Stress whitening resistant low-temperature impact resistant polypropylene material and preparation method thereof

A technology of anti-stress whitening and polypropylene materials, which is applied in the field of modified polypropylene materials and its production, can solve the problems of unsatisfactory mechanical properties, poor low-temperature impact performance, and unsuitable parts, etc., to improve the bending stress Whitening performance, improved low temperature impact resistance, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

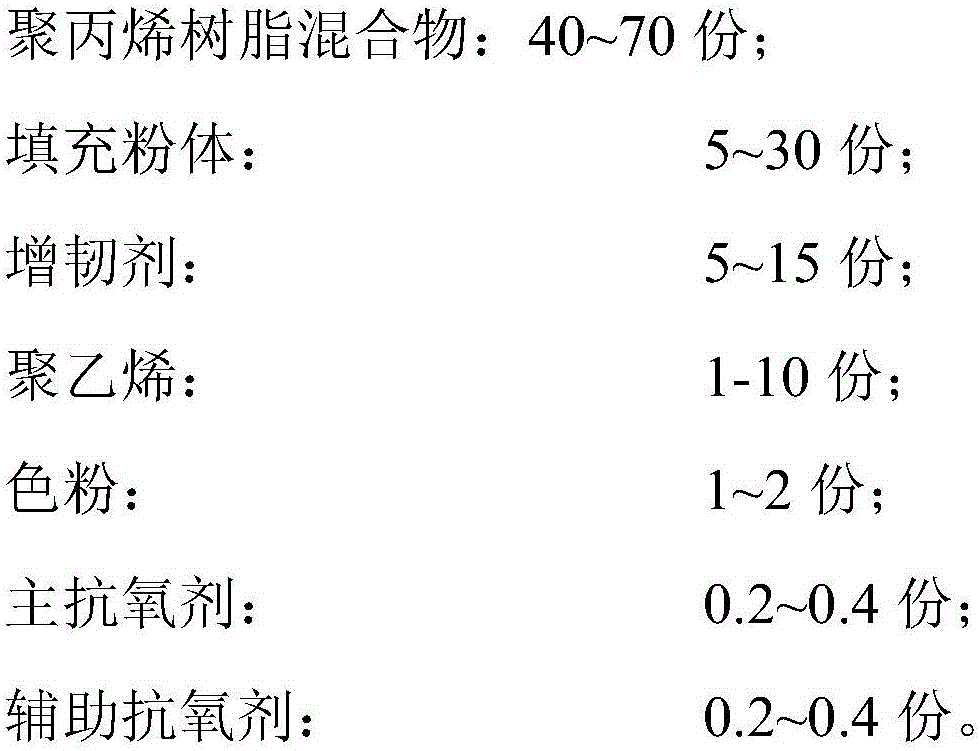

Method used

Image

Examples

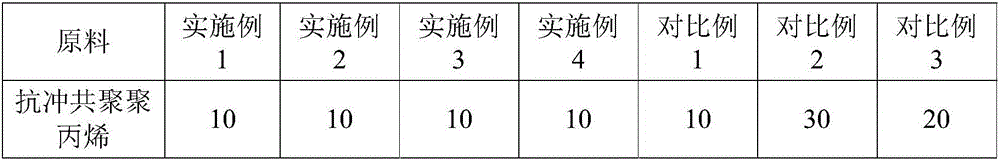

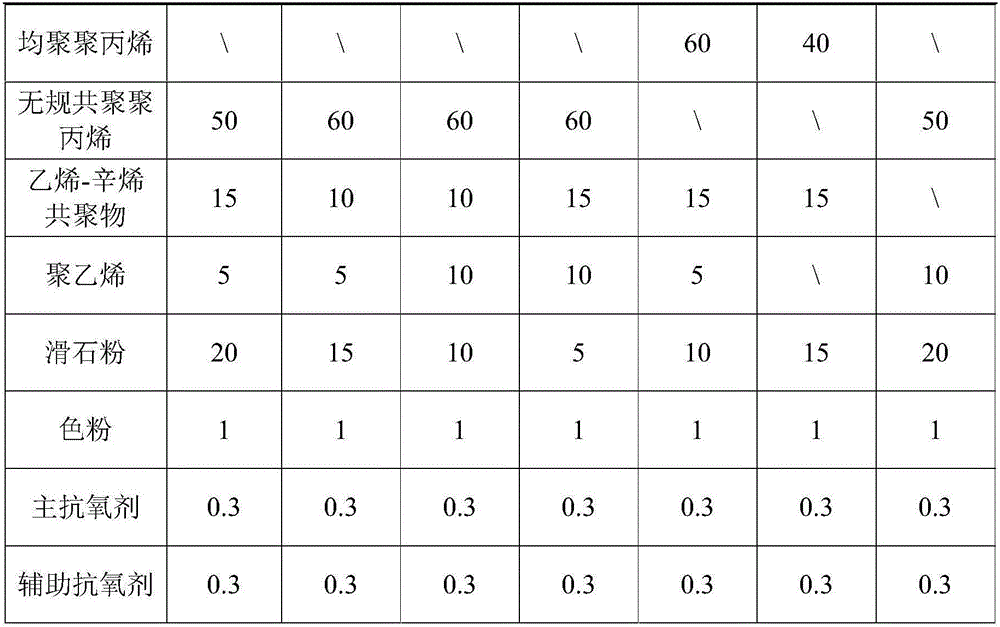

Embodiment 1

[0031] Weigh the components according to the following parts by weight: 10.0 parts of impact copolymerized polypropylene, 50.0 parts of random copolymerized polypropylene, 15.0 parts of ethylene-octene copolymer, 5.0 parts of high-density polyethylene, 20.0 parts of talcum powder, toner 1.0 part, 0.3 part of antioxidant 1010, 0.3 part of antioxidant 168, each component is placed in the high-speed mixer and fully stirred to obtain a premix, and the premix is added to the main feeding port of the twin-screw extruder , melt extrusion, granulation and drying to obtain stress-whitening and low-temperature impact-resistant polypropylene materials.

[0032] The melt extrusion conditions of the twin-screw extruder are: the temperature of the first zone is 80-120°C, the temperature of the second zone is 190-210°C, the temperature of the third zone is 210-230°C, the temperature of the fourth zone is 210-230°C, and the temperature of the fifth zone is 210- 230°C, the temperature in the...

Embodiment 2

[0034] Weigh the components according to the following parts by weight: 10.0 parts of impact copolymerized polypropylene, 60.0 parts of random copolymerized polypropylene, 10.0 parts of ethylene-octene copolymer, 5.0 parts of high-density polyethylene, 15.0 parts of talcum powder, toner 1.0 part, 0.3 part of antioxidant 1010, 0.3 part of antioxidant 168, each component is placed in the high-speed mixer and fully stirred to obtain a premix, and the premix is added to the main feeding port of the twin-screw extruder , melt extrusion, granulation and drying to obtain stress-whitening and low-temperature impact-resistant polypropylene materials.

[0035] The melt extrusion conditions of the twin-screw extruder are: the temperature of the first zone is 80-120°C, the temperature of the second zone is 190-210°C, the temperature of the third zone is 210-230°C, the temperature of the fourth zone is 210-230°C, and the temperature of the fifth zone is 210- 230°C, the temperature in the...

Embodiment 3

[0037] Weigh the components according to the following parts by weight: 10.0 parts of impact copolymerized polypropylene, 60.0 parts of random copolymerized polypropylene, 10.0 parts of ethylene-octene copolymer, 10.0 parts of high-density polyethylene, 10.0 parts of talcum powder, toner 1.0 part, 0.3 part of antioxidant 1010, 0.3 part of antioxidant 168, each component is placed in the high-speed mixer and fully stirred to obtain a premix, and the premix is added to the main feeding port of the twin-screw extruder , melt extrusion, granulation and drying to obtain stress-whitening and low-temperature impact-resistant polypropylene materials.

[0038] The melt extrusion conditions of the twin-screw extruder are: the temperature of the first zone is 80-120°C, the temperature of the second zone is 190-210°C, the temperature of the third zone is 210-230°C, the temperature of the fourth zone is 210-230°C, and the temperature of the fifth zone is 210- 230°C, the temperature in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com