Yarn feeder of seamless underwear knitter

The technology of a seamless underwear machine and a yarn feeding device is applied in the directions of textile and paper making, weft knitting, knitting, etc., which can solve the problems that the seamless knitting underwear machine cannot realize the plating yarn, multi-color jacquard weave, etc., and achieve colorful styles. , Improve the effect of weaving performance and organizational structure diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

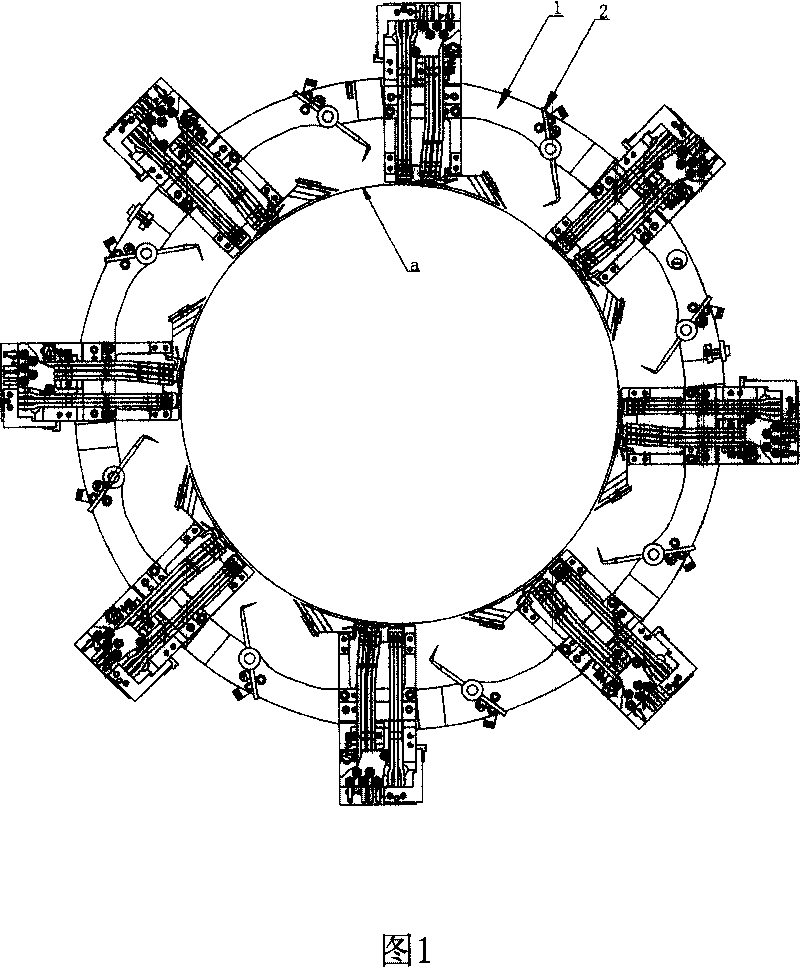

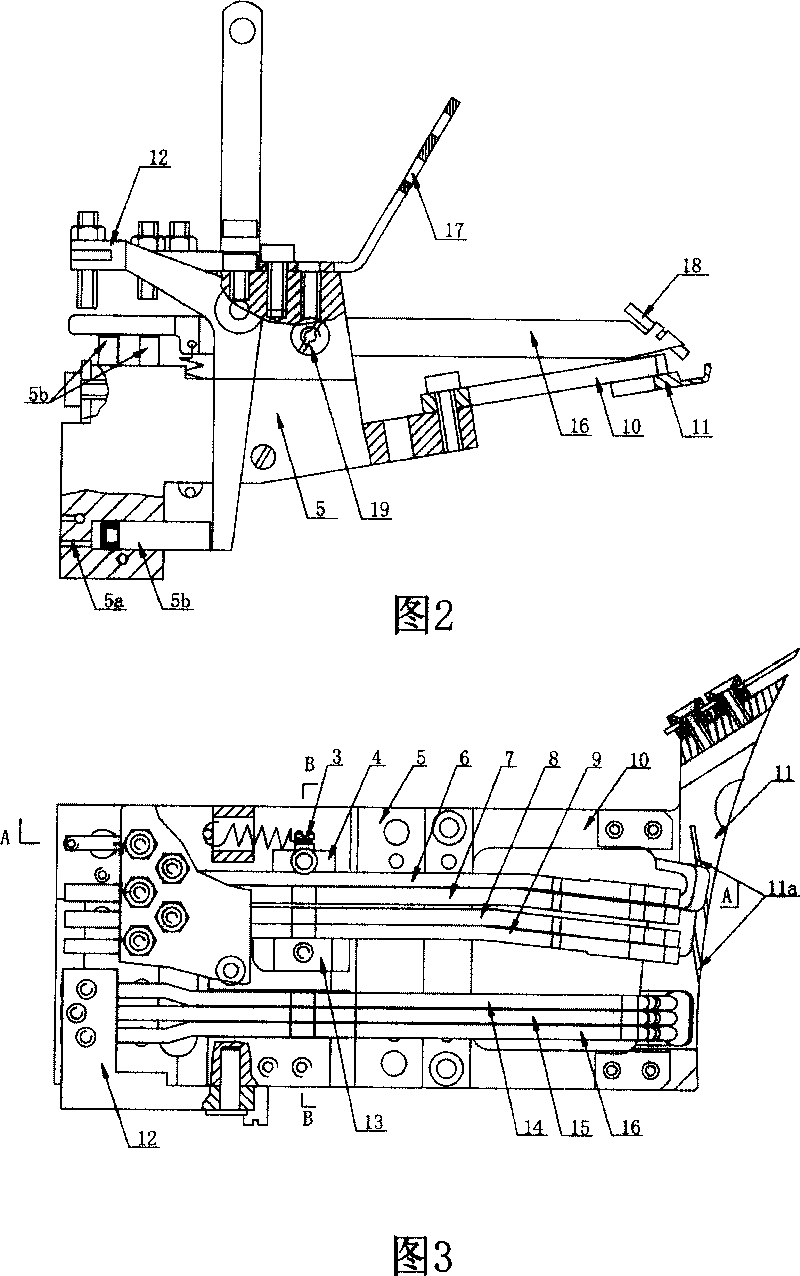

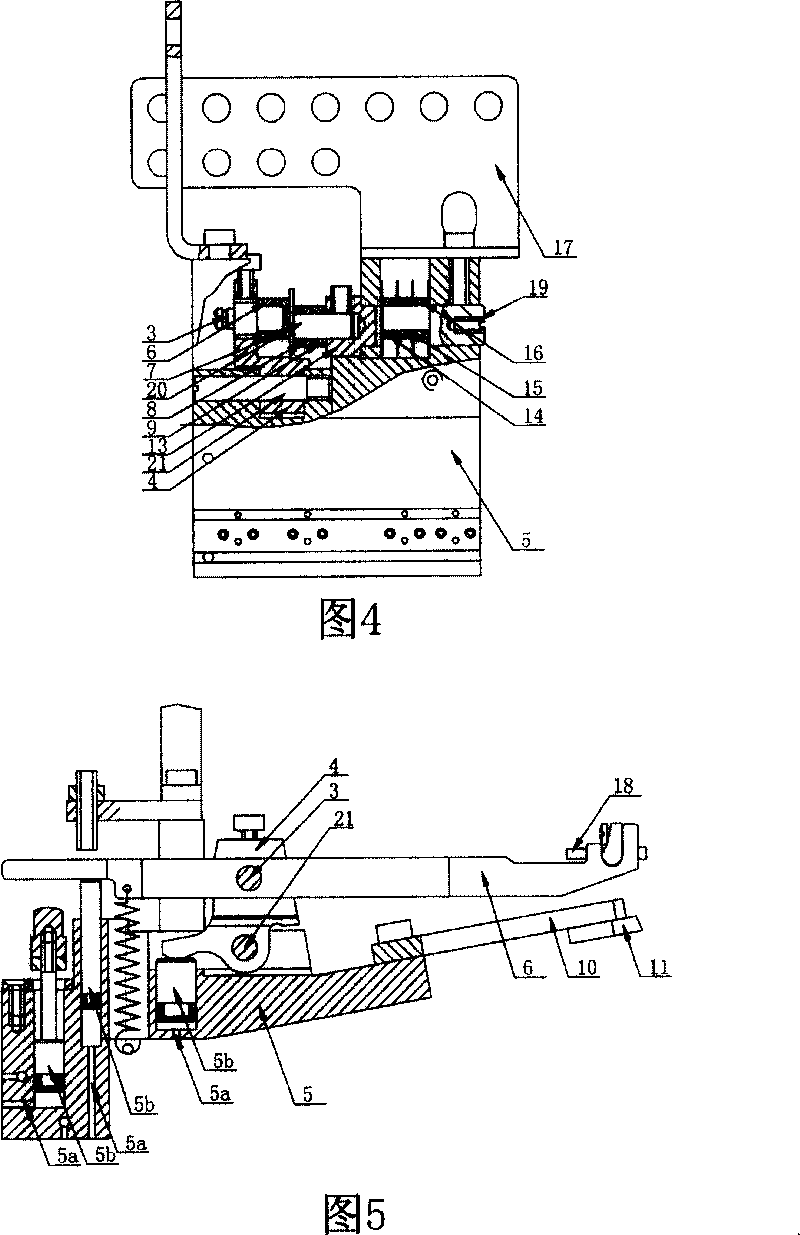

[0023] With reference to the accompanying drawings, the present invention includes an integrated cylinder 5 installed on a disc 1, a square shuttle board 11, some knitting needles 24 and the front of the integrated cylinder 5 which is installed on the same disc for opening the knitting needle. Needle grabbing 2 of the needle latch also includes several plating shuttles for conveying different yarns, such as: plating shuttle 6 for veil, plating shuttle 7, 8, 9 for colored yarn, plating shuttle 14, 15 for bottom yarn , 16, each plating shuttle has several working positions.

[0024] Refer to attached figure 2 , attached Figure 5 and attached Figure 6 , The integrated cylinder 5 is provided with numerous air passages 5a leading to several pistons 5b inside, and the pistons are respectively used to control the working positions of several plating shuttles.

[0025] Refer to attached figure 2 to attach Figure 5 Plating shuttle is connected with integrated cylinder 5 by sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com