Preparation method of cerium oxide nanoballs

A technology of nanospheres and cerium oxide, which is applied in the fields of nanostructure manufacturing, chemical instruments and methods, nanotechnology, etc., can solve the problems of harsh conditions, non-uniform morphology, complicated procedures, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

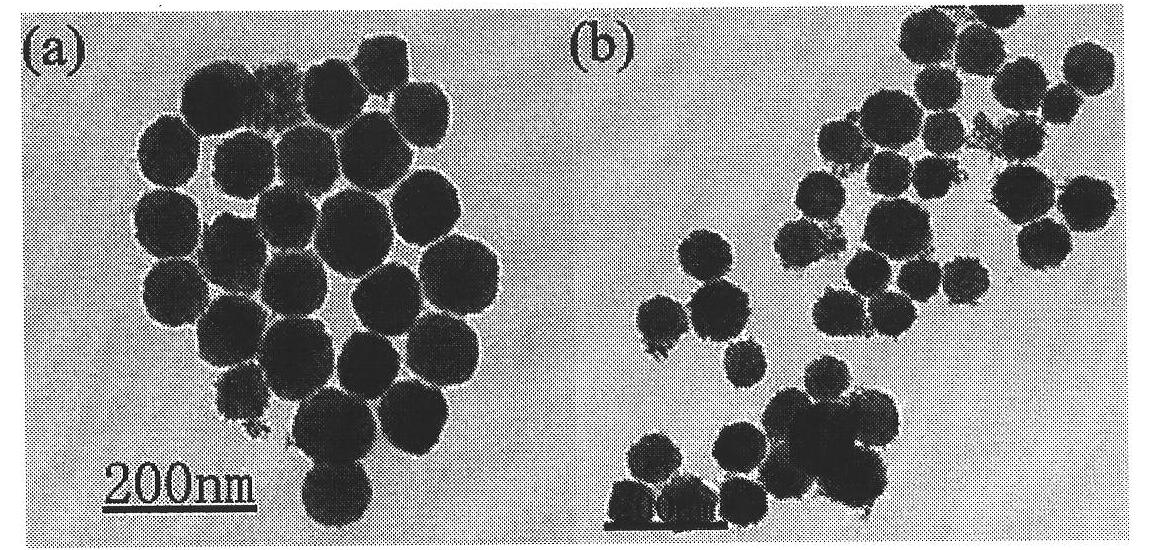

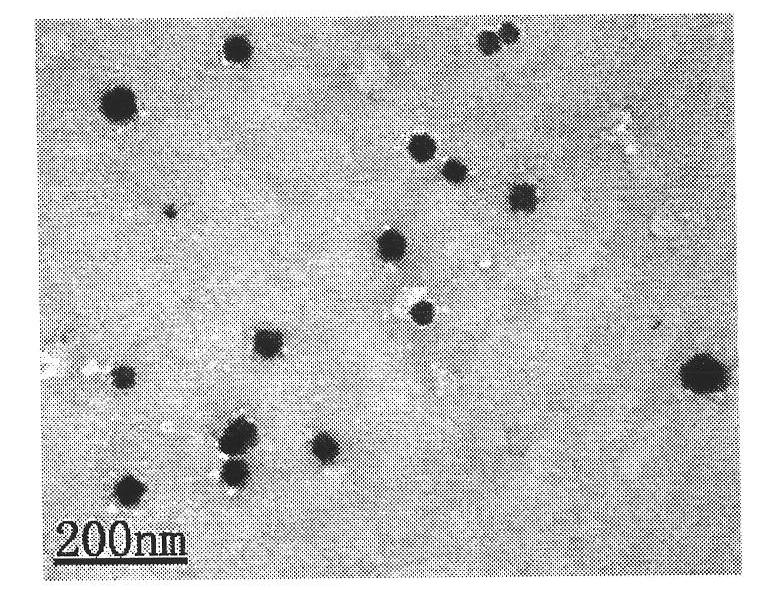

Embodiment 1

[0021] Dissolve 2mmol of cerium nitrate and 0.5g of polyvinylpyrrolidone in 10mL of water with stirring at room temperature for 5min, then add 30mL of diethylene glycol, stir for 5min until they are evenly mixed, then transfer to a 50mL autoclave, and let stand at 180°C for 24h. After cooling, a stable, uniform and stable cerium oxide nanosphere sol was obtained. After being evaporated to dryness at 180° C., it was calcined at 500° C. for 2 hours to obtain a yellow cerium oxide nanosphere solid powder.

Embodiment 2

[0023] Dissolve 2mmol of cerium nitrate and 4g of polyvinylpyrrolidone in 10mL of water by ultrasonication at room temperature for 5min, then add 30mL of diethylene glycol, mix well by ultrasonication for 5min, then transfer to a 50mL autoclave, let stand at 180°C for 24h, and cool down naturally A uniform and stable cerium oxide nanosphere sol was obtained; after being evaporated to dryness at 150°C, it was calcined at 600°C for 1 hour to obtain a yellow cerium oxide nanosphere solid powder.

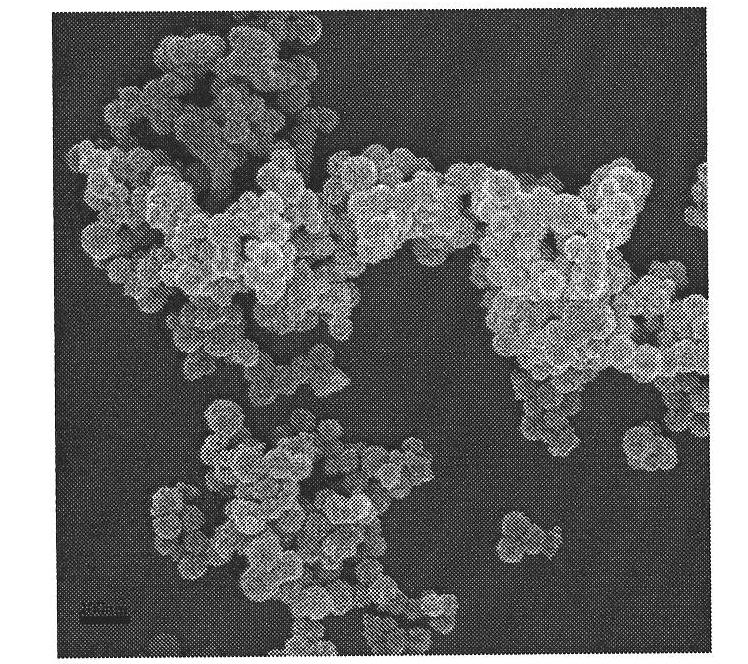

Embodiment 3

[0025] Dissolve 2mmol of cerium chloride and 0.5g of polyvinylpyrrolidone in 15mL of water by ultrasonication for 5min at room temperature, then add 25mL of diethylene glycol, mix well by ultrasonication for 5min, then transfer to a 50mL autoclave, stand at 120°C for 24h, and cool naturally After that, a uniform and stable cerium oxide nanosphere sol was obtained; after being evaporated to dryness at 170°C, it was calcined at 450°C for 3 hours to obtain a yellow cerium oxide nanosphere solid powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com