Polypropylene composition with low VOC (volatile organic compounds), scratch resistance and stress whitening resistance and preparation method of polypropylene composition

A polypropylene composition, anti-stress whitening technology, applied in the field of polypropylene composition, can solve problems such as poor compatibility, easy to induce silver cracks or cracks, surface scratch resistance, low surface resistivity and mechanical properties , to achieve the effects of reducing the generation of low molecular volatile organic compounds, improving scratch resistance, and solving high stress whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

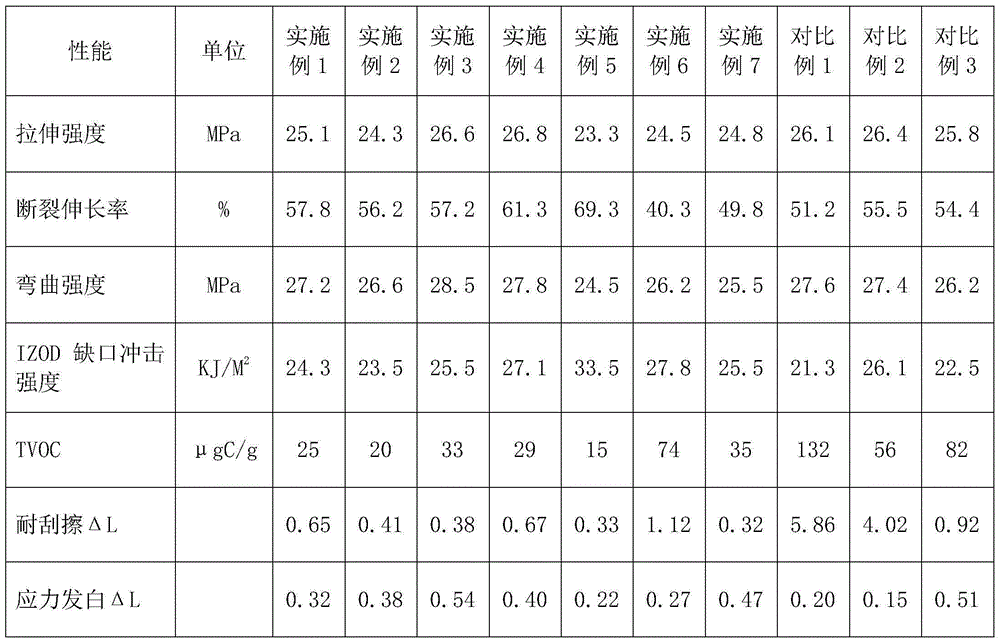

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with specific embodiments, where the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

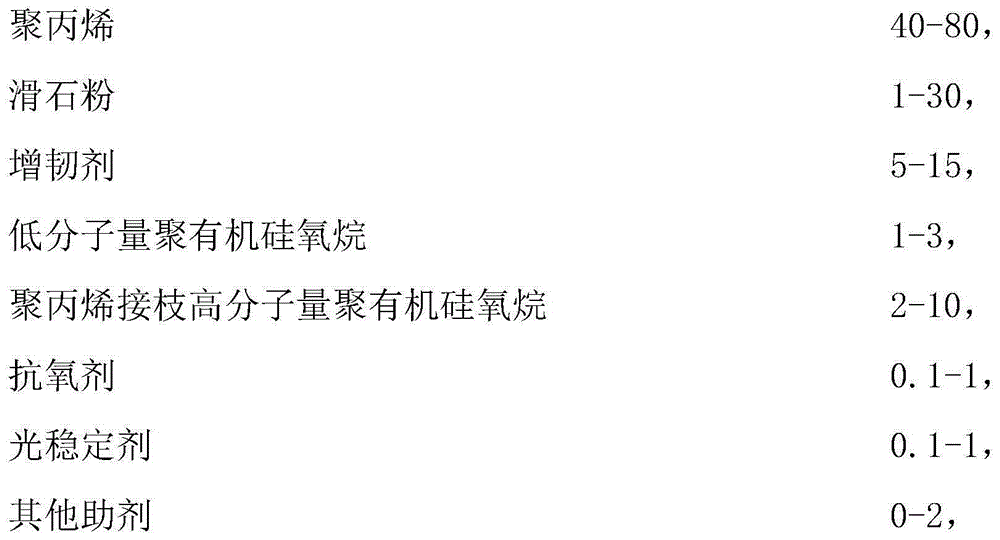

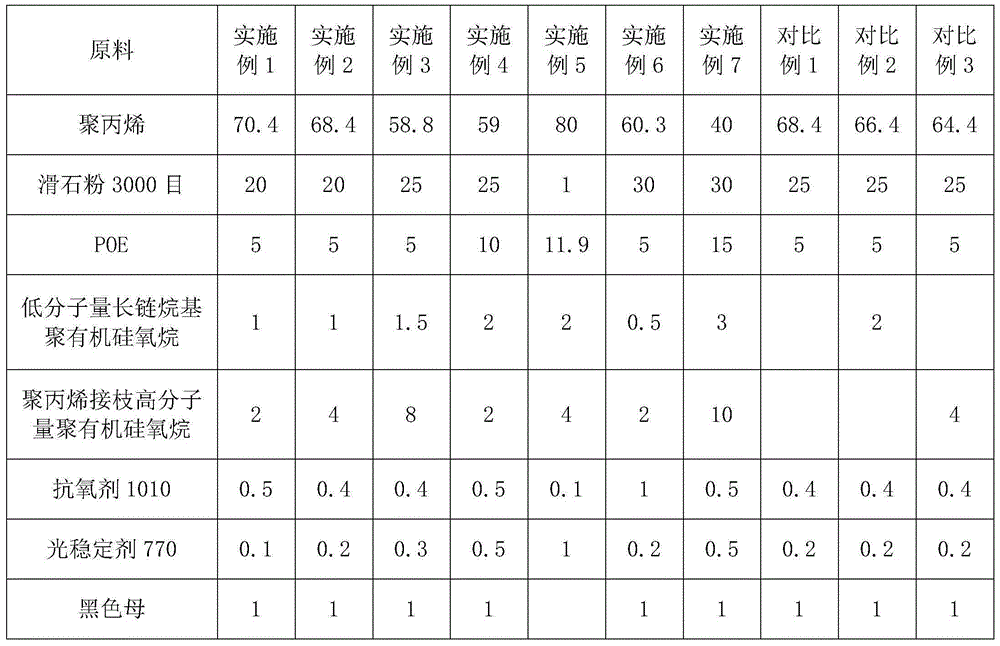

[0027] Each component was weighed according to the content percentage of the product components described in Table 1.

[0028] Table 1 Low VOC, scratch-resistant and anti-stress whitening automotive interior polypropylene composition formulation

[0029]

[0030] In each embodiment and the comparative example polypropylene composition material formula, the polypropylene used is the copolymerized polypropylene of melt flow rate 20; The talcum powder mesh number used is 3000 meshes, and average particle diameter is 4.5 microns; The toughening agent used is POE; The low molecular weight long-chain alkyl polyorganosiloxane used is a product of Shaoxing Jiahua Polymer Materials Co., Ltd., the brand name A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com