Stress whitening resistance ABS (Acrylonitrile Butadiene Styrene) composite material as well as preparation method and application thereof

A composite material and stress-resistant technology, applied in the field of ABS materials, can solve the problems affecting product performance and quality, stress whitening, etc., to achieve excellent stress whitening resistance and improve the effect of stress whitening resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

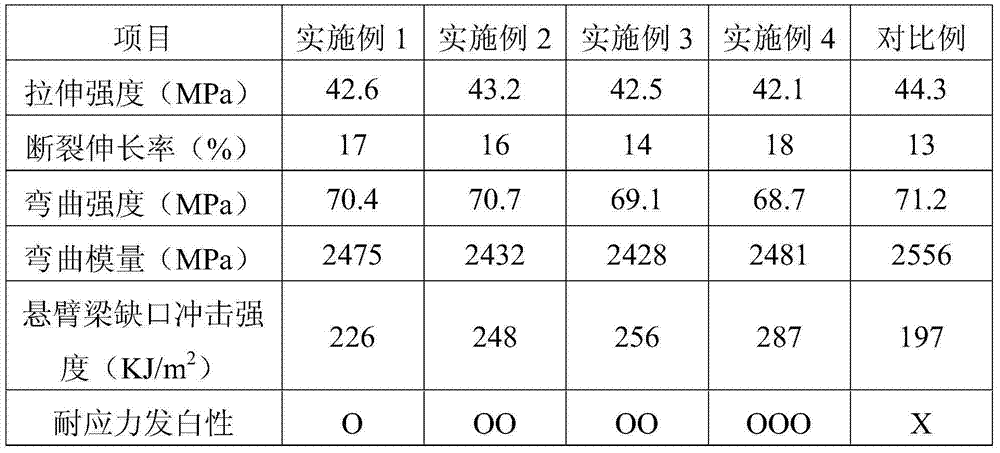

Examples

Embodiment 1

[0032] Example 1: Preparation of a stress-whitening resistant ABS composite material

[0033] 90wt% ABS121H, 9wt% modifier, the modifier is a mixture of styrene toughener and ABS high rubber powder with a mass ratio of 1:1, wherein the styrene toughener is selected from LG Chem, the specific model is SBS LG501S (LG-BOTIAN), the ABS high rubber powder is from Kumho, South Korea, the specific model is HR181, 0.3wt% antioxidant 1010, 0.2wt% antioxidant 168 and 0.5wt% % processing aid (EBS) is added to the high-speed mixer and mixed evenly, fed into the extruder through the feeder, mixed, melted and extruded, drawn, cooled, and pelletized to obtain the stress-whitening resistant ABS composite material .

[0034] The processing conditions for melt extrusion of the extruder are as follows: the temperature of the first zone is 150-200°C, the temperature of the second zone is 190-240°C, the temperature of the third zone is 190-240°C, the temperature of the fourth zone is 190-240°C, a...

Embodiment 2

[0035] Example 2: Preparation of a stress-whitening resistant ABS composite material

[0036] 80wt% ABS121H, 19wt% modifier, the modifier is a mixture of styrene toughener and chlorinated polyethylene toughener in a mass ratio of 2:1, wherein the styrene toughener The agent is selected from LG Chemical, the specific model is SBS LG501S (LG-BOTIAN), and the chlorinated polyethylene is selected from Shandong Yaxing, and the specific model is CPE7130, 0.2wt% antioxidant 1010, 0.2wt% antioxidant 168 and Add 0.6wt% processing aid (EBS) into a high-speed mixer and mix evenly, feed it into the extruder through a feeder, knead, melt extrude, pull strands, cool, and pelletize to obtain stress-resistant whitening ABS composite material.

[0037] The processing conditions for melt extrusion of the extruder are as follows: the temperature of the first zone is 150-200°C, the temperature of the second zone is 190-240°C, the temperature of the third zone is 190-240°C, the temperature of the...

Embodiment 3

[0038] Embodiment 3: Preparation of a kind of anti-stress whitening ABS composite material

[0039] 75wt% ABS121H, 24wt% modifier, the modifier is a mixture of styrene toughener, ABS high rubber powder, and chlorinated polyethylene toughener in a mass ratio of 1:1:1, Among them, the styrene toughening agent is selected from Sinopec, the specific model is QIM-03, the ABS high rubber powder is selected from Korea Kumho, the specific model is HR181, and the chlorinated polyethylene is selected from Shandong Yaxing, the specific model is CPE5236, The antioxidant 1010 of 0.2wt%, the processing aid (white mineral oil) of the antioxidant 168 of 0.3wt% and 0.5wt% add in the high-speed mixer and mix uniformly, feed in the extruder through the feeder, mix Refining, melt extrusion, drawing, cooling and pelletizing to obtain stress-whitening-resistant ABS composite materials.

[0040] The processing conditions for melt extrusion of the extruder are as follows: the temperature of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com