A method for weaving wavy convex strips

A technology of wavy and convex strips, which is applied in the field of weaving wavy convex strips, can solve the problems of lack of change, application limitations of convex strips, etc., and achieve the effect of enriching the organizational structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0018] The method for weaving wavy convex strips comprises the following weaving procedures:

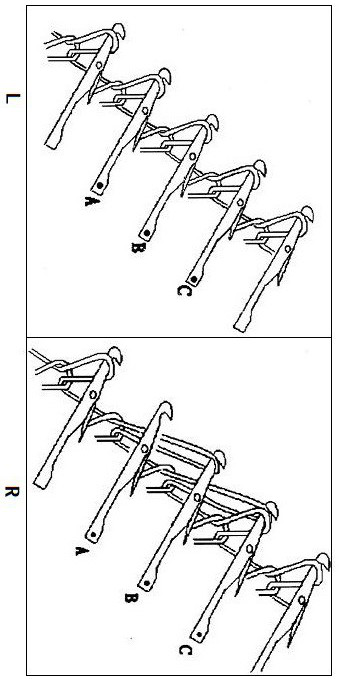

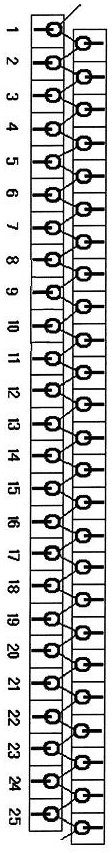

[0019] (1) if figure 2 As shown, the needle beds are staggered, and the knitting needles of the front and rear needle beds of the 25 needle positions all participate in knitting.

[0020] (2) if image 3 As shown in , the rear needle bed suspends knitting, but all loops are still hung on the knitting needles of the rear needle bed, and the knitting needles of the front needle bed continuously knit five courses.

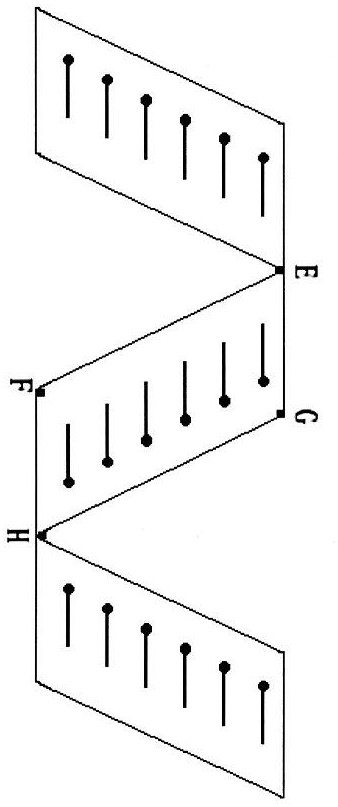

[0021] (3) if Figure 4 As shown, transfer the loop knitted on the rear needle bed to the corresponding needle position on the front needle bed (if you want to increase the convex effect, you can also transfer the needle in a misplaced position to tighten the loop knitted on the rear needle bed), so that the convex Strip weaving is complete. If there is no subsequent stitch transfer action, then the knitting forms a horizontal straight line.

[0022] (4) if Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com