Stress whitening resistant modified polypropylene material and preparation method thereof

A polypropylene material and stress-resistant technology, applied in the field of modified polypropylene and its preparation, can solve the problems of increasing material costs and achieve the effects of low cost, broad application prospects, and easy industrialized large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

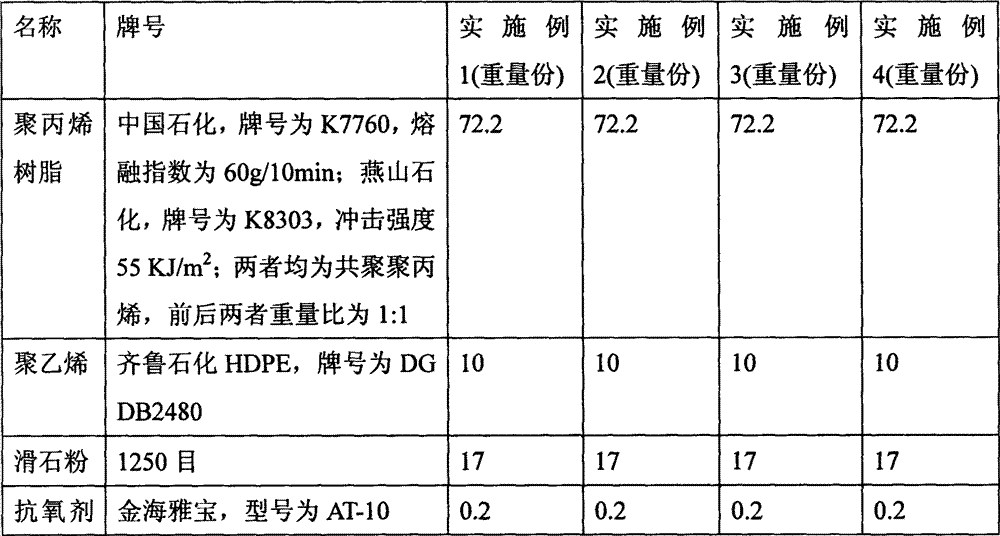

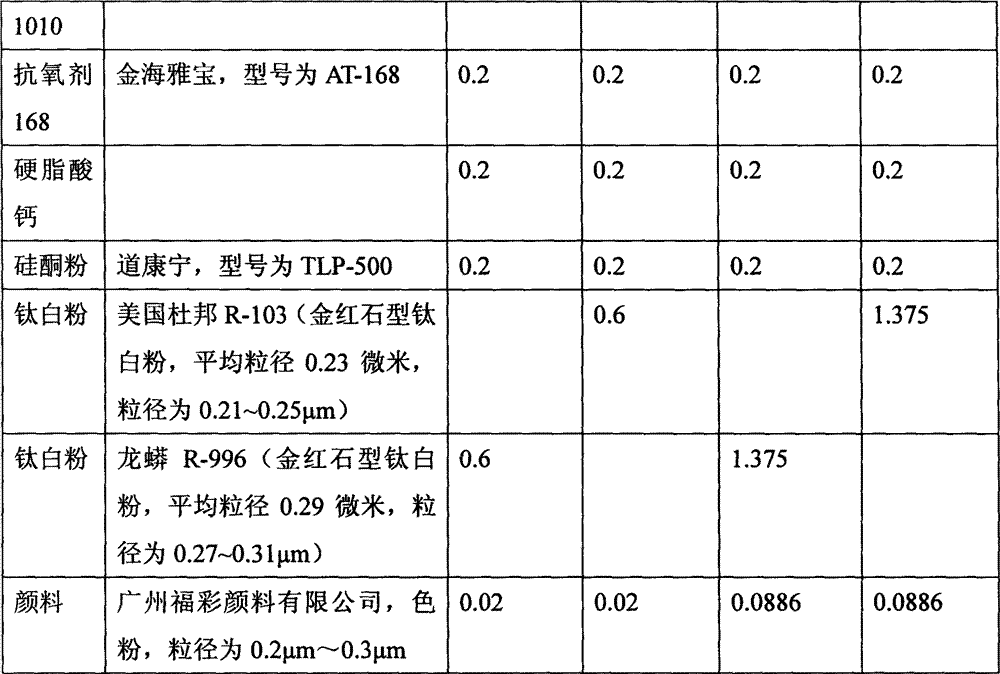

Embodiment 1~4

[0044] Weigh the raw materials according to the components and contents listed in Table 1, first mix polypropylene resin, filler (talcum powder), polyethylene, antioxidant (antioxidant 1010 and antioxidant 168), lubricant (stearic acid) Calcium acid and talcum powder), titanium dioxide and pigments were mixed in a pre-mixer (800-1200 rpm, slowly increasing from low speed to high speed) for 30 minutes, mixed evenly to obtain a mixture, and then the mixture was added to the twin-screw extruder Melting and kneading, extruding and granulating in the extruder, the temperature of melting and kneading in the twin-screw extruder is 180 ° C ~ 230 ° C (that is, the temperature of the mixture passing through the twin-screw extruder in turn is 180 ° C, 190 ° C, 200 ° C , 210 ° C, 210 ° C, 210 ° C, 220 ° C, 220 ° C, 220 ° C, the melting and mixing zone of the die head 225 ° C) to obtain stress whitening modified polypropylene material.

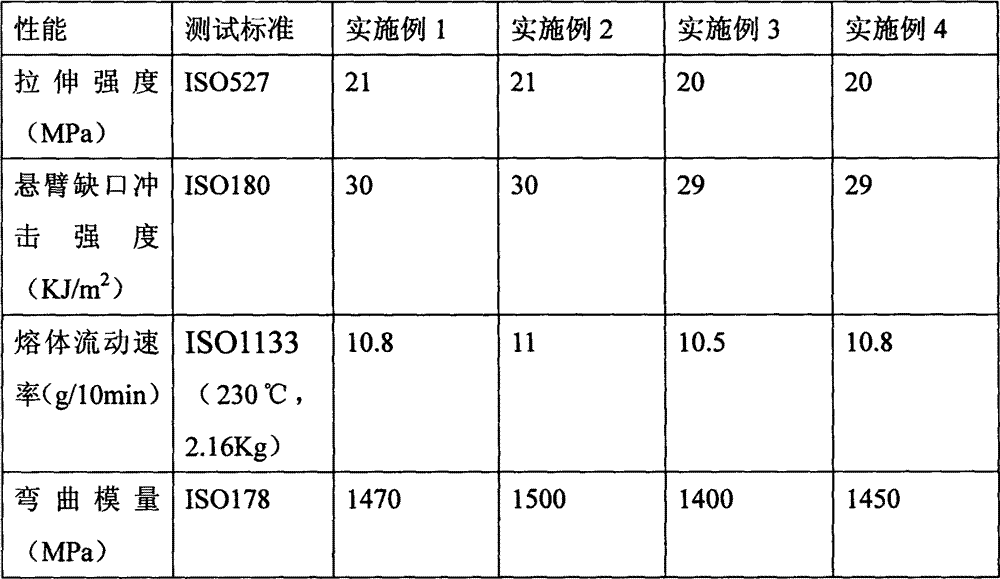

[0045] The stress-whitening-resistant modified polyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com