone is an active group-containing long side chain-grafted high molecular weight polysiloxane, and the raw materials also contain polypropylene, a reinforcing agent, an anti-aging agent and other assistants. The raw materials are internally mixed at 200-220 DEG C, and then are extruded and granulated under certain conditions by a twin-screw extruder to obtain the silicone master batch with long-lasting scratch resistance. The silicone master batch prepared by the invention contains the active group-containing long side chain-grafted high molecular weight polysiloxane, so the problems of unabiding scratch resistance and stress whitening of common silicone are well solved, the plastic processing performance is improved, and the device wearing is reduced. The preparation method of the invention has the advantages of simple process, environmental protection, safety, good repeatability, and easiness in industrialization. The silicone masterbatch prepared in the invention is mainly used for preparing a scratch-resistant automotive interior polypropylene composite material.

Owner:CHENGDU GUIBAO SCI & TECH

Composition Coextrudable with PVDF and having no stress-whitening effect

InactiveUS20050187354A1Good mechanical integritySolve the lack of mechanical propertiesSynthetic resin layered productsThin material handlingMeth-Ultraviolet

The present invention relates to a composition coextrudable with PVDF and comprising: 30 to 50 parts of PVDF; 70 to 50 parts of a copolymer comprising, by weight, 90 to 50% of methyl methacrylate (MMA) per 10 to 50% of an alkyl (meth)acrylate respectively, the alkyl having from 2 to 24 carbon atoms; 1 to 4 parts of a UV absorber; the total making 100 parts. The invention also relates to coextruded films consisting of this composition as the adhesive layer and a PVDF-based layer of 50 to 100 parts of PVDF per 50 to 0 parts of PMMA respectively. These films possess mechanical properties sufficient to allow them to be used as a coating transparent to visible light but opaque to UV radiation.

Owner:ARKEMA FRANCE SA

Stress whitening-resistant modified polypropylene material and preparation method thereof

The invention discloses a stress whitening-resistant modified polypropylene material and a preparation method thereof. The stress whitening-resistant modified polypropylene material is prepared from the following raw materials in percentage by weight: 76 to 97.5 percent of polypropylene, 2 to 10 percent of nano calcium carbonate, 0.1 to 3 percent of nucleating agent, 0 to 5 percent of toughening agent polyolefin elastomer (POE), 0 to 4 percent of compatilizer, 0.1 to 2 percent of antioxidant and 0 to 3 percent of other aids. According to the stress whitening-resistant modified polypropylene material, the crystallinity of a polypropylene (PP) matrix is improved by utilizing the nucleating crystallization capacity of the nucleating agent; the nano calcium carbonate and the POE are combined to achieve an effect of synergetic toughening, and the stress whitening-resistant performance of copolymerization polypropylene is improved while the high mechanical performance of the modified polypropylene material is kept; and the prepared modified polypropylene material has high transparency, and also can be used for preparing plastic products with high transparency stress whitening resistance.

Owner:SHANGHAI PRET COMPOSITES

Polypropylene composition for producing bottle cap of carbonated beverage

The invention relates to a polypropylene composition for producing a bottle cap of a carbonated beverage. The composition comprises the following substances: 30-60 parts of homopolymerized polypropylene with an isotacticity higher than 99% and an MFR of 1-30g / 10 min; 30-60 parts of block copolymerized polypropylene with an MFR of 1-15g / 10 min; 4-20 parts of polyethylene with a density of 0.955-0.968 g / cm<3> and an MFR of 1-15 g / 10 min; 5-15 parts of polyolefin elastomer; 0.05-0.2 part of nucleating agent; and 0.3-1 part of slipping agent. The product has excellent rigidity, good impact resistance and good stress whitening resistance.

Owner:CHINA PETROLEUM & CHEM CORP

Stress whitening resistant modified polypropylene material and preparation method thereof

ActiveCN102863697AGood mechanical propertiesSolve the problem of stress whiteningAntioxidantMature technology

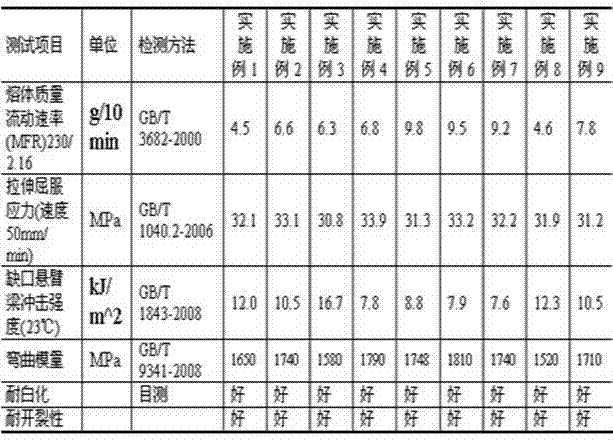

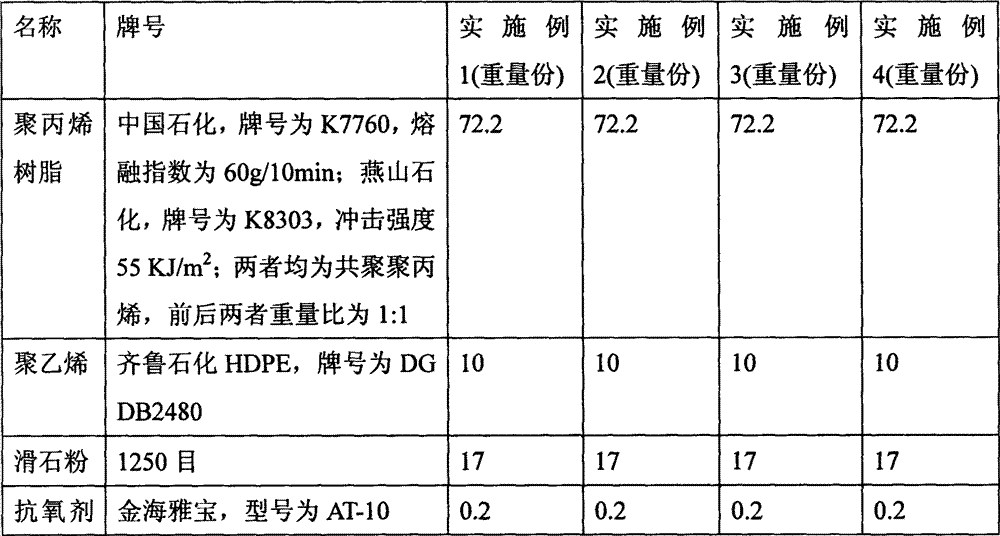

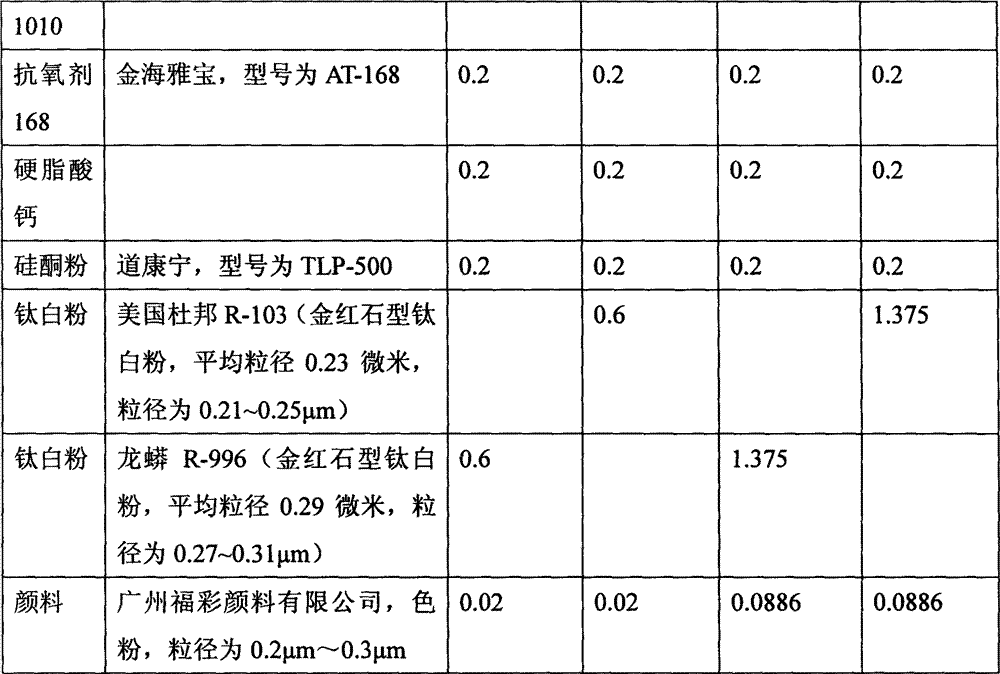

The invention discloses a stress whitening resistant modified polypropylene material. The material comprises, by weight, 60-83 parts of polypropylene resin, 10-25 parts of filling agents, 5-15 parts of polyethylene, 0.2-1 part of antioxidant, 0.2-1 part of lubricating agent, 0.3-2 parts of titanium pigment and 0.01-0.3 part of pigment, wherein grain diameters of the titanium pigment are in a range from 0.1 mu m to 0.5 mu m, the titanium pigment is added and is combined with other components, the polypropylene stress whitening phenomenon is reduced, the production cost is reduced and the good mechanical property of the material is kept. The invention also discloses a preparation method of the stress whitening resistant modified polypropylene material. The implementation is easy, industrial production of a prior twin-screw extruder in a mature technology is achieved, the preparation is simple, the large-scale industrial production is easy, and the method and the device have good economical benefits and wide application prospects.

Owner:中广核俊尔(上海)新材料有限公司 +1

Modified polypropylene material, preparation method and applications thereof

InactiveCN103160028AGood resistance to stress whiteningImprove performanceMaterials preparationProcedure Agents

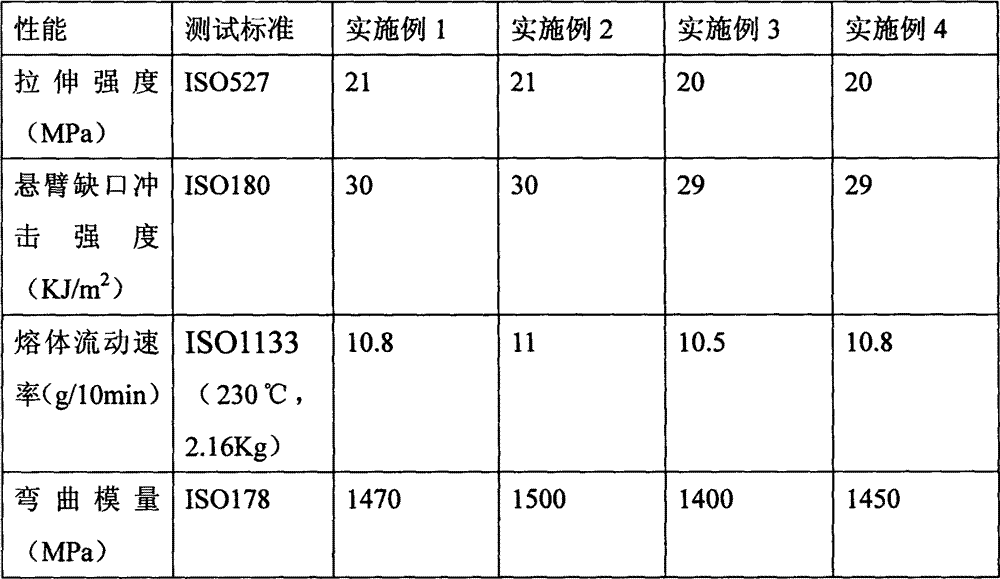

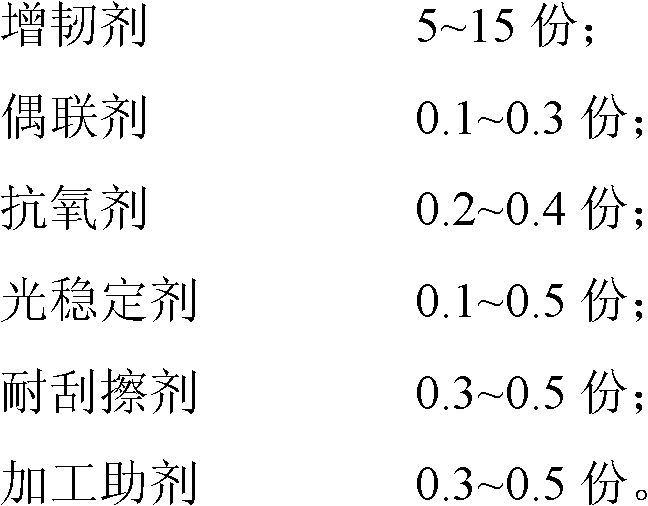

The invention belongs to the technical field of polymer material modification and processing, and discloses a modified polypropylene material, a preparation method and applications thereof. The modified polypropylene material is prepared from the following components, by weight, 58-84 parts of polypropylene, 10-25 parts of a mineral, 5-15 parts of a toughening agent, 0.1-0.3 part of a coupling agent, 0.2-0.4 part of an antioxidant, 0.1-0.5 part of a light stabilizer, 0.3-0.5 part of a scratch-resistance agent, and 0.3-0.5 part of a processing additive. The modified polypropylene material preparation method comprises: adding 58-84 parts by weight of polypropylene, 10-25 parts by weight of a mineral, 5-15 parts by weight of a toughening agent, 0.1-0.3 part by weight of a coupling agent, 0.2-0.4 part by weight of an antioxidant, 0.1-0.5 part by weight of a light stabilizer, 0.3-0.5 part by weight of a scratch-resistance agent, and 0.3-0.5 part by weight of a processing additive to a high speed mixer to mix for 3-5 min; adding the obtained mixture to an extruder to extrude, wherein the extruder barrel temperature is controlled to a range of 180-230 DEG C; carrying out extrusion cooling to achieve a room temperature, and drying; and adding into a granulator to carry out granulation to obtain the modified polypropylene material. The modified polypropylene material has excellent stress whitening resistance and can be adopted as vehicle inner decoration parts.

Owner:HEFEI GENIUS NEW MATERIALS

Stress-whitening-resisting glass fiber reinforced polypropylene composite and preparation method thereof

The invention discloses a special stress-whitening-resisting glass fiber reinforced polypropylene composite for automotive trims and a preparation method thereof. The special stress-whitening-resisting glass fiber reinforced polypropylene composite for automotive trims is characterized by comprising the following raw materials by weight percentage: 27-83 percent of polypropylene, 0-2 percent of heat stabilizer, 0-2 percent of processing agent, 0-2 percent of light stabilizer, 0-2 percent of special nucleating agent for polypropylene, 5-20 percent of flexibilizer, 2-10 percent of compatilizer, 5-20 percent of ultrafine talcum powder and 5-15 percent of chopped glass fiber. The preparation method comprises the following steps that after the raw materials are mixed, the mixture is added into a double-screw extruder with the length-diameter ratio of (30-60):1 to be molten and dispersed, meanwhile, the chopped glass fiber is fed into the double-screw extruder from a side feeding mouth to be extruded and pelletized, and the product is obtained. The composite has the characteristics of high stiffness, high heat resistance and stress whitening resistance and meets the requirement of the automotive trim material on stress whitening resistance.

Owner:SHANGHAI KINGFA SCI & TECH +1

Special stress whitening resistant polypropylene composite for automotive upholsteries and method for preparing special stress whitening resistant polypropylene composite

InactiveCN102617935AImprove liquidityExcellent resistance to stress whiteningElastomerPolypropylene composites

The invention discloses a special stress whitening resistant polypropylene composite for automotive upholsteries and a method for preparing the special stress whitening resistant polypropylene composite. The special stress whitening resistant polypropylene composite comprises raw materials including, in weight percent, 47-95% of polypropylene, 0-1% of heat stabilizers, 0-1% of processing agents, 0-6% of compatilizers, 5-20% of metallocene elastomers and 0-25% of talcum powder. The composite has excellent flowability, fine comprehensive mechanical performance, quite high breaking elongation and excellent stress whitening resistance, the melt flow rate is higher than or equal to 15g / 10min, the tensile strength is higher than or equal to 17MPa, the bending modulus is higher than or equal to 1500MPa, normal-temperature (23 DEG C) notch impact strength is higher than or equal to 7KJ / M2, the breaking elongation is higher than or equal to 200%, the heat deflection temperature is higher than or equal to 100 DEG C, and whitening is avoided under 3mm disc falling-ball impact (500g steel ball at a 50cm height). The special stress whitening resistant polypropylene composite can be used for the automotive upholsteries such as an automobile door panel, a vertical column, an instrument panel and the like requiring high stress whitening resistance.

Owner:SHANGHAI KINGFA SCI & TECH +1

Stress-whitening-resistant polypropylene composite material

The invention provides a stress-whitening-resistant polypropylene composite material. The stress-whitening-resistant polypropylene composite material comprises the following materials in parts by weight: 40-85 parts of polypropylene resin, 4-7 parts of stress-whitening-resistant agent, 15-45 parts of filling agent, 5-15 parts of compatilizer, 0.1-1.0 part of antioxygen, and 0.5-2 part of processing additive, wherein the polypropylene resin is co-polypropylene of polypropylene and polyethylene, and the weight ratio of polypropylene to polyethylene in the co-polypropylene is (95: 5)-(99: 1); the stress-whitening-resistant agent is one of or the mixture of more of TiO2, MnO2, ZnO and ZrO2. The stress-whitening-resistant polypropylene composite material has excellent stress-whitening resistance and favorable comprehensive mechanical property, and is relatively low in economic cost and suitable for mass production and application in industries of automobiles and the like.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

Polyeste blends with improved stress whitening for film and sheet applications

Disclosed are polyester blends that provide improved stress whitening behavior. The blends may be prepared from a polyester having crystallization half-time of at least 5 minutes and a polyester elastomer. The polyesters blends may be extruded or, in the presence of a release additive, calendered to produce film or sheet. Also disclosed are processes for making a film or sheet by extrusion or calendering the above blends and the film or sheet produced therefrom. The polyester blend and the film or sheet produced therefrom also may include plasticizers and / or flame retardants to increase their flexibility and enable their use in commercial applications requiring flame resistance. The film and sheet have excellent appearance and can be used in a wide range of decorative and packaging applications.

Owner:EASTMAN CHEM CO

Stress-whitening-resistant filling-modified polypropylene composite material and preparation method thereof

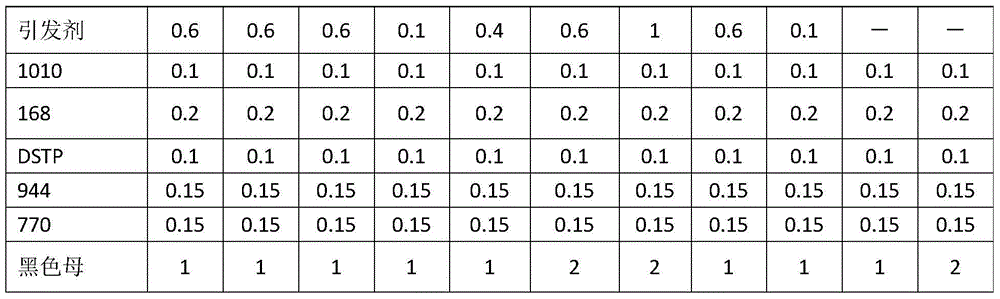

ActiveCN103254507AEnhanced interactionHigh strengthPolypropylene compositesHindered amine light stabilizers

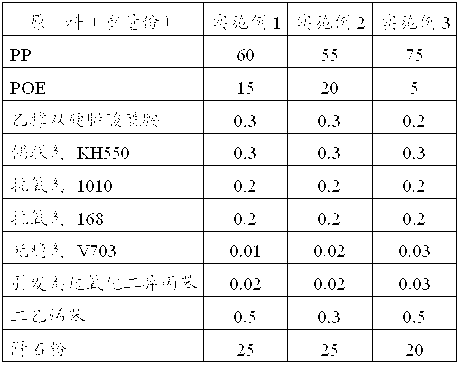

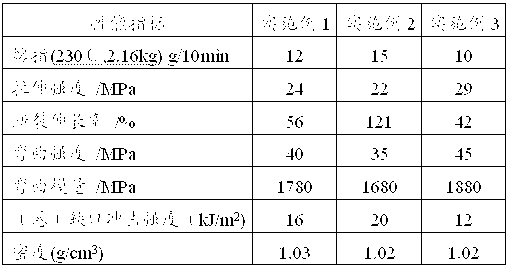

The invention discloses a stress-whitening-resistant filling-modified polypropylene composite material. The composite material comprises the following components by weight parts: 55-75 parts of polypropylene, 5-20 parts of a flexibilizer, 20-30 parts of mineral fillers, 0.2-0.4 parts of a dispersant, 0.1-0.3 parts of a coupling agent, 0.1-0.3 parts of a phenols anti-oxidant 1010, 0.1-0.3 parts of a phosphite anti-oxidant 168, 0.01-0.03 parts of a hindered amine light stabilizer V703, 0.01-0.1 parts of an initiator and 0.2-0.5 parts of a auxiliary crosslinking agent. The invention further discloses a preparation method of the stress-whitening-resistant filling-modified polypropylene composite material. According to the invention, through the initiator and the auxiliary crosslinking agent, interaction of each phase in a blending system is improved, the problem of stress whitening can be fundamentally solved through forming part chemical bonds, a production cost is low and performances are stable.

Owner:HEFEI GENIUS NEW MATERIALS

Polyolefin material with enhanced surface durability

Thermoplastic polyolefin blends with a good stiffness / impact balance, as well as enhanced surface durability, contain semi-crystalline polypropylene resin component, a propylene-based elastomer component, and an optional but preferred styrene-based elastomer component. The propylene-based elastomer (PBE) is characterized as having at least one of a) a plurality of identifying band positions at 998 cm−1, 974 cm−1, and 733 cm−1, as measured by Fourier Transform Infrared Spectroscopy (FTIR); or one or more glass transition temperatures (Tg) from about −15° C. to −35° C., as measured by Differential Scanning Calorimetry. The surface of articles made from such a thermoplastic blend shows increased scratch resistance and a decrease in stress whitening.

Owner:LYONDELLBASELL ADVANCED POLYOLEFINS USA

Stress whitening resistant low-VOC (Volatile Organic Compounds) low-linear-expansion-coefficient polypropylene material

InactiveCN106832598AImprovement of bending stress whitening performanceGood dimensional stabilityAntioxidantSorbent

The invention provides a stress whitening resistant low-VOC (Volatile Organic Compounds) low-linear-expansion-coefficient polypropylene material. The stress whitening resistant low-VOC low-linear-expansion-coefficient polypropylene material is prepared from the following raw materials in parts by weight: 40 to 70 parts of polypropylene resin mixture, 5 to 30 parts of filling powder, 5 to 15 parts of toughening agent, 1 to 10 parts of polyethylene, 2 to 5 parts of smell adsorbent, 1 to 2 parts of toner, 0.2 to 0.4 part of primary antioxidant and 0.2 to 0.4 part of auxiliary antioxidant. In the stress whitening resistant low-VOC low-linear-expansion-coefficient polypropylene material, random copolymerization polypropylene is taken as a substrate, so that the anti-bending stress whitening performance of the material is enhanced remarkably; the toughening agent and the polyethylene are added, so that the stress whitening resistance is enhanced, the linear expansion coefficient and smell of the material are lowered on the basis of keeping other physical properties, and the size stability of the material is improved.

Owner:TIANJIN KINGFA NEW MATERIAL

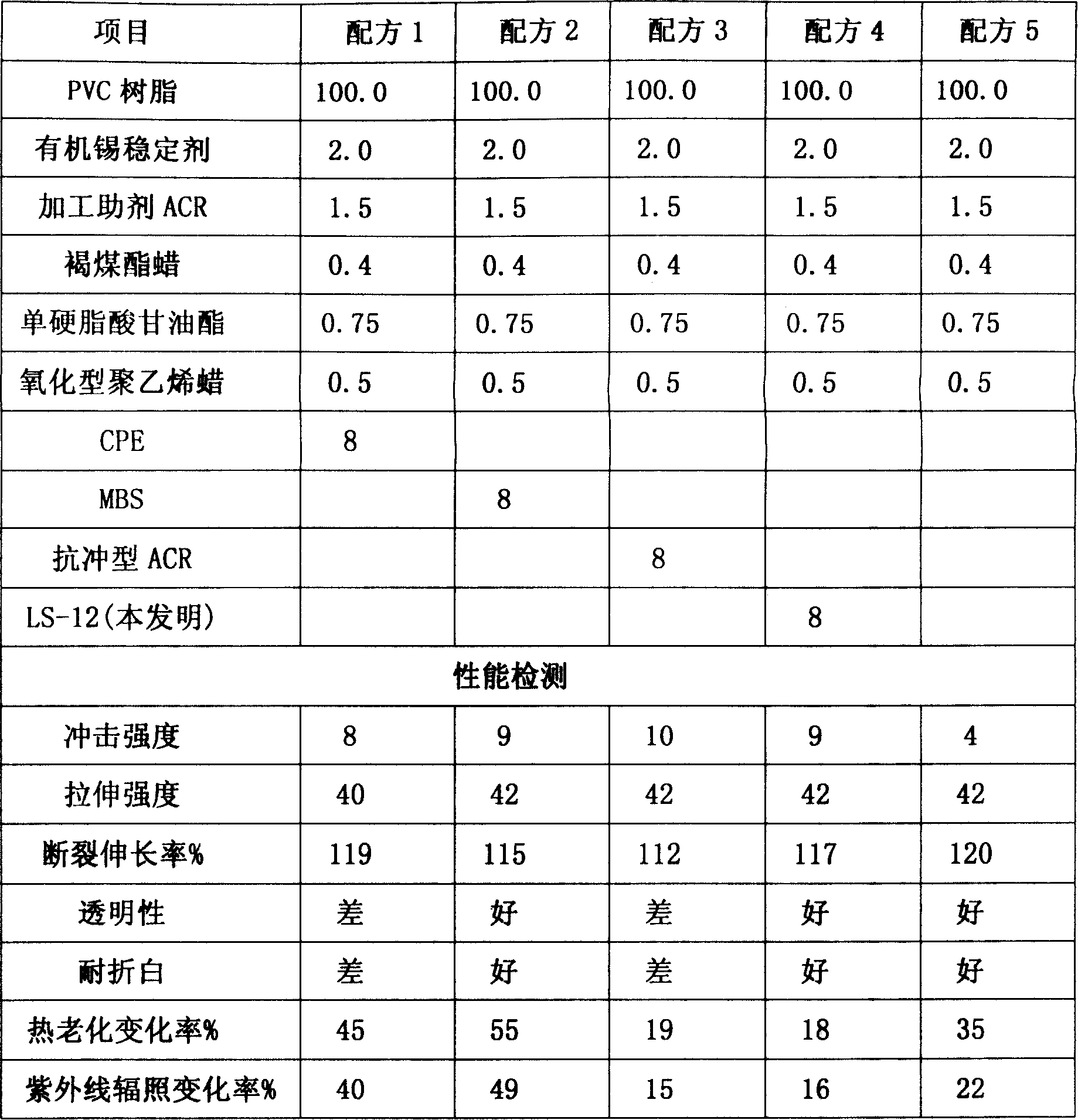

Transparent acrylic ester impact-resisting modifier for PVC

ActiveCN101190992ASolve the weather resistanceSolve the weather resistance problemEmulsionEmulsion polymerization

The inventions relates to transparent type acrylic impact modifier used in PVC, which is core-shell structural copolymer. Crosslinking agent is added into the polymeric monomer butyl acrylate and the styrene to carry out emulsion polymerization, thus obtaining the core layer; the shell layer is obtained through continuous emulsion polymerization grafting reaction of polymeric monomer styrene and methyl methacrylate on the core layer. The core layer polymeric monomer accounts for 80-90 percent of total polymeric monomer, the polymeric monomer of the shell layer accounts for 10-20 percent of the total polymeric monomer and pH of emulsion is controlled between 2 and 7. The emulsifier and the pH of the emulsion are used for adjusting granulation size of the copolymer between 80-150nm so as to guarantee the uniform with the refractive index of the PVC, thereby the product has stress whitening resistance and transparency when is used in PVC. Besides having the property of MBS resin, the product also solves the weather resistant problem of the MBS resin and can be used in polyvinyl chloride PVC transparent exterior products.

Owner:SHANDONG RUIFENG CHEM

A layer for cables having improved stress whitening resistance

The present invention relates to a Insulation layer for cables, a composition and a process thereof, showing improved stress whitening resistance by maintaining good mechanical and electrical properties and being environmental friendly.

Owner:ボレアリステクノロジーオイ

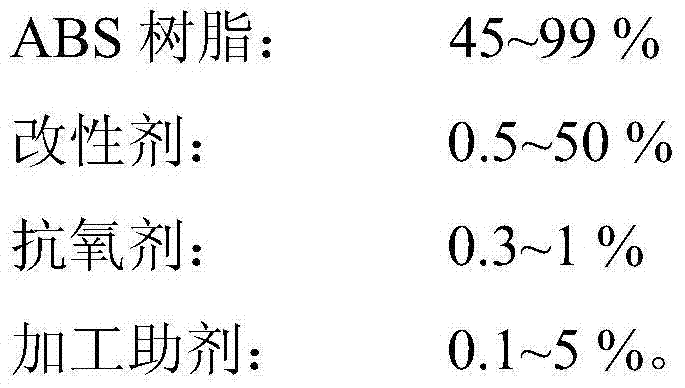

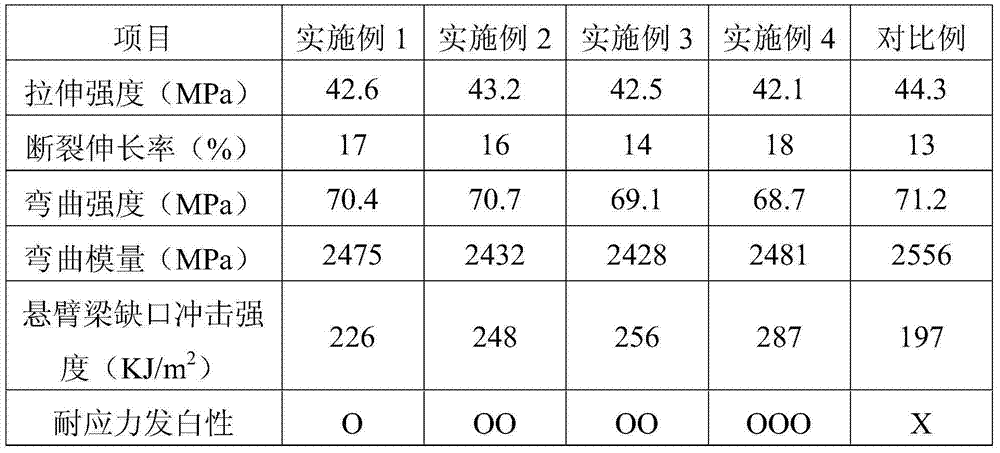

Stress whitening resistance ABS (Acrylonitrile Butadiene Styrene) composite material as well as preparation method and application thereof

ActiveCN103756240AImproved resistance to stress whiteningExcellent resistance to stress whitening effectAntioxidantStress-whitening

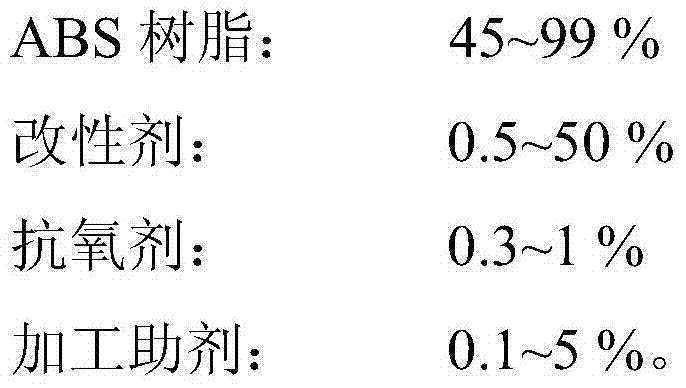

The invention belongs to the technical field of ABS materials, and discloses a stress whitening resistance ABS (Acrylonitrile Butadiene Styrene) composite material as well as a preparation method and an application thereof. The composite material comprises the following components in percentage by mass: 45-99% of ABS resin, 0.5-50% of modifying agent, 0.3-1% of antioxidant and 0.1-5% of machining additive. Due to addition of the modifying agent and by utilizing a formed 'island structure', microcrack is prompted to occur in the composite material, so that the impact energy can be absorbed, and the ABS composite material which maintains the good mechanics properties of the ABS resin and has the excellent stress whitening resistance effect can be prepared. As no additive for fixing color is needed to add, the stress whitening resistance ABS composite material provided by the invention can be also prepared into products with various requirements on color, and can be widely applied to different fields.

Owner:TIANJIN KINGFA NEW MATERIAL +1

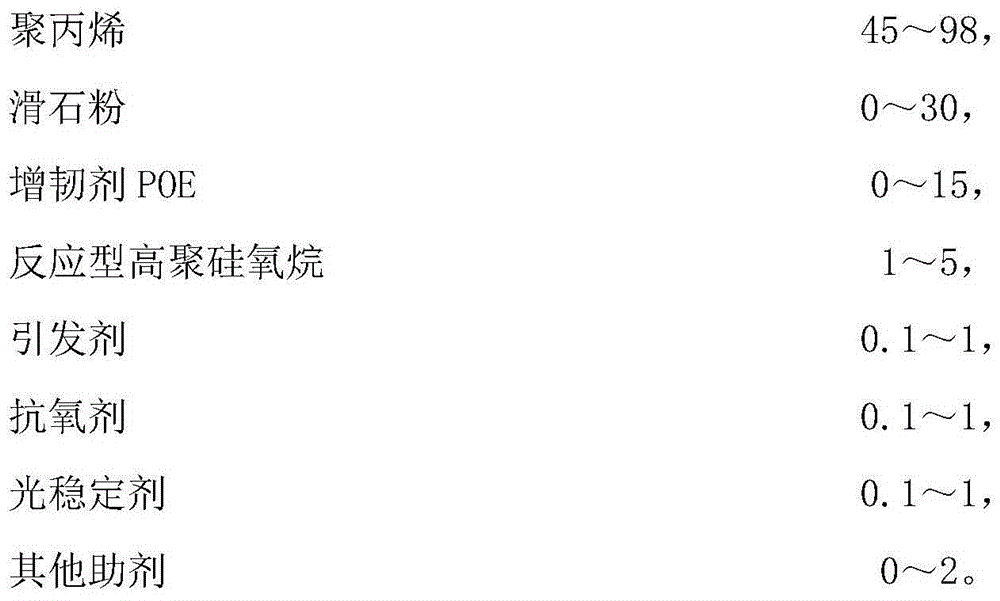

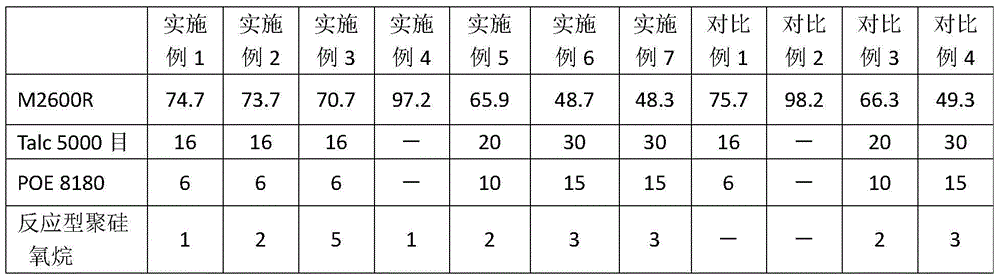

Scratching-resistant polypropylene composite material capable of resisting stress whitening and preparation method thereof

InactiveCN104558836AImprove scratch resistanceSolve the problem of severe stress whiteningPolypropylene compositesPolymer science

The invention discloses a scratching-resistant polypropylene composite material capable of resisting stress whitening and a preparation method thereof. The polypropylene composite material is prepared from the following raw materials in percentage by weight: 45-98% of polypropylene, 0-30% of talcum powder, 0-15% of a flexibilizer POE, 1-5% of reaction type high polysiloxane, 0.1-1% of an initiator, 0.1-1% of an antioxidant, 0.1-1% of a light stabilizer, and 0-2% of other auxiliaries. According to the preparation method disclosed by the invention, under the action of the initiator, the reaction type high polysiloxane and the polypropylene material are crosslinked, so that when the scratching resistance of the polypropylene material is improved, the stress whitening problem of the product caused by addition of the polysiloxane scratching-resistant agent can be solved; the scratching-resistant polypropylene composite material is simple in preparation process and convenient to use.

Owner:SHANGHAI PRET COMPOSITES +2

Flexible polypropylene cable sheath material

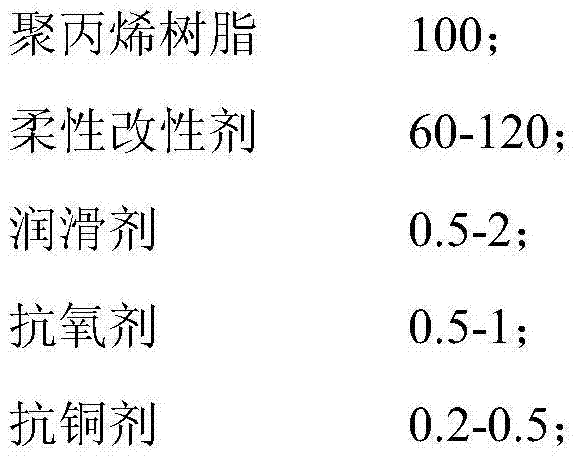

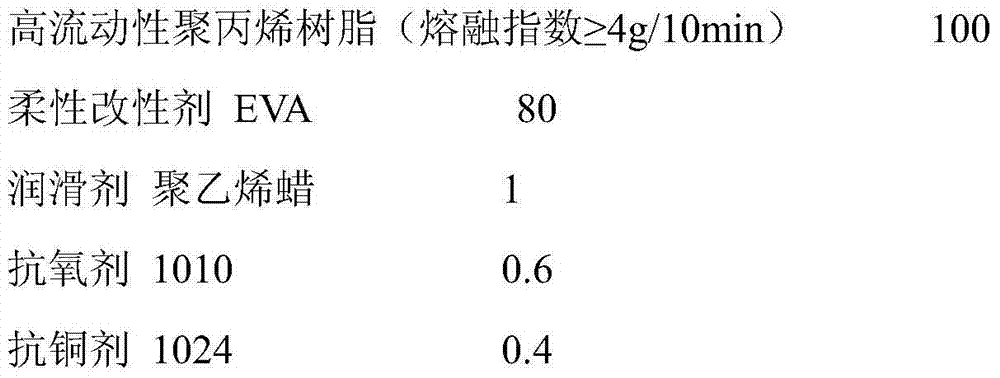

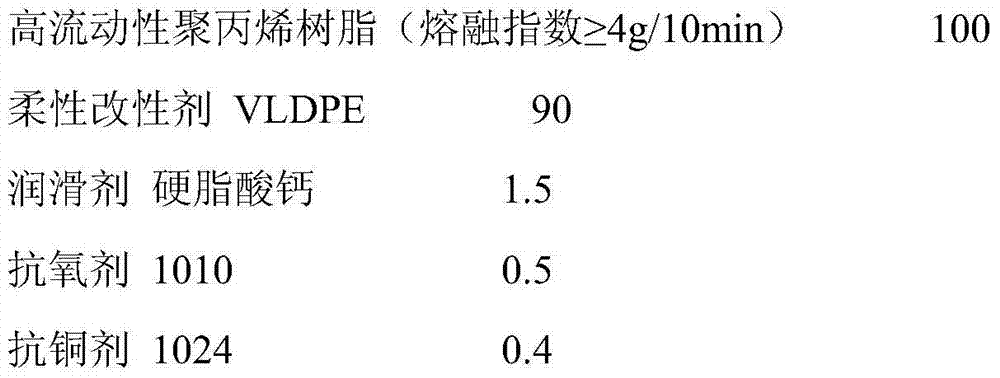

InactiveCN104744807AGood flexibilityImproves stress whiteningPlastic/resin/waxes insulatorsEngineeringCopper

The invention relates to a flexible polypropylene cable sheath material. The material comprises the following components by weight: 100 parts of polypropylene resin, 60 to 120 parts of a flexible modifier, 0.5 to 2 parts of a lubricant, 0.5 to 1 part of an anti-oxidant and 0.2 to 0.5 part of an anti-copper agent. The flexible polypropylene cable sheath material has good low temperature resistance and flexibility and can effectively improve original stress whitening of a polypropylene cable material and enhance low temperature resistance of the polypropylene cable material.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Stress blanching and stress crack resistant filling modified polypropylene, preparation method and application

The invention discloses a stress-tolerant whitening and stress cracking filling modifying polypropylene and making method and application, which is characterized by the following: making each index of polypropylene reach or exceed the preset request; solving the defect of stress whitening and stress cracking after reaching rigid and fexible balance; fitting for automobile industry and assembling property; making the bending modulus of material to 1300Mpa at 23 deg. c and collision strength of cantilever beam notch over 25KJ / m2; reaching and exceeding the integrated property of automobile industry.

Owner:SHANGHAI KINGFA SCI & TECH +1

Polypropylene composition

The invention discloses a polypropylene composition which comprises the following components in parts by weight: 70-90 parts of impact polypropylene, 4-20 parts of random polypropylene and 4-20 parts of an ethylene homopolymer. The polypropylene composition provided by the invention is of a multi-phase structure, has a relatively good rigid-tough balance characteristic and also has relatively good stress whitening resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com