Stain-resistant and easy-to-clean yarn and production process thereof

An easy-to-clean and stain-resistant technology, applied in the field of textile yarns, which can solve the problems of easy pilling, restricted yarn development, and easy to be polluted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

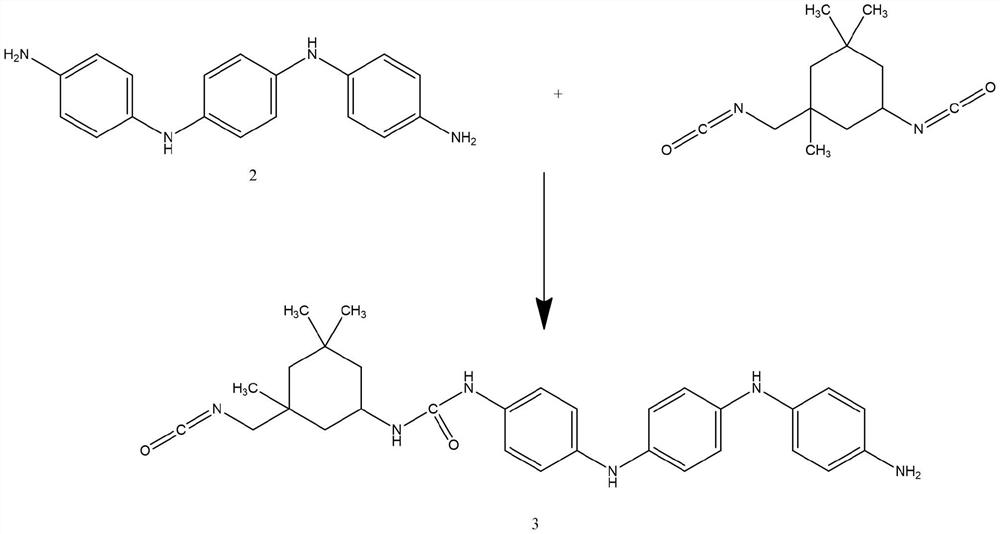

[0053] This embodiment is an anti-wrinkle monomer, and the preparation method of the anti-wrinkle monomer is as follows:

[0054] A1: Add p-chloronitrobenzene, p-phenylenediamine, potassium carbonate, phase transfer catalyst, copper oxide, and half of xylene to a four-way tank equipped with a magnetic stirrer, thermometer, water separator, air guide tube, and reflux condenser. In the flask, heated in an oil bath, stirred and reacted for 7 hours at a temperature of 180°C and a stirring rate of 200r / min, added the remaining xylene under the condition of cooling to 110°C after the reaction, stirred at a constant temperature for 30min, and cooled to 80 Add hot water at 60°C under the condition of ℃, let it stand for 1h, separate layers, collect the organic phase and wash with distilled water, and rotate to evaporate to obtain intermediate 1; control p-chloronitrobenzene, p-phenylenediamine, potassium carbonate, phase transfer The dosage ratio of catalyst, copper oxide, xylene and ...

Embodiment 2

[0061] This embodiment is an anti-wrinkle monomer, and the preparation method of the anti-wrinkle monomer is as follows:

[0062] A1: Add p-chloronitrobenzene, p-phenylenediamine, potassium carbonate, phase transfer catalyst, copper oxide, and half of xylene to a four-way tank equipped with a magnetic stirrer, thermometer, water separator, air guide tube, and reflux condenser. In the flask, heated in an oil bath, stirred and reacted for 9 hours at a temperature of 190°C and a stirring rate of 400r / min, added the remaining xylene under the condition of cooling to 120°C after the reaction, stirred at a constant temperature for 50min, and cooled to 85 Add hot water at 80°C under the condition of ℃, let it stand for 2h, separate layers, collect the organic phase and wash with distilled water, and rotary evaporate to obtain intermediate 1; control p-chloronitrobenzene, p-phenylenediamine, potassium carbonate, phase transfer The dosage ratio of catalyst, copper oxide, xylene and hot...

Embodiment 3

[0069] This embodiment is a pollution-resistant monomer, and the preparation method of the pollution-resistant monomer is as follows:

[0070]Add 2,2,3,3-tetrafluoropropanol and phenothiazine into a three-necked flask equipped with a magnetic stirrer, a thermometer and a constant pressure dropping funnel, and gradually stir while stirring at a stirring rate of 200r / min. Add acryloyl chloride dropwise, and control the dropping rate to 1 drop / s. After the dropwise addition, continue to stir and react for 2 hours under the condition of raising the temperature to 65°C, and then continue stirring and reacting for 2 hours under the condition of raising the temperature to 85°C. After the reaction, the reaction product is Wash with sodium hydroxide solution and distilled water until neutral, then distill under reduced pressure, collect fractions at 56.5°C to obtain stain-resistant monomers; The dosage ratio is 100mL: 2.0g: 118.2g, and the mass fraction of sodium hydroxide solution is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com