A layer for cables having improved stress whitening resistance

A cable insulation and polarity technology, applied in circuits, electrical components, insulators, etc., can solve undisclosed problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

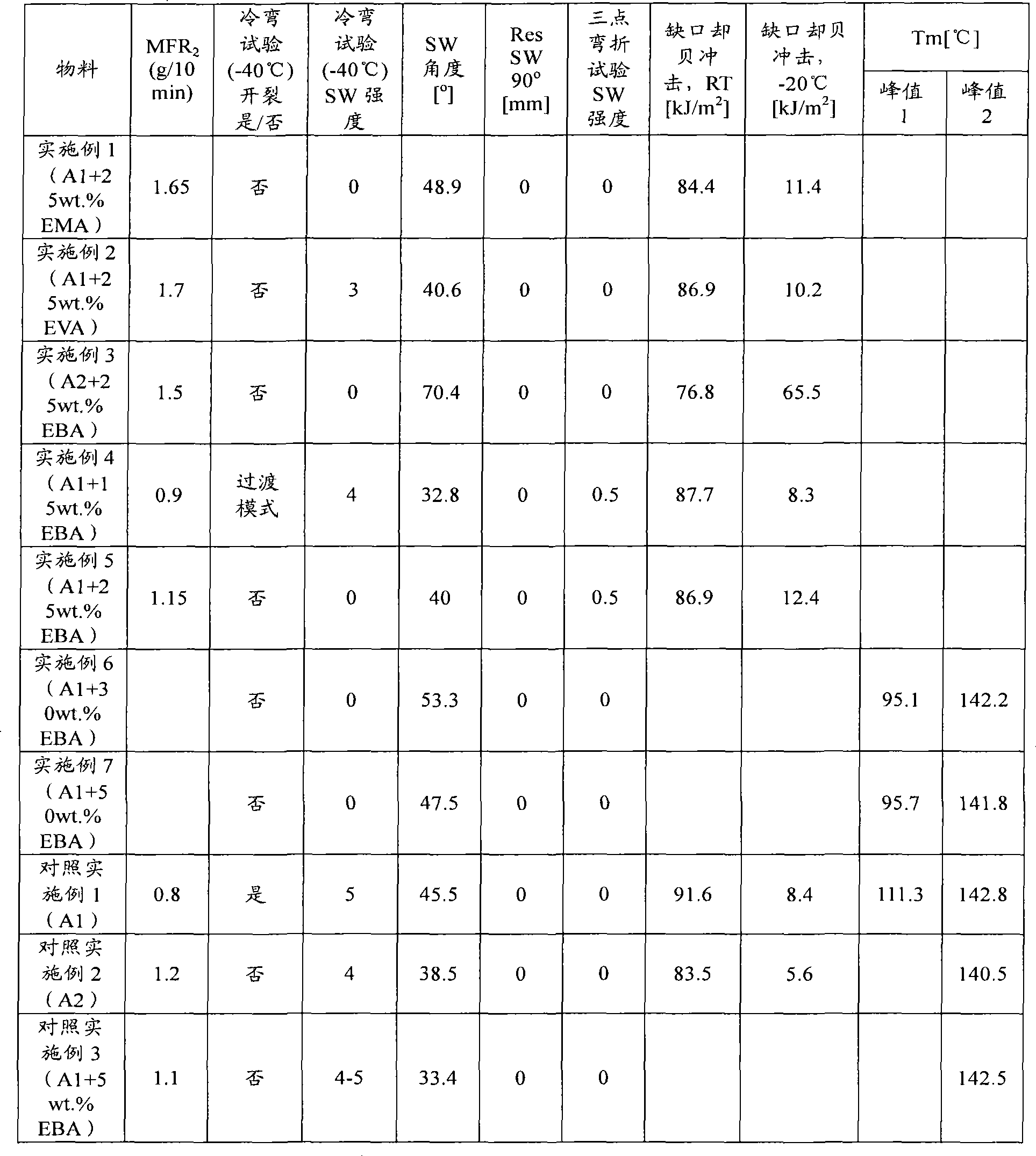

[0106] Different polypropylene compositions are extruded on round aluminum conductors. The diameter of the conductor is 3mm and the thickness of the insulating layer is 0.7mm. The wire travel speed was 75m / min and the temperature on the wire was set at 178-241°C, resulting in a melting temperature of approximately 240°C. The temperature of the cooling bath was 23°C. At a line speed of 75 m / min the extrudability of the polypropylene composition according to the invention is good, a smooth surface can be obtained.

[0107] materials:

[0108] a) Polypropylene-based resin (A):

[0109] Two different polypropylene-based resins (A) were used in the examples.

[0110] Polypropylene-based resin A1 is a heterophasic polypropylene copolymer of polypropylene-random copolymer as the matrix phase and ethylene-propylene-rubber as the dispersed phase, and its total C 2 - The content is about 15 wt.%, the total XS (xylene solubles) content is about 27 wt.%, and the MFR (230°C / 2.16kg) is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com