Polypropylene composition for producing bottle cap of carbonated beverage

A polypropylene composition and composition technology, applied in the field of polypropylene compositions, can solve problems such as deformation of bottle caps, poor toughness of anti-theft rings of bottle caps, brittleness of anti-theft rings of bottle caps, etc., to improve performance and improve stress The effect of bleaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

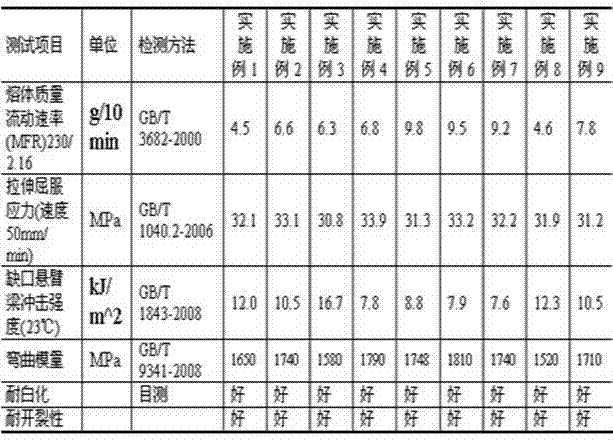

Examples

Embodiment 1

[0009] Example 1: homopolypropylene: MFR: 8.0g / 10 minutes, 40 parts, block copolymer polypropylene: MFR: 3.0g / 10 minutes, 40 parts; polyethylene: density: 0.955, MFR: 6g / 10 minutes , 15 parts; POE: 5 parts; nucleating agent NA21 (2,2′-methylenebis(4,6-tert-butylphenol) phosphine aluminum salt) 0.1 part; oleic acid amide: 0.5 part; After mixing in medium for 1 minute, pelletize in a twin-screw extruder, sample preparation and test.

Embodiment 2

[0010] Example 2: homopolypropylene: MFR: 8.0g / 10 minutes, 50 parts, block copolymer polypropylene: MFR: 3.0g / 10 minutes, 30 parts; polyethylene: density: 0.955, MFR: 6g / 10 minutes , 15 parts; POE: 5 parts; nucleating agent NA21: 0.1 part; oleic acid amide: 0.5 part; after mixing in a high-speed mixer for 1 minute, carry out granulation, sample preparation and testing in a twin-screw extruder.

Embodiment 3

[0011] Example 3: homopolypropylene: MFR: 8.0g / 10 minutes, 40 parts, block copolymer polypropylene: MFR: 3.0g / 10 minutes, 40 parts; polyethylene: density: 0.955, MFR: 6g / 10 minutes , 10 parts; POE: 10 parts; nucleating agent NA21: 0.1 parts; oleic acid amide: 0.5 parts; after mixing in a high-speed mixer for 1 minute, granulate in a twin-screw extruder, sample preparation and testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com