Structure optimization design method for automobile damping board

A technology of optimized design and damping plate, applied in the direction of vehicle components, transportation and packaging, to achieve the effect of overall shape optimization and lightweight design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

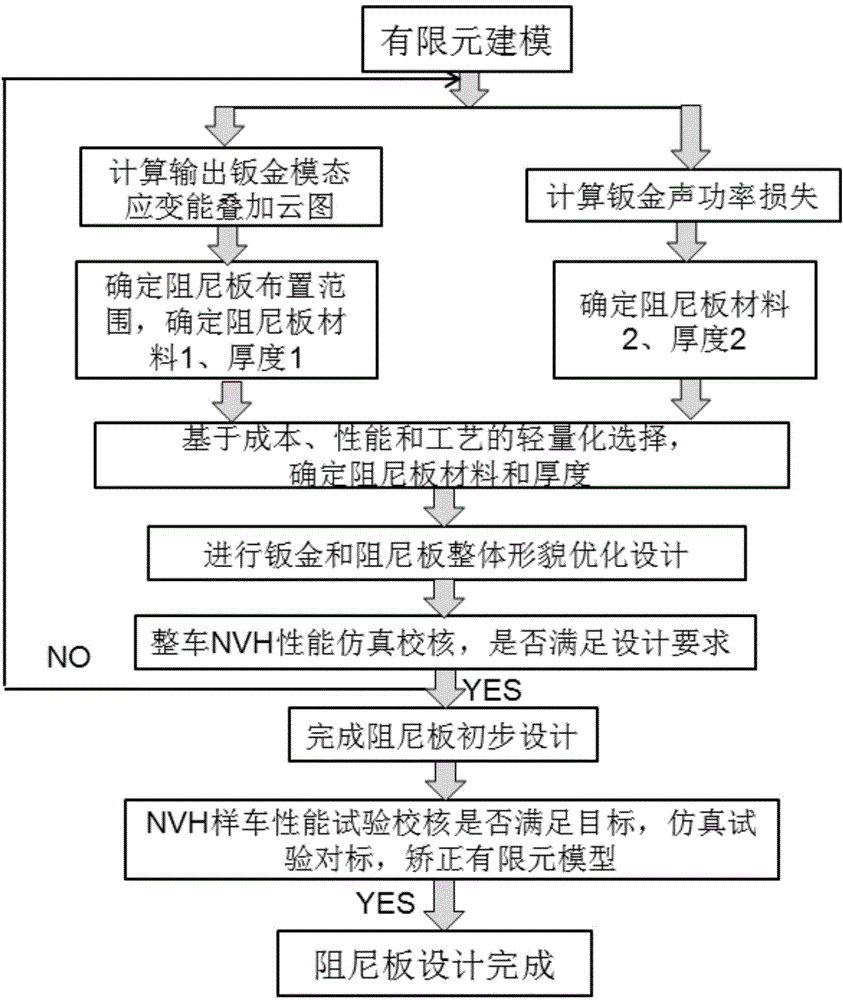

[0026] The invention discloses a method for optimal design of an automobile damping plate structure, which comprises the following steps:

[0027] A. Establish BIW modal analysis finite element model, and establish NTF and VTF models based on Trimbody;

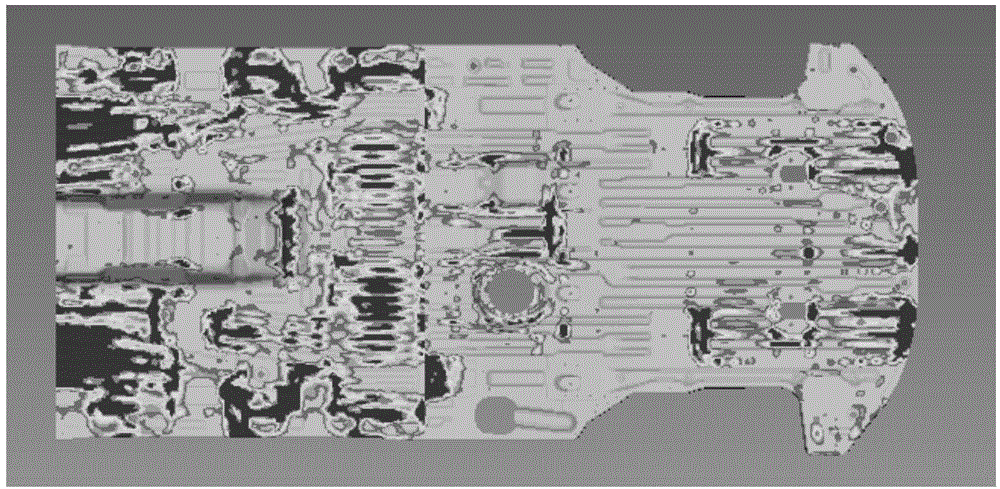

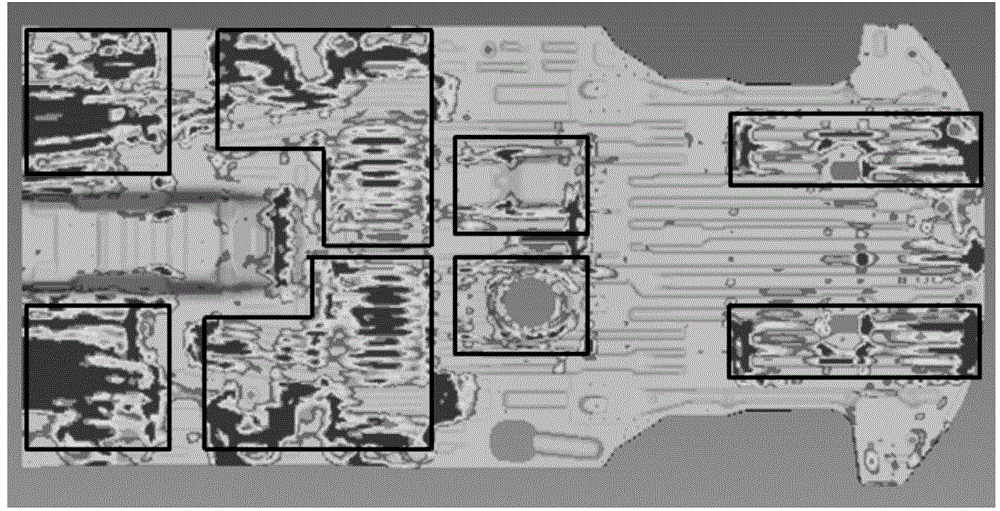

[0028] B. Including the step of calculating the sheet metal modal and the step of calculating the sound power of the sheet metal, in the step of calculating the sheet metal modal, calculate and output the superimposed cloud diagram of the sheet metal modal strain energy, then determine the layout range of the damping plate, and determine the damping material 1 , thickness 1; in the step of calculating sheet metal sound power, calculate sheet metal sound power loss, then determine damping plate material 2, thickness 2;

[0029] C. According to the low-frequency sheet metal modal strain energy superposition cloud image and the mid-frequency sheet metal sound power loss results, the damping plate material and thickness are prelim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com