Preparation method of song brocade fabric

A fabric and rewinding technology, which is applied in the processing of textile materials, liquid/gas/vapor textile material processing, and weaving, etc., can solve the problems of wear resistance and pilling of Song brocade fabrics that cannot meet the needs of users. Achieving the effects of enriching uses, improving pilling and reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

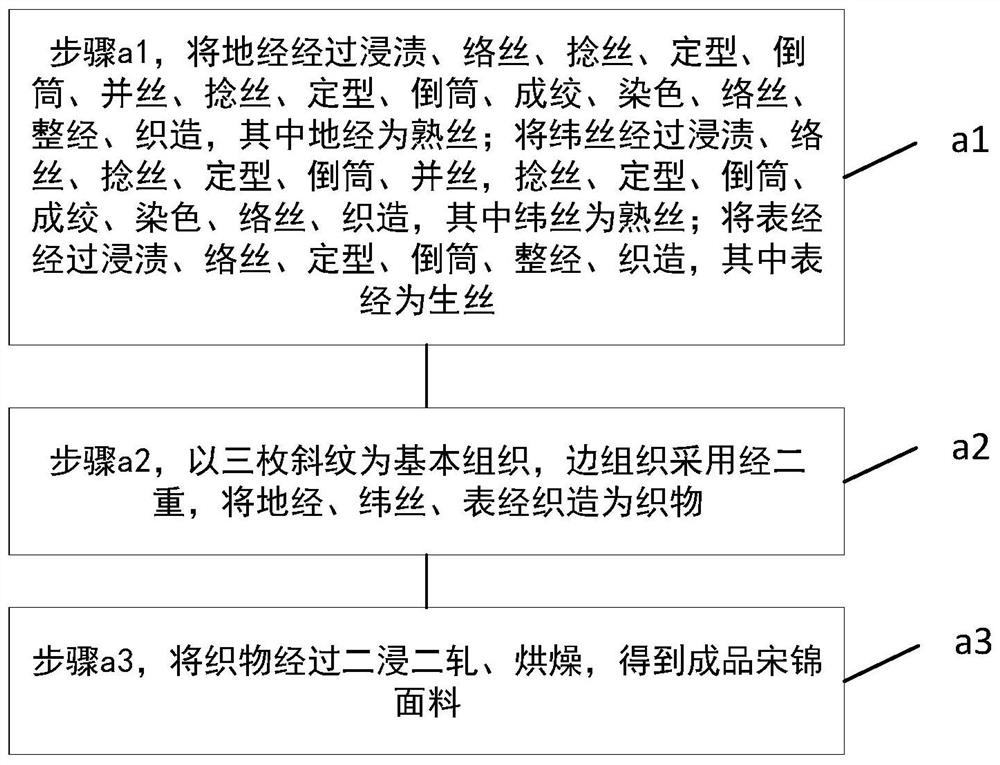

[0042] Such as figure 1 As shown, the embodiment of the invention provides a kind of preparation method of Song brocade fabric, comprising:

[0043] step a1, dipping, winding, twisting, shaping, rewinding, doubling, twisting, shaping, rewinding, twisting, dyeing, winding, warping, and weaving the ground warp, wherein the ground warp is boiled silk ;Dipping the weft yarn through impregnation, winding, twisting, shaping, rewinding, doubling, twisting, shaping, rewinding, twisting, dyeing, winding, and weaving, wherein the weft is cooked silk; Dipping, winding, shaping, rewinding, warping, and weaving, where the surface warp is raw silk;

[0044] In step a2, three pieces of twill weave are used as the basic weave, and the side weave adopts double warp, and the ground warp, weft and surface warp are woven into a fabric; the warp density of the fabric is ≥ 120 threads / cm, and the weft density is ≥ 90 threads / cm;

[0045] In step a3, the fabric is subjected to two dipping, two rol...

specific Embodiment 2

[0058] The embodiment of the invention provides a method for preparing Song brocade fabric.

[0059] Polyester raw materials: warp yarn 1 / 50D polyester yarn; first weft 2 / 50D polyester yarn, second weft 2 / 50D polyester yarn, propylene weft 4 / 27 / 29D cooked colored yarn; warp density 120 / cm, weft density 90 / cm, warp and weft are combined to show flowers, and Bingwei is used as the embellishment of the pattern, so there are not many flowers.

[0060] The manufacturing process is as follows: 1. For warp yarn: winding, double twisting, shaping, warping, and weaving; 2. For weft yarn: winding, double twisting, shaping, rewinding, and weaving.

[0061] The fabric is woven by an electronic jacquard machine at a speed of 220 rpm.

[0062] The finishing process is: double dipping, two rolling, drying, the concentration of the working solution (cationic water-based aliphatic polyurethane reagent) is 140g / L, the temperature is kept at 30-40°C, the soaking time of each sample is about 20...

specific Embodiment 3

[0070] The embodiment of the invention provides a method for preparing Song brocade fabric.

[0071] Silk raw materials: A warp (1 / 20 / 22D8T / Z×2) 6T / S cooked silk, B warp 1 / 20 / 22D raw silk; weft 4 / 27 / 29D factory silk 1.5T / S cooked silk (3 color); warp density 80 / cm, weft density 90 / cm; warp and weft combined to show flowers.

[0072] The manufacturing process is: 1. Ground warp (cooked silk): dipping, winding, twisting, shaping, rewinding, doubling, twisting, shaping, rewinding, twisting, dyeing, winding, warping, weaving; 2. Weft (cooked silk): dipping, winding, twisting, shaping, rewinding, doubling, twisting, shaping, rewinding, twisting, dyeing, winding, weaving; 3. Surface warp (raw silk) : Dipping, winding, shaping, rewinding, warping, weaving.

[0073] The fabric is woven by an electronic jacquard machine at a speed of 240 rpm.

[0074] The finishing process is: two dipping and two rolling, drying, the concentration of the working solution (cationic water-based alipha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com