Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73 results about "Ideal surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An ideal solid surface is flat, rigid, perfectly smooth, and chemically homogeneous, and has zero contact angle hysteresis. Zero hysteresis implies the advancing and receding contact angles are equal.

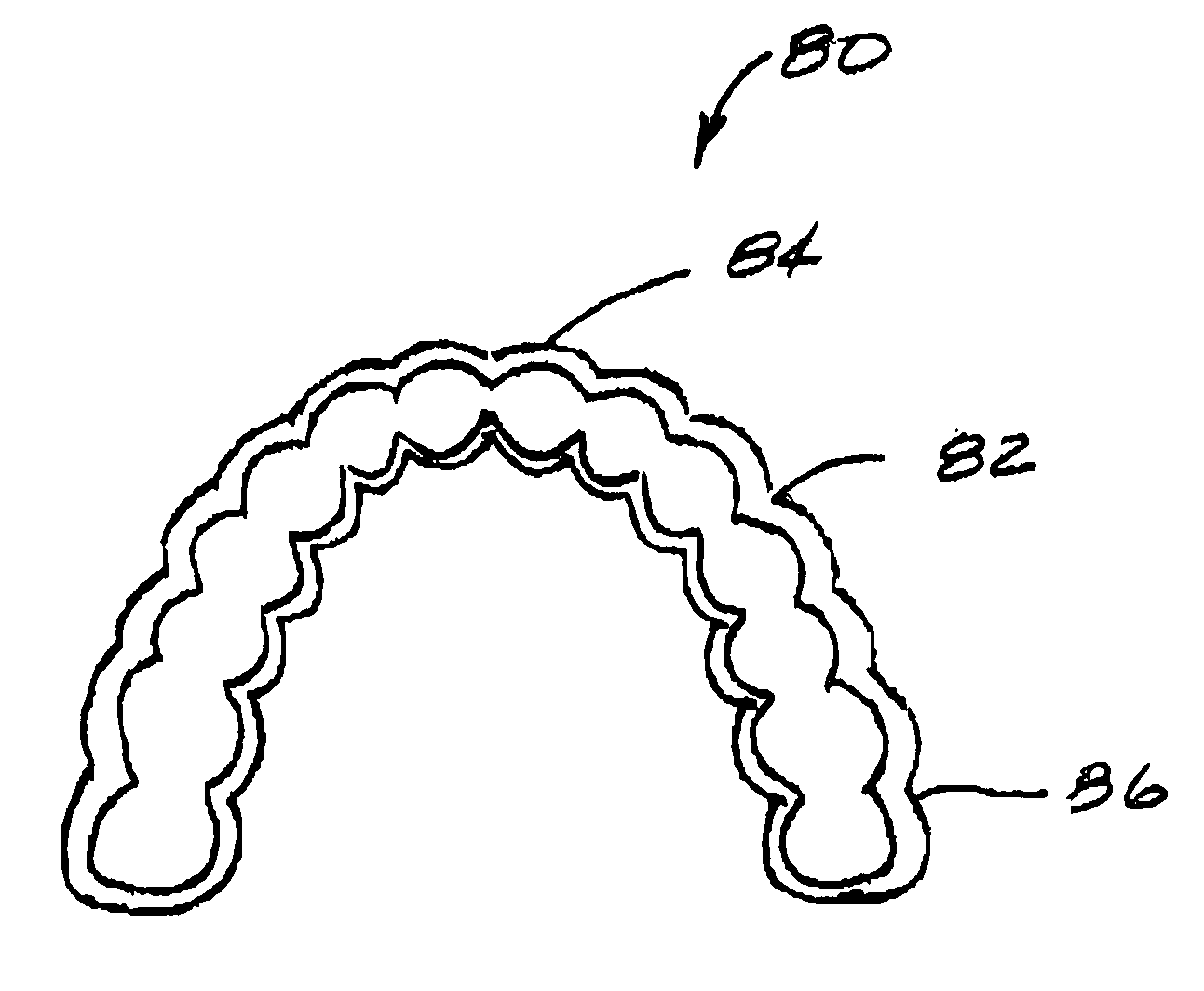

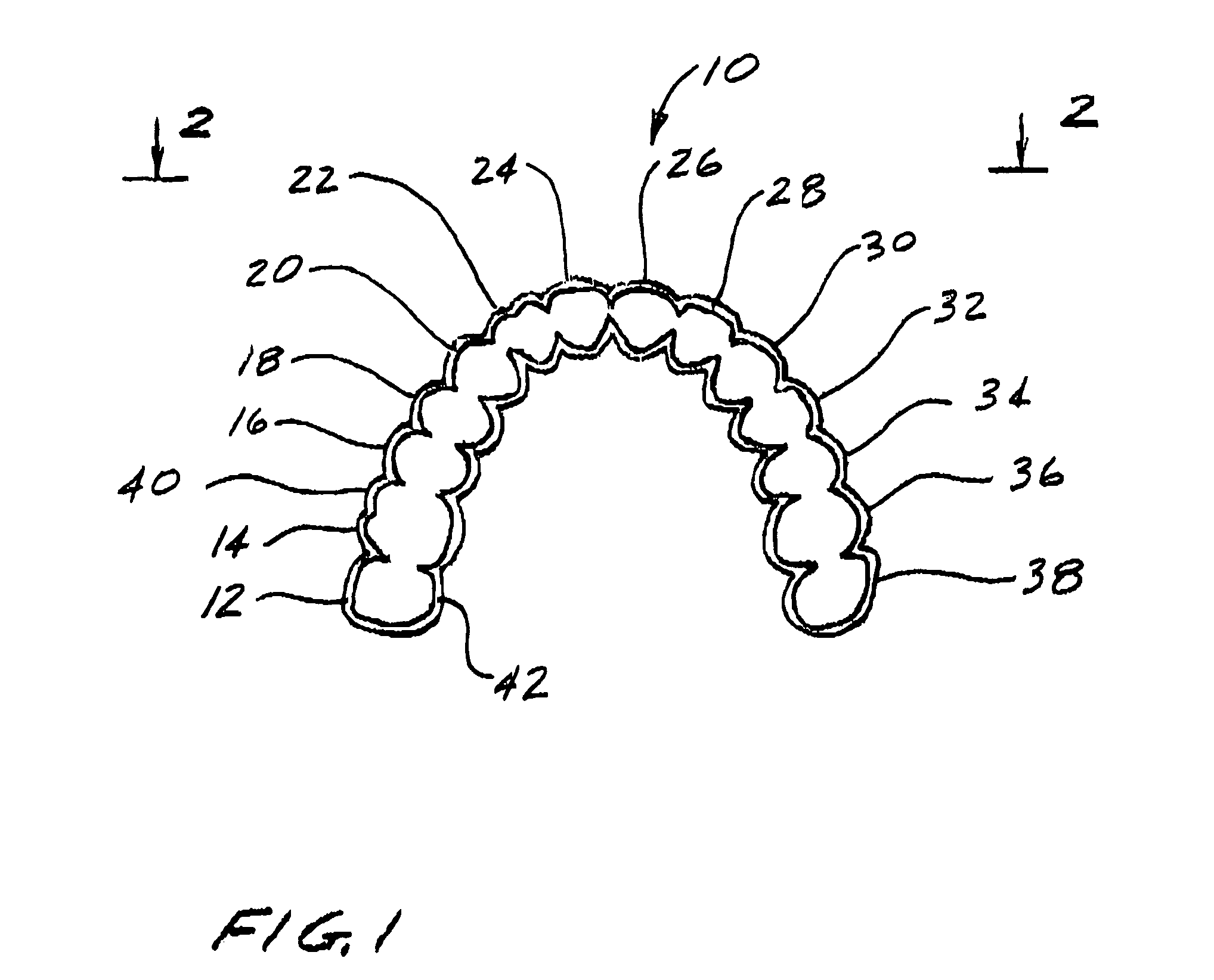

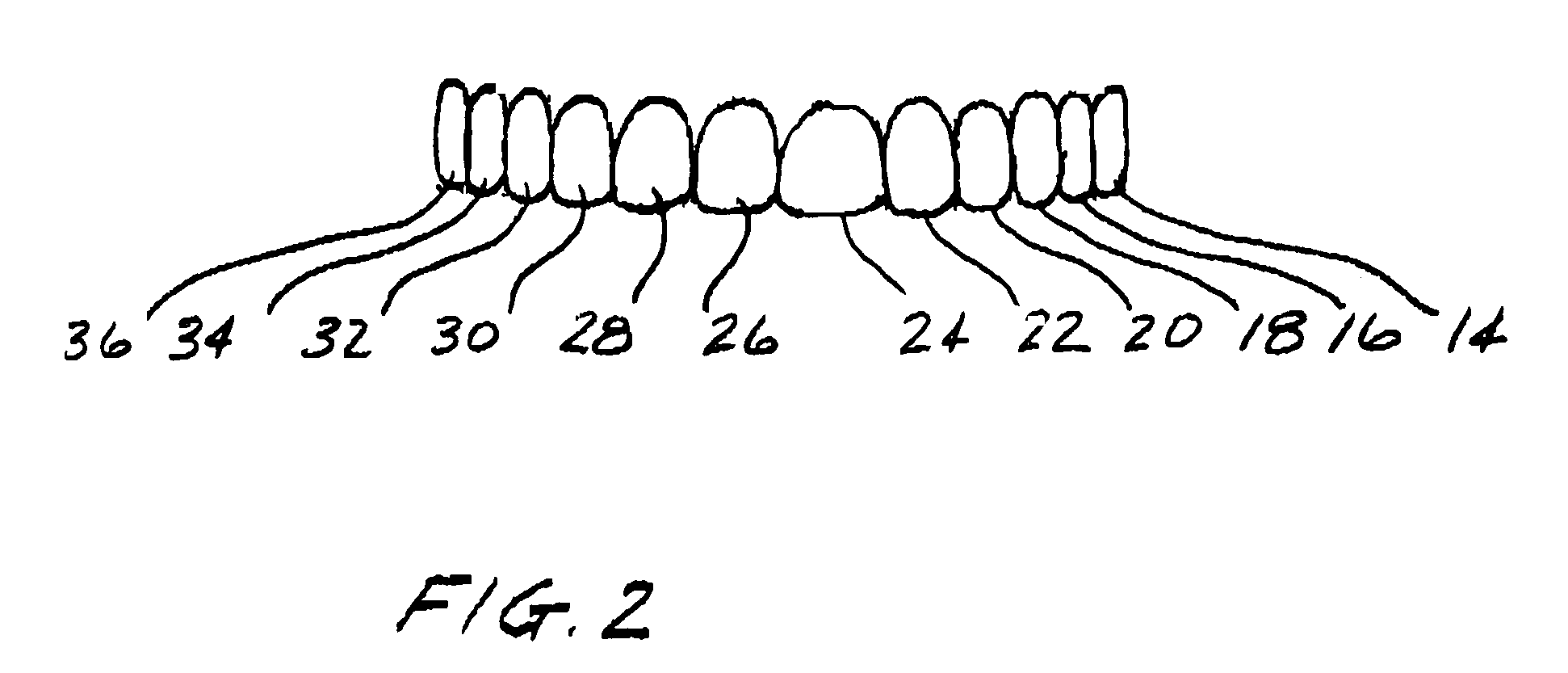

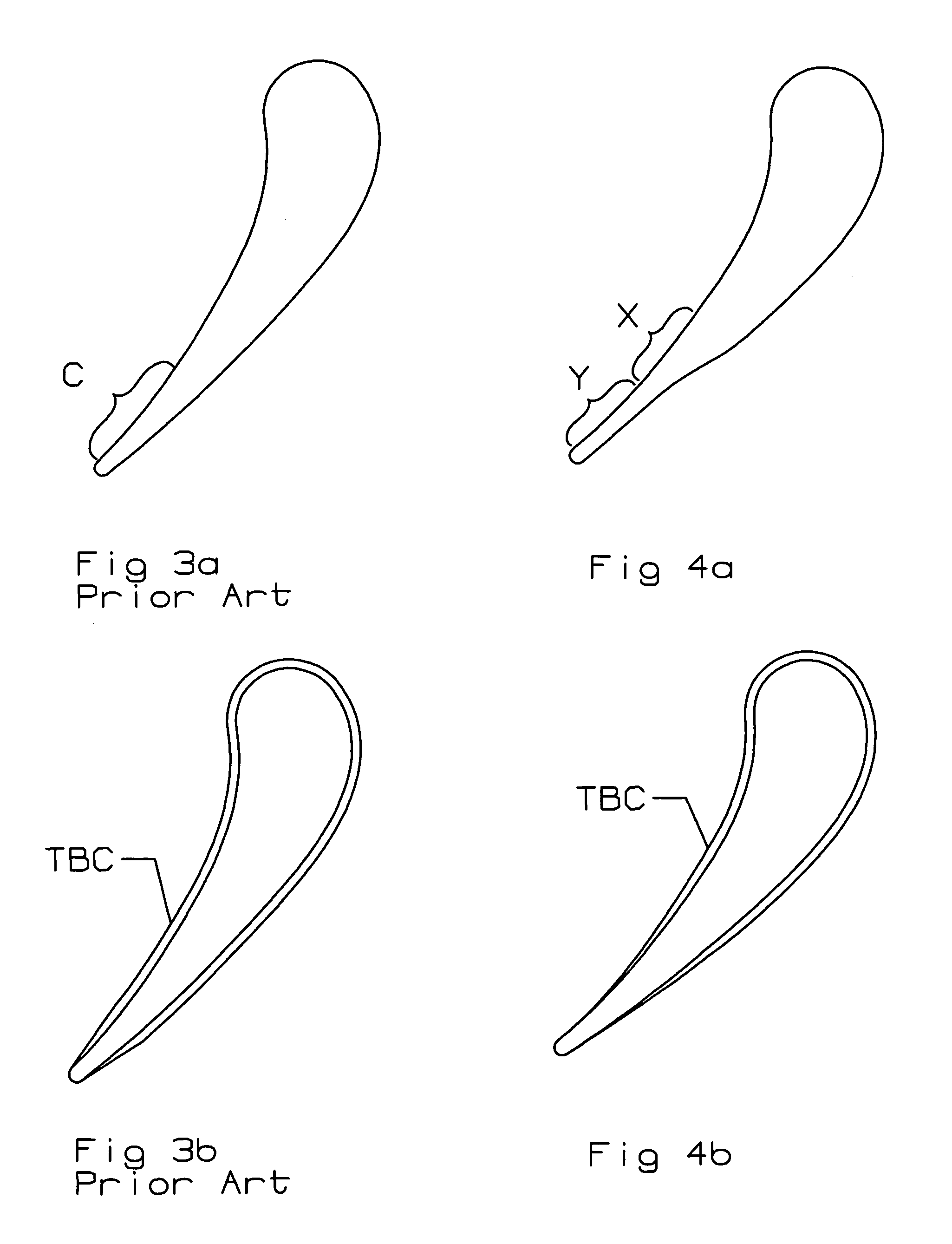

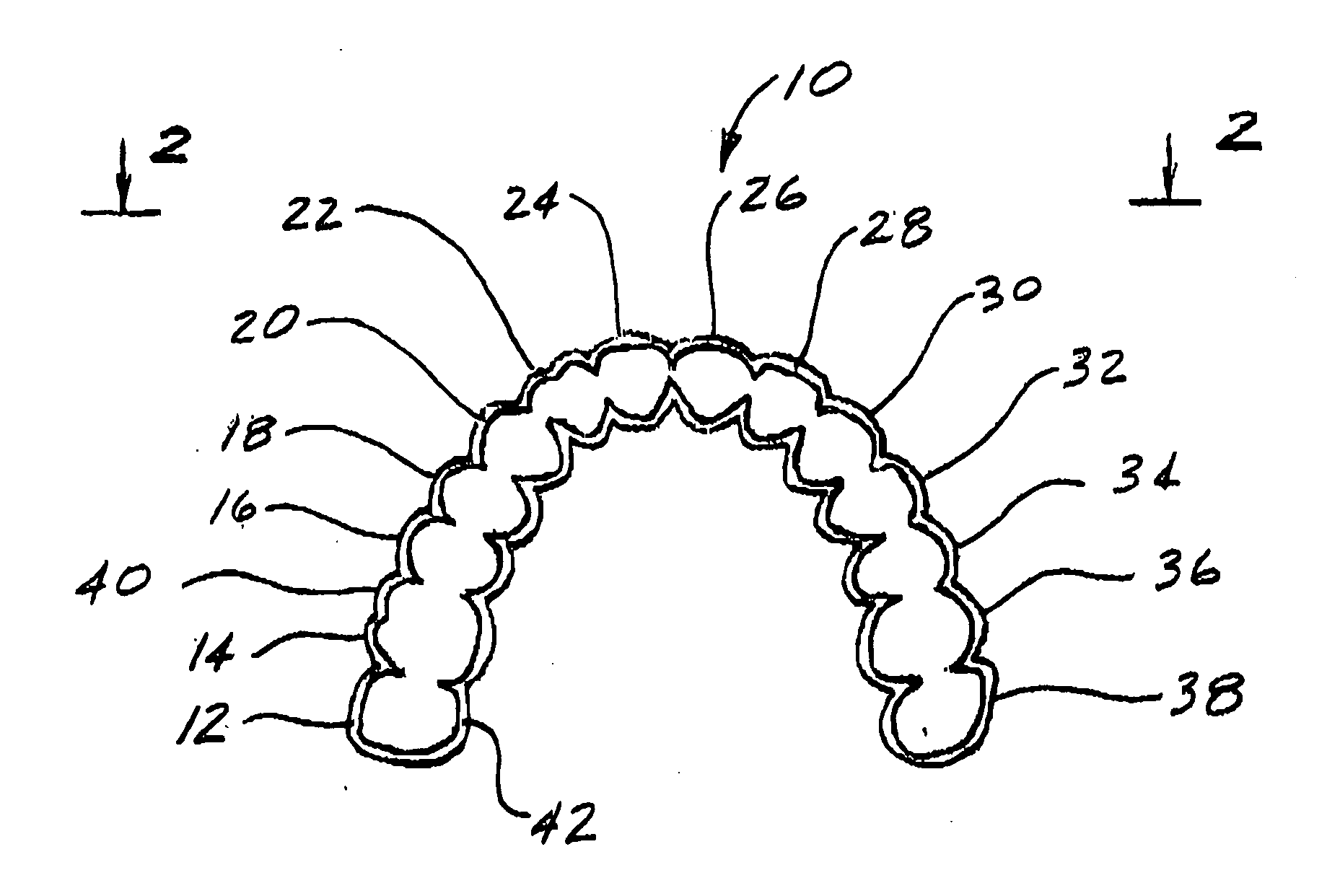

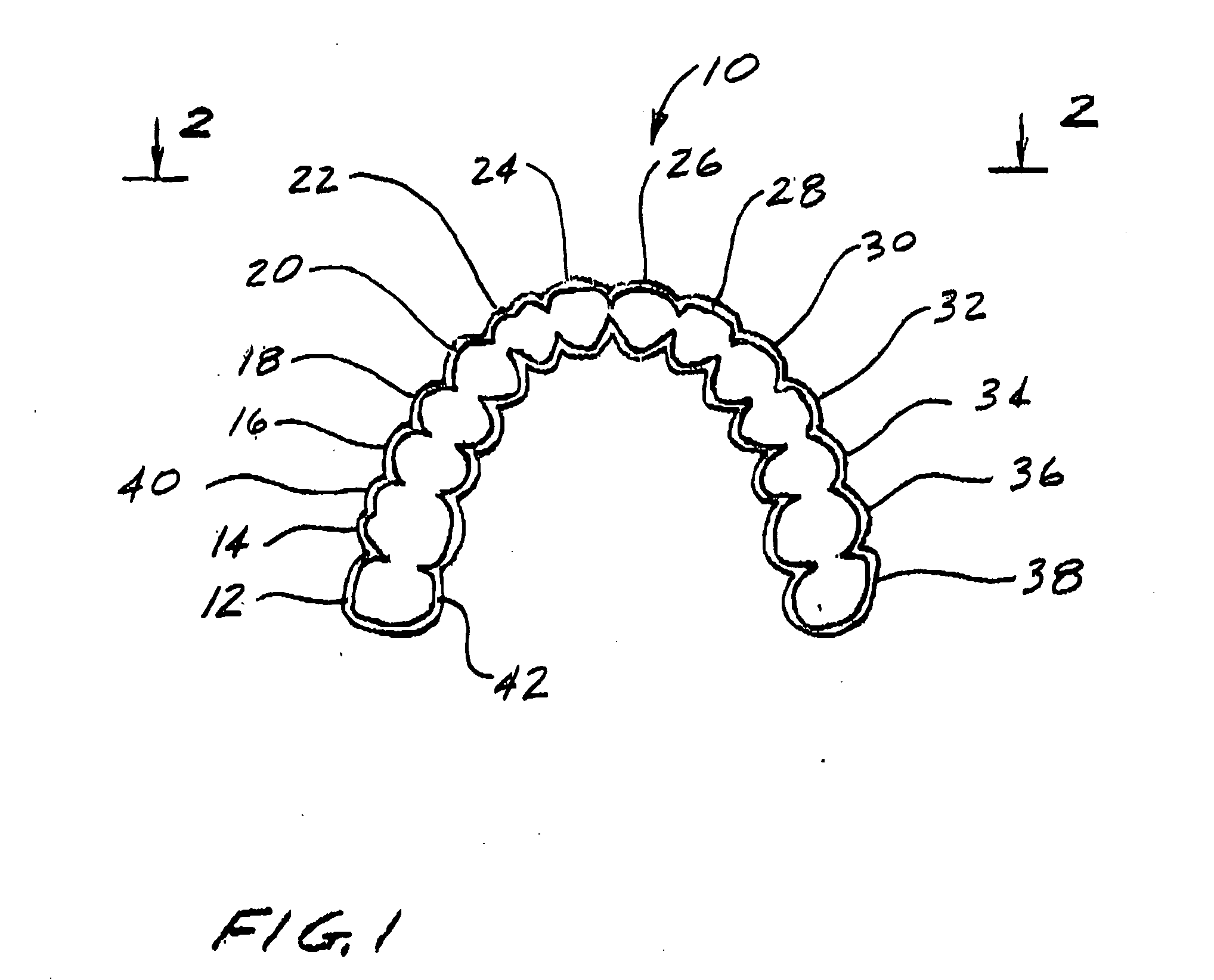

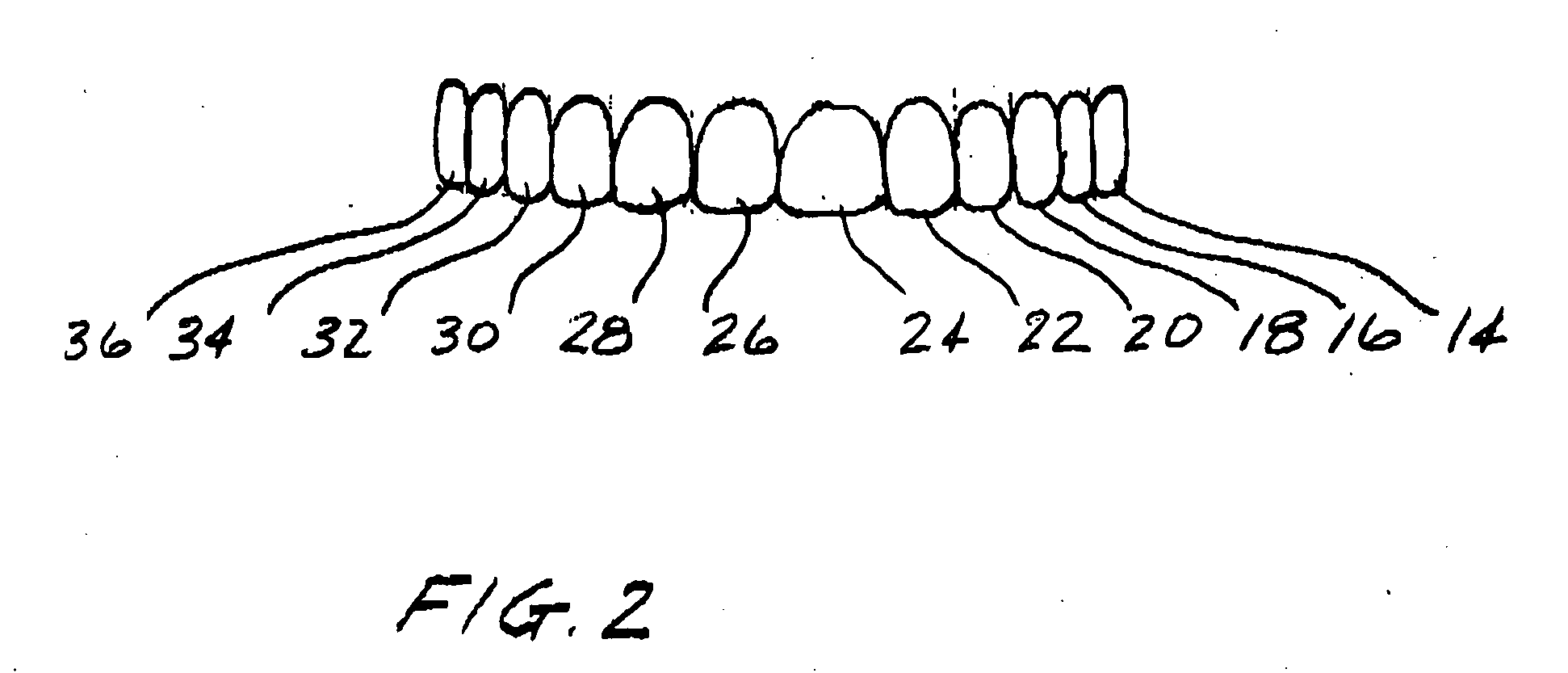

Dental appliance

ActiveUS7357637B2Efficient use ofBeautiful smileOthrodonticsTooth crownsInterior spaceCosmetic appearance

An appliance fabricated to improve the appearance of a patient's smile includes a plurality of simulated teeth. The interior surfaces of each of the teeth closely fits and conforms to the surface of a patient's real teeth while the outer surfaces of each of the simulated teeth has an ideal surface configuration. The dental appliance provides the patient with the appearance of a perfect set of teeth and an ideal smile without a need to alter the dental structure of the patient's teeth.

Owner:DEN MAT HLDG

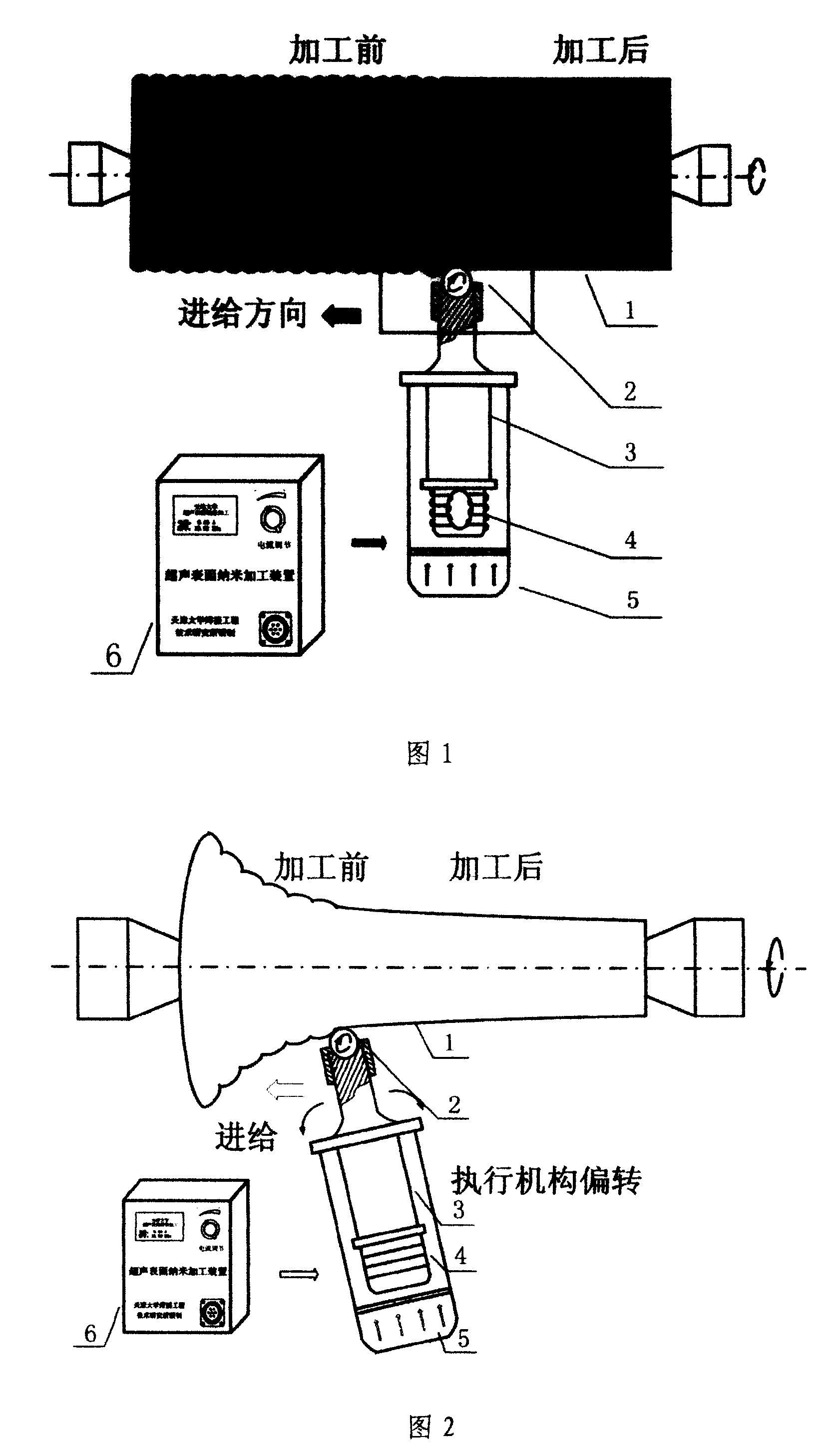

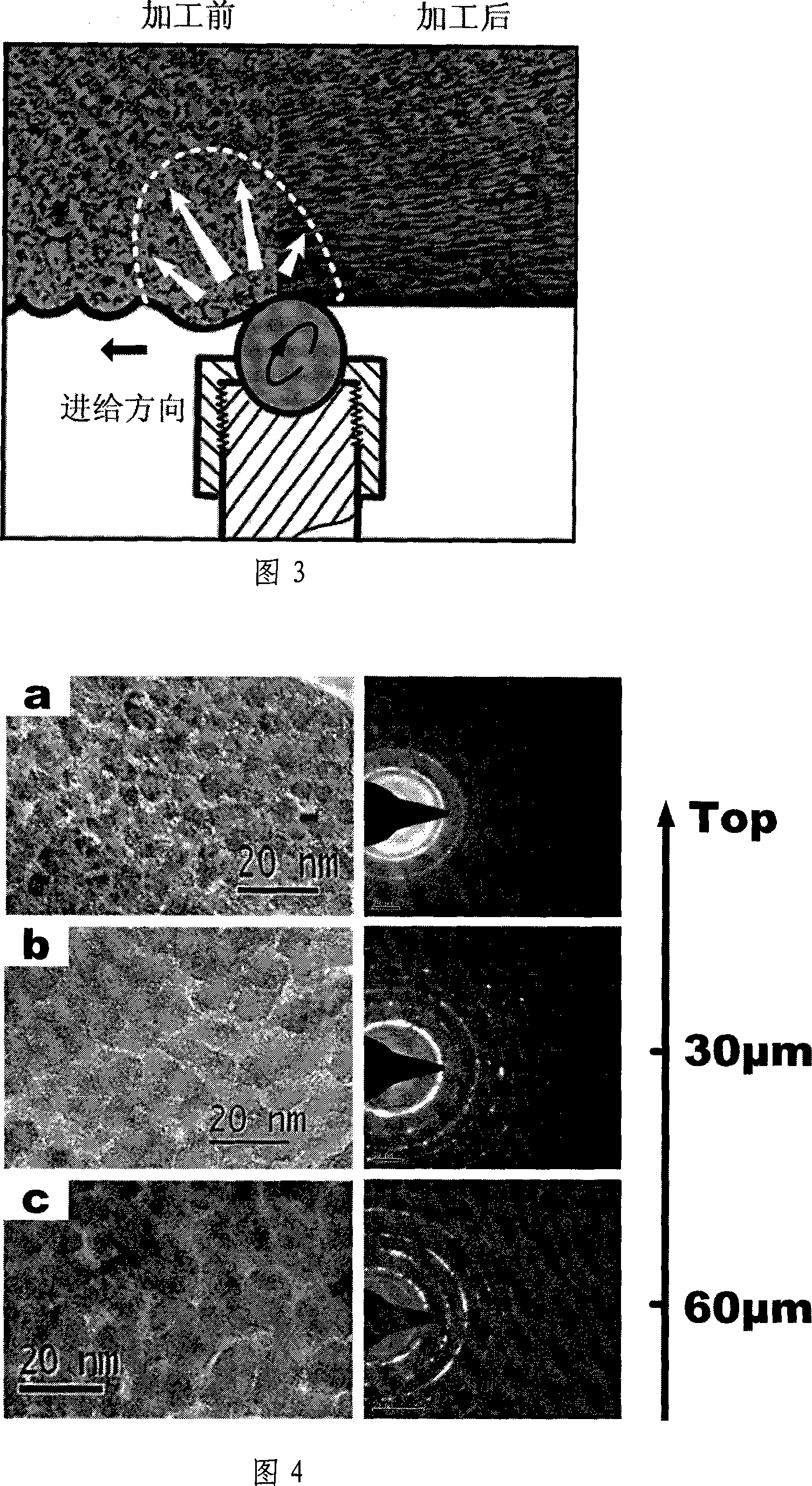

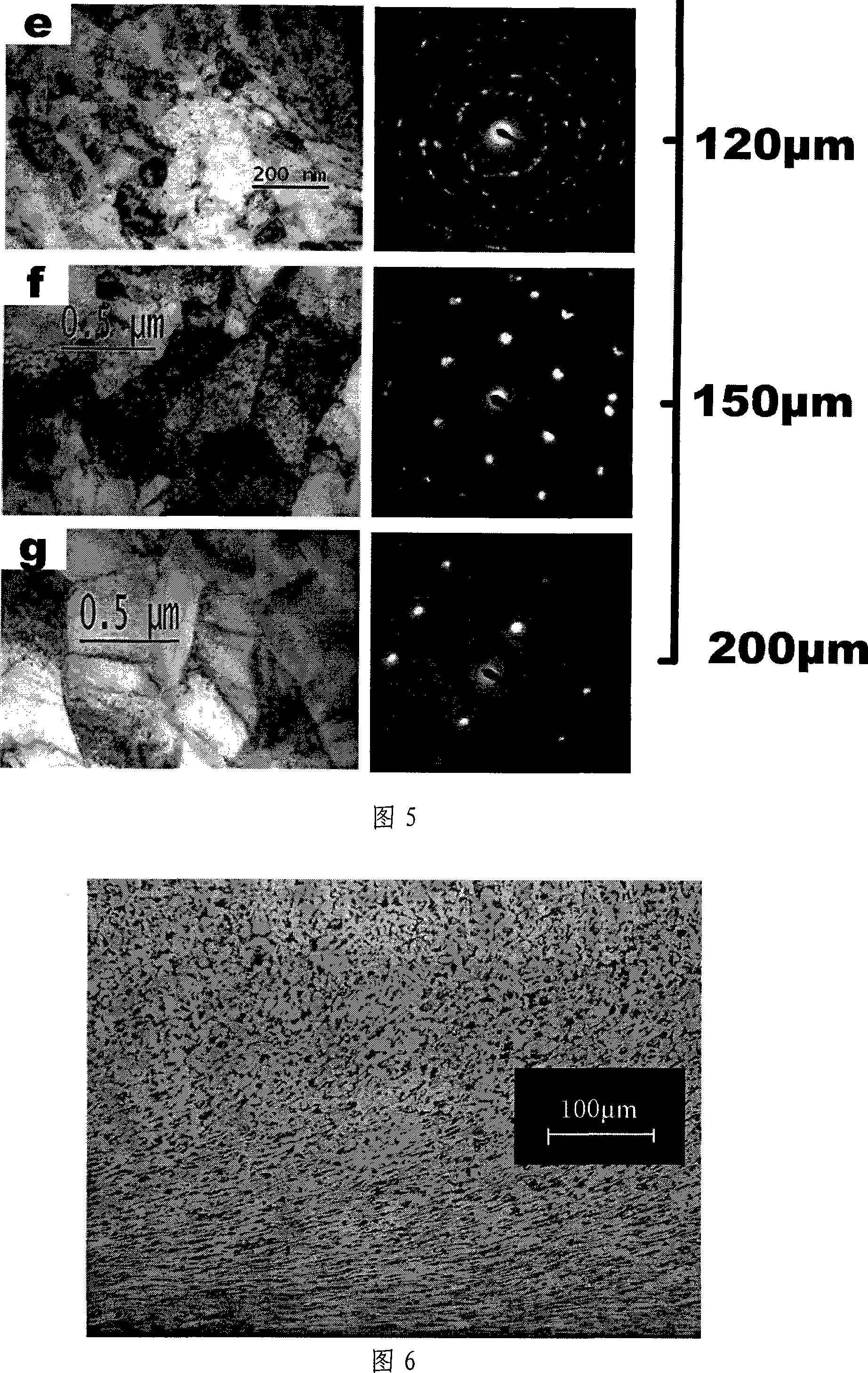

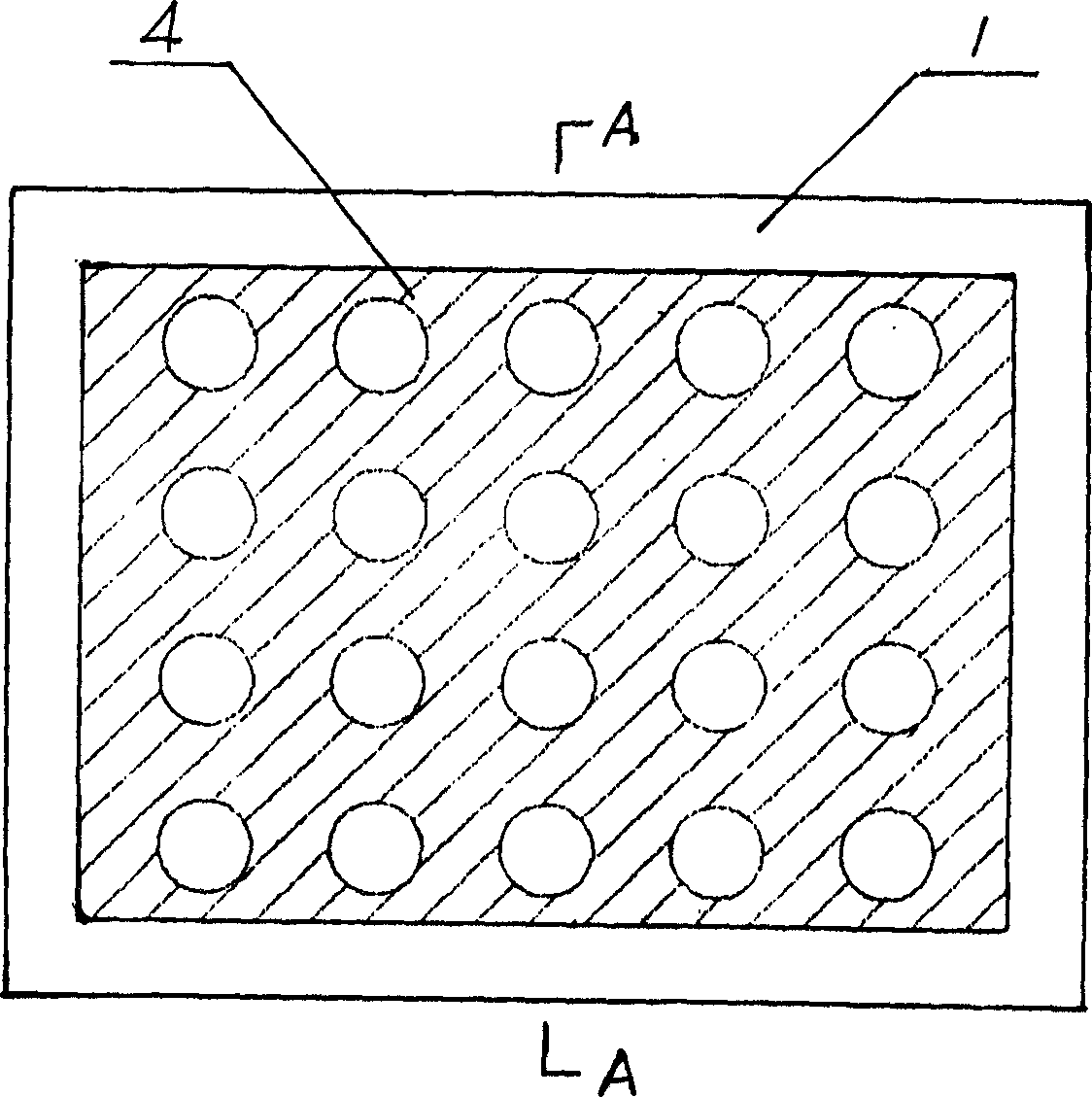

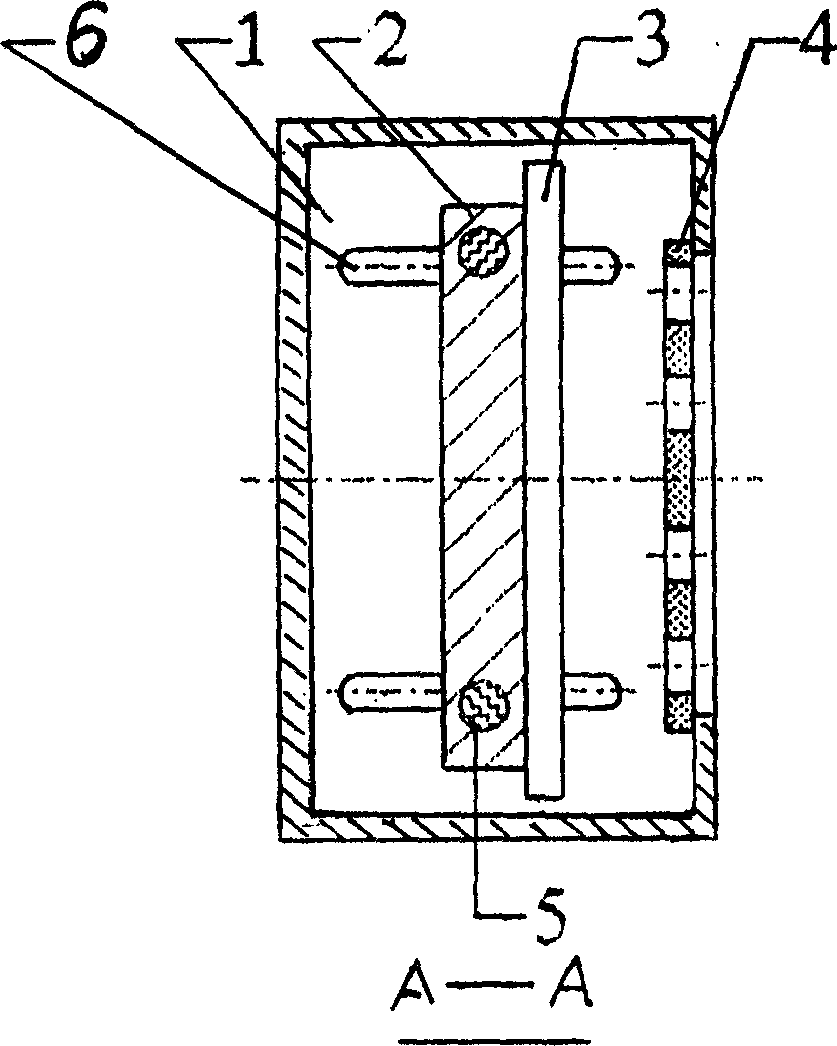

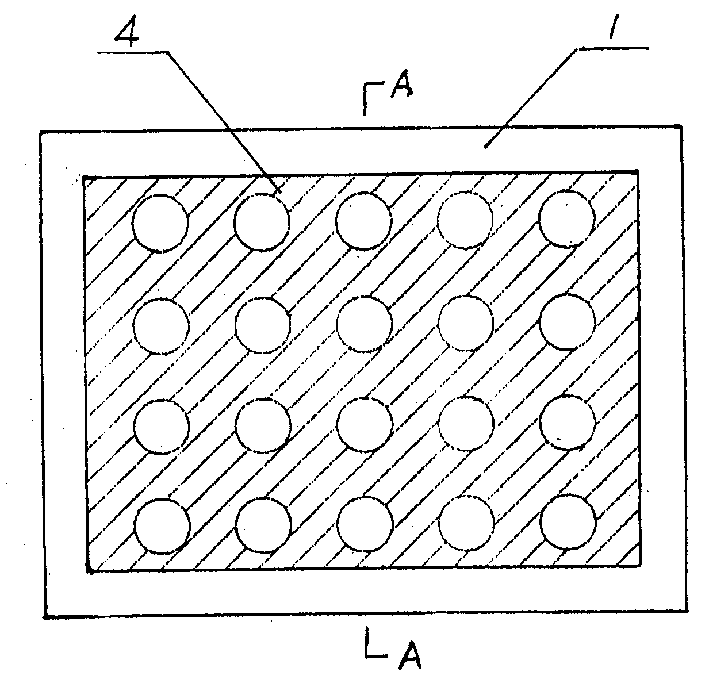

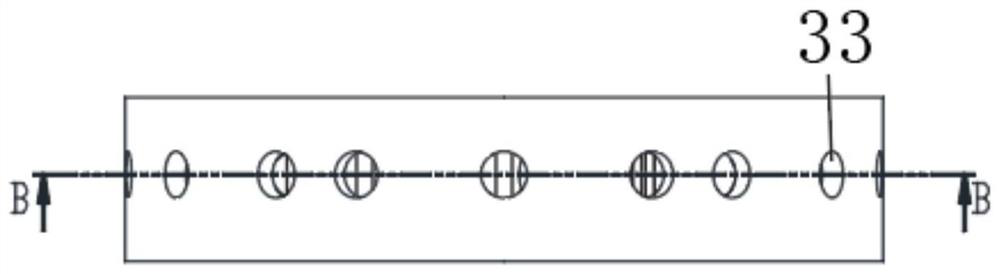

Ultrasonic surface rolling process nanoparticlization method and apparatus

The invention provides an ultrasonic surface rolling process nanostructure device and method, belonging to the mental surface process technical field, which comprises an ultrasonic generator and an executive mechanism. The executive mechanism consists of an ultrasonic transducer, an ultrasonic horn and an ultrasonic working joint, which is characterized in that the ultrasonic working joint is a rolling ball body. The method includes two steps: (1) the choice of the parameters is that the rotary speed of the Machine Tool Spindle is 200r to 700r per min; the axial direction feeding quantity of the working joint is 0.02mm to 0.1mm per r; the static pressure of the executive mechanism is 50N to 500N; the output terminal swing of the working joint is 5mm to 25 mm; (2) the reciprocating process is 2 times to 15 times. By adopting the device to carry out the nanostructure, the working life of the working joint can be prolonged and the crystal fineness of the same depth from the area closer to the surface is ensured to be more strict and even, thus obtaining the ideal surface finish. The surface can form noncrystalline nanometer crystal layer of about 100 mm depth.

Owner:TIANJIN UNIV

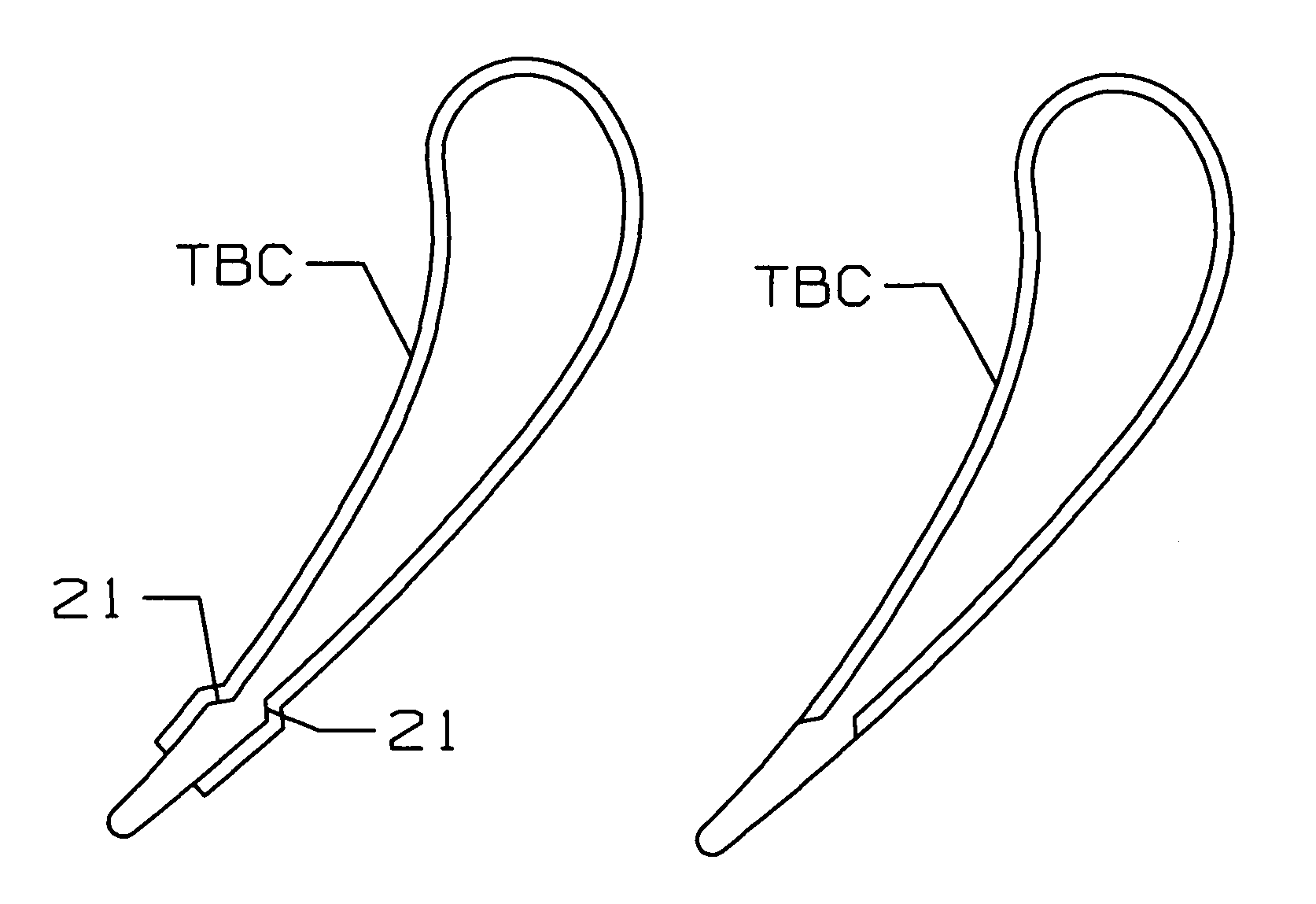

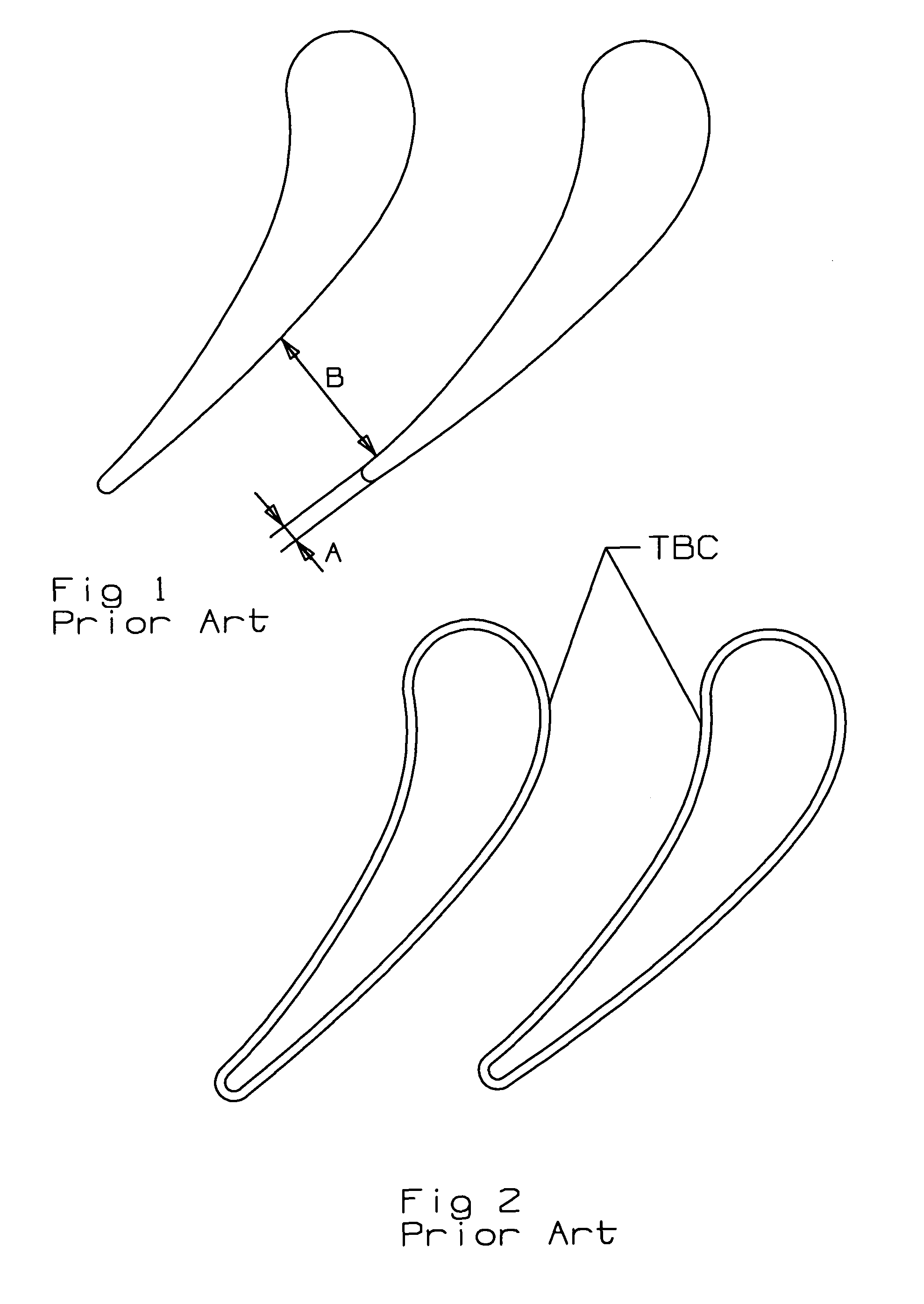

Turbine airfoil with trailing edge

ActiveUS8070454B1Improved sensitivity to spallationImprove aerodynamic performancePropellersEngine manufactureTrailing edgeTurbine

A turbine airfoil with a relatively thick TBC applied over the airfoil surface. The airfoil has a surface contour on the trailing edge region with a forward end having a large amount of taper and a rearward end with less taper such that a substantially constant wall thickness is formed in the rearward end. The TBC is applied over the airfoil surface and tapers off at the trailing edge ends on the pressure side and the suction side walls to produce an ideal surface contour on the airfoil. In another embodiment, the airfoil surface includes a tapered section at the trailing edge region, and the TBC is applied over the taper so that an over-coating is formed. The TBC over-coating is then removed and a smooth and ideal surface contour is produced along the airfoil surface. Small raised bumps each having a height of the desired thickness of the TBC to be applied over the respective bump is used to control the finished thickness of the TBC.

Owner:FLORIDA TURBINE TECH

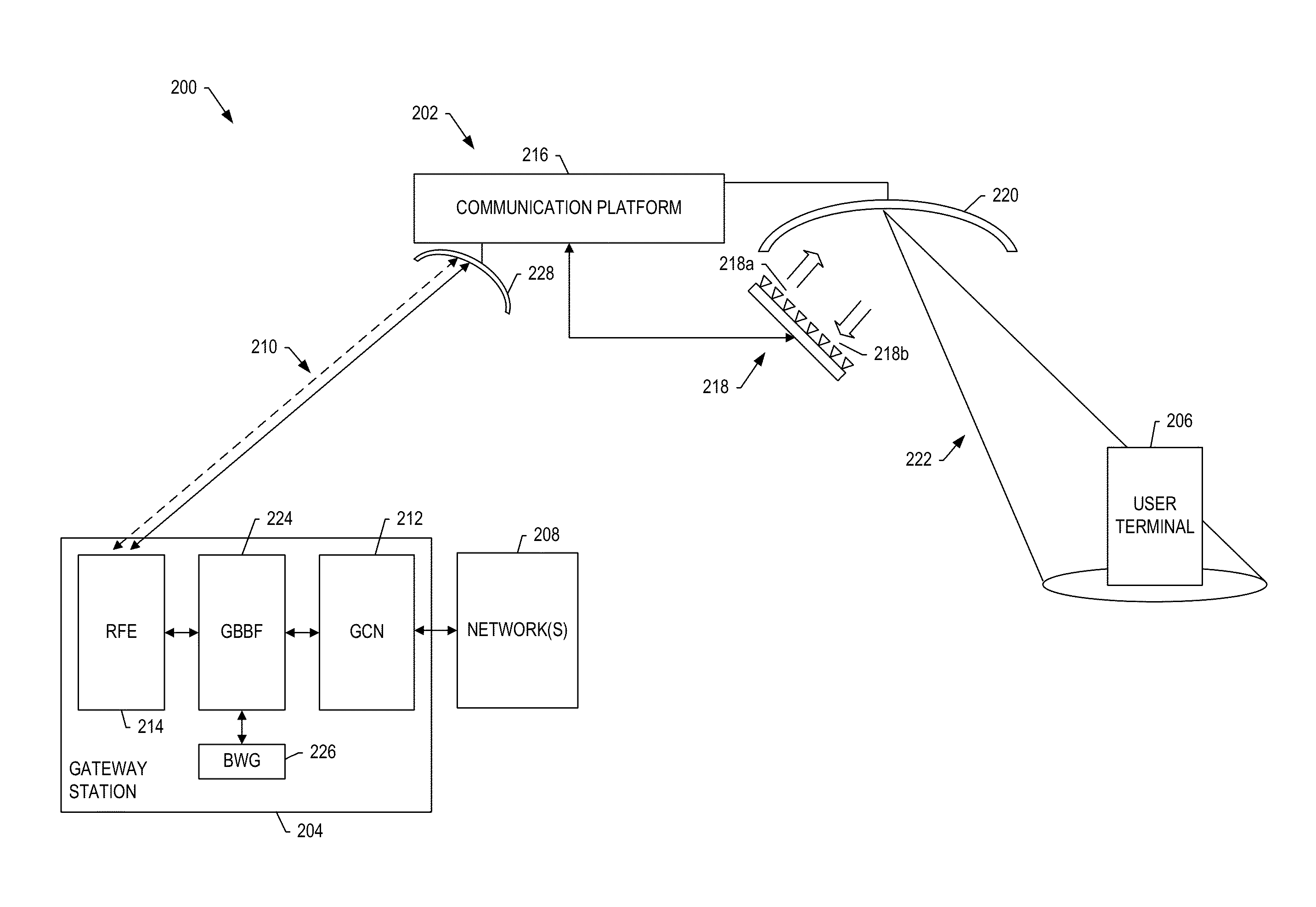

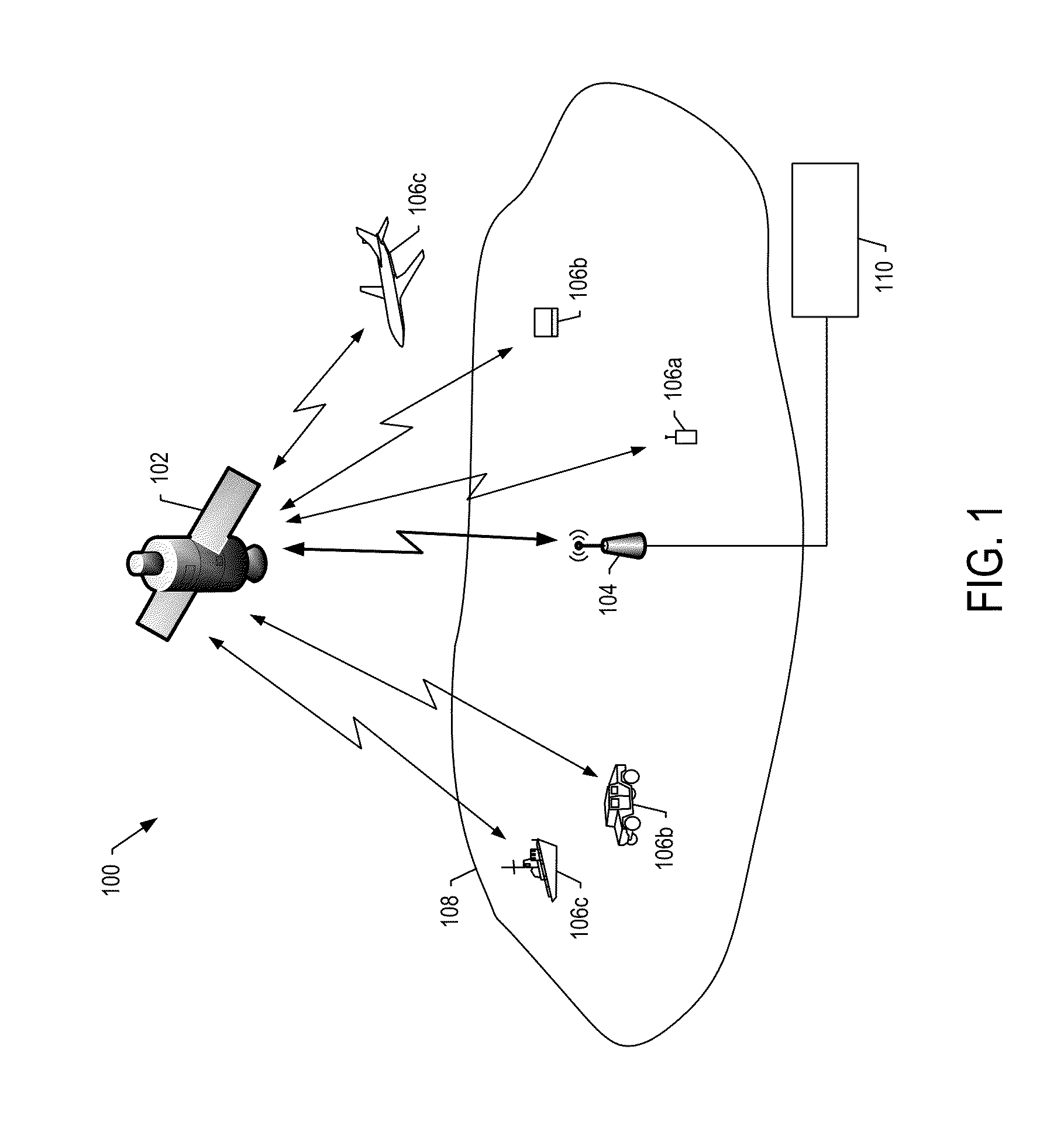

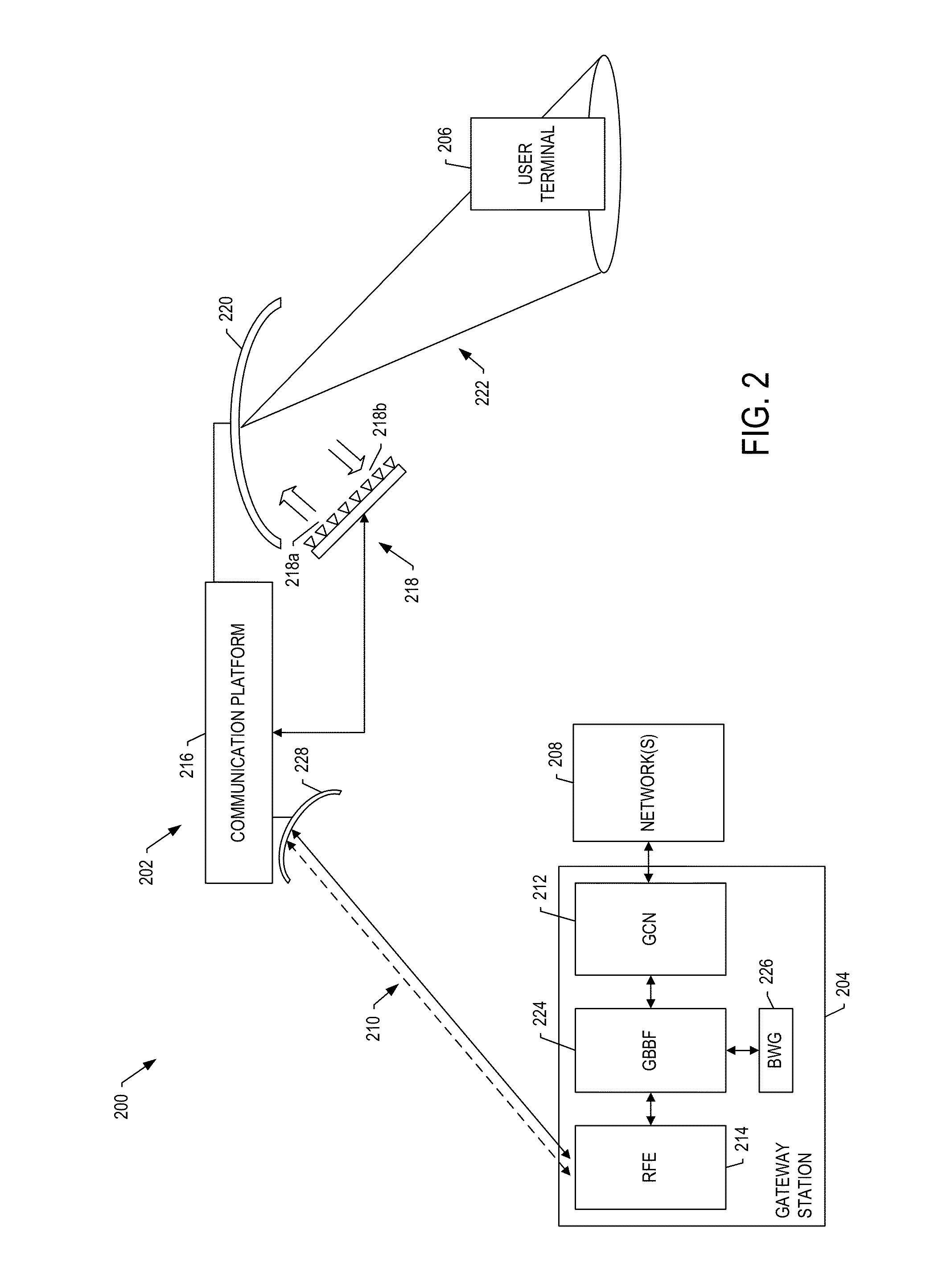

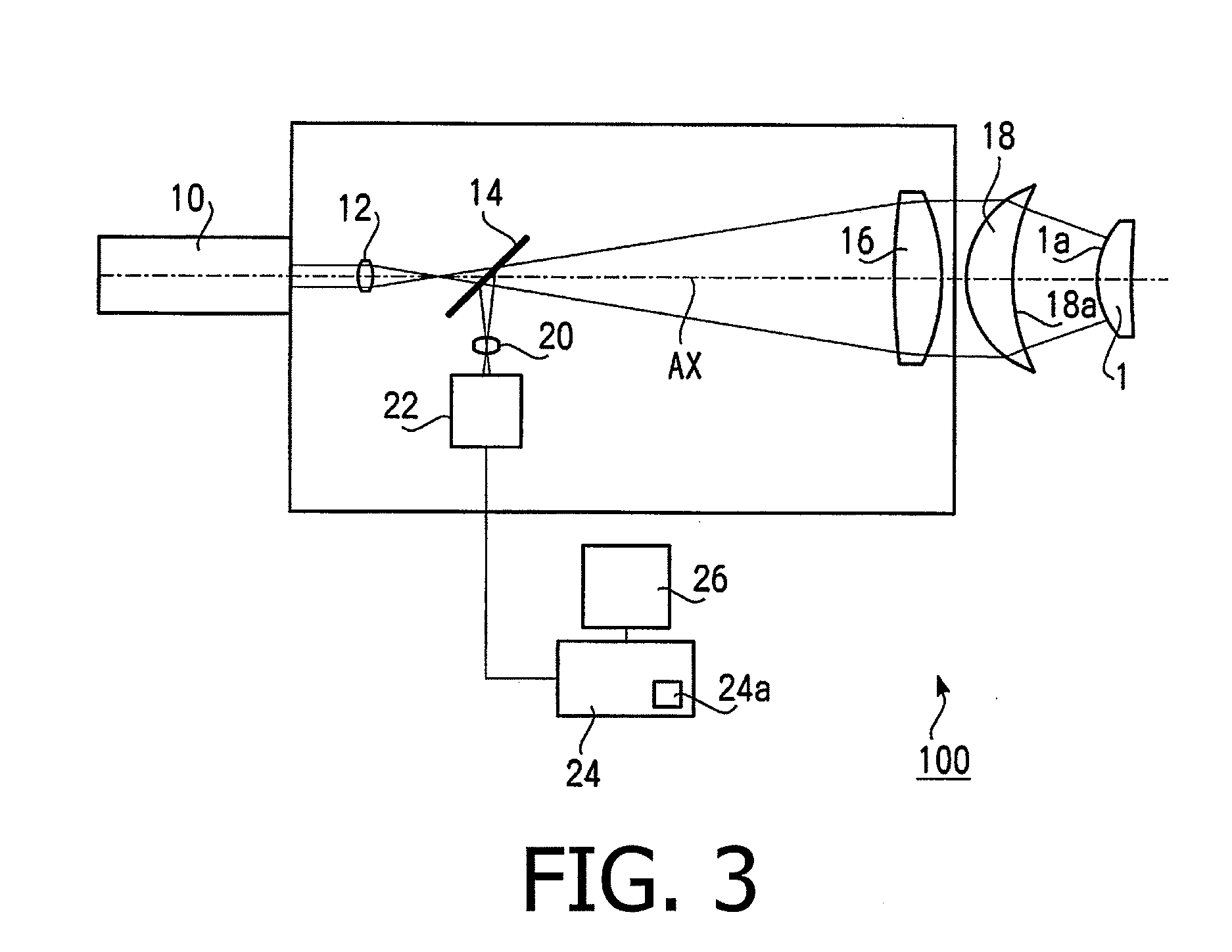

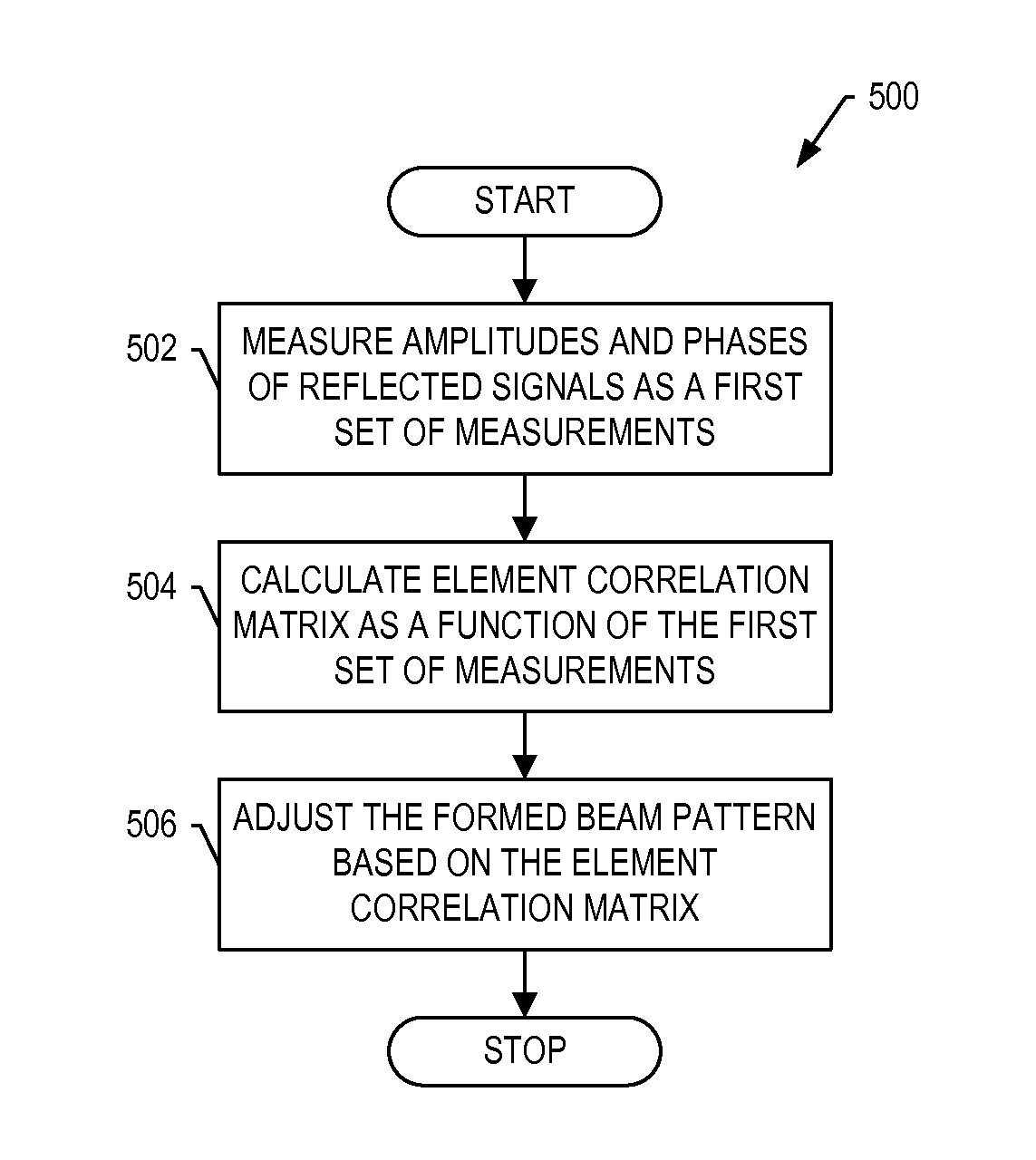

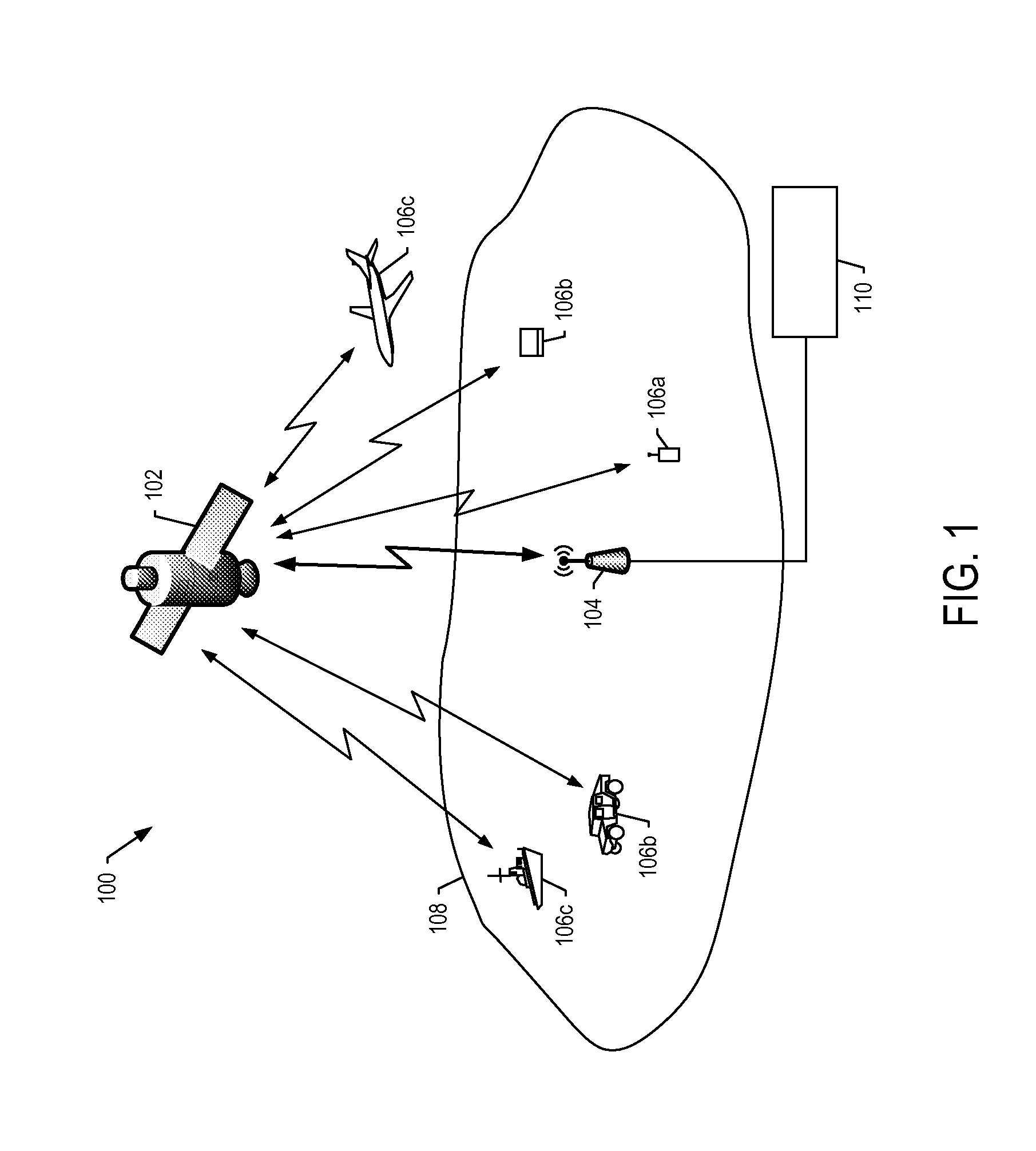

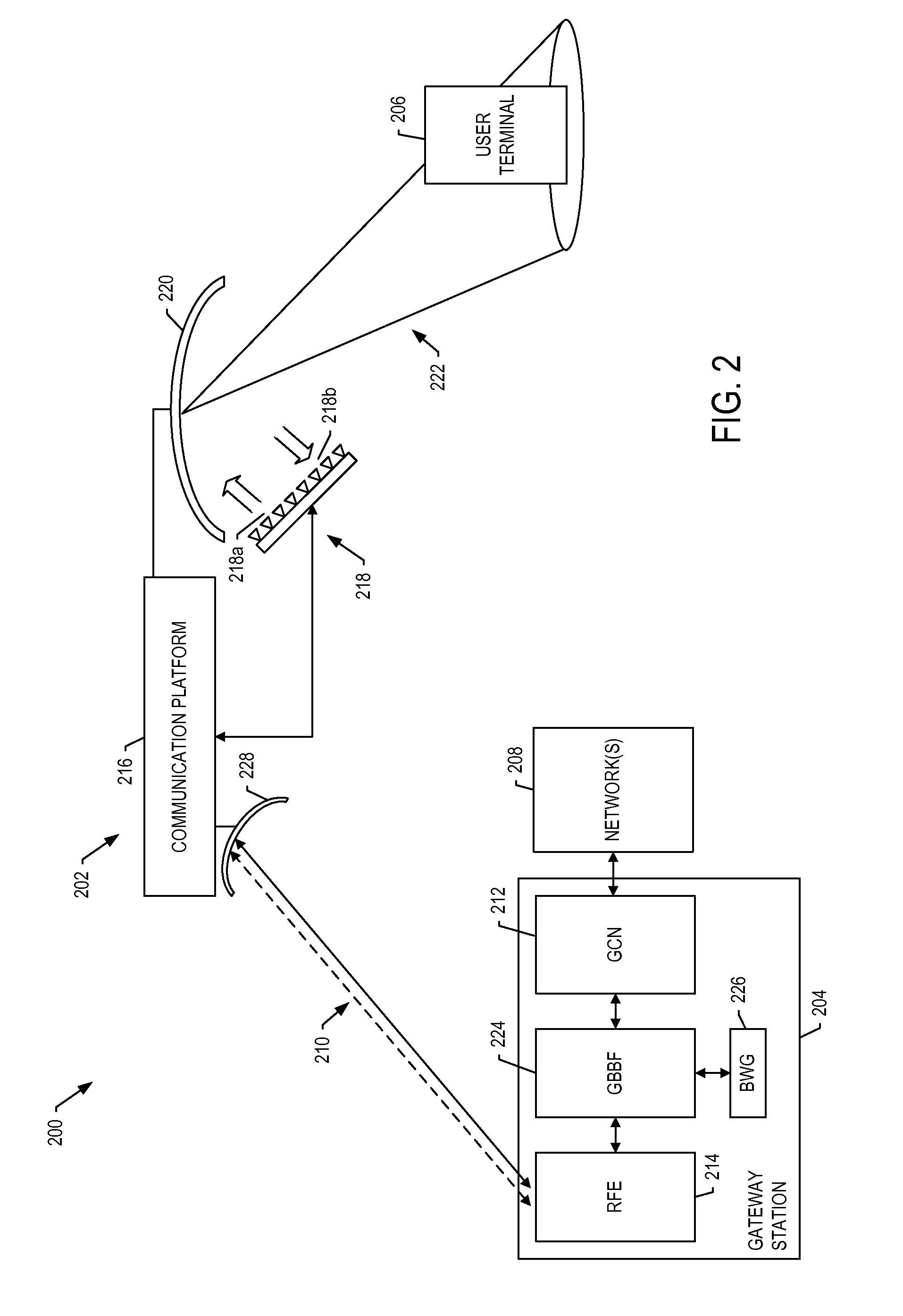

Compensating for a non-ideal surface of a reflector in a satellite communication system

ActiveUS9293820B2Simultaneous aerial operationsAntenna adaptation in movable bodiesCommunications systemBeam pattern

A method is provided that includes measuring amplitudes and phases of signals reflected off a reflector of a satellite, with the amplitudes and phases forming a first set of measurements. The method includes calculating an element correlation matrix as a function of the first set of measurements. The element correlation matrix represents a radiated feed element pattern off the reflector. And the method includes adjusting a formed beam pattern of a beamformer based on the element correlation matrix to thereby compensate for a non-ideal surface of the reflector.

Owner:THE BOEING CO

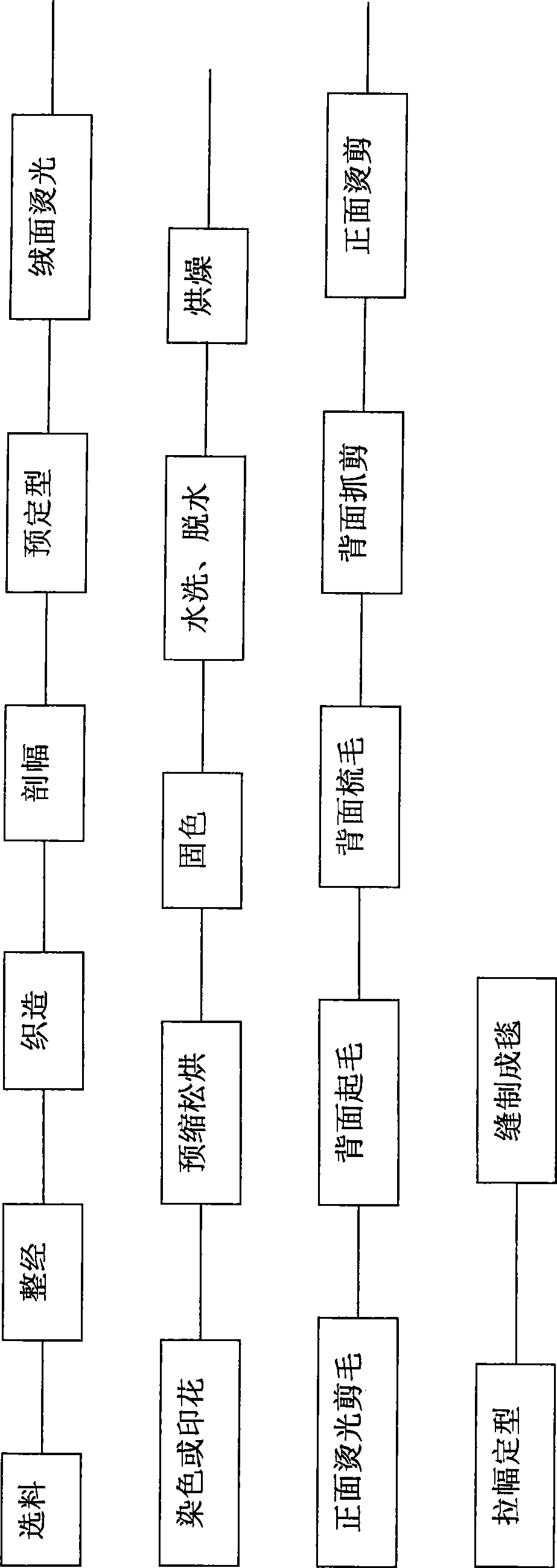

Full dacron soft pile blanket and its processing method

InactiveCN101397719AReasonable choiceGood surface smoothnessPattern makingWarp knittingYarnPolyester

The invention relates to a full polyester Soft fleece blanket and a processing method thereof, which pertains to the technical field of polyester fiber products and the processing thereof. The fleece blanket comprises fleece yarns and ground yarns; the raw material used by the fleece yarns is DTY yarns of 111dtex to 167dtex, while the raw material used by the ground yarns is FDY yarns of 55dtex to 167dtex, wherein, the DTY yarns account for 50 percent to 80 percent in the blanket according to mass percentage, while the FDY yarns account for 50 percent to 20 percent in the blanket according to the mass percentage. The invention has the advantages that: the raw materials are chosen reasonably; the crystal structure of fibers is changed by carrying out elasticizing modification to the DTY yarns serving as the fleece yarns by POY yarns, thereby getting rid of chemical finishing agents used in the prior art; in addition, pre-shaping, surface lustre finishing and then dyeing or printing are carried out after slitting, thus causing the surface of the obtained blanket to have more ideal surface flatness, smoothness and elasticity than coral fleece blankets.

Owner:常熟市锦绣经纬编有限公司

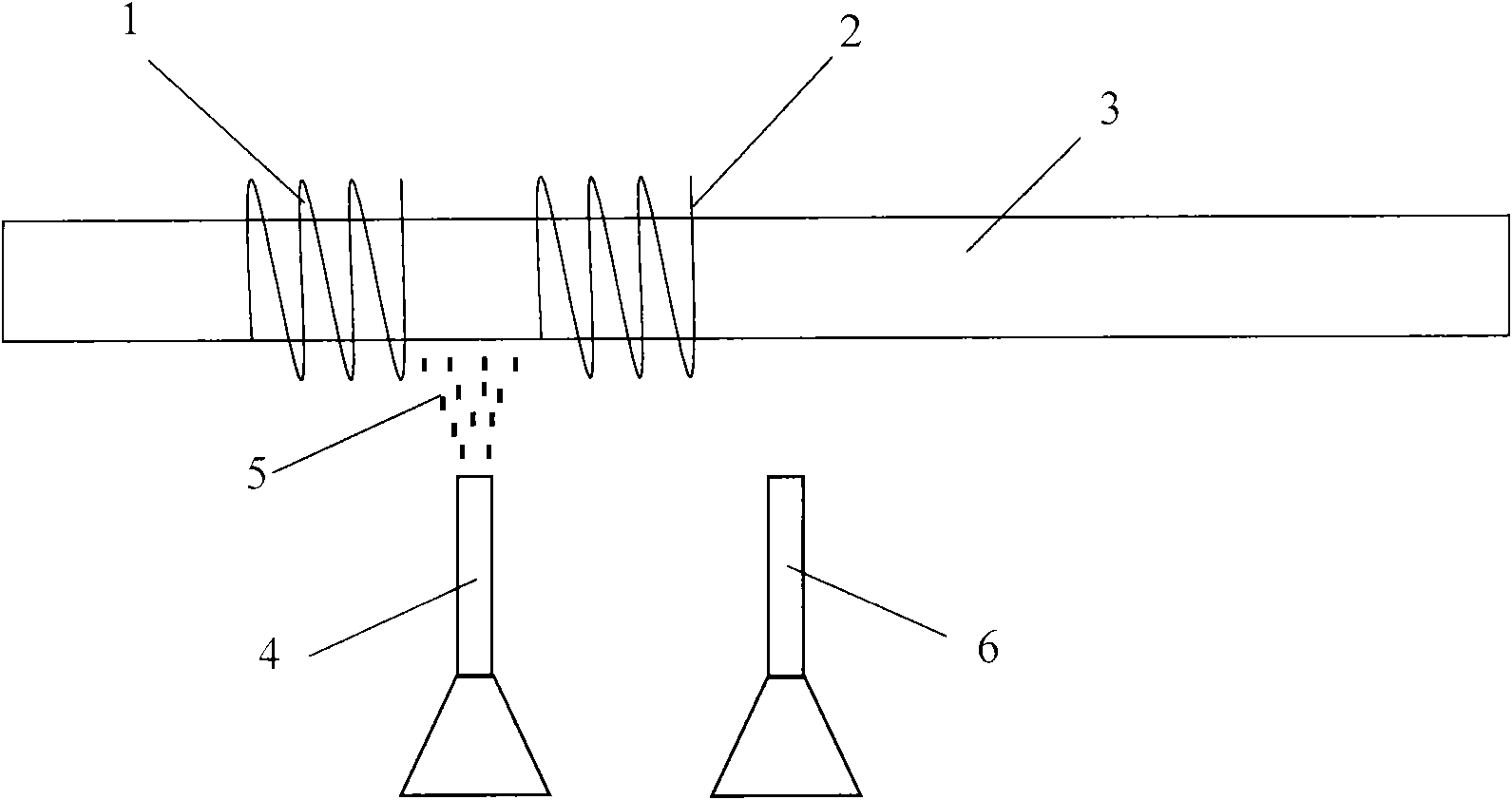

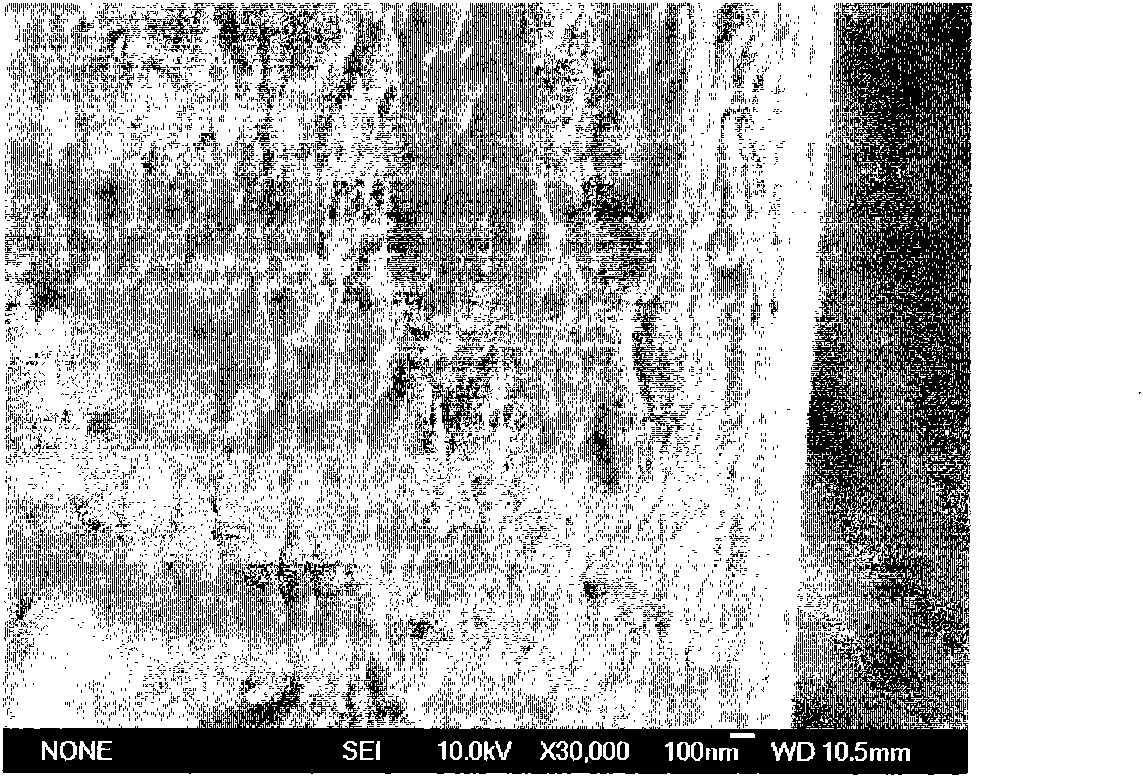

Method for nano reconstruction of surface texture of metal roller

ActiveCN101660033AEliminate or reduce surface deformation resistanceGrain refinementHigh pressureMaterials science

The invention relates to a method for the nano reconstruction of the surface texture of a metal roller, which comprises the following steps: 1) heating the matrix surface of a high-hardness metal roller by adopting an induction coil, wherein the temperature of the roller is between 0.2 and 0.5Tm DEG C, and the Tm is the melting point of a roller material; 2) using high pressure gas and a nozzle toaccelerate hard metal particles with the diameter between 40 and 500 microns to the supersonic speed to form a supersonic speed gas-solid two-phase flow to bombard the surface of the roller, performmicro-forging deformation on a surface layer material of the roller, and bombard the surface layer material so as to ensure that the surface layer of the roller generates strong partial plastic deformation and crystal grains are thinned to the nano magnitude; and 3) adopting a high-speed gas flow to perform quick cooking on the surface of the roller, wherein the cooling speed is between 50 and 200DEG C per second, and the cooling gas may be an inert gas or a reducing gas. The method achieves the surface nano reinforcement of high-hardness roller workpieces, obtains ideal surface nano-grain layers and ultrafine grain layers, and can perform online adjustment on the texture of the processed roller workpieces to ensure the stability of the texture.

Owner:BAOSHAN IRON & STEEL CO LTD

Dental appliance

ActiveUS20060216670A1Efficient use ofBeautiful smileOthrodonticsTooth crownsInterior spaceCosmetic appearance

An appliance fabricated to improve the appearance of a patient's smile includes a plurality of simulated teeth. The interior surfaces of each of the teeth closely fits and conforms to the surface of a patient's real teeth while the outer surfaces of each of the simulated teeth has an ideal surface configuration. The dental appliance provides the patient with the appearance of a perfect set of teeth and an ideal smile without a need to alter the dental structure of the patient's teeth.

Owner:DEN MAT HLDG

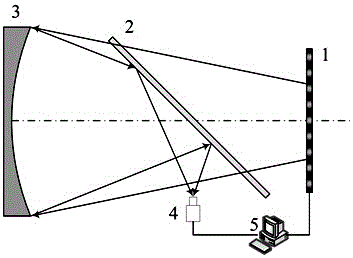

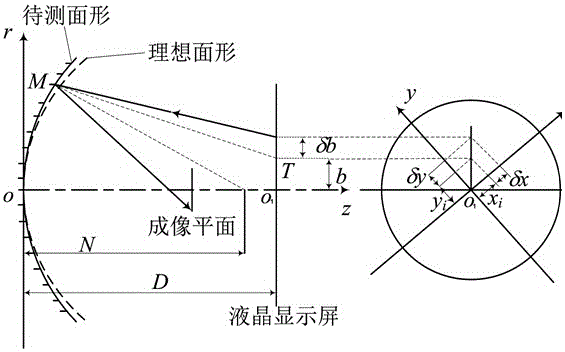

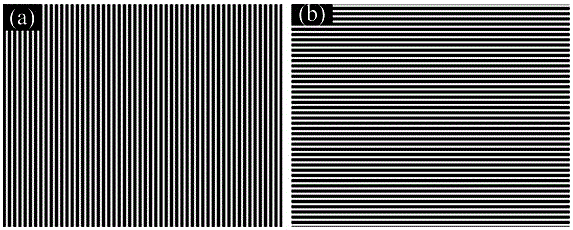

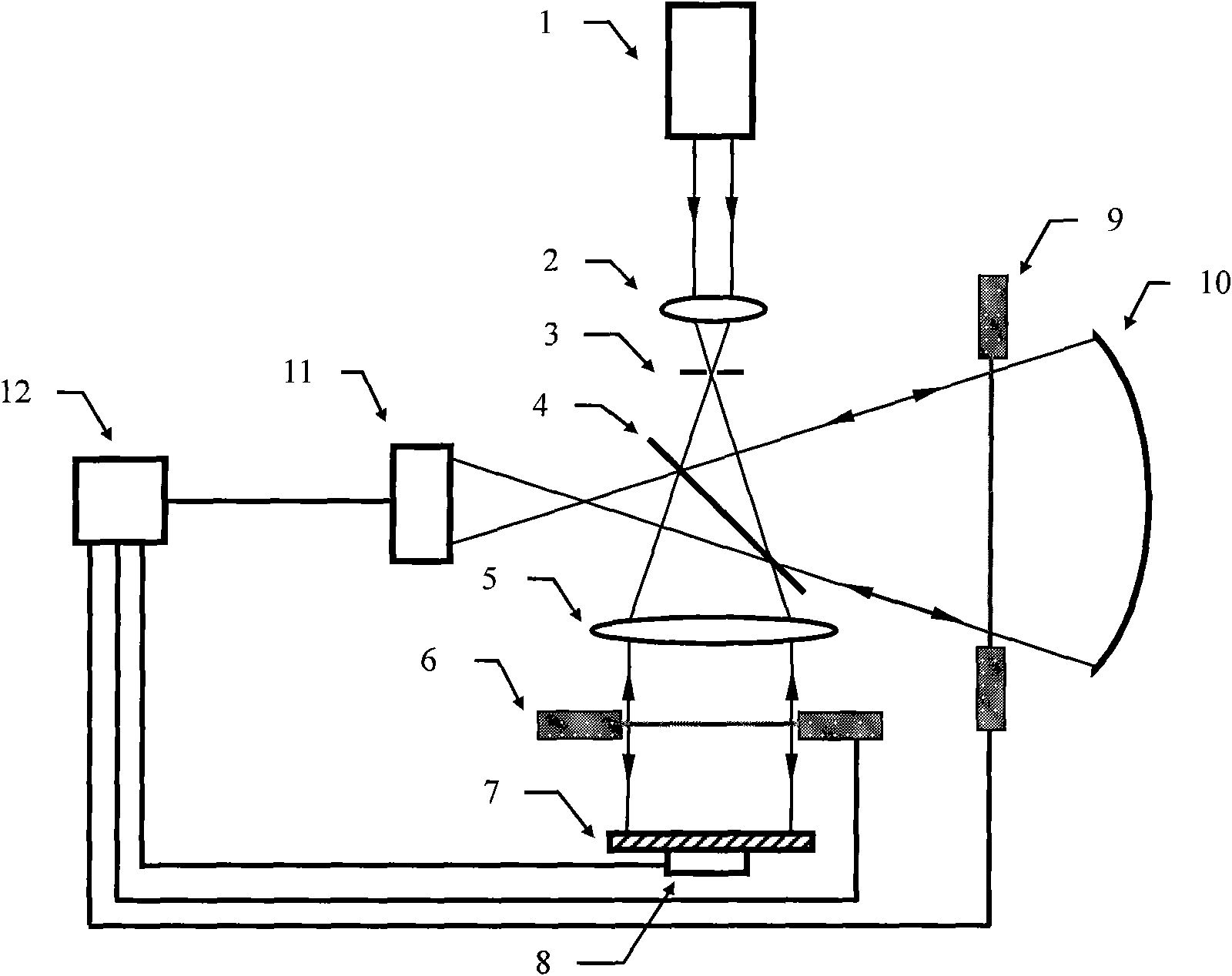

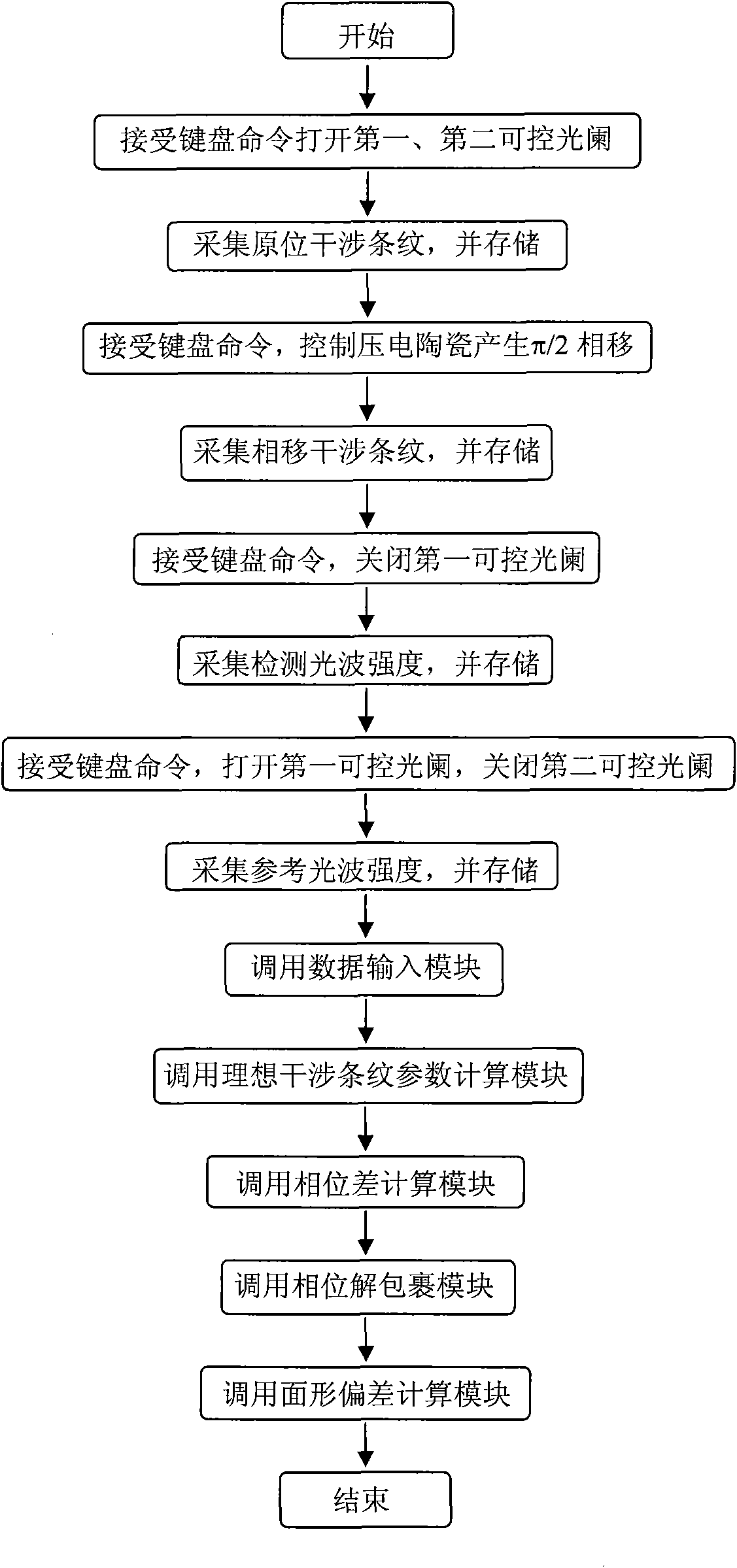

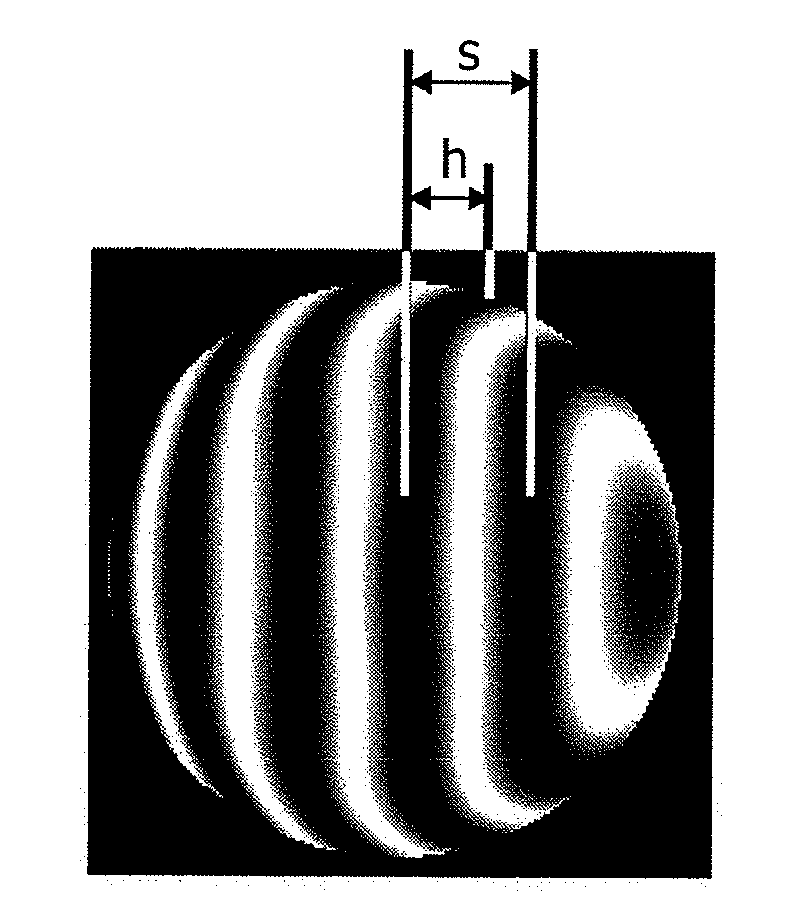

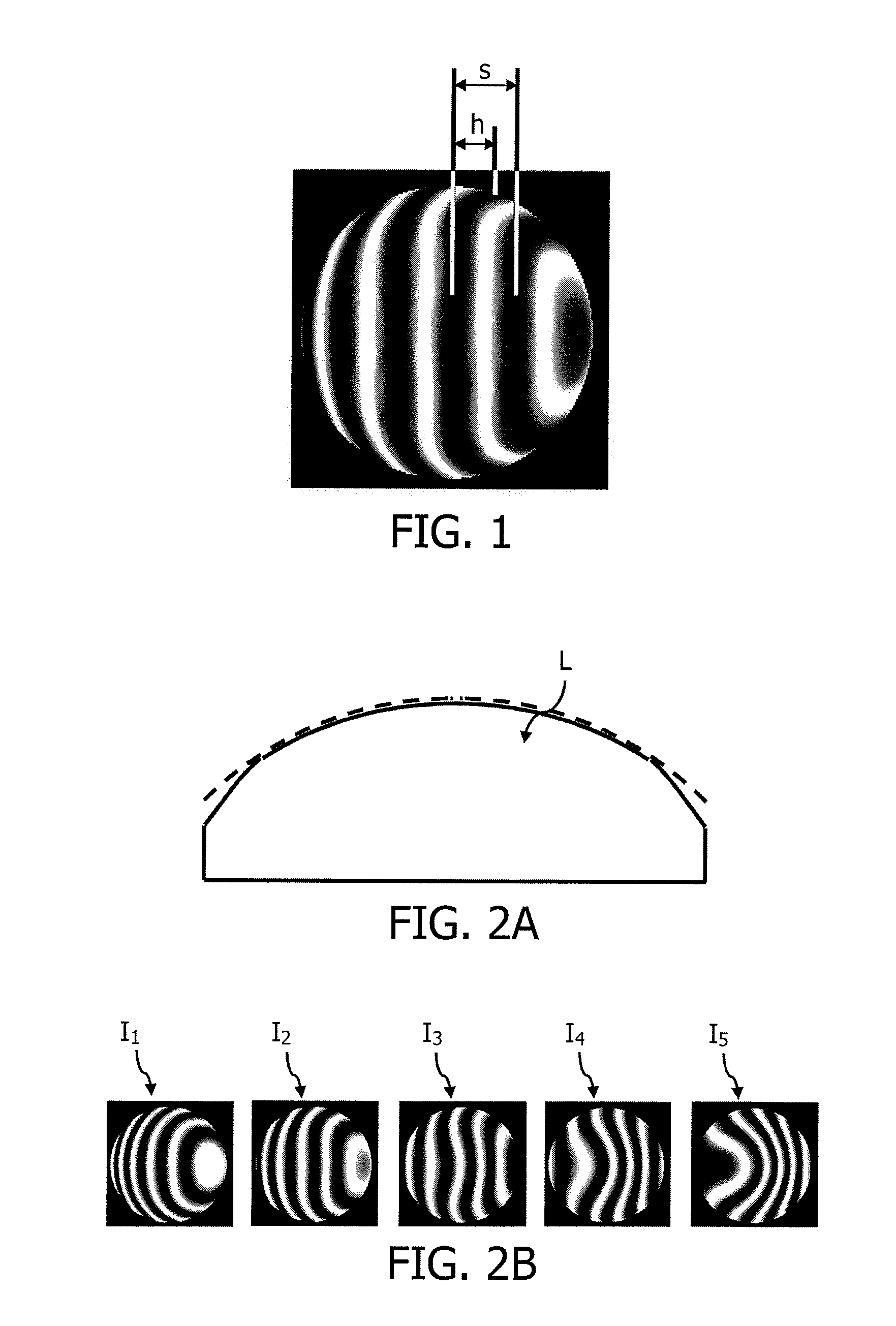

Phase measurement deflection method for aspheric surface detection

InactiveCN106017863AImprove detection accuracySimple structureUsing optical meansOptical apparatus testingFull fieldComputational physics

The invention relates to a phase measurement deflection method for aspheric surface detection. On the basis of a geometric principle of Ronchi test, a reverse optical path analysis is carried out on an improved phase measurement deflection detection method for an aspheric surface so as to obtain a deviation gradient of a to-be-detected mirror surface relative to an ideal surface shape; and integrating processing is carried out on the gradient to recover the deviation of the to-be-detected mirror surface and thus the to-be-detected mirror surface is reconstructed, so that non-contact full-field detection is carried out on the aspheric surface. With the method, a problem that incident light is obtained by display screen moving, calibration or approximation during the existing phase measurement deflection process or Ronchi testing and thus aspheric surface detection becomes inconvenient.

Owner:SHANGHAI INST OF TECH

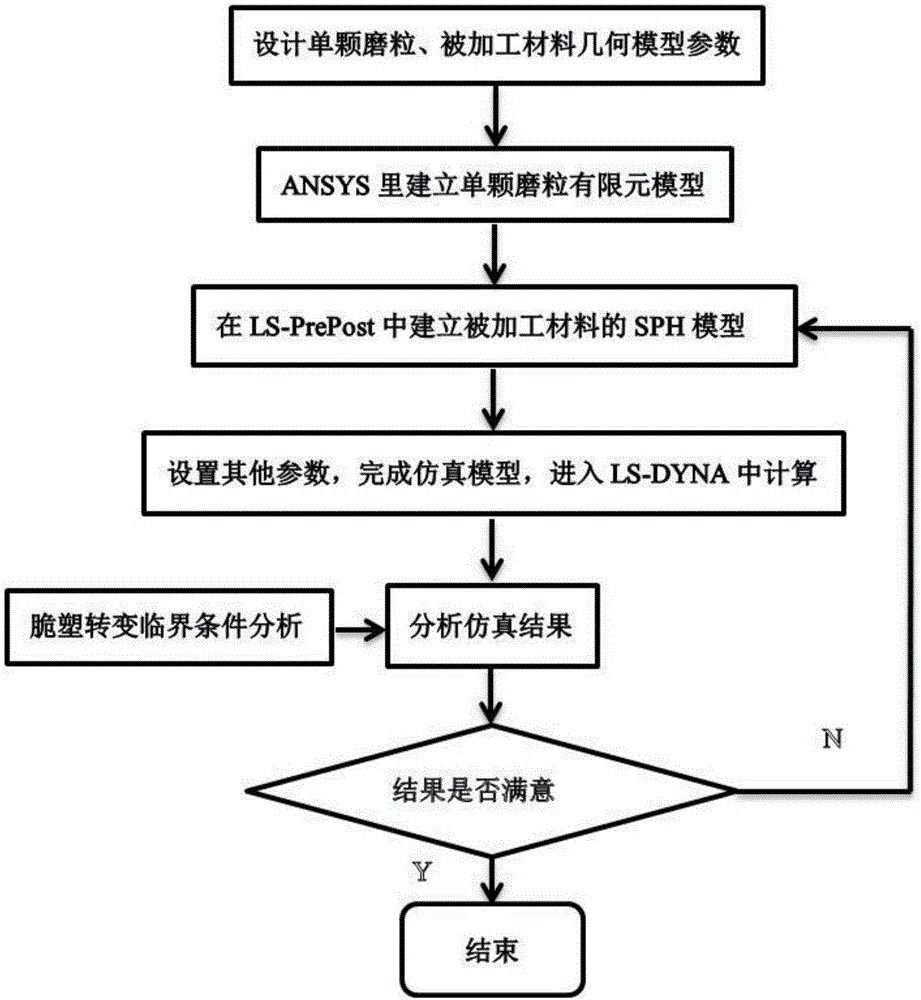

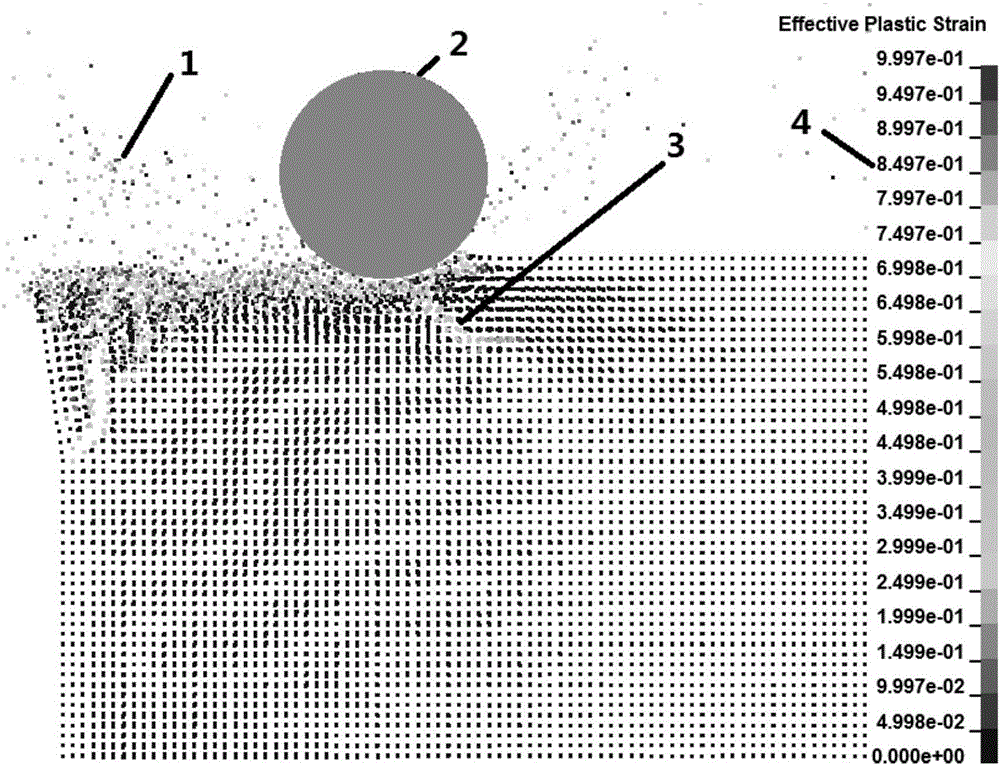

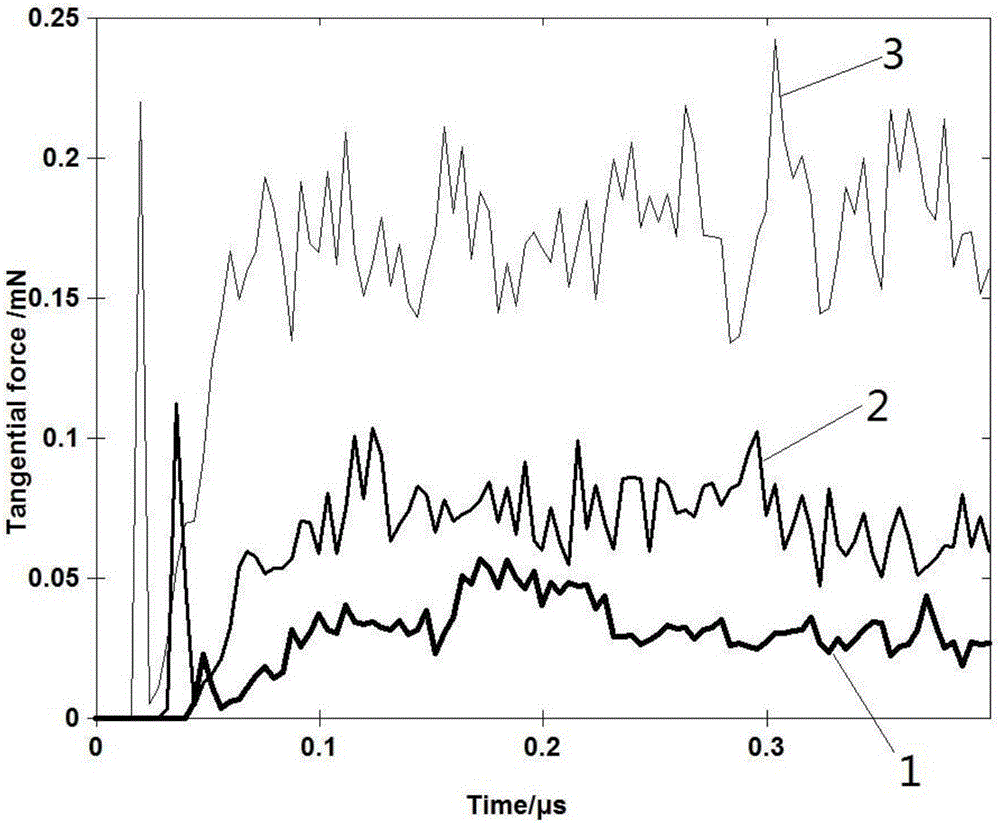

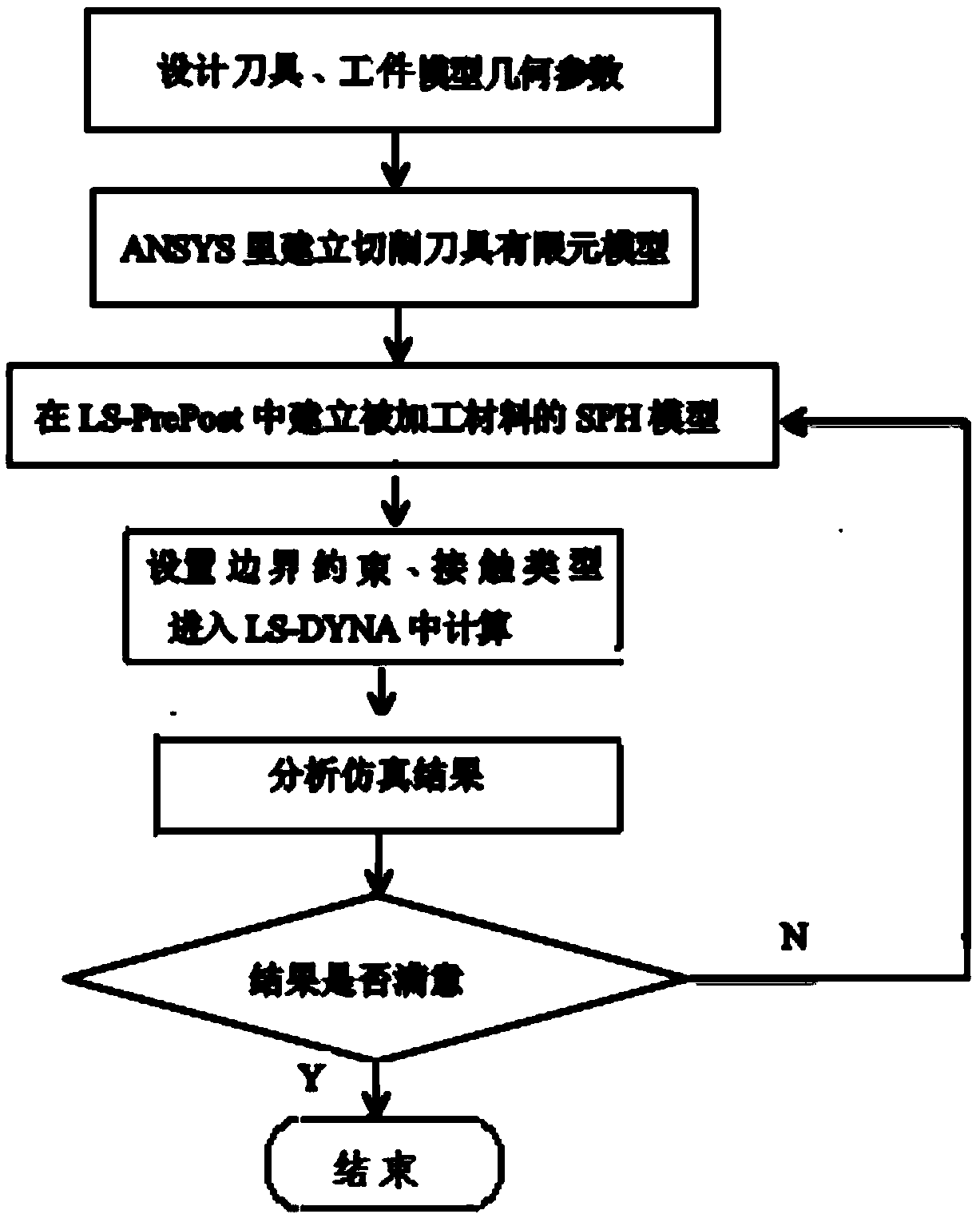

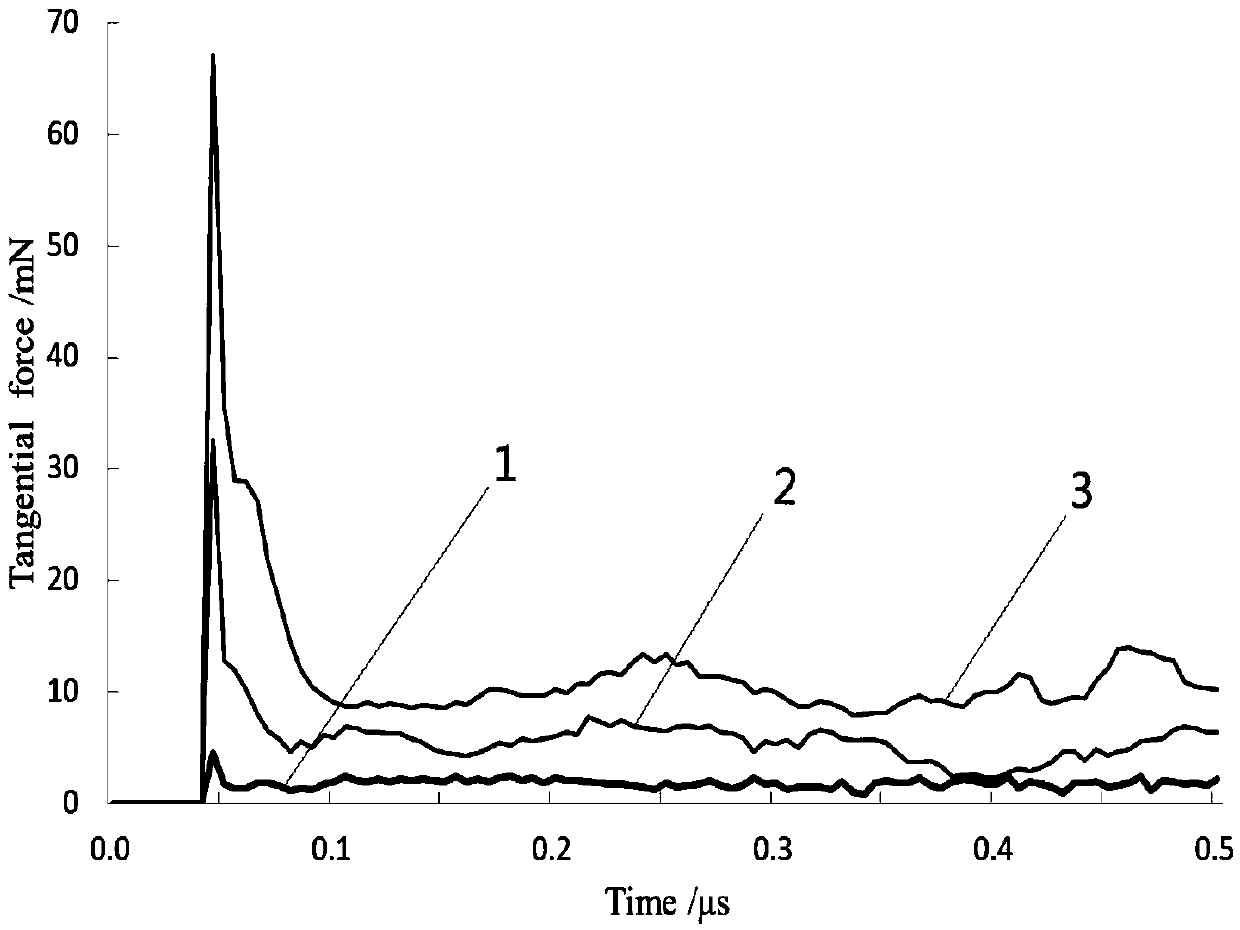

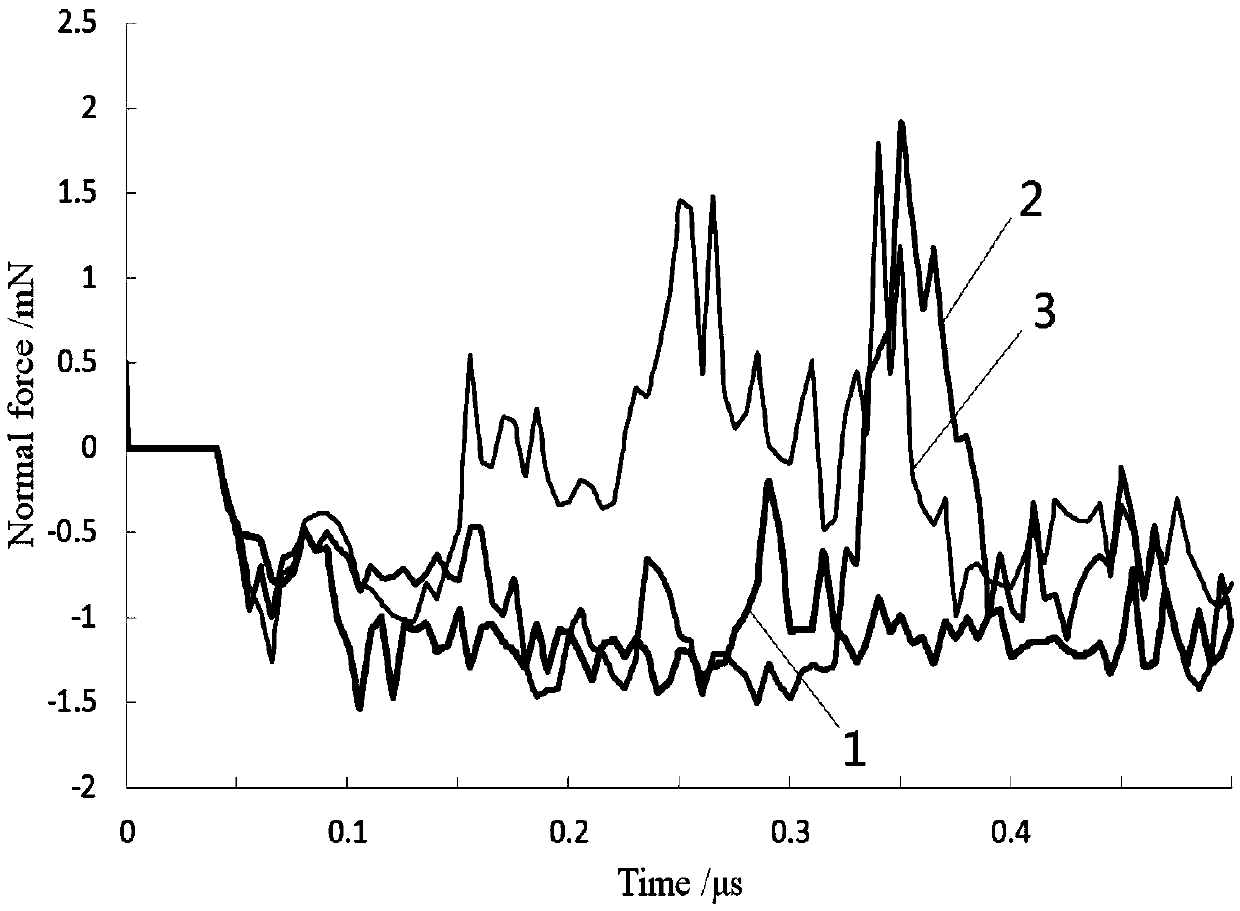

Brittle material grinding process modeling simulation method

InactiveCN106650021AAvoid the difficult problem of online observationImprove surface qualityDesign optimisation/simulationSpecial data processing applicationsMicro nanoSmoothed-particle hydrodynamics

The invention discloses a brittle material grinding process simulation method, belongs to the field of micro-nano ultraprecision machining numeric simulation, and relates to a three-dimensional micro-nano single grain grinding simulation method based on a smoothed particle hydrodynamics method. The method comprises the steps of firstly setting the sizes of a grinding grain and a machined material; secondly, building a three-dimensional single grinding grain finite element model in ANSYS, building an SPH model of a workpiece material in LS-PrePost, setting related model parameters, and performing calculation in LS-DYNA; and finally, analyzing a simulation result. According to the simulation method, data such as a stress, a strain, density and the like in the grinding process can be obtained more clearly and accurately; a brittle material is removed in a plastic region by controlling a processing depth, and a damage mechanism of the brittle material is analyzed, so that relatively ideal surface quality is obtained; and a large amount of labor costs, experimental costs and economic costs are reduced and the difficult problem of difficult online observation of an experimental method is avoided.

Owner:DALIAN UNIV OF TECH

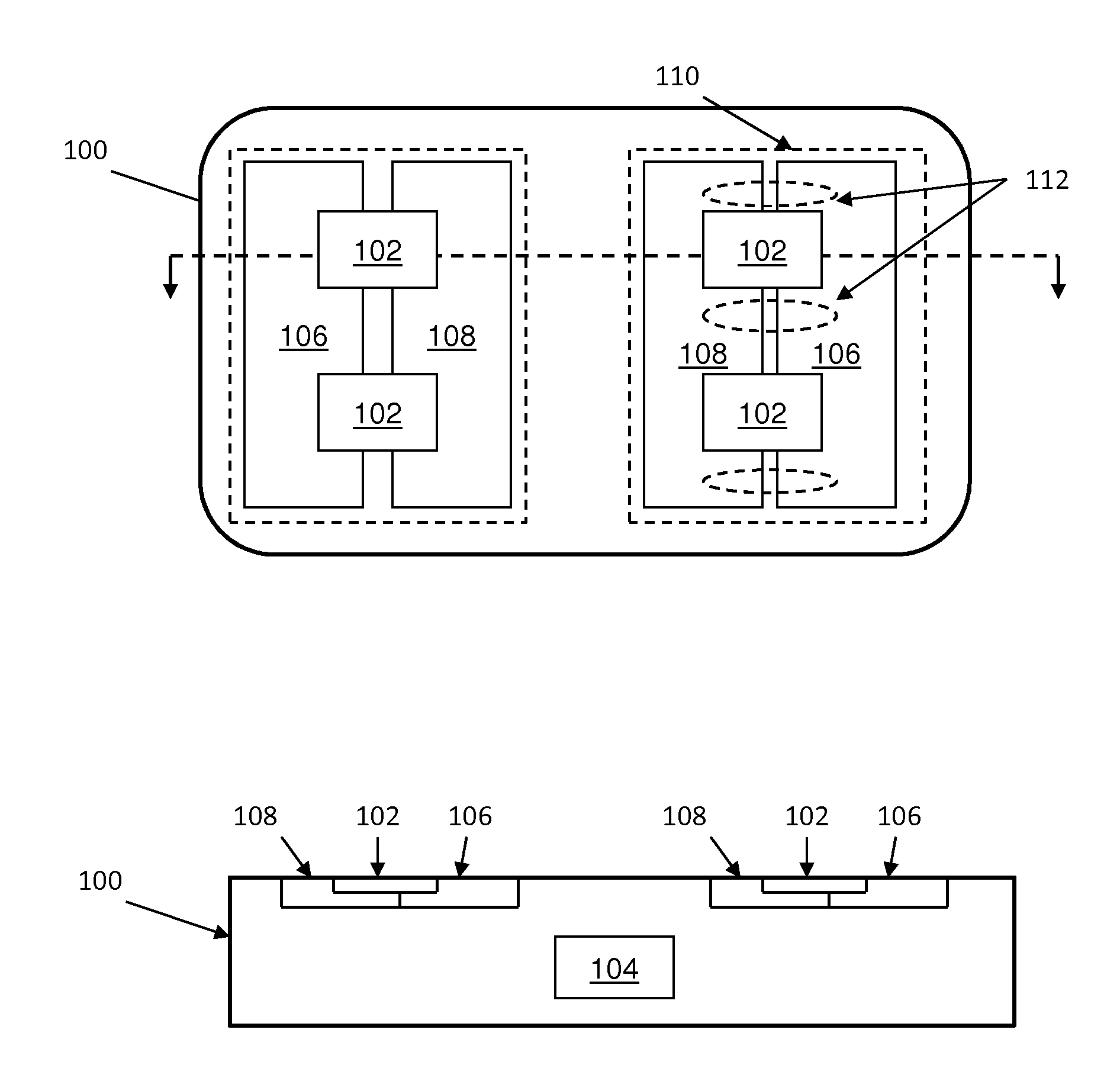

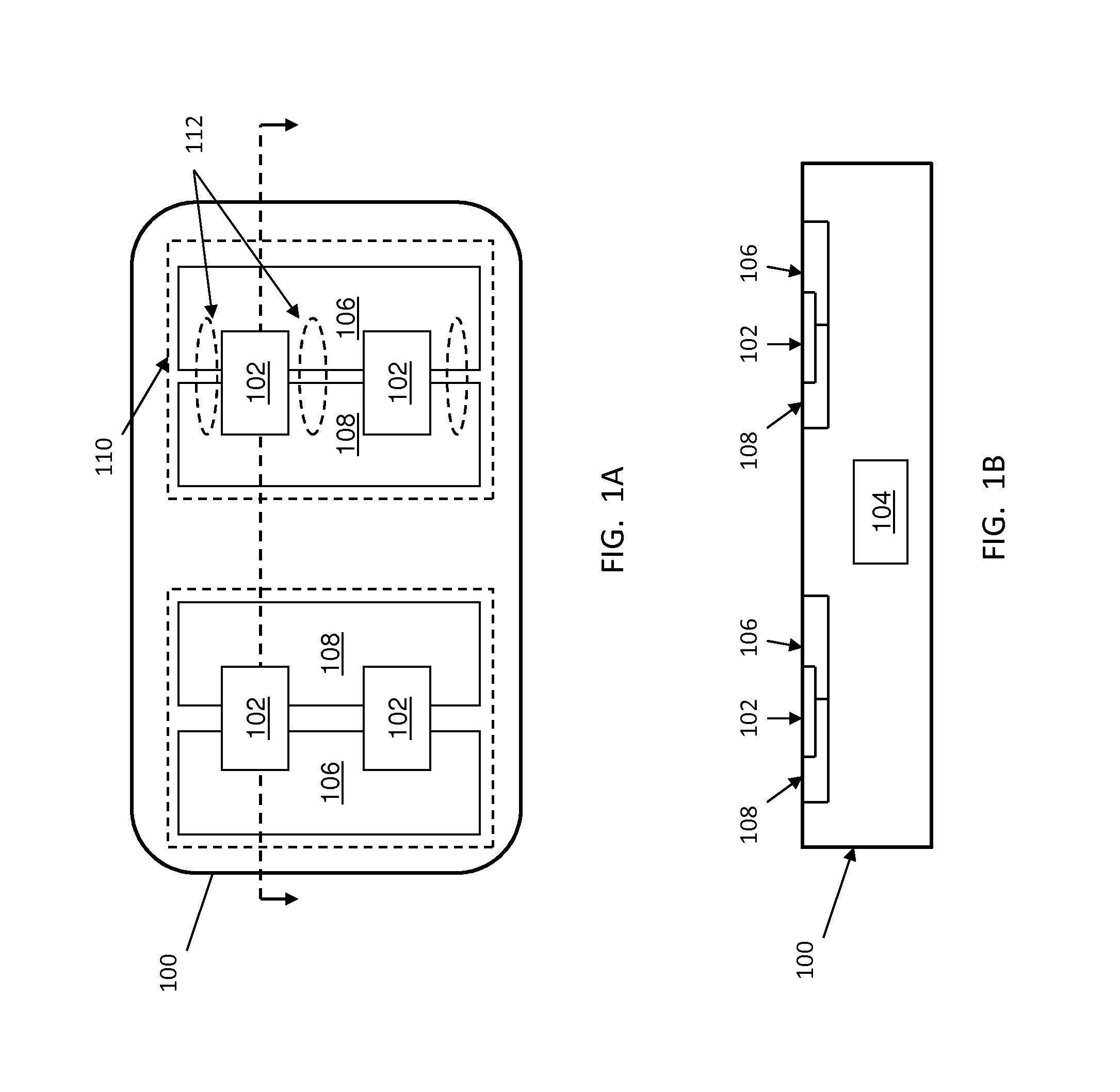

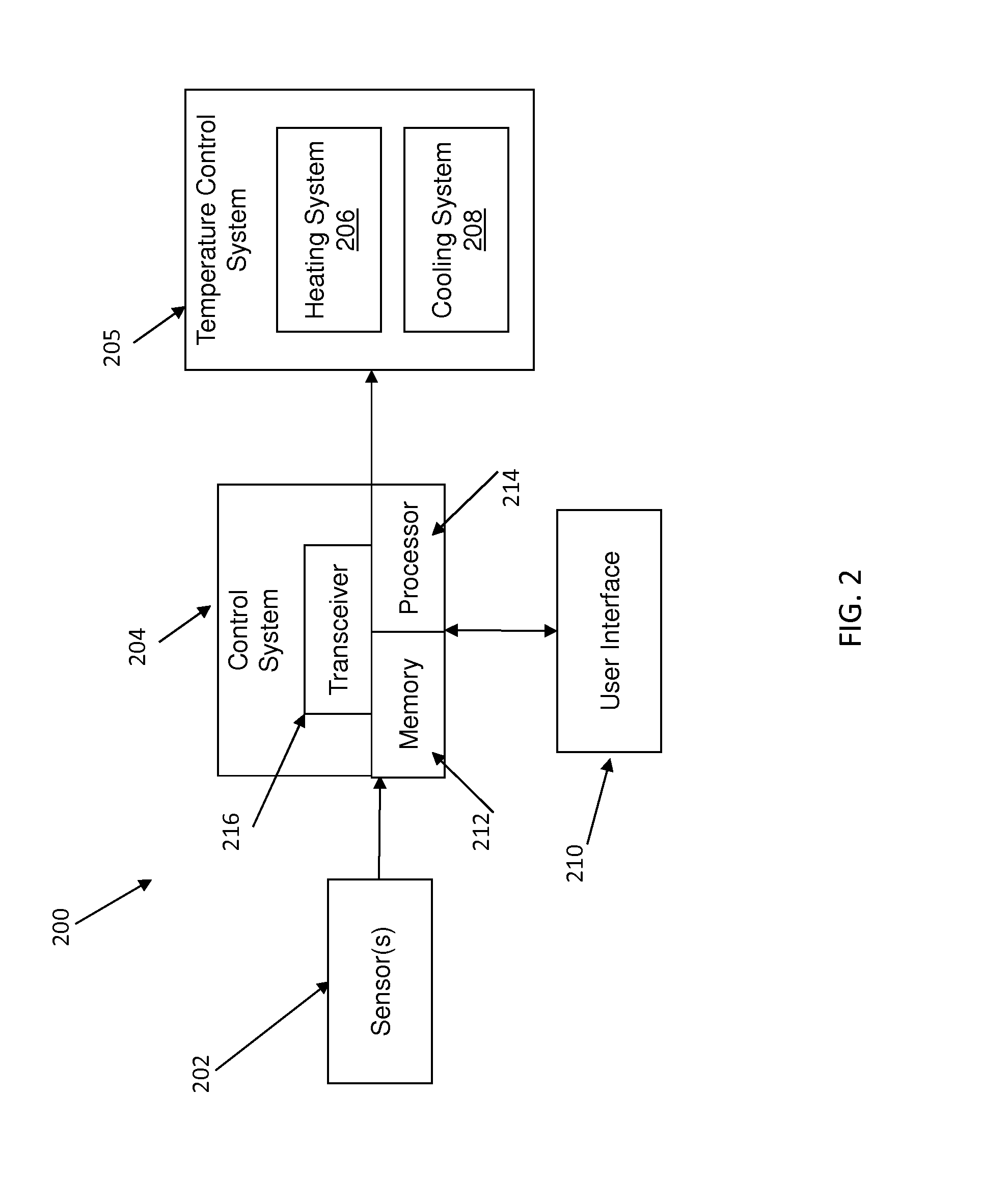

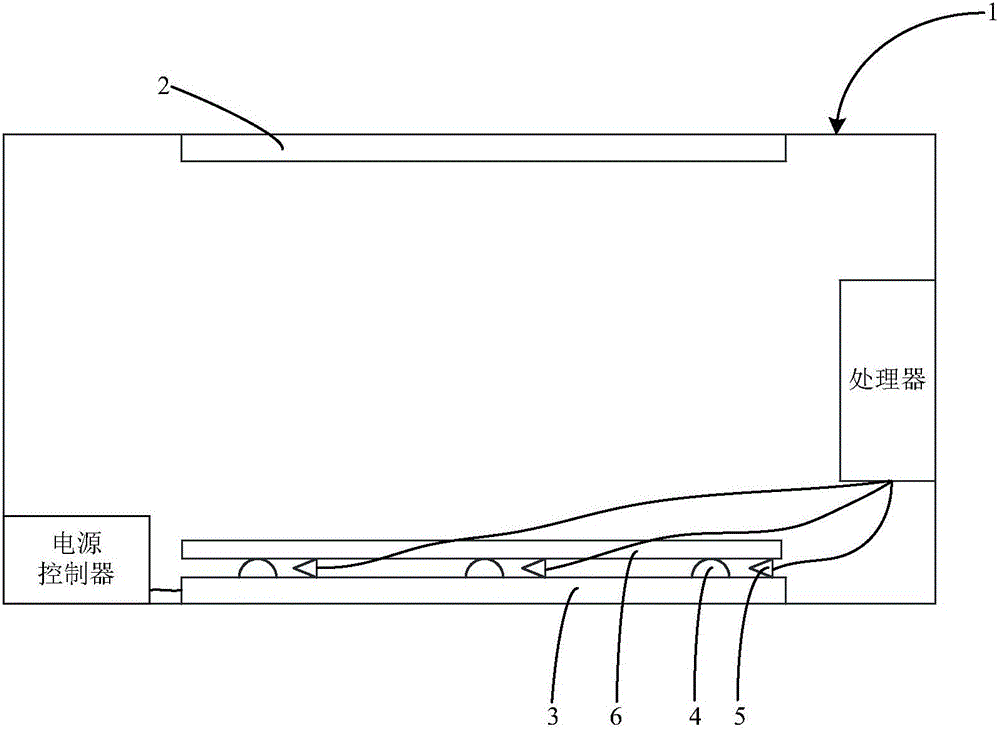

Active Thermal Mattress

InactiveUS20150366365A1Improve sleep qualityTemperature control using plurality of sensorsSofasTemperature controlControl system

An active thermal mattress assembly having a plurality of sensors disposed within the active thermal mattress assembly, wherein at least one of the plurality of sensors monitors a surface temperature of the active thermal mattress assembly. The active thermal mattress assembly also including a temperature control system disposed within the active thermal mattress assembly and a processor disposed within the active thermal mattress assembly. The processor receives signals from each of the plurality of sensors and responsively controls an operation of the temperature control system to maintain an ideal surface temperature of the active thermal mattress assembly.

Owner:DREAMWELL

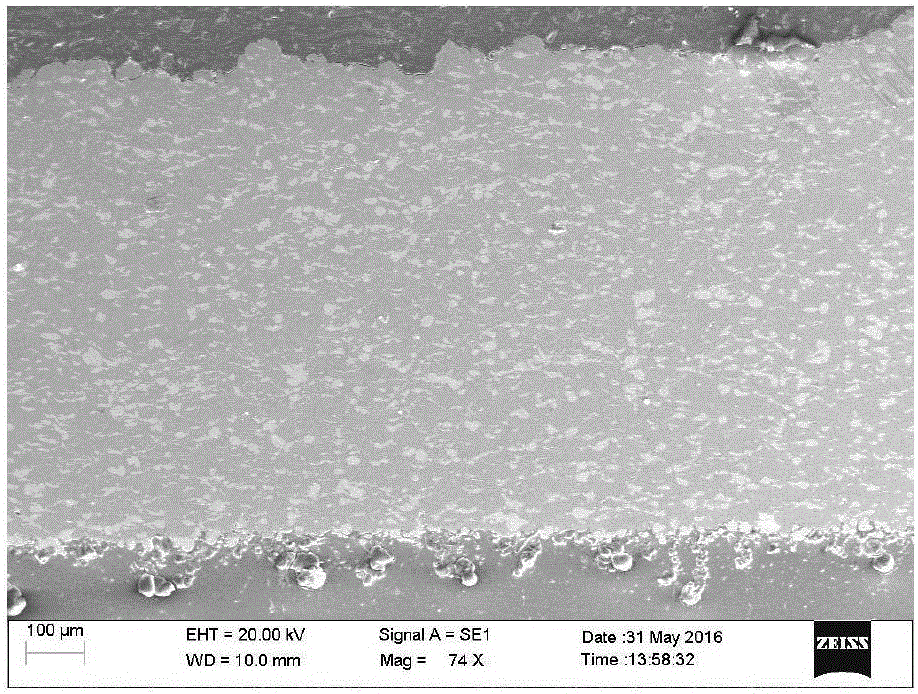

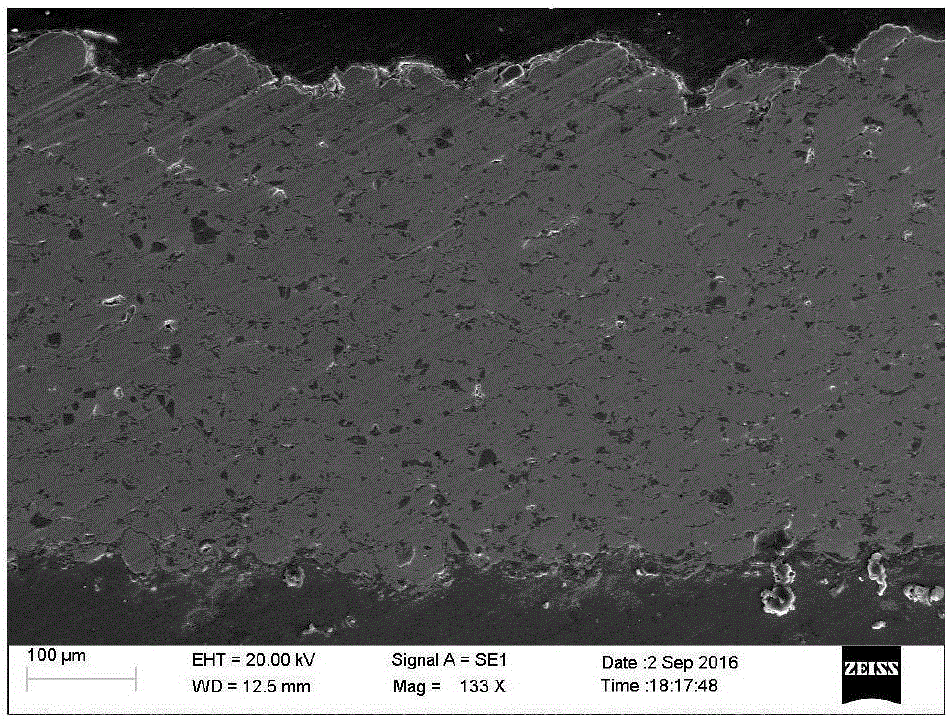

Preparation method for 420 stainless steel composite coating cold-sprayed on magnesium alloy surface

InactiveCN106835112ACompact structureGuaranteed wear resistancePressure inorganic powder coatingSand blastingMaterials science

The invention relates to a preparation method for a 429 stainless steel composite coating sprayed on a magnesium alloy surface. The preparation method comprises the steps that 95-40wt% of 420 stainless steel powder and 5-60wt% of hard reinforcement phase material powder according to a powder mixing ratio; the above two kinds of powder are placed in a mechanical material mixing machine to be mixed so that coating powder is prepared; the magnesium alloy base material surface is sequentially subjected to acetone cleaning and sand-blasting roughening treatment; the coating powder is arranged in a powder conveying device of cold-spraying equipment; then a magnesium alloy base material is fixed on a spraying clamp, and the 420 stainless steel composite coating is manufactured on the magnesium alloy base material surface with a cold-spraying technique; and the hard reinforcement phase material is one or more of SiC, Al2O3, TiC, WC-12Co, WC-17Co, WC-CoCr, WC-NiCr. The preparation method is simple in technique; thermal influence on the magnesium alloy base material is small by adopting the cold-spraying technique; the prepared composite coating is combined with the base body firmly; the structure is compact and uniform; the coating has good corrosion-resistance and abrasion-resistance, and is an ideal surface reinforcement coating for surfaces of the magnesium alloy and components of the magnesium alloy.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

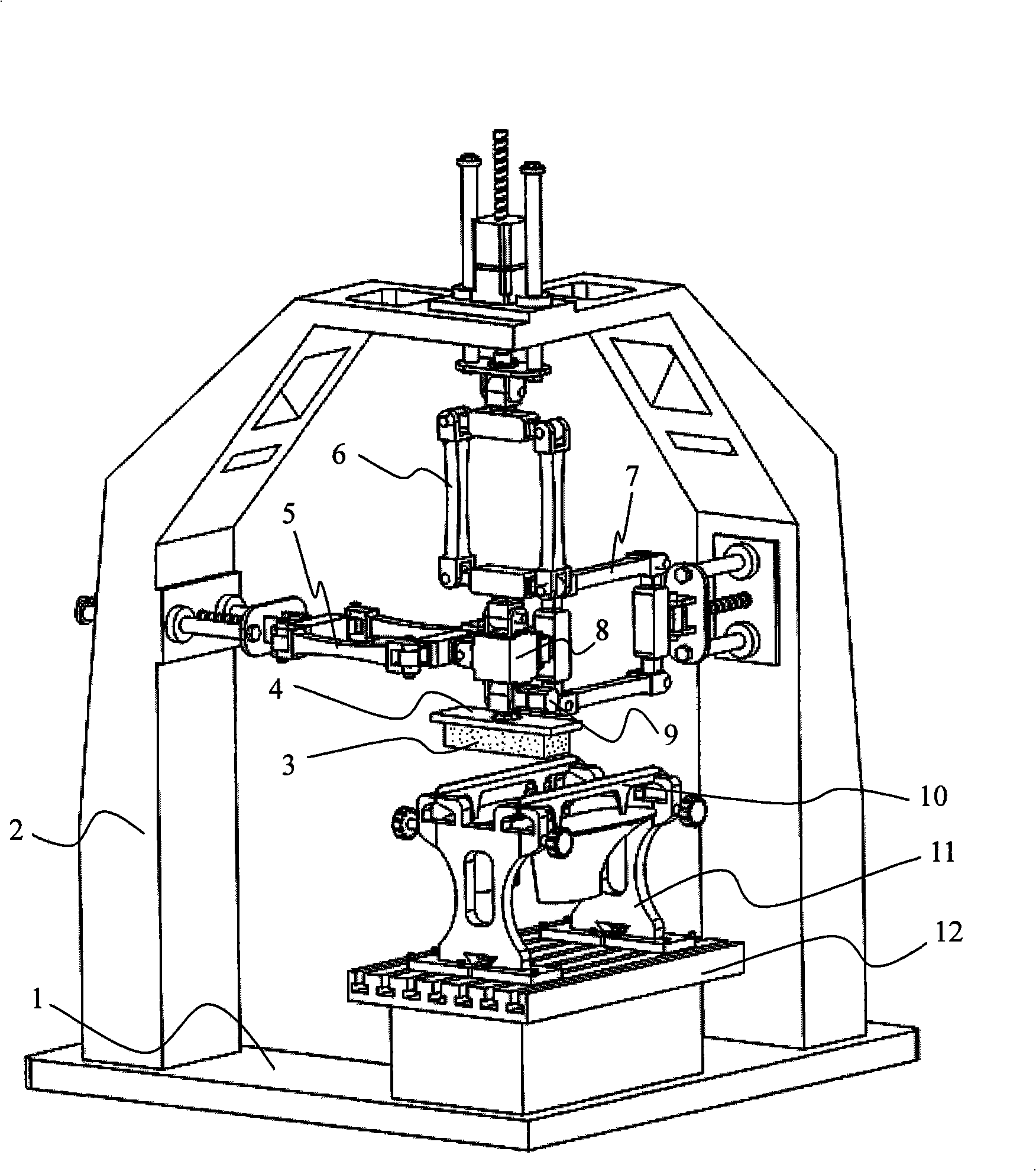

Aspheric optical element surface shape detection device

The invention discloses an aspheric optical element surface shape detection device. Based on prior interference method surface shape detection devices, the aspheric optical element surface shape detection device realizes the measurement of the light intensities of detection light waves and reference light waves by additionally arranging two controllable optical stops and can acquire phase shift interference fringes by additionally arranging piezoelectric ceramics. An aspheric surface shape measurement software package can conveniently acquire a phase offset between the surface shape and an ideal surface shape of an aspheric optical element to be detected by computing the phase offset between the surface shape to be detected and a standard surface shape of the aspheric optical element to bedetected and the phase offset between the ideal surface shape and the standard surface shape of the aspheric optical element to be detected. Therefore, the aspheric optical element surface shape detection device can effectively solve the surface shape detection problem of aspheric optical elements with large offset without a practical processing computed hologram, thereby reducing detection cost,shortening detection cycle and improving detection accuracy.

Owner:CHINA NORTH IND NO 205 RES INST

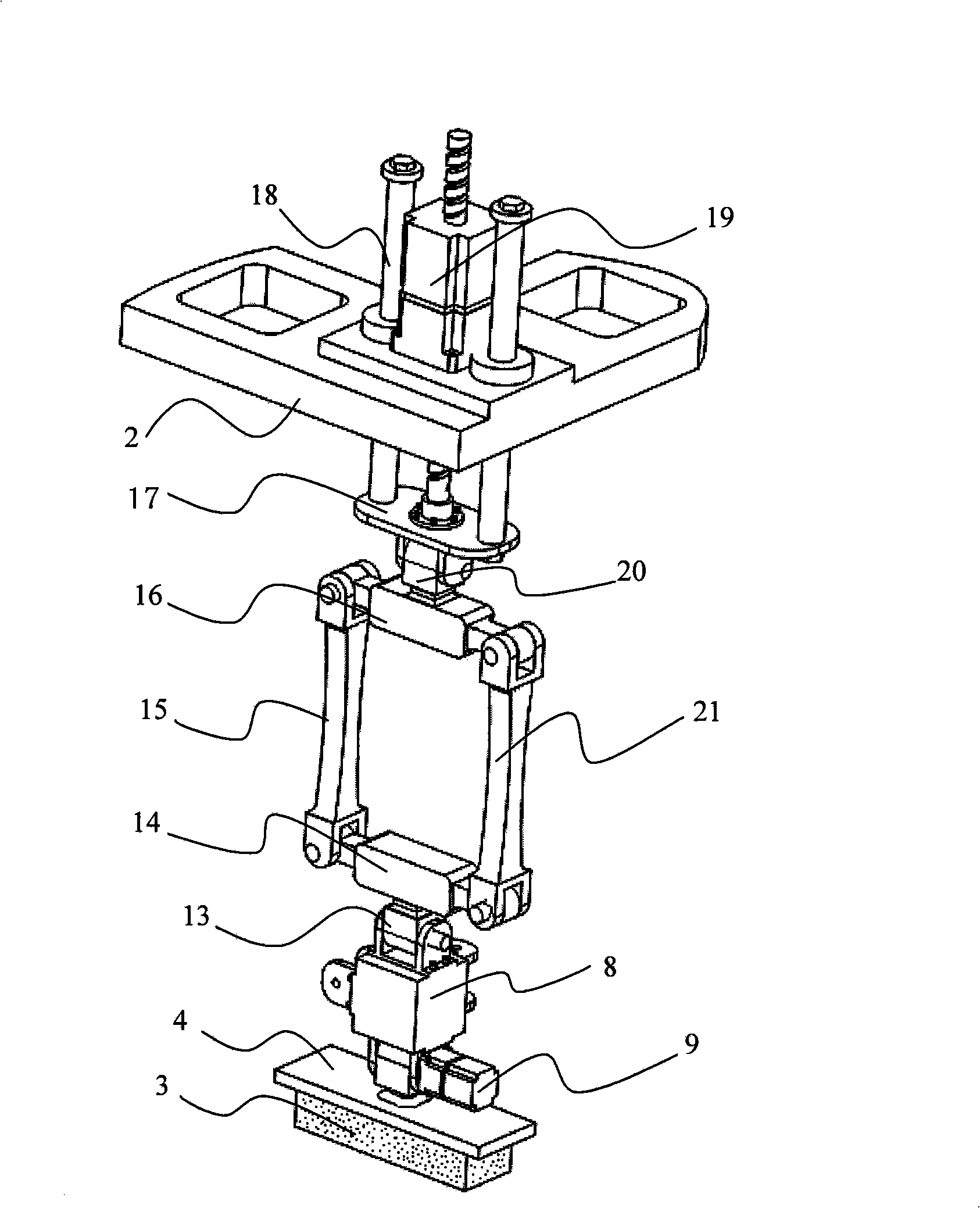

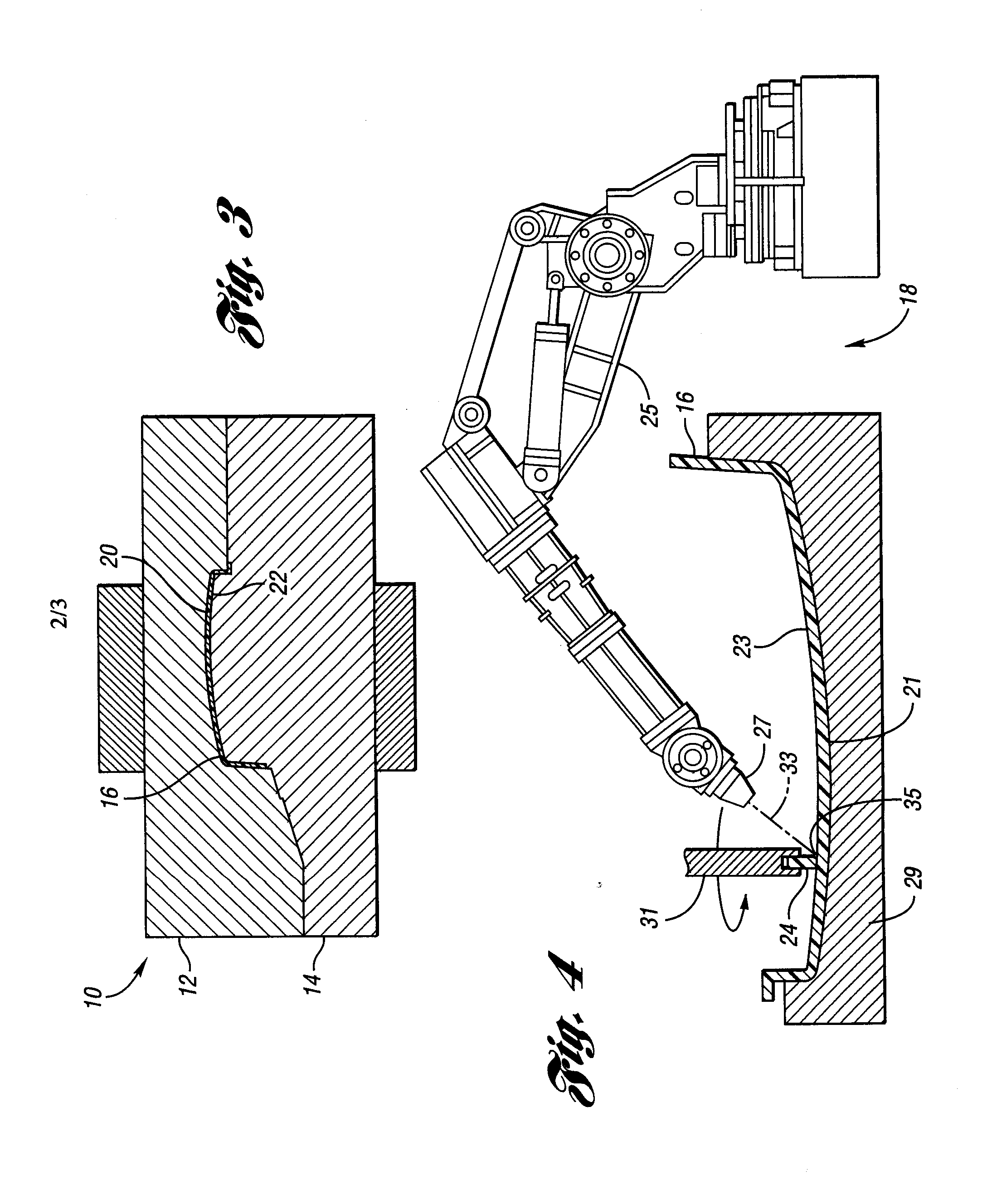

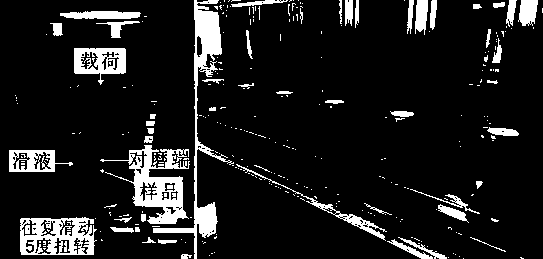

Four-dimensional skate edge grinding apparatus

InactiveCN101407032ACompact structureGood mechanical transmission performanceOther manufacturing equipments/toolsSurface roughnessEngineering

The invention discloses a four-dimensional ice skate sharpening device, which is characterized in that a bracket (2) and a moving platform (8) are connected through three moving branched chains (5, 6, 7) with same structures; in the moving branched chains, four connecting rods (14, 15, 16, 21) are connected with four rotating pairs to form a parallelogram mechanism respectively; the connecting rod (14) is connected with the moving platform (8) through a first rotating pair (13), the connecting rod (16) is connected with a connecting plate (17) fixedly connected with the front end of a guide bar (18) through a second rotating pair (20), and the connecting plate (17) is connected with a push rod of a linear motor (19); and an angle control motor (9) is arranged on the moving platform (8), an oil stone support (4) is connected with an output shaft of the angle control motor (9), and an oil stone or an emery stick (3) is arranged on the oil stone support (4). Through the driving of the three linear motors (19) on the three moving branched chains (5, 6, 7) and the angle control motor (9) arranged on the moving platform (8), three-dimensional movement and one-dimensional rotation of the oil stone or the emery stick (3) can be achieved. The four-dimensional ice skate sharpening device has the advantages of concise structure, good manufacturability for machining and assembling, and the like, and can obtain ideal surface roughness of the ice skate edge and crossing surface texture.

Owner:YANSHAN UNIV

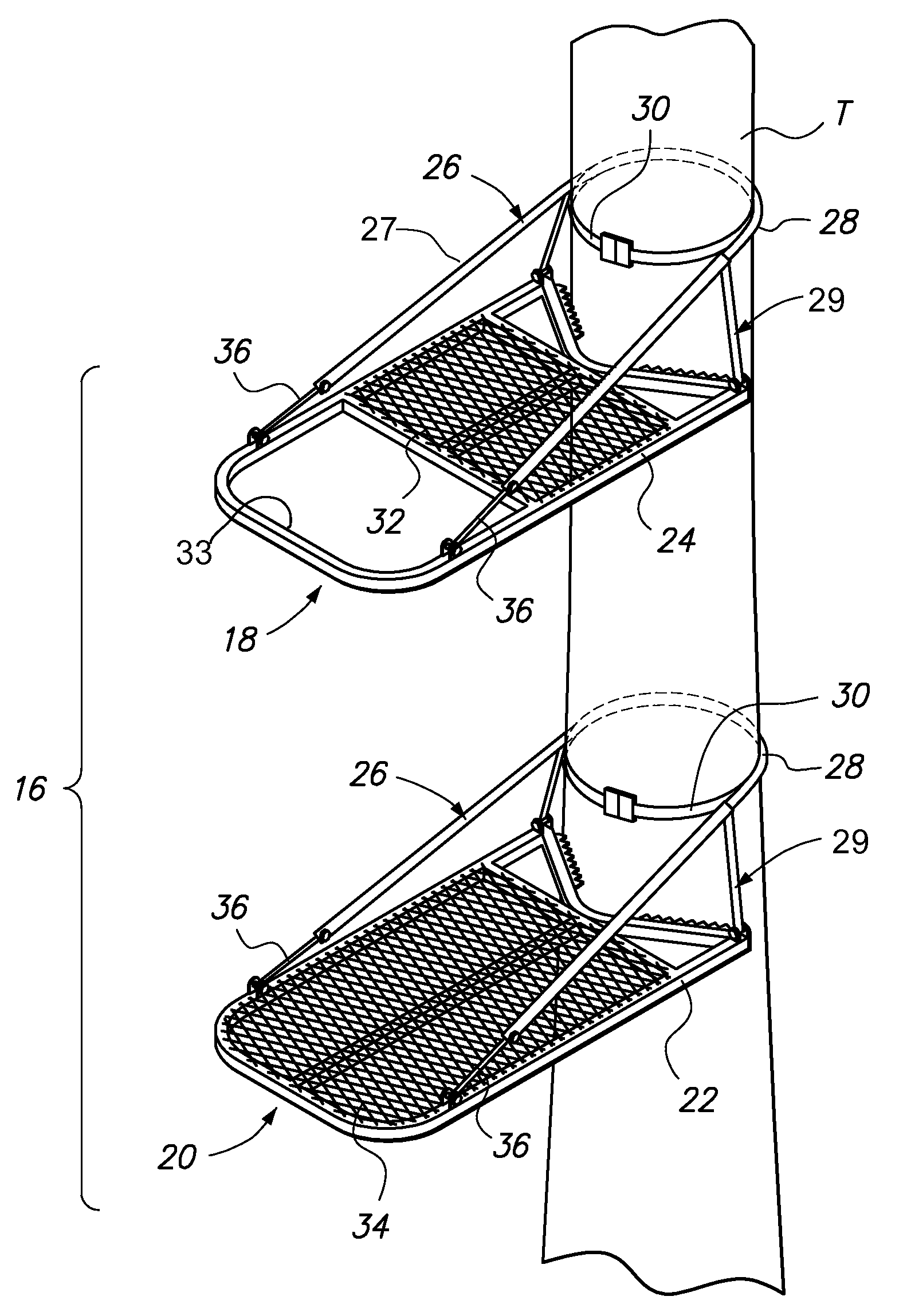

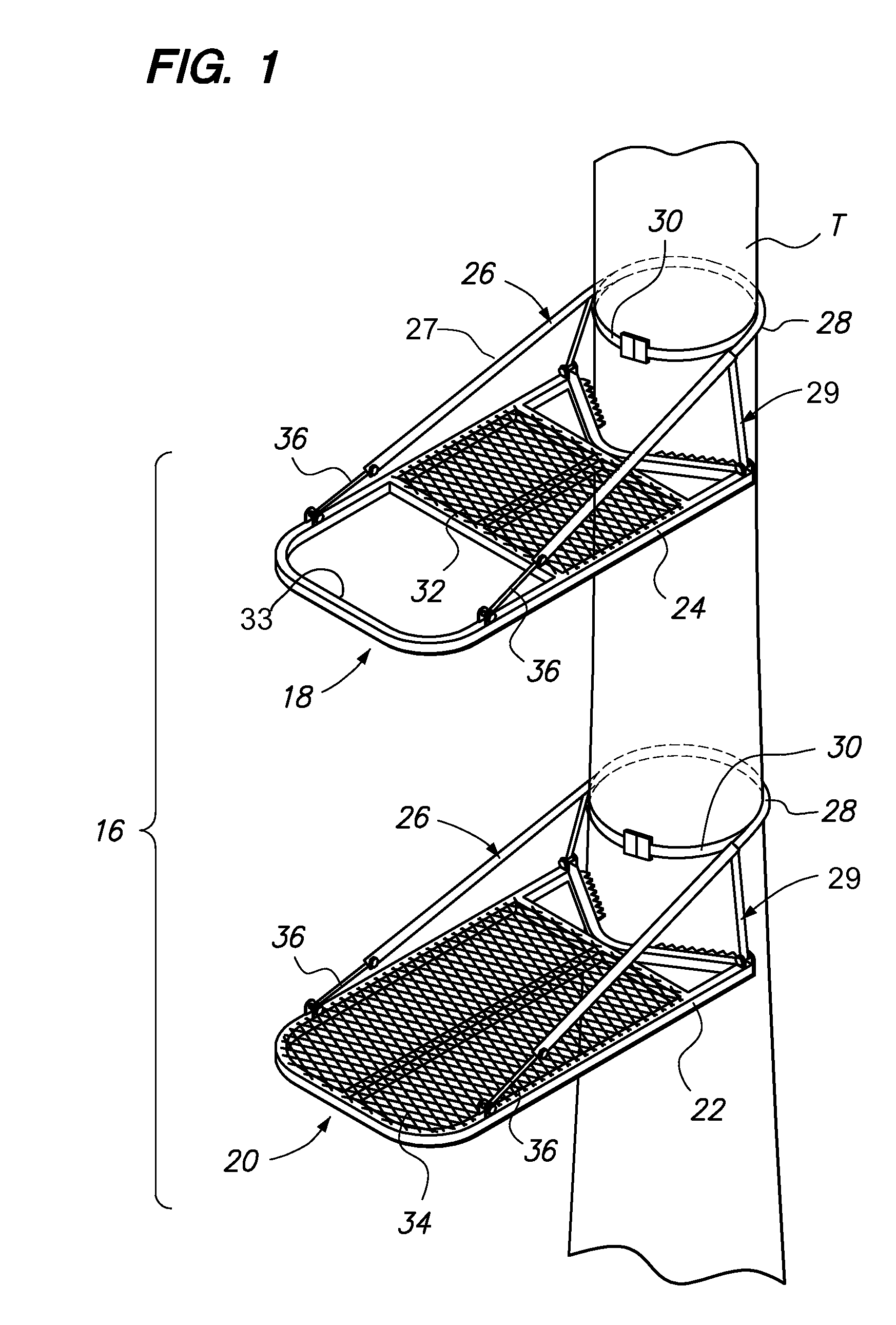

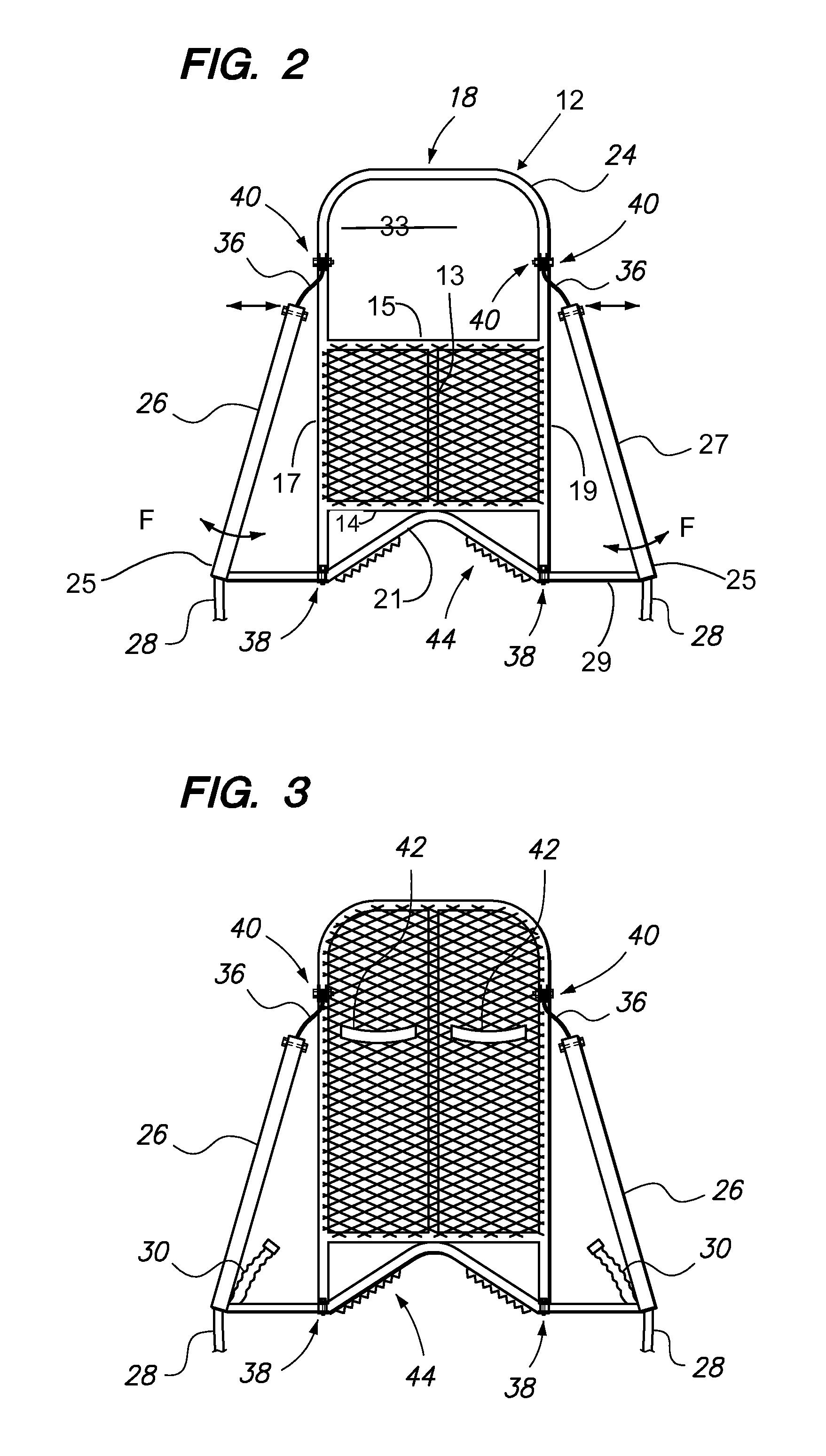

Climbing Tree Stand

InactiveUS20080156586A1Easy to adjustEasy to transportAnimal huntingClimbingStanding frameTree stand

A climbing tree stand according to the invention comprises a seat support assembly and a standing platform assembly. Each of the respective support assemblies has a pair of arms which are attached to a standing frame member and a main frame member. The arms are pivotally movable relative to the foot and main frame member, respectively. A flexible attachment is used to affix the arms to the platforms allowing the climbing tree stand to more easily climb trees that may not have ideal surface features or relatively consistent diameters. This allows the user of the climbing tree stand to have more options with respect to the type and size of tree used to climb and secure the tree stand. The flexible arms permit the tree stand to adjust slightly around obstacles on the trunk of the tree, such as limb stumps while alternately moving each assembly up the tree.

Owner:EASTMAN OUTDOORS

Composite heat treatment method

InactiveCN101994121AReduce distortionAdd depthSolid state diffusion coatingSurface layerMetallic materials

The invention provides a composite heat treatment method and relates to a metal material carburizing and nitriding composite heat treatment process method. By the composite heat treatment method provided by the invention, the depth of a metal heat treatment permeating layer is improved; deformation is reduced; advantages of various processes are organically combined and completely exerted; the defects of the processes are overcome; and high using performance of metal is achieved. The composite heat treatment method comprises the following steps of: heating a workpiece to an austenite state and performing carburizing or carbonitriding to obtain an ideal permeating layer; cooling the permeating layer in a furnace to the austenite nitriding temperature of between 640 and 720 DEG C and performing nitriding or carbonitriding, so that the nitrogen concentration of the austenite on the surface layer of the workpiece is increased to that of the austenite nitriding layer; and directly quenching at the temperature of about 800 DEG C and performing aging treatment in the range of 300 DGE C, or directly performing isothermal quenching at the temperature of between 200 and 240 DEG C, so that the high-nitrogen austenite is decomposed and ideal surface hardness and wear resistance of the meal are achieved.

Owner:闫欧

Cutting process simulation process for brittle materials

InactiveCN105512400AAvoid the difficult problem of online observationImprove surface qualitySpecial data processing applicationsMicro nanoSmoothed-particle hydrodynamics

The invention provides a cutting process simulation process for brittle materials, belongs to the field of micro-nano ultraprecision machining numerical simulation and relates to a three-dimensional micro-nano cutting machining simulation method based on an SPH (smoothed particle hydrodynamics) method. According to the simulation method, dimensions of a cutter and a workpiece material are set firstly; then a three-dimensional cutter finite element model is established in ANSYS, an SPH model of the workpiece material is established in LS-PrePost, parameters of contact, boundary, the material and the like are set, and calculation is performed in LS-DYNA; finally, a simulation result is analyzed, and whether the result meets the actual machining condition is judged. The simulation method has the advantages that data including stress, strain, density and the like in a cutting machining process can be obtained more clearly and more accurately, the brittle materials are removed from a ductile region through control of cutting depth, and acquisition of more ideal surface quality is more facilitated. A large quantity of labor cost, experimental cost and economic cost is saved, and the problem of on-line observation difficulty of an experimental method is solved.

Owner:DALIAN UNIV OF TECH

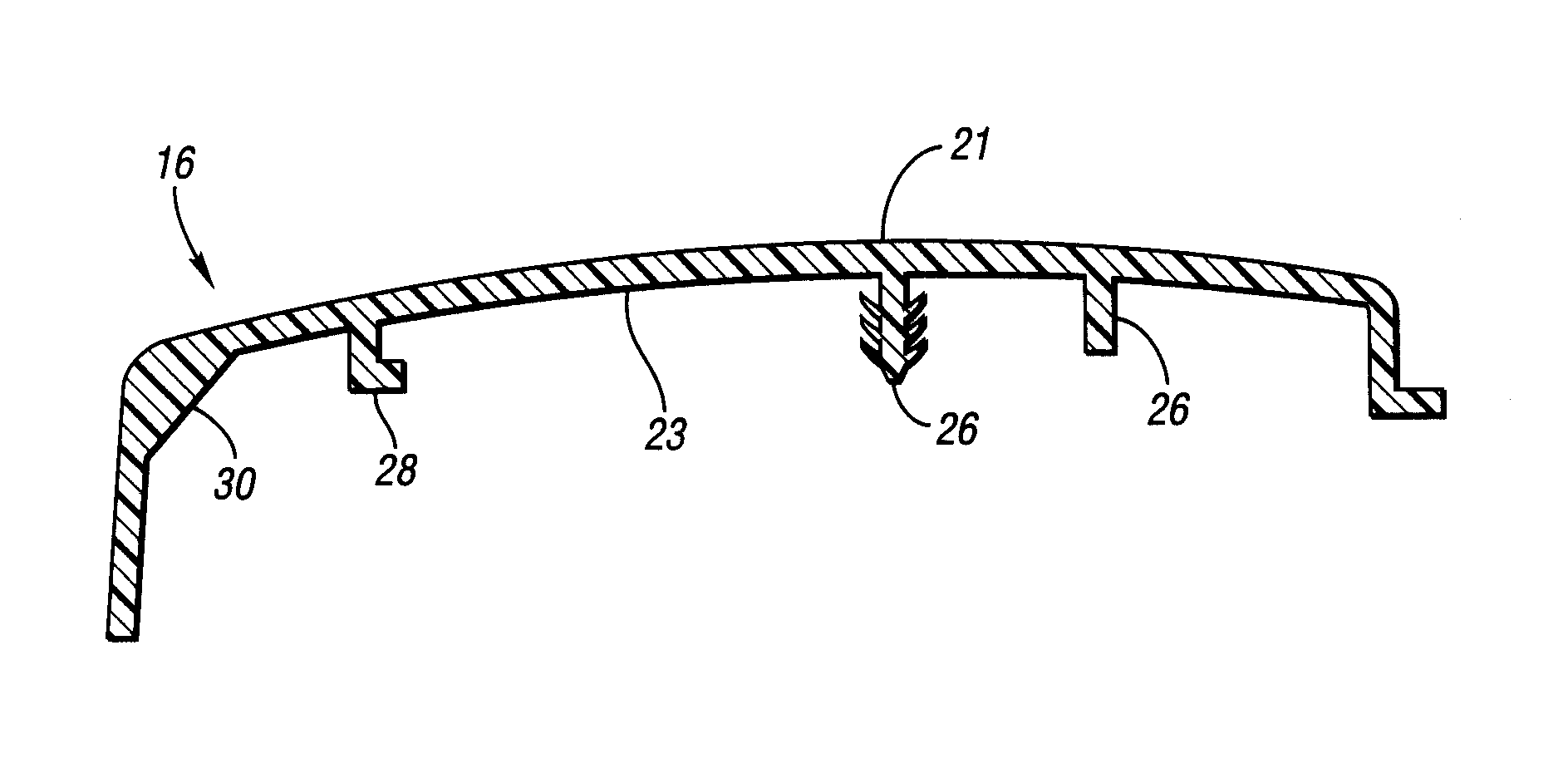

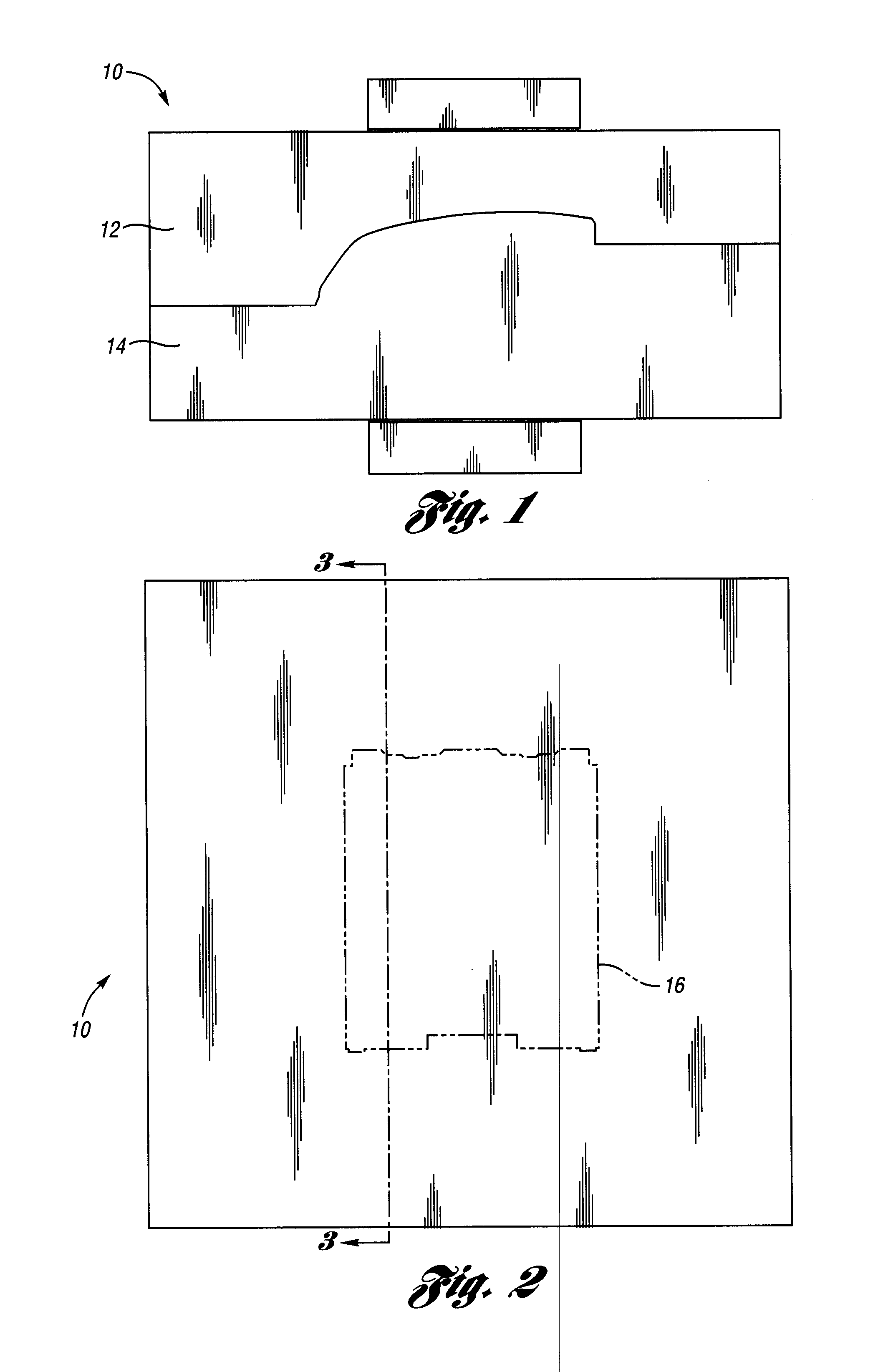

Molded-in-color panel and method for molding

InactiveUS20080318052A1Improve surface propertiesFacilitate ideal surface characteristicTailstocks/centresLayered productsShell moldingMaterials science

In one embodiment, a method for molding a molded-in-color panel in a mold includes providing a mold having a first mold member and a second mold member. One of the first mold member and the second mold member has an appearance portion forming surface and the other of the first mold member and the second mold member has a concealed portion forming surface corresponding with the appearance portion forming surface. The concealed portion forming surface forms a concealed portion of a panel and is free of any protuberances and ancillary structural members for facilitating ideal surface characteristics of an appearance portion of the panel. Molded-in-color resin is injected in the mold and cooled to form a molded-in-color panel. At least one ancillary structural member is welded to the concealed portion of the panel.

Owner:FORD GLOBAL TECH LLC

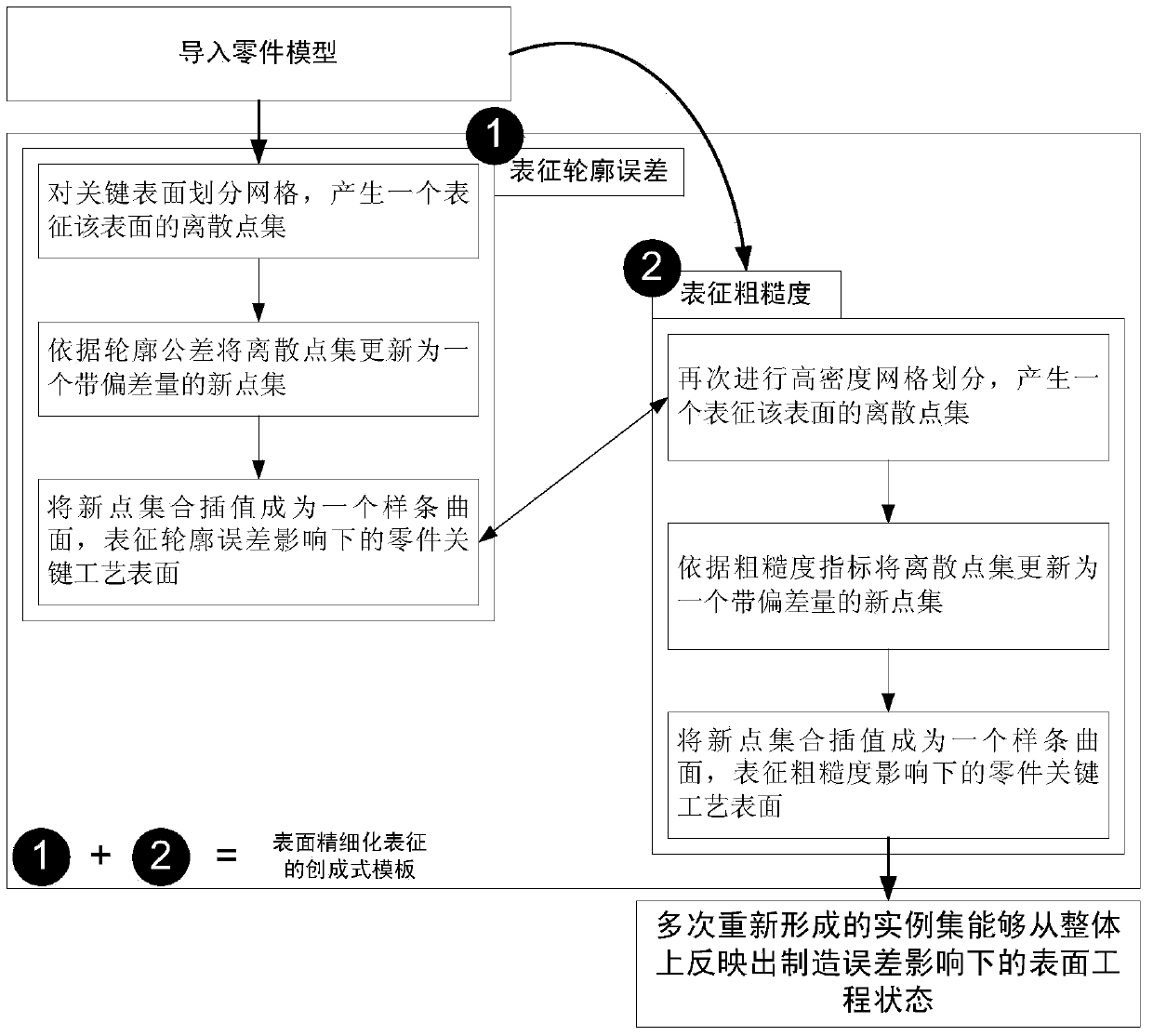

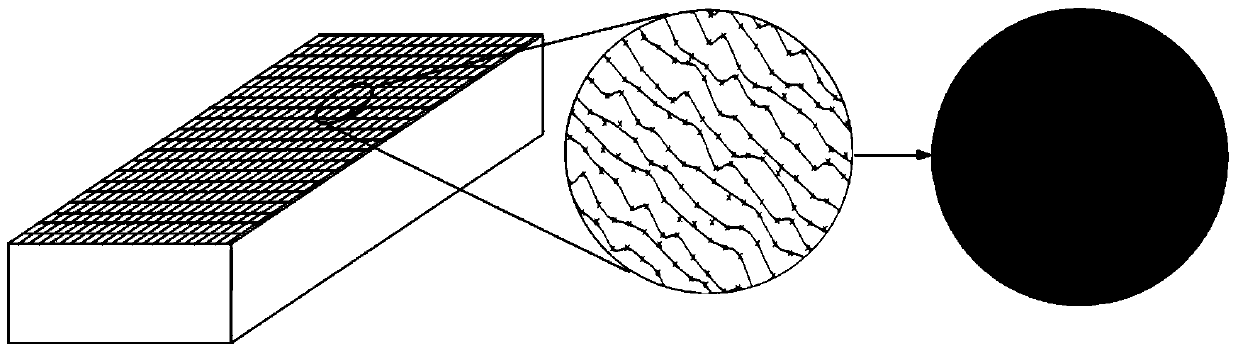

Generative fining characterization method for part key technology surface

The invention provides a generative fining characterization method for a part key technology surface. The method includes the first step of carrying out meshing on the surface to form a discrete point assembly and generating a new discrete point assembly with random deviation according to profile tolerance demands, the second step of carrying out interpolation on the discrete point assembly to form a spline surface in order to form an example with contour errors on an ideal surface, the third step of continuing to carry out high-density meshing on the surface of the contour errors to form a discrete point assembly and generating a new discrete point assembly with random deviation according to roughness demands, the fourth step of continuing to carrying out interpolation on the discrete point assembly to form a spline surface in order to form a fining characterization example with manufacturing errors on the surface of a part, and the fifth step of utilizing the new fining surface to replace an original surface on a part nominal model to form a new example with the manufacturing errors on an original part model. A part example set with the manufacturing errors can be reestablished repeatedly by repeating the steps, and the examples can reflect the actual engineering state of the part key technology surface on the whole. The generative fining characterization method has the advantages of being efficient, accurate and low in cost.

Owner:TSINGHUA UNIV +1

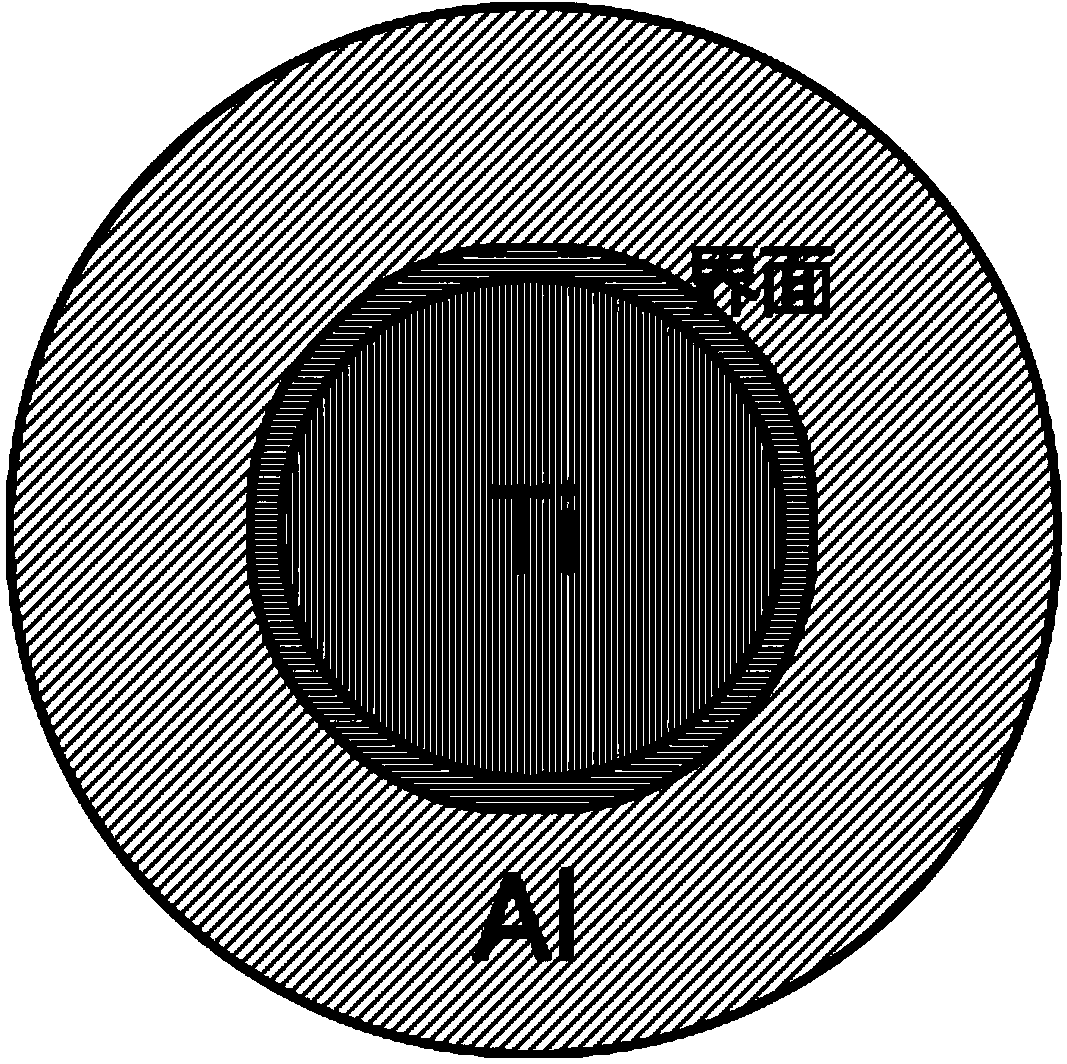

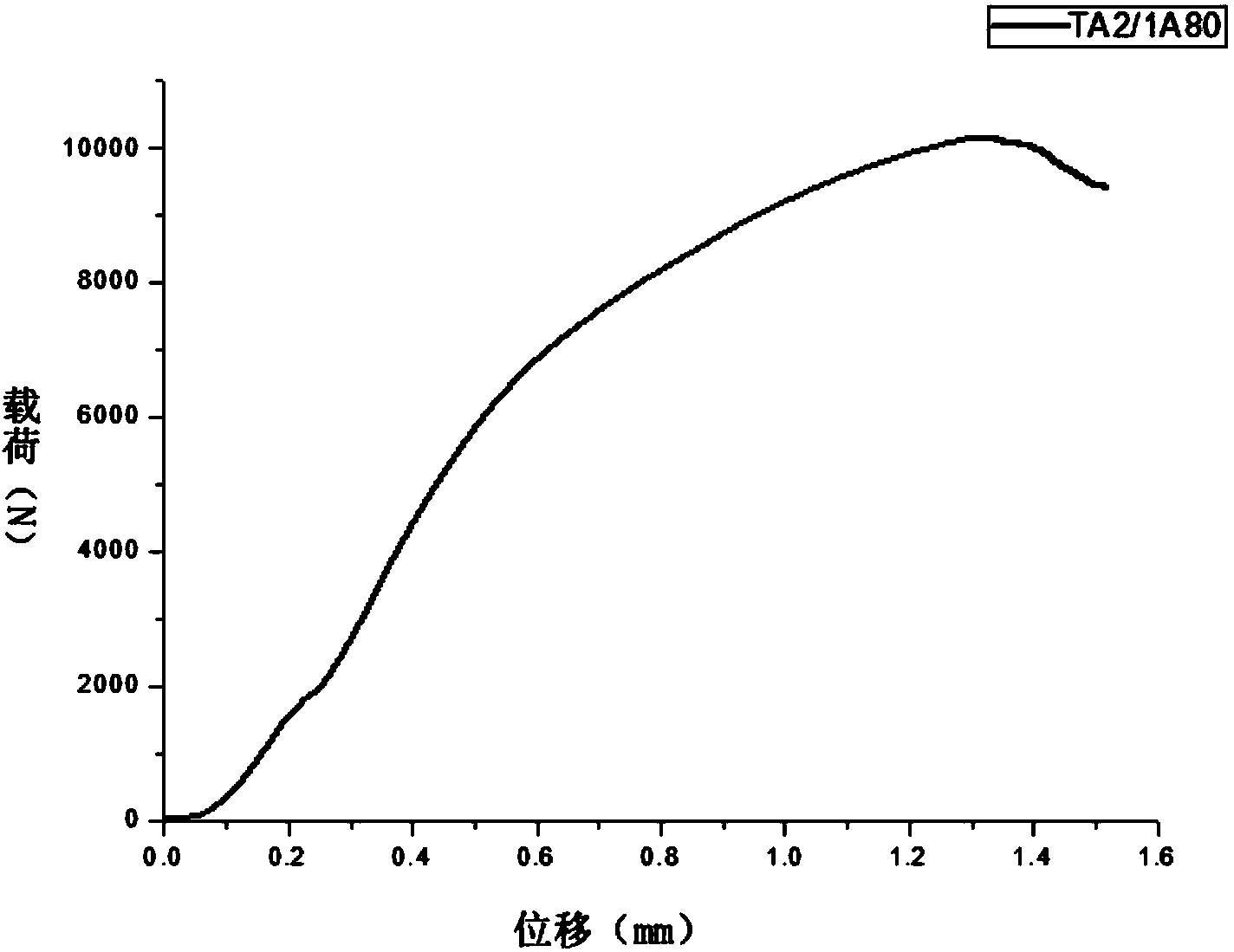

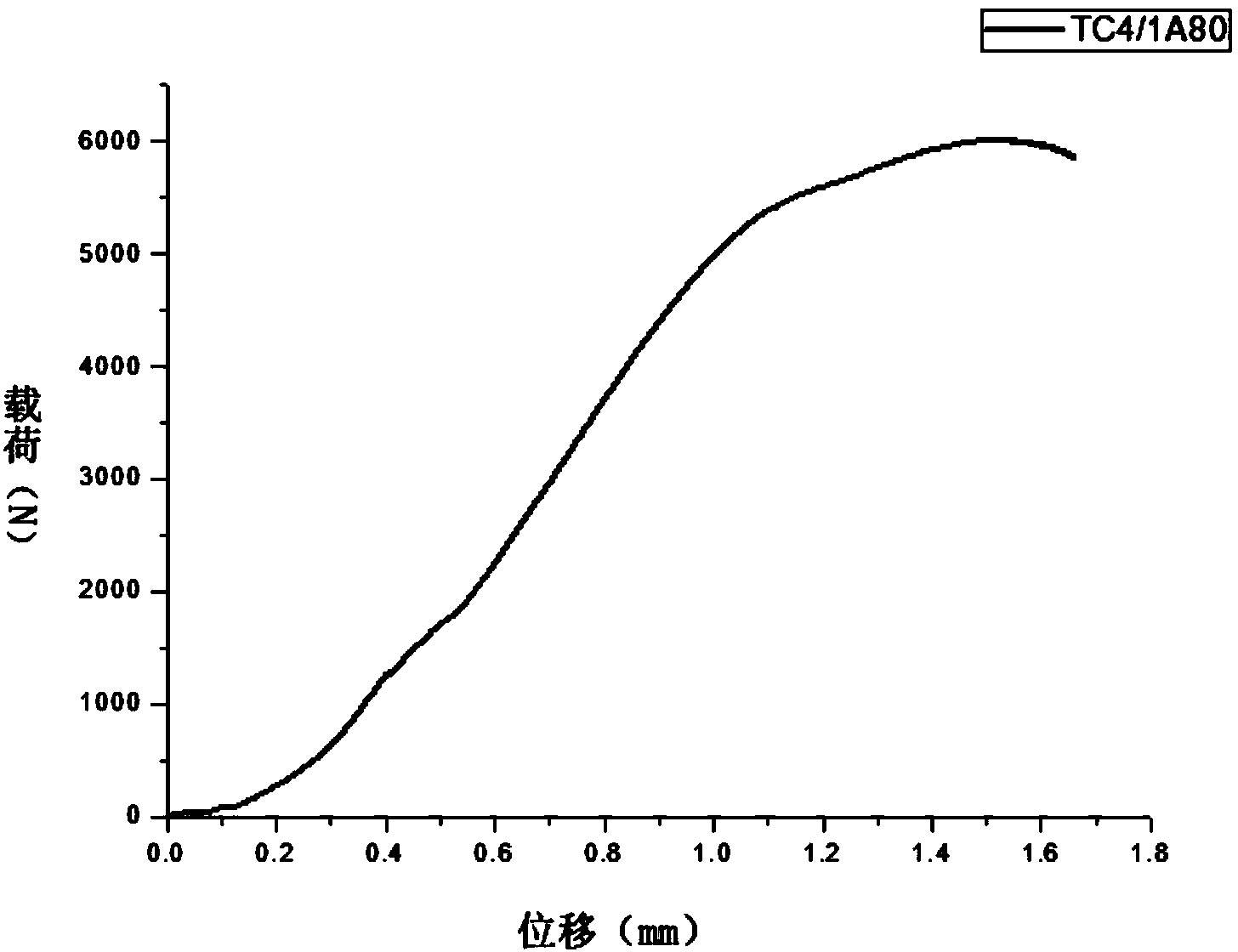

Titanium/aluminum solid-liquid composite casting forming method

The invention relates to a titanium / aluminum solid-liquid composite casting forming method, and belongs to the field of material processing engineering. The method is to prepare an aluminum-encapsulated titanium casting by placing solid titanium alloy in aluminum alloy melt, and a laboratory preparation technology comprises the following implementation steps of (1) obtaining a titanium alloy bar with a 3mm to 30mm diameter in a processing way, and turning and polishing the aluminum alloy bar for an ideal surface roughness; (2) chemically cleaning the surface of the prefabricated titanium bar to remove greasy dirt and oxides on the surface; (3) smelting the aluminum melt in a corundum crucible by adopting a pit type resistance furnace; (4) inserting the titanium bar which is previously completely processed into the melt at the temperature of 670 DEG C to 840 DEG C; (5) implementing heat preservation in the pit type furnace for 5 minutes to 15 hours, then taking the titanium bar out, and cooling the titanium bar in air to a room temperature. According to the titanium / aluminum solid-liquid composite casting forming method, the metallurgical bonding between pure titanium and pure aluminum, between titanium alloy and pure aluminum and between titanium alloy and aluminum alloy is realized by a solid-liquid composite casting method; an obtained composite casting is integrated with the characteristics i.e. lightness and corrosion resistance of titanium alloy and aluminum alloy, and has the performances, i.e. high strength and high toughness of the titanium alloy and easy heat transfer, electric conduction and the like of the aluminum alloy.

Owner:UNIV OF SCI & TECH BEIJING

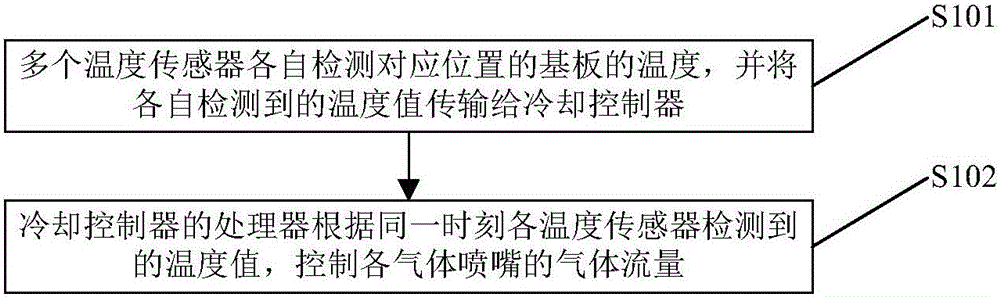

Dry etching machine table and application method thereof

ActiveCN105097408ATemperature controlImprove stabilityElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringDry etching

The invention discloses a dry etching machine table and an application method thereof, which belongs to the technical field of display and can be used for solving the technical problem of non-ideal surface temperature uniformity of a substrate during dry etching process. The dry etching machine table comprises a sealed process cavity for dry etching on the substrate, an upper-part electrode, a lower-part electrode, a plurality of temperature sensors and a cooling controller are arranged in the process cavity, the upper-part electrode is arranged at the top of the cavity, the lower-part electrode is arranged at the bottom of the cavity and is opposite to the upper-part electrode, the plurality of temperature sensors are arranged on the upper surface of the lower-part electrode, the cooling controller comprises a plurality of gas nozzles and a processor, one of the gas nozzles is arranged near each temperature sensor, when the substrate is placed on the lower-part electrode, the temperature sensors contact the lower surface of the substrate and are used for detecting the temperature of the substrate at the position where the temperature sensors are located and transmitting temperature values of the detected substrate to the cooling controller, and the processor of the cooling controller is used for controlling gas flow of each gas nozzle according to the temperature value detected by each temperature sensor at the same time.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

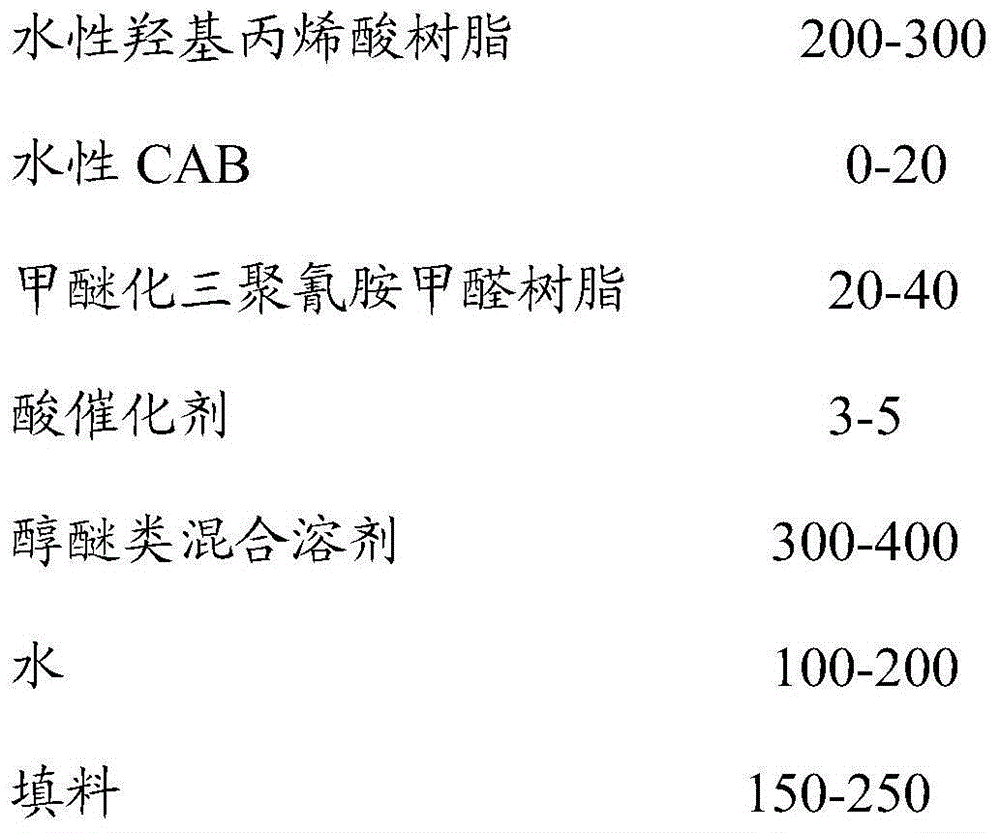

Aqueous crackle paint and coating technology thereof

ActiveCN104130648ASolve the problem of water-basedReduce pollutionPretreated surfacesCoatingsLacquerAcrylic resin

An aqueous crackle paint is prepared by using an aqueous crackle primer, an aqueous crackle finish and an aqueous enamel through a coating technology, the primer and the finish form a crackle shape, and the enamel has color modification and crackle effect finish protection effects. The above three coatings use aqueous acrylic resin as a main body resin of a film and contain methylated melamine formaldehyde resin as a high temperature crosslinking agent, aqueous CAB and parts of an alcoholic solvent are introduced to a formula system in order to achieve an ideal surface drying speed, and fumed silica, talcum powder and other high oil absorbing fillers are used to adjust the critical PVC concentration of the formula system and adjust the shrinkage stress of the film. The coating technology of the aqueous crackle paint comprises the following steps: spring the aqueous crackle primer, carrying out surface drying at normal temperature for 5min, spraying the aqueous crackle finish, carrying out constant temperature treatment at 150DEG C for 20min, spraying the aqueous crackle enamel, and carrying out constant temperature treatment at 150DEG C for 20min to obtain the aqueous crackle paint.

Owner:XINHE NEW MATERIALS CO LTD

Device, method and computer readable medium for evaluating shape of optical element

InactiveUS20110222755A1High precisionImage analysisCharacter and pattern recognitionEngineeringPupil

A method for evaluating a shape of an optical element, including: executing polynomial approximation to obtain a deviation shape of a testing surface of an optical element with respect to an ideal surface; calculating an evaluation shape by extracting a rotationally symmetric irregularity component of the deviation shape from a result of the polynomial approximation; adding a 2nd order component to the evaluation shape so that a region including a pupil center of the evaluation shape is planarized; and calculating a rotationally symmetric irregularity value of the testing surface based on the evaluation shape to which the 2nd order component has been added.

Owner:HOYA CORP

Compensating for a non-ideal surface of a reflector in a satellite communication system

ActiveUS20140266870A1Simultaneous aerial operationsAntenna adaptation in movable bodiesCommunications systemBeam pattern

A method is provided that includes measuring amplitudes and phases of signals reflected off a reflector of a satellite, with the amplitudes and phases forming a first set of measurements. The method includes calculating an element correlation matrix as a function of the first set of measurements. The element correlation matrix represents a radiated feed element pattern off the reflector. And the method includes adjusting a formed beam pattern of a beamformer based on the element correlation matrix to thereby compensate for a non-ideal surface of the reflector.

Owner:THE BOEING CO

Liquid crystal back lighting optical target

InactiveCN1450380ASolve the problem of uniform lightingOvercoming the problem of uneven illuminationUsing optical meansOptical elementsBody shapeEngineering

The invention discloses a liquid crystal backlighting optical target, composed of the pedestal, the liquid crystal backlighting board and the optical target. The pedestal is box-body shaped, and the front panel of the box body is set with the optical target whose surface is set with geometrical pattern. The backlighting board is set in the box body and the condensation cathode fluorescent tube isset on the external edge of the backlighting board. The backlighting board and ground glass pieces can be set on the adjusting guide way in the box body, which can remarkably adjust the optical output property and quality of the optical target. Because of adopting 4-tube liquid crystal backlight board and of simulating ideal surface light source by plate light source, the heat productivity is by far the less than the traditional filament lamp and halogen lamp.

Owner:TIANJIN UNIV

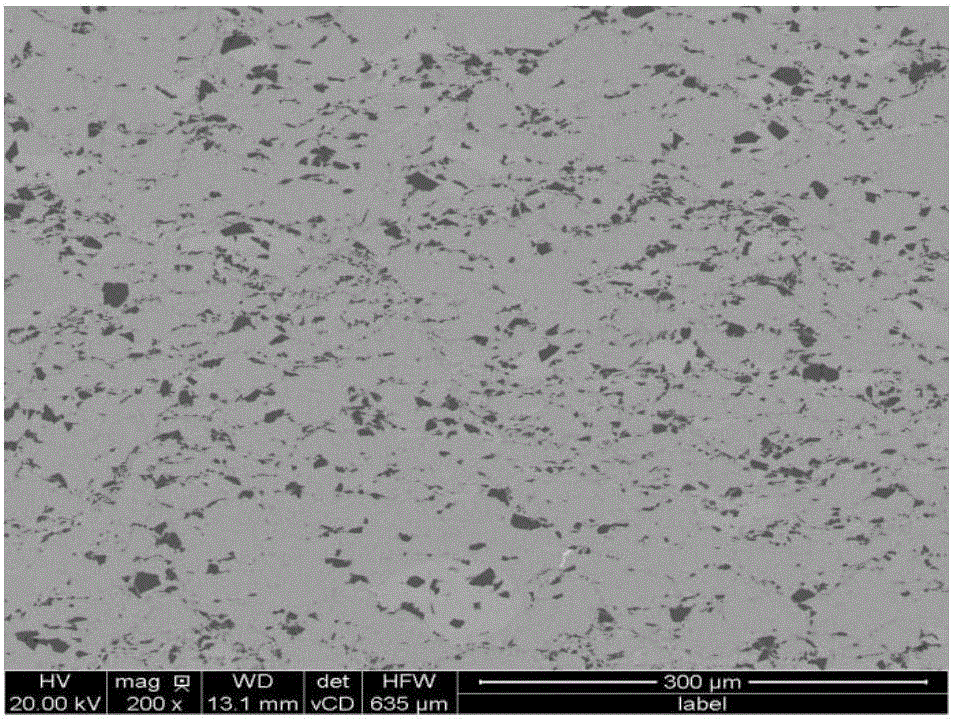

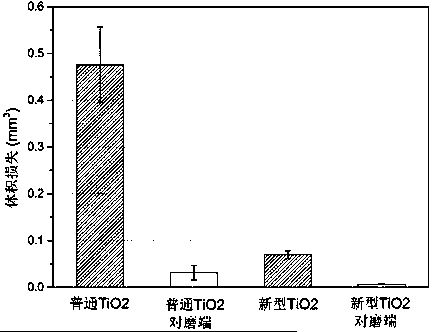

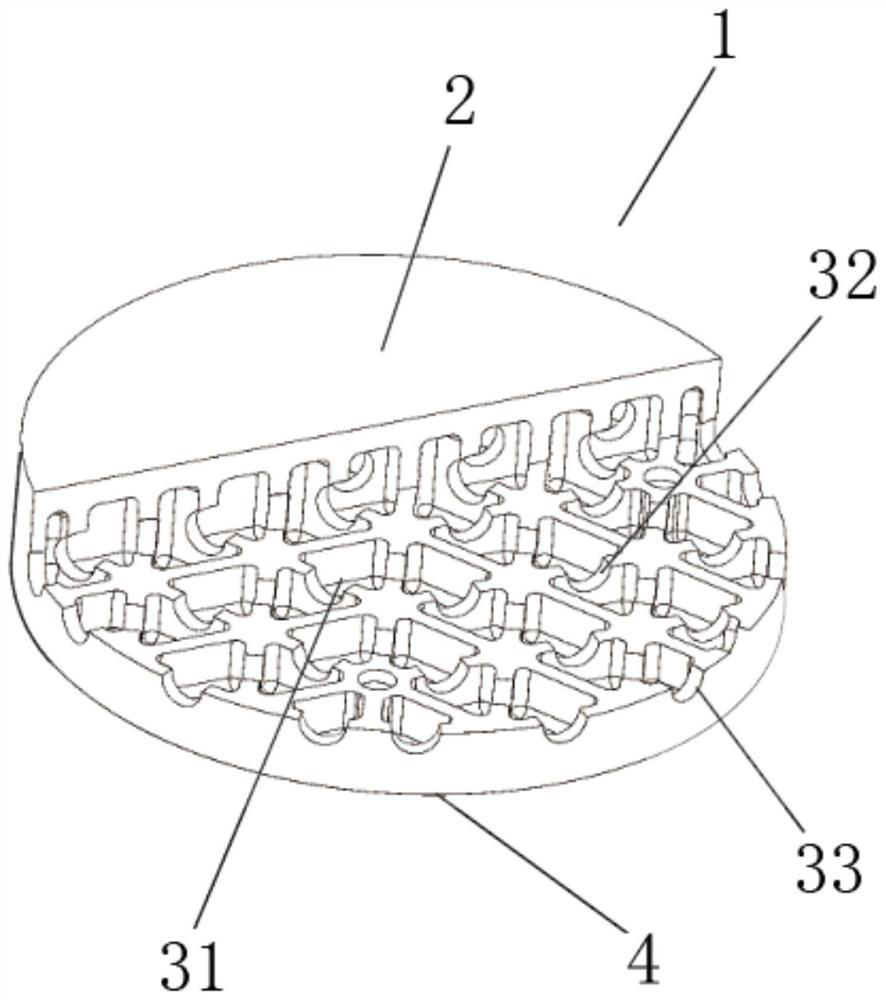

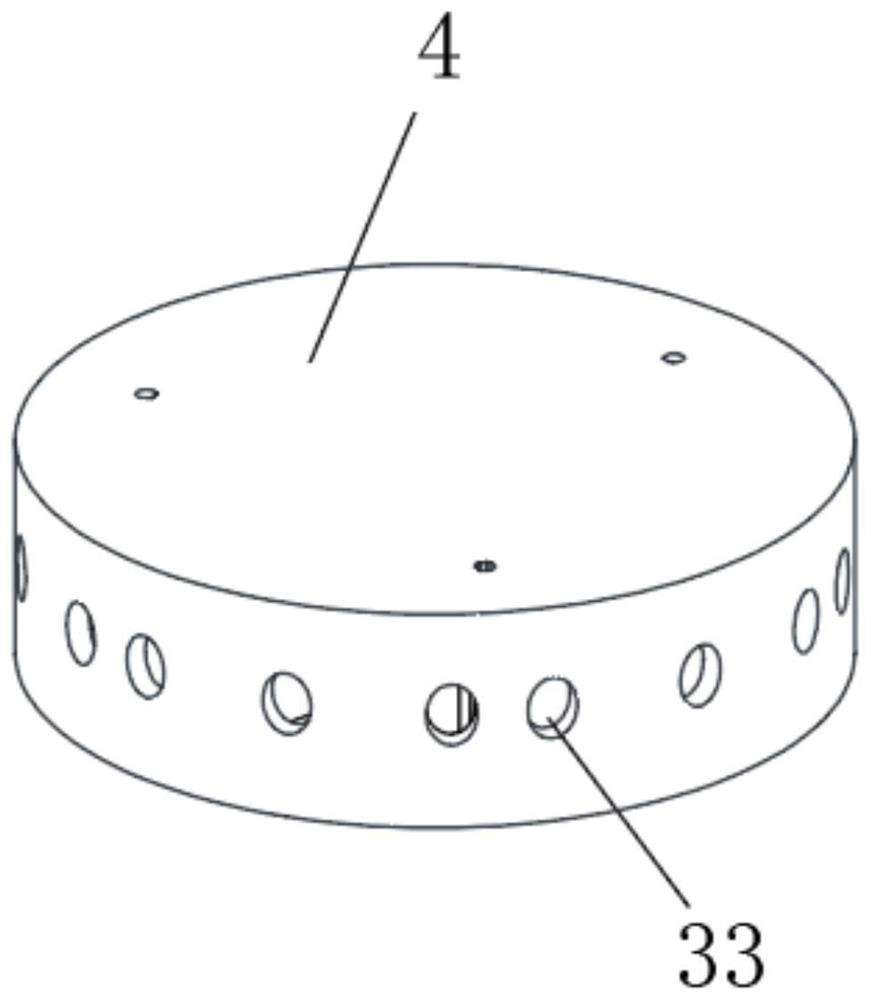

Medical titanium material surface oxidization strengthening method

ActiveCN108707947ALow costEasy to operateSurface reaction electrolytic coatingTio2 nanotubeTitanium alloy

The invention discloses a medical titanium material surface oxidization strengthening method. According to the method, on the basis of an anodic oxidation two-step method, an organic acid solution isutilized as an electrolyte, short-time anodic oxidation is conducted, a bonding layer is formed at the interface position of the bottom of a TiO2 nano tube and a Ti substrate, and accordingly a novelshearing-resisting, abrasion-resisting and corrosion-resisting novel titanium (titanium alloy)-TiO2 nanotube engineering material is obtained. Compared with an existing TiO2 nanotube preparing technology, the technical problems that an ordinary anodic oxidation TiO2 nano tube is prone to stripping, and mechanical stability is poor are solved on the premise that material structures are not changed;meanwhile, the corrosion resisting performance of the TiO2 nano tube is improved, the bottleneck of limitation of actual TiO2 nano tube engineering material application is broken through, and the beneficial effects that cost is low, simpleness and rapidness are achieved, and additional equipment does not need to be introduced are achieved; and the medical titanium material surface oxidization strengthening method is an ideal surface modification technology applied to the medical titanium-based material, and the material has important application prospects in the biomedical field.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Metal reflector and manufacturing method thereof

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

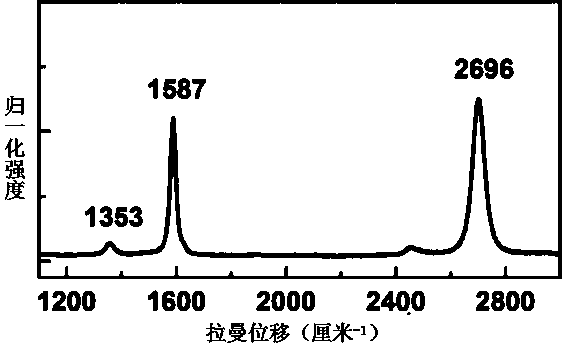

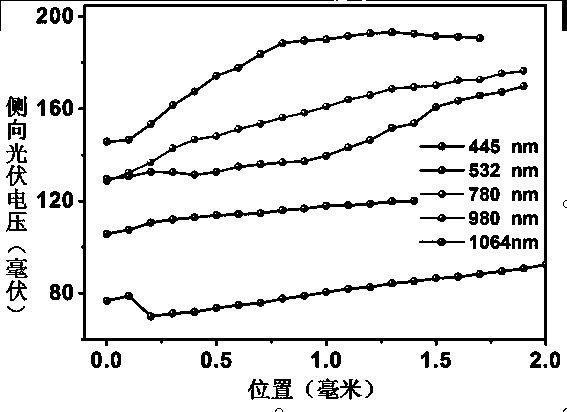

Construction method of semiconductor quantum dot/graphene Van der Waals junction film flexible device with good surface photovoltaic performance

ActiveCN110148643AGood photoresponse cycle stabilityThe construction method is simple and controllableFinal product manufacturePhotovoltaic energy generationSingle layer grapheneCvd graphene

The invention relates to a construction method of a semiconductor quantum dot / graphene Van der Waals junction film flexible device with a good surface photovoltaic performance. By employing method forpreparing single-layer graphene by a flexible substrate mechanical stripping chemical vapor deposition method, semiconductor quantum dots are modified on graphene, the annealing temperature and timeof the device are controlled, the Van der Waals contact between the semiconductor quantum dots and the graphene is optimized to successfully construct the semiconductor quantum dot / graphene Van der Waals junction film flexible surface photovoltaic device with ideal surface photovoltaic response performances, and the semiconductor quantum dot / graphene Van der Waals junction film flexible surface photovoltaic device can be used for relative position detection or photoelectric detection.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

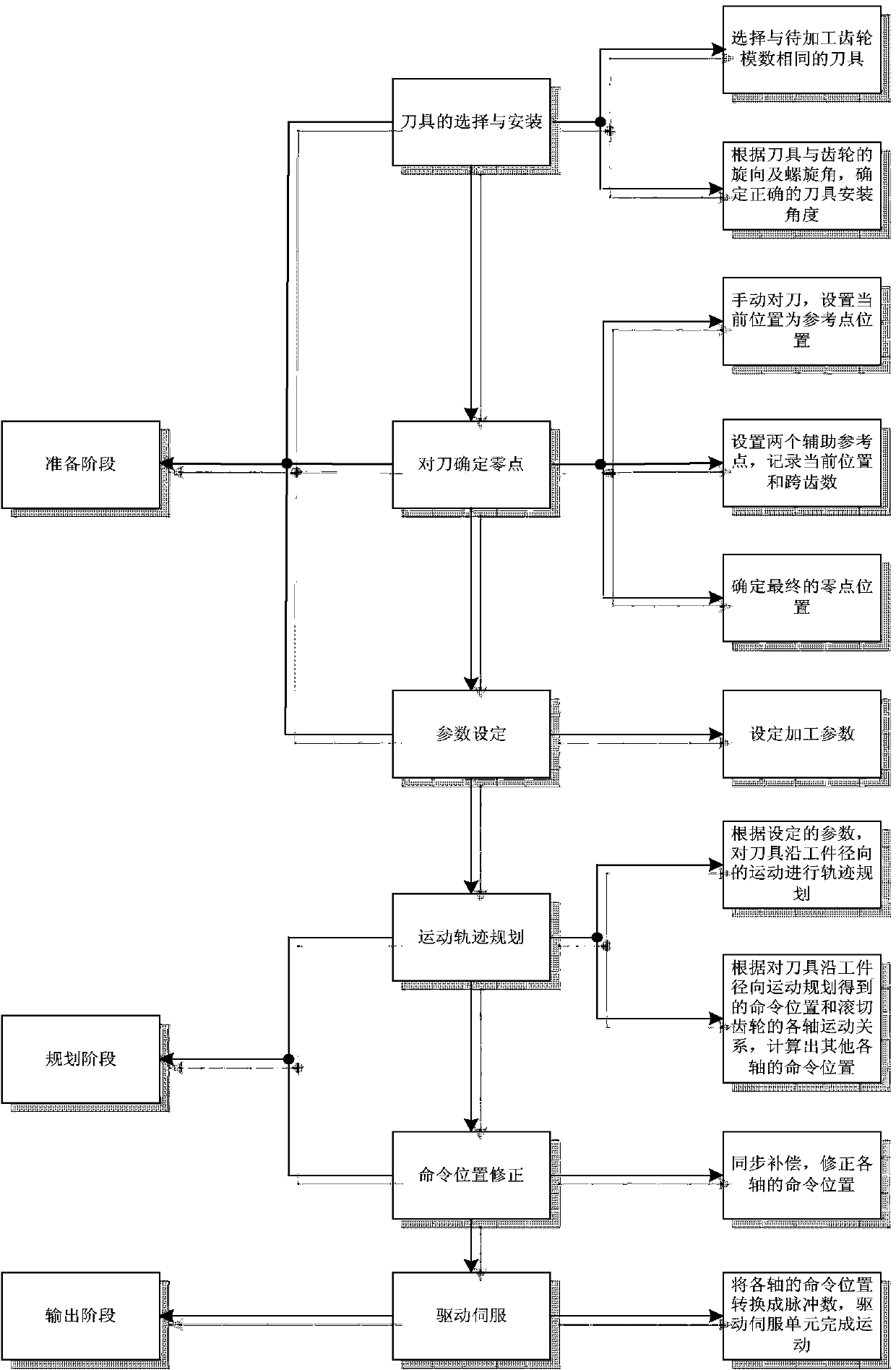

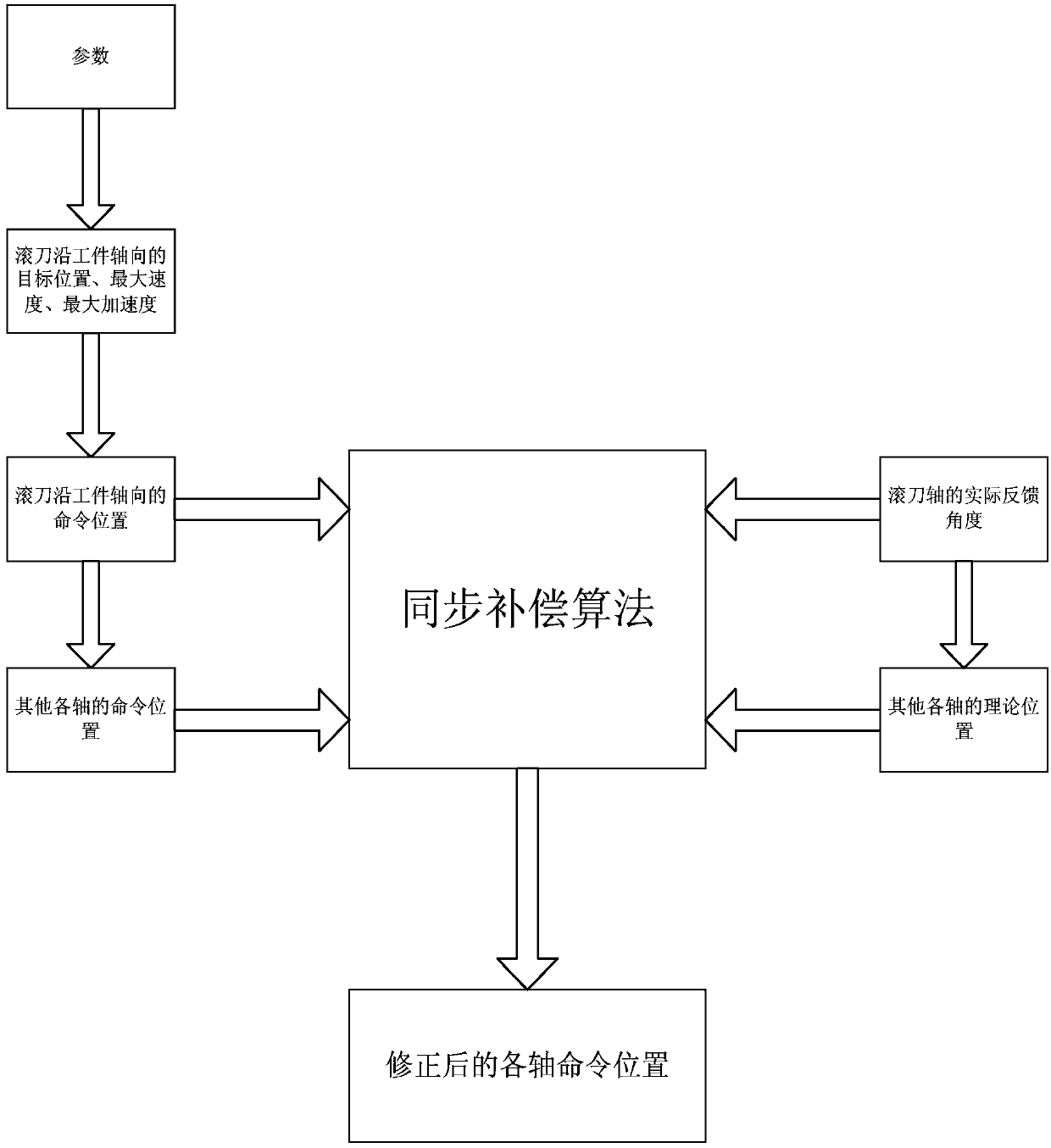

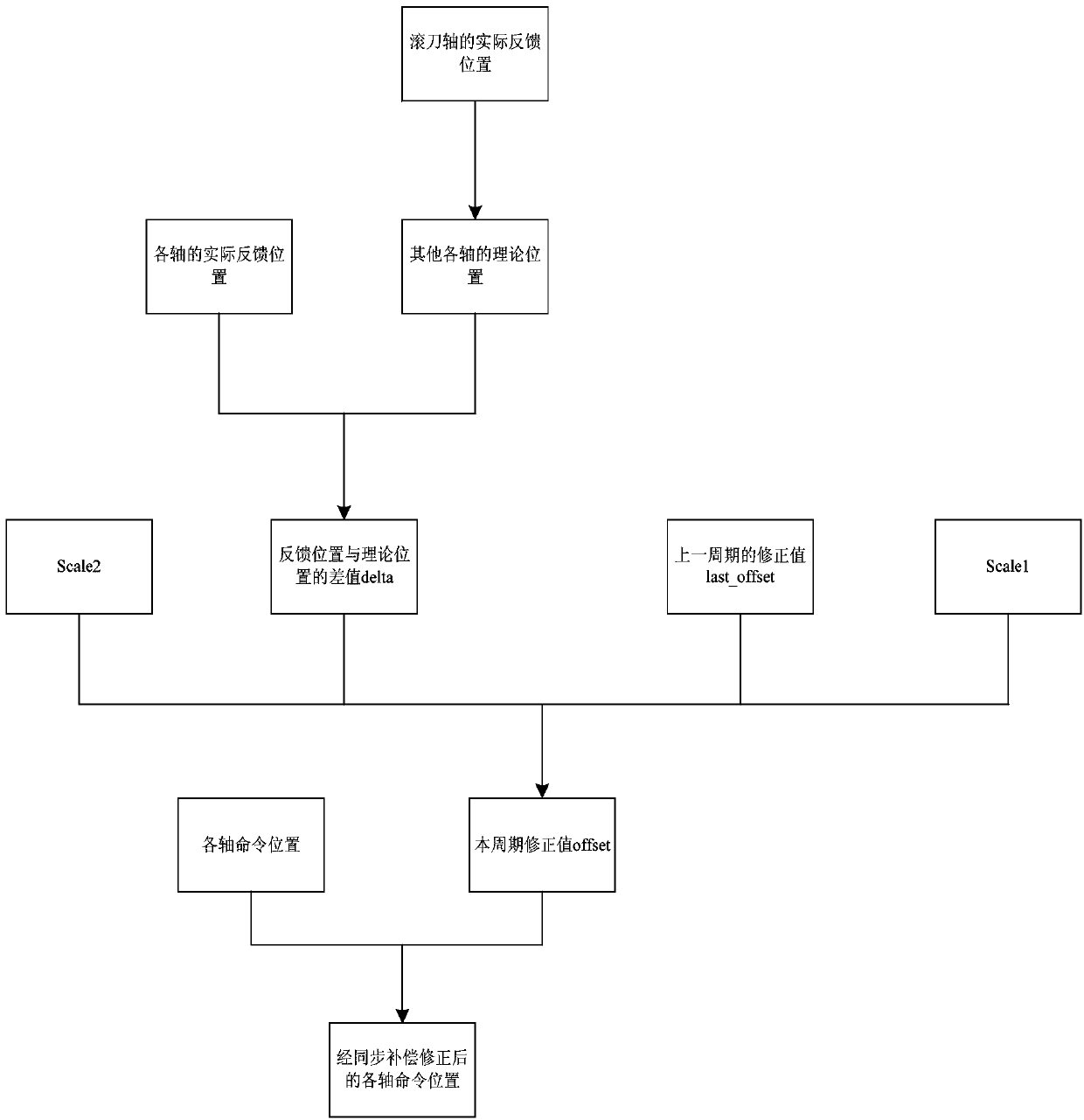

Numerical control gear hobbing control method for gear repairing

ActiveCN105583474AImprove repair accuracyImprove surface roughnessGear teethNumerical controlGear grinding

The invention provides a numerical control gear hobbing control method for gear repairing. The gear hobbing manner is used for repairing a gear with non-ideal surface roughness and precision, and therefore the gear reaches the machining requirement. Repeated tool setting is used for obtaining a reference point position, the ideal zero positions of all shafts are determined, and then a synchronous compensation algorithm is adopted to carry out hobbing on the gear to be repaired again; and the follow-up property of the shafts is improved, the machining process is more stable, the machining precision and the surface roughness are effectively improved, and the gear repairing aim is achieved. The problem that in the gear hobbing process, after a workpiece is disassembled, positioning cannot be carried out again is solved, the synchronous compensation algorithm is adopted to carry out hobbing on the gear to be repaired again, and as for the occasion with the non-specially-severe gear precision requirement, compared with traditional gear repairing methods of gear shaving, gear grinding and the like, the numerical control gear hobbing control method has the beneficial effects that the machining precision is met, meanwhile, the machining efficiency is greatly improved, and the repairing cost is greatly reduced.

Owner:中国科学院沈阳计算技术研究所有限公司

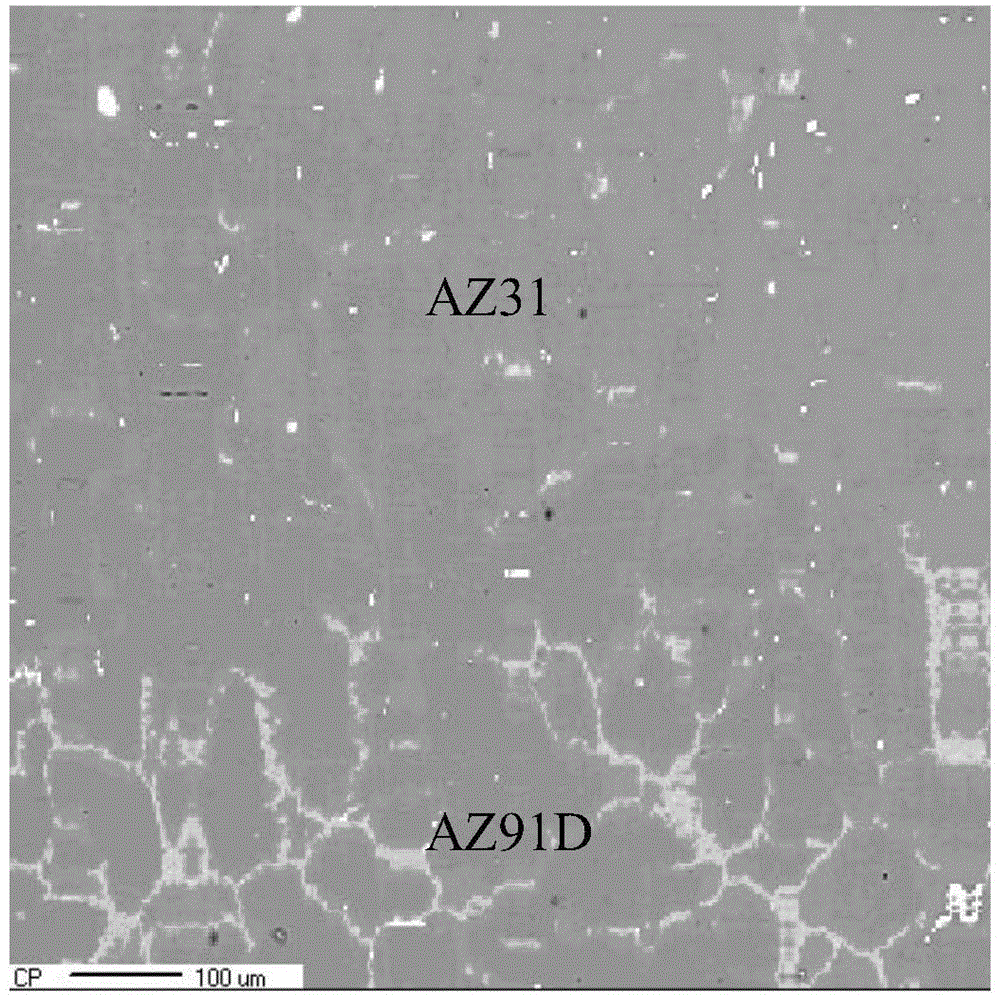

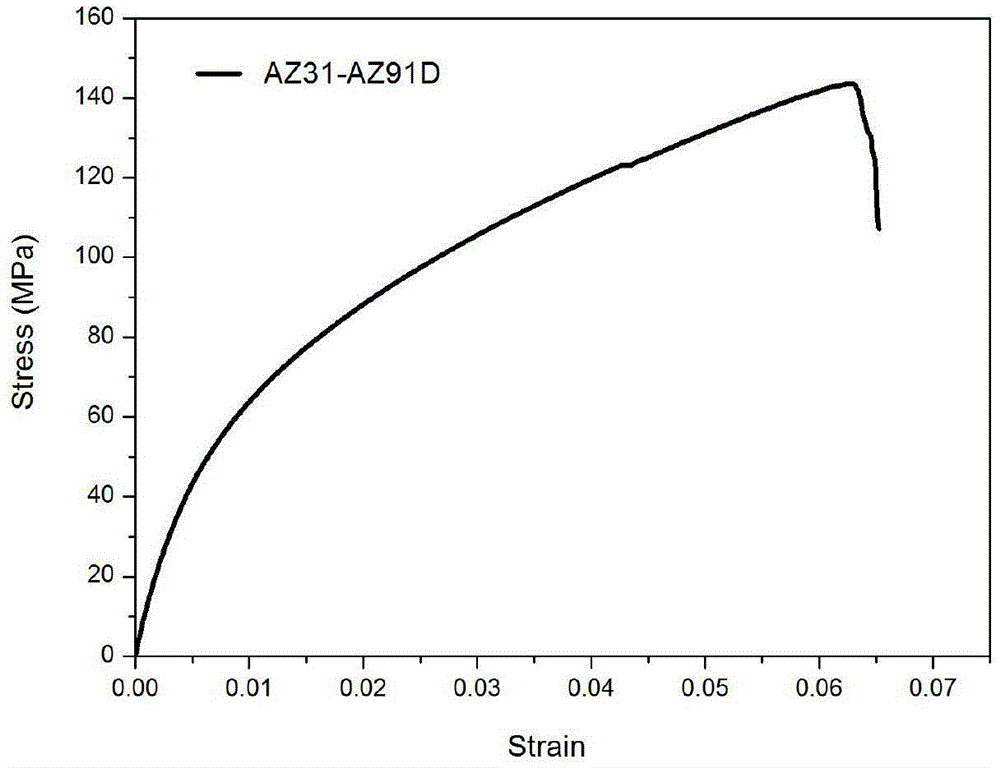

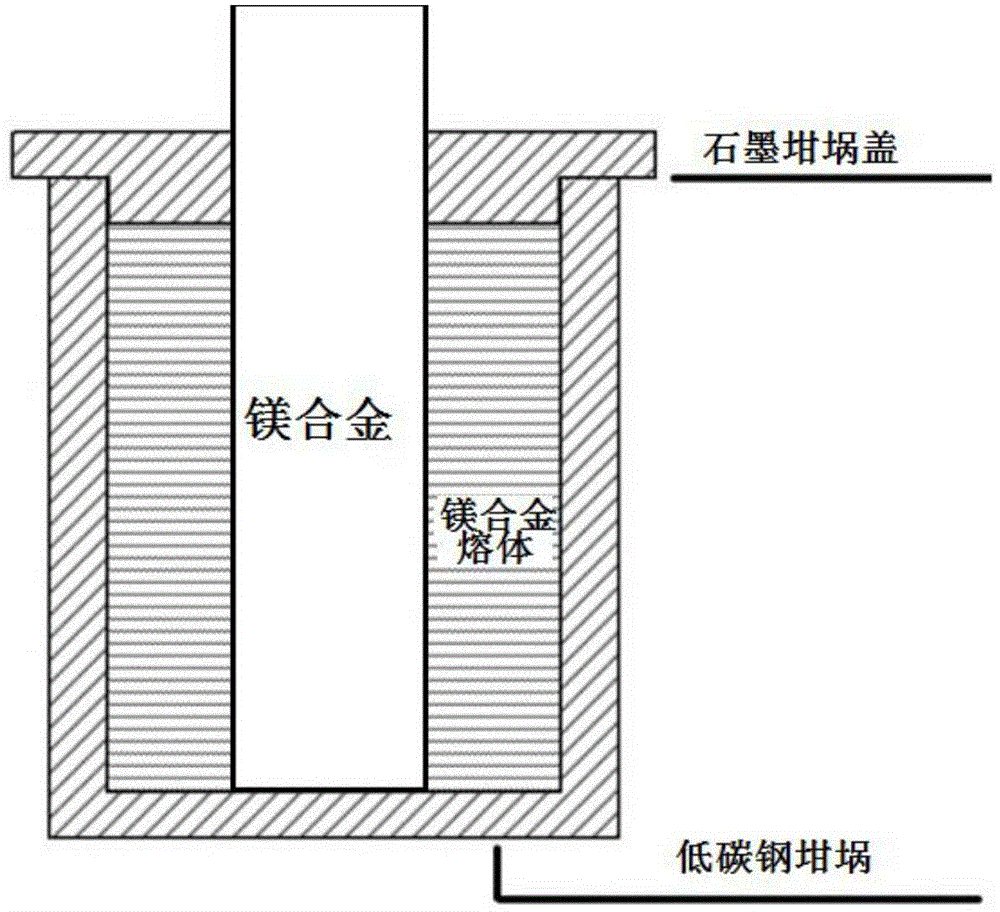

Magnesium/solid and liquid magnesium composite casting forming method

ActiveCN104368791AExcellent interface tensile strengthExcellent shear mechanical propertiesGearingCylindersAviationMaterials processing

The invention provides a magnesium / solid and liquid magnesium composite casting forming method and belongs to the field of material machining engineering. According to the method, solid magnesium alloy is arranged in magnesium alloy melt for preparation of magnesium-coated magnesium castings. The method includes the following steps that (1) the solid magnesium alloy is machined, so that a required material type is acquired, and the ideal surface roughness is acquired through turning and grinding; (2) the surface of the prefabricated solid magnesium alloy is chemically washed, so that oil dirt and oxide on the surface are removed; (3) magnesium alloy with other components is smelted until the magnesium alloy is completely fused; (4) the treated magnesium alloy of the different material type is inserted in the magnesium alloy melt, wherein the temperature is kept between 610 DEG C to 690 DEG C in the inserting process; (5) after the treated magnesium alloy is inserted, the temperature is maintained for 5 min to 15 min, and then the whole melt is taken out and cooled through air to the indoor temperature. According to the solid and liquid magnesium composite casting forming method, the metallurgical combination purpose that an interface of the magnesium alloy with the different components is completely even is achieved, the defects of magnesium alloy with a single component are overcome, the interface is excellent in tensile resistance and shearing resistance mechanical property and high in ductility and toughness, and therefore the magnesium alloy is hopefully and widely applied to the fields of traffic, national defense, aviation, aerospace, chemical engineering and the like.

Owner:UNIV OF SCI & TECH BEIJING

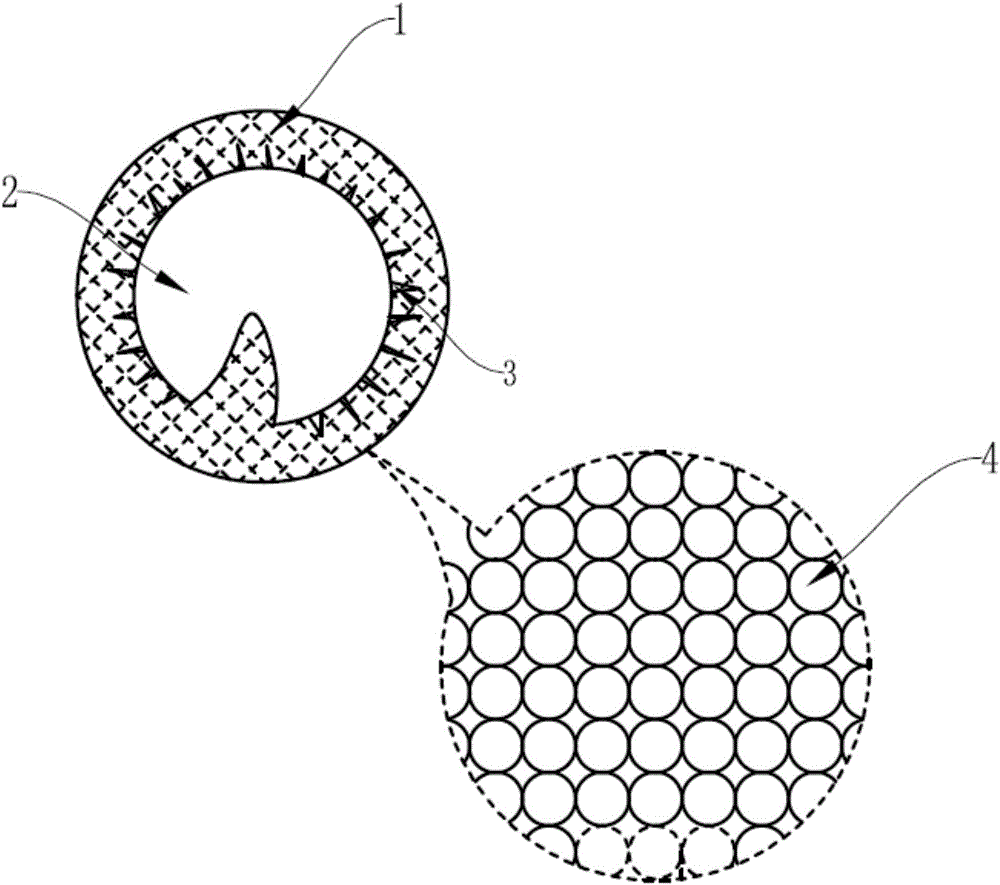

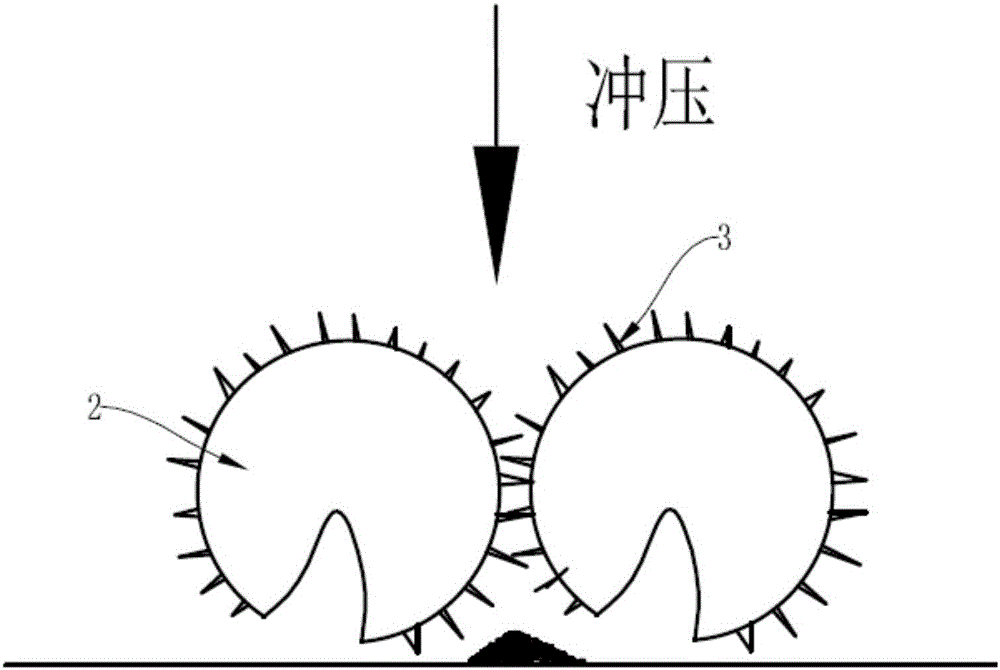

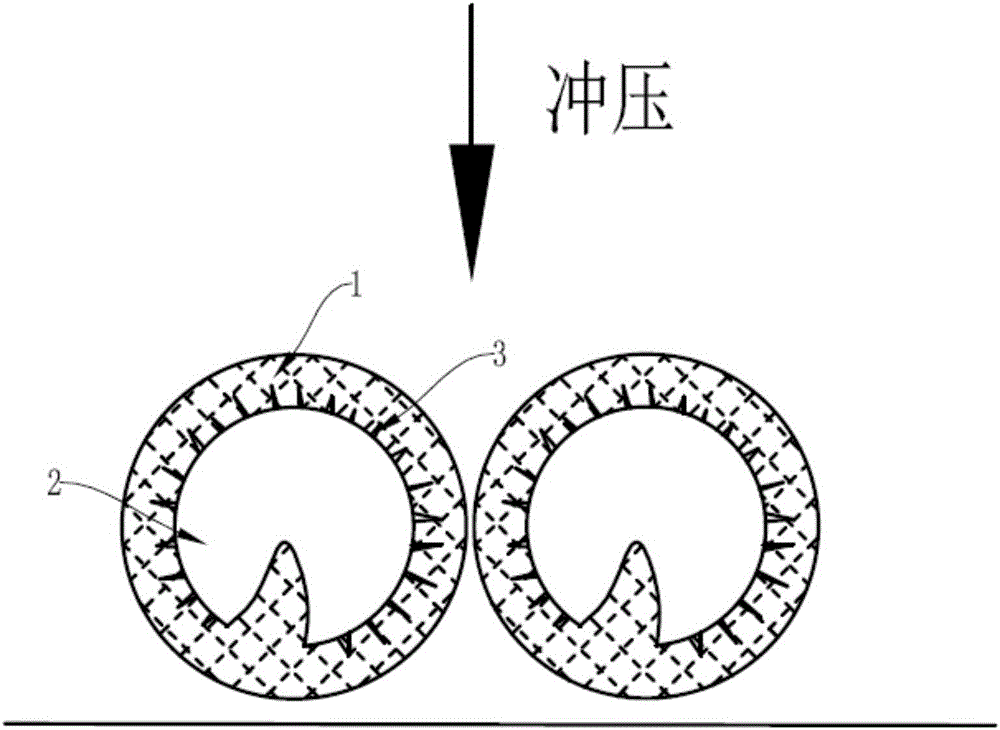

Manufacturing method for ceramic powdery granule with coating and granule structure of ceramic powdery granule

The invention provides a manufacturing method for a ceramic powdery granule with a coating and a granule structure of the ceramic powdery granule. According to the manufacturing method for the ceramic powdery granule, a coating solution is sprayed in the process of formation of slurry into powder in widely-known spraying and granulation process, and after drying, the ceramic powdery granule with the coating is obtained. The manufacturing method provided by the invention enables coating particles on the surface of the ceramic granule to have good coating effect and has the characteristics of reduction in manufacturing procedures and in cost and high in manufacture benefits. The ceramic powdery granule with the coating protects burrs on the surface of the core of the slurry, overcomes the problem of low manufacture benefits, has a smooth surface, improved fluidity, and uniform quality and distribution; so the problem that the ceramic powdery granule has nonuniform quality and disorder distribution in compaction into a brick is overcome, little burr damage occurs, and a green body is not prone to deformation and cracking; and a prepared tile has more ideal surface effect.

Owner:FOSHAN DONGPENG CERAMIC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com