Stress-whitening-resistant filling-modified polypropylene composite material and preparation method thereof

A technology for anti-stress whitening and composite materials, which is applied in the field of anti-stress whitening filled modified polypropylene composite materials and its preparation, can solve the problems of not being able to fundamentally eliminate stress whitening, reduce stress whitening, etc., and achieve elimination of stress whitening. Filled modified polypropylene with stress whitening defects, low production cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

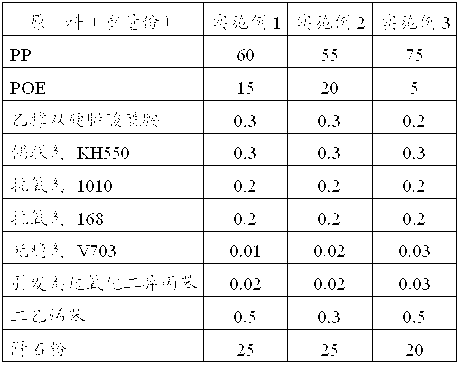

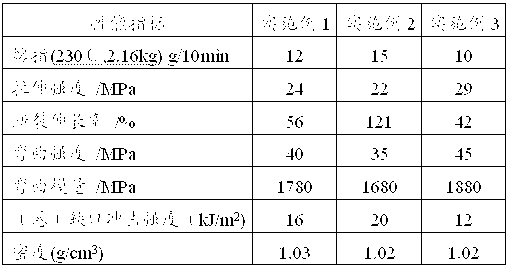

Examples

Embodiment 4

[0049] (1) Weigh the raw materials of each component according to the following parts by weight:

[0050] Copolymerized polypropylene (melt index at 20g / 10min) 65 parts,

[0051] Toughener POE (tensile strength at 10MPa) 10 parts,

[0052] Mineral filler talcum powder (particle size is 800 mesh) 25 parts,

[0053] Dispersant ethylene bis stearic acid amide 0.4 part,

[0054] Silane coupling agent KH-550 (purity greater than 97%) 0.1 parts,

[0055] Antioxidant 1010 0.1 part,

[0056] Antioxidant 168 0.3 parts,

[0057] Light stabilizer V703 0.015 parts,

[0058] 0.01 part of initiator dicumyl peroxide,

[0059] 0.2 parts of auxiliary crosslinking agent divinylbenzene;

[0060] (2) Add the mineral filler into the high-speed mixer, then add the dispersant and coupling agent and stir at 1000rpm for 1min, then add polypropylene, toughener, phenolic antioxidant 1010, phosphite antioxidant 168 in sequence , hindered amine light stabilizer V703, initiator and co-crosslinking ag...

Embodiment 5

[0063] (1) Weigh the raw materials of each component according to the following parts by weight:

[0064] Copolymerized polypropylene (melt index at 30g / 10min) 70 parts,

[0065] Toughener POE (tensile strength at 15MPa) 5 parts,

[0066] 30 parts of mineral filler talcum powder (particle size is 1250 mesh),

[0067] Dispersant ethylene bis stearic acid amide 0.35 parts,

[0068] Silane coupling agent KH-550 (purity greater than 97%) 0.2 parts,

[0069] Antioxidant 1010 0.3 parts,

[0070] Antioxidant 168 0.1 parts,

[0071] Light stabilizer V703 0.015 parts,

[0072] 0.1 part of initiator dicumyl peroxide,

[0073] 0.4 parts of auxiliary crosslinking agent divinylbenzene;

[0074] (2) Add the mineral filler to the high-speed mixer, then add the dispersant and coupling agent and stir at 900rpm for 3 minutes, then add polypropylene, toughener, phenolic antioxidant 1010, and phosphite antioxidant 168 in sequence , hindered amine light stabilizer V703, initiator and co-cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com