Planetary framework diamond abrasive tools

A planetary mechanism and diamond technology, which is applied in the field of devices for grinding and processing workpieces with diamond grinding wheels, can solve the problems of single-layer brazed diamond grinding wheel manufacturing difficulties, small size of single-layer brazed diamond grinding wheels, and no participation in processing, etc., to achieve structural size Small size, maintaining self-sharpening sharpness, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following embodiments will further illustrate the mechanical transmission type end surface planetary structure grinding tool of the present invention in conjunction with the accompanying drawings.

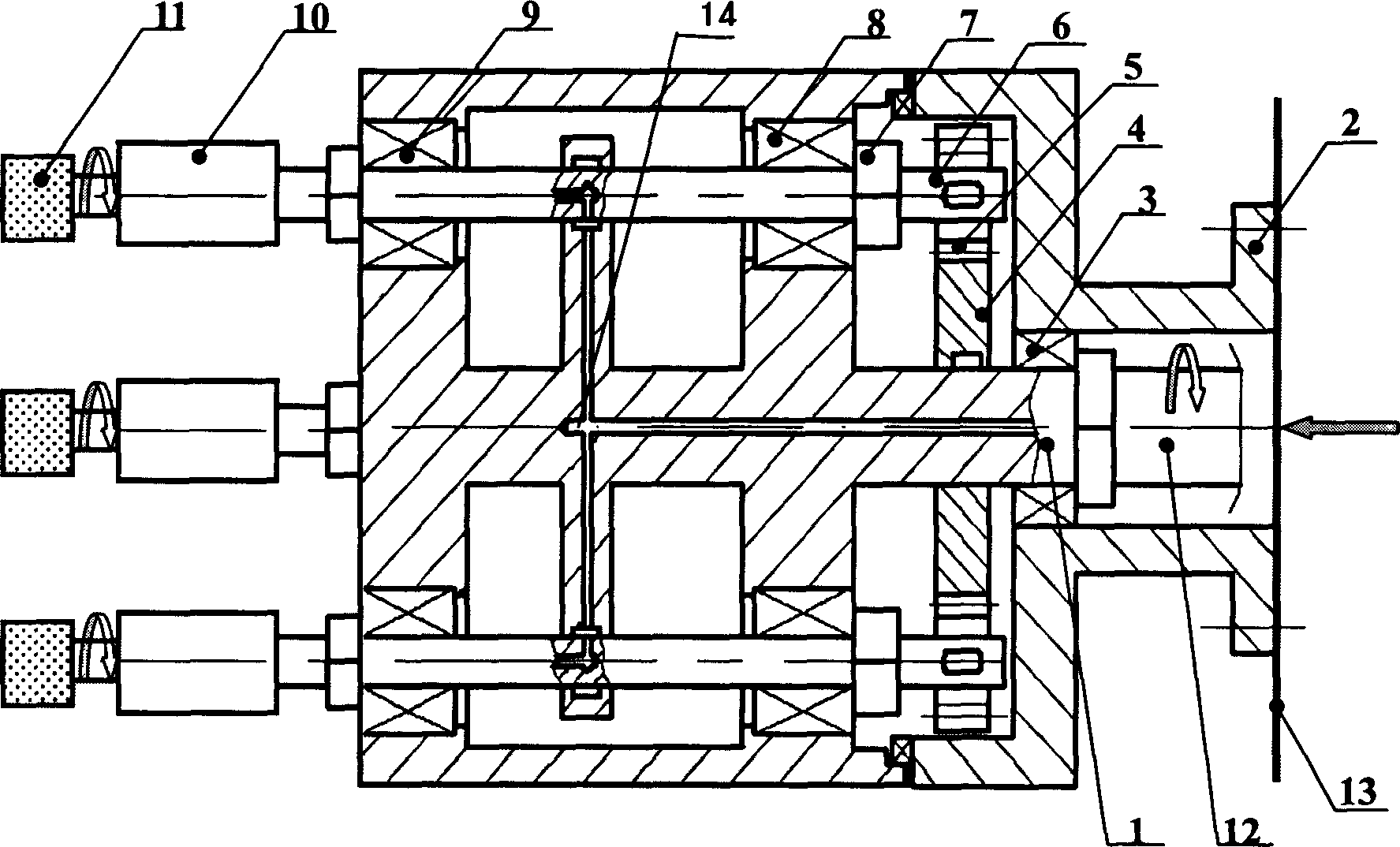

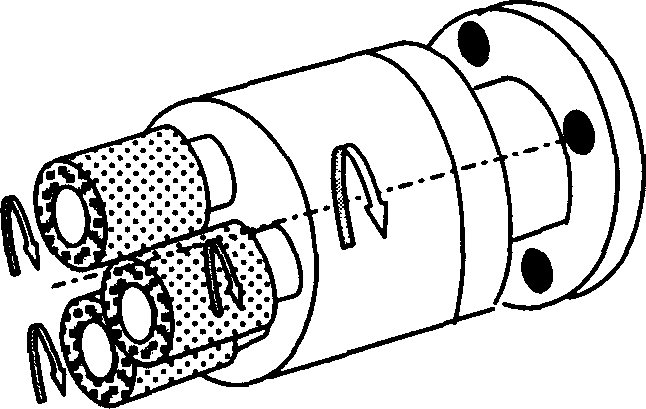

[0021] see figure 1 and 2 , this embodiment provides a mechanical transmission type face planetary gear mechanism grinding tool. The present invention is provided with a planetary gear mechanism, a grinding head spring ferrule 10, a built-in cooling pipeline 14, a rotating housing 1, a fixed connection housing 2, and the like. The planetary gear mechanism is provided with a bearing 3, a sun gear 4, a planetary gear 5, a planetary shaft 6, a nut 7, a bearing 8, and a bearing 9. The top of the rotating housing 1 is connected and integrated with the input end of the drive shaft 12. The input end of the drive shaft 12 is connected to the rotating shaft of the machine tool through a coupling for revolution movement. The bearing 3 is arranged on the drive shaft 12 and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com