A three-dimensional sandwich structure fabric and its weaving method

A technology of sandwich structure and layered structure, applied in the direction of fabrics, multi-strand fabrics, textiles and papermaking, etc., can solve the problems such as the inability of integral continuous weaving, the single cross-sectional shape of the fabric, and the lack of high strength, so as to be suitable for continuous weaving. Weaving, fabric size range, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

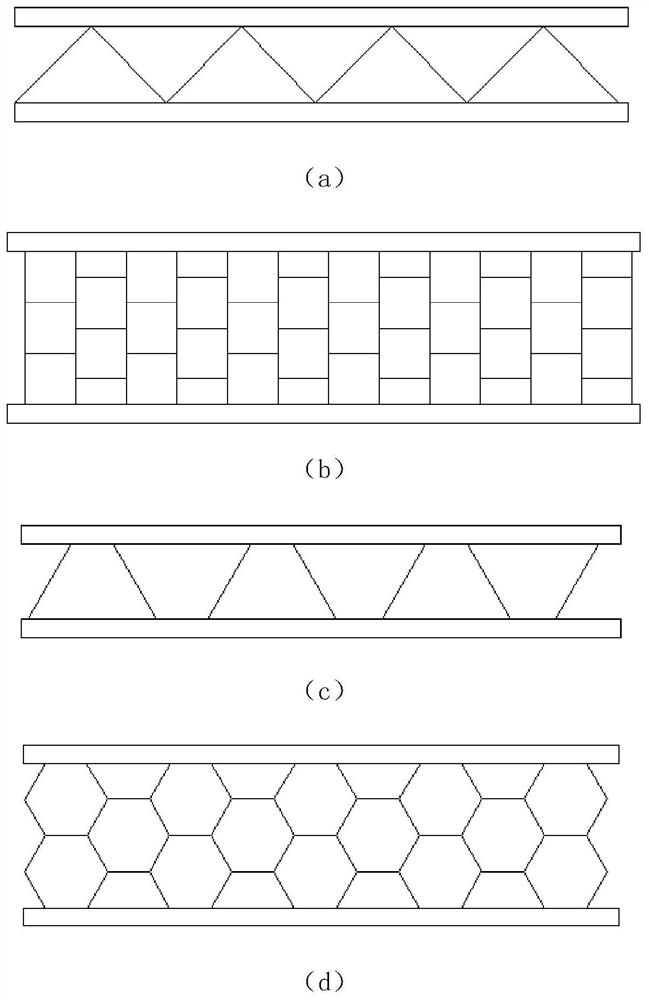

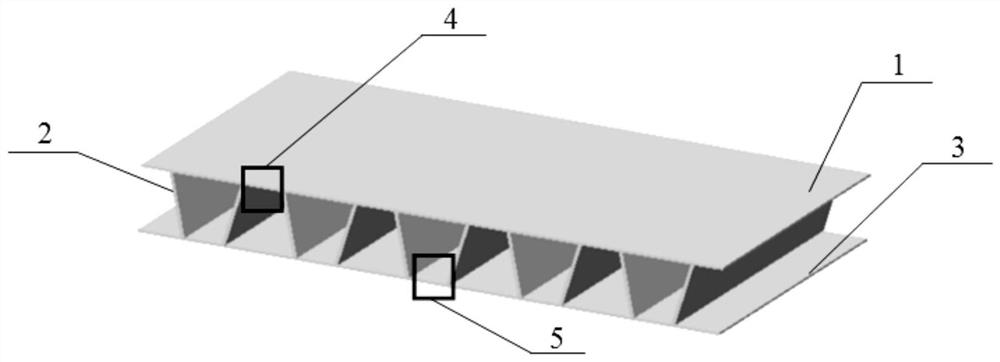

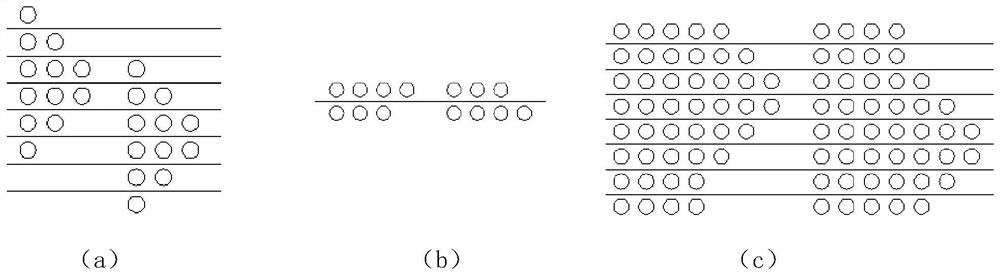

[0040] refer to figure 2 , embodiment 1 provides a kind of three-dimensional sandwich structure fabric of trapezoidal cross-section, comprises the upper panel layer that is formed by interweaving three layers of upper warp yarns and weft yarns, the lower panel layer that is formed by interweaving three layers of lower layer warp yarns and weft yarns, and a The core layer is formed by interweaving the warp and weft yarns in the middle layer; the upper and lower panel layers and the core layer are connected by a layer-by-layer structure, and are shaped by continuous weaving as a whole.

[0041] The layered structure can be shallow cross-curved, shallow cross-straight, deep cross-curved, deep cross-straight, twill or satin. In this embodiment, the shallow cross-curved structure is the representative.

[0042] The three-dimensional sandwich structure fabric can be woven with one high-performance fiber, or mixed with a variety of high-performance fibers. In this embodiment, glass...

Embodiment 2

[0061] refer to Figure 6 , Embodiment 2 provides a regular hexagonal three-dimensional sandwich structure fabric, including an upper panel layer formed by interweaving three layers of upper layer warp yarns and weft yarns, a lower panel layer formed by interweaving three layers of lower layer warp yarns and weft yarns, and composed of The core layer is formed by the interweaving of warp yarn and weft yarn in the middle layer of four layers; the connection between the upper and lower panel layers and the core layer is formed by a layer-by-layer structure, and is shaped by continuous weaving as a whole.

[0062] The layered structure can be shallow cross-curved, shallow cross-straight, deep cross-curved, deep cross-straight, twill or satin. In this embodiment, the shallow cross-curved structure is the representative.

[0063] The three-dimensional sandwich structure fabric can be woven with one high-performance fiber, or mixed with a variety of high-performance fibers. In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com