A kind of anti-pilling fabric and its preparation process

A technology of anti-pilling and preparation technology, which is applied in the field of textile and clothing, can solve the problems of fabric surface structure damage, surface snagging, poor pilling index, and unqualified surface physical properties, so as to achieve good surface physical properties and anti-pilling Good ball, excellent elasticity and recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

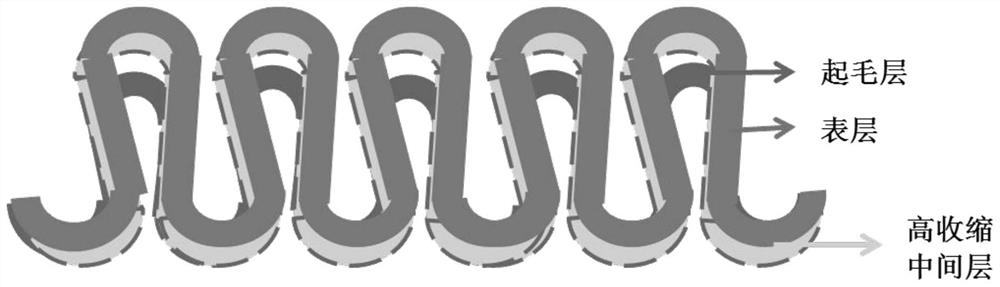

[0034] Common anti-pilling fabrics are composed of surface yarn and raised yarn, such as figure 1 shown. And a kind of anti-pilling fabric among the present invention, as figure 2 As shown, the anti-pilling fabric is a single-sided fabric, and the single-sided fabric is composed of surface yarn, raised yarn and isolation yarn; the isolation yarn connects the surface yarn and the raised yarn, It is used to separate the surface yarn from the raised yarn; the isolation yarn is a high-shrinkage elastic yarn. The surface yarn is a high-shrinkage elastic yarn.

[0035] The weaving process diagram of the common single-sided small terry is as follows image 3 shown. And the preparation technology of anti-pilling fabric among the present invention is as Figure 4 shown, including the following steps:

[0036] Step 1. The anti-pilling fabric is woven on a common circular knitting machine, and the common large circular knitting machine is a single-jersey knitting machine. High-sh...

specific Embodiment 1

[0046] An anti-pilling fabric, the denier of the high-shrinkage elastic yarn is 30D, and the CR value is 3.8. The fineness of the surface yarn is 30D. The fineness of the raised yarn is 30D. The grammage of described napping anti-pilling fabric is 120g / m 2 . The thickness of the fuzzing-resistant pilling fabric is 0.05mm.

specific Embodiment 2

[0048] An anti-pilling fabric, the denier of the high-shrinkage elastic yarn is 100D, and the CR value is 5.0. The denier of the surface yarn is 200D. The denier of the raised yarn is 300D. The grammage of described raising anti-pilling fabric is 450g / m 2 . The thickness of the fuzzing-resistant pilling fabric is 0.3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com