Polypropylene composition

A polypropylene composition and polypropylene technology, applied in the field of polymers, can solve problems such as recycling and environmental pollution, affecting the appearance of products, stress whitening, etc., and achieve good stress whitening resistance, broad application prospects, and high stress resistance The effect of whitening properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

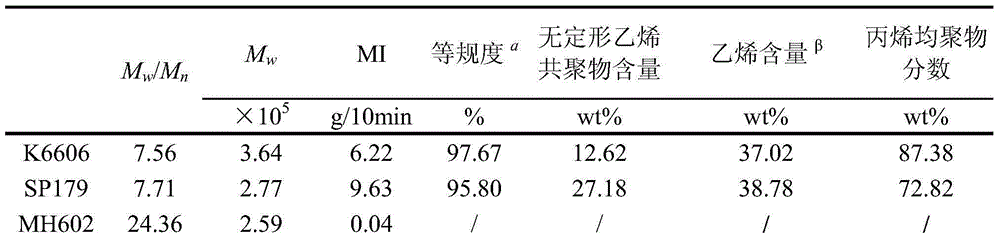

[0033]1. The impact polypropylene resin (Yanshan Petrochemical, trade name is K6606, the melt index under 230 ℃, 2.16kg load is 6.2g / 10min), polypropylene random copolymer (Yanshan Petrochemical, trade name is 4220, 230 ℃, 2.16kg load under the melt index of 0.3g / 10min, wherein the weight content of comonomer ethylene is 3.8%) and polyethylene homopolymer (Shanghai Petrochemical, trade name MH602, 190 ℃, 2.16kg load under the The melt index is 0.04g / 10min) according to the weight ratio of 80:8:12, adding 0.3% antioxidant, and the antioxidant is made by mixing BASF1010 and BASF168 according to the weight ratio of 1:1. Mix well in a high speed mixer to obtain a polypropylene composition. Then, the polypropylene composition material is melt-blended and extruded at 180-230° C. to pelletize with a twin-screw extruder.

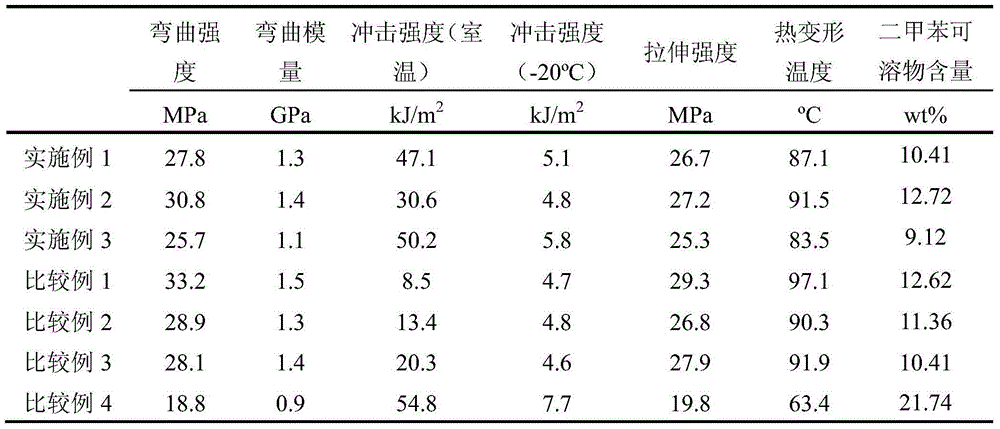

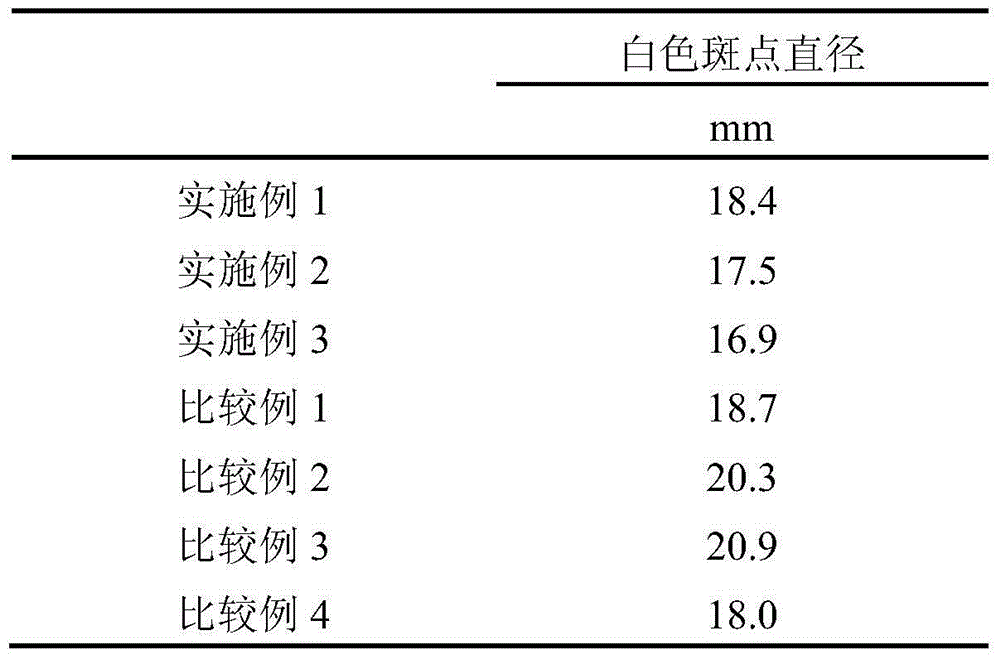

[0034] 2. According to the above-mentioned standards, injection molded samples were tested, and the data are shown in Tables 1 to 3.

Embodiment 2

[0036] Same as Example 1, except that the weight ratio of impact polypropylene resin, polypropylene random copolymer and polyethylene homopolymer is adjusted to 90:4:6. Samples were injection molded according to the above-mentioned standards and tested. The data are shown in Tables 1 to 3.

Embodiment 3

[0038] Same as Example 1, except that the weight ratio of impact polypropylene resin, polypropylene random copolymer and polyethylene homopolymer is adjusted to 75:10:15. Samples were injection molded according to the above-mentioned standards and tested. The data are shown in Tables 1 to 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com