Stress whitening-resistant modified polypropylene material and preparation method thereof

A polypropylene material and anti-stress whitening technology, which is applied in the field of polypropylene material preparation, can solve problems such as stress whitening, stress cracking, and stress whitening resistance of clip feet, and achieve improved stress whitening resistance and good mechanical properties. Performance, effect of improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation

[0029] Below in conjunction with embodiment, the present invention is described in further detail.

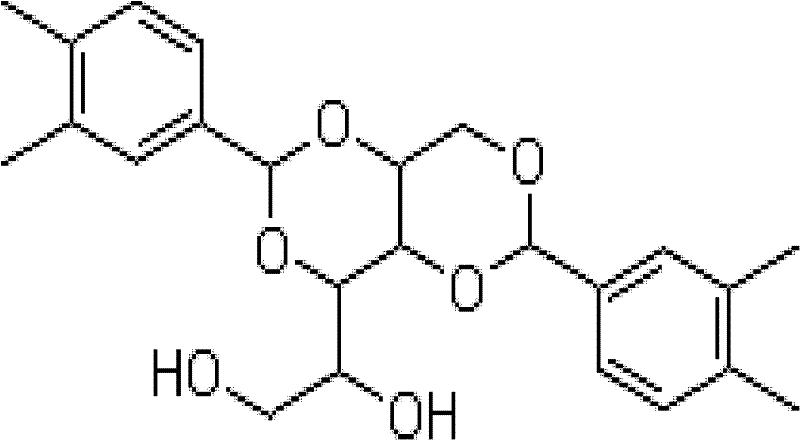

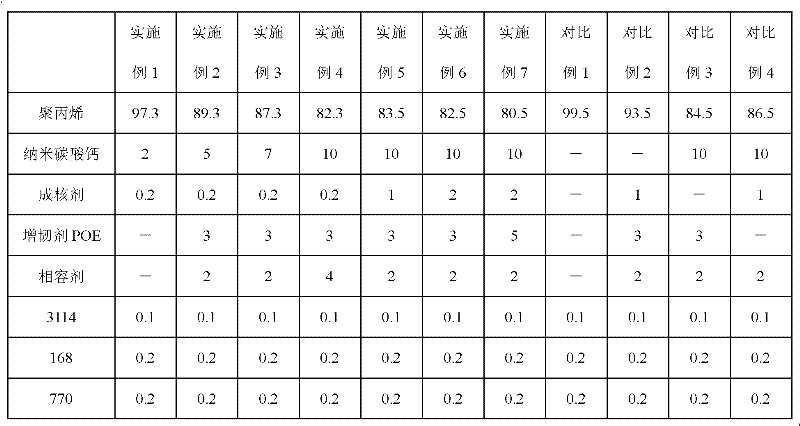

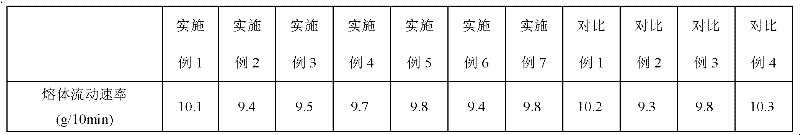

[0030] In the composite material formula of the embodiment and the comparative example, the polypropylene is a copolymerized polypropylene produced by SK Korea, the trade name is BX3500, and its melt flow rate is 10g / 10min (test condition: 230 ° C × 2.16Kg); Nano-calcium carbonate is produced by Jiangxi Huaming Nano-Calcium Carbonate Co., Ltd., and its trade name is nano-calcium carbonate SPSL-2, and its particle diameter is at 100~300nm; Described nucleating agent is the DMDBS that Milliken company produces, and chemical name is two ( 3,4-dimethyldibenzylidene) sorbitol; the toughening agent POE is Engage8180 produced by DuPont, and its melt index is 0.5g / 10min (test condition: 190°C×2.16Kg). The compatibilizer is maleic anhydride grafted polypropylene produced by Nanjing Deba Chemical Co., Ltd., the melt flow rate is 50g / 10min, and the grafti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com