Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Reduce roll consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

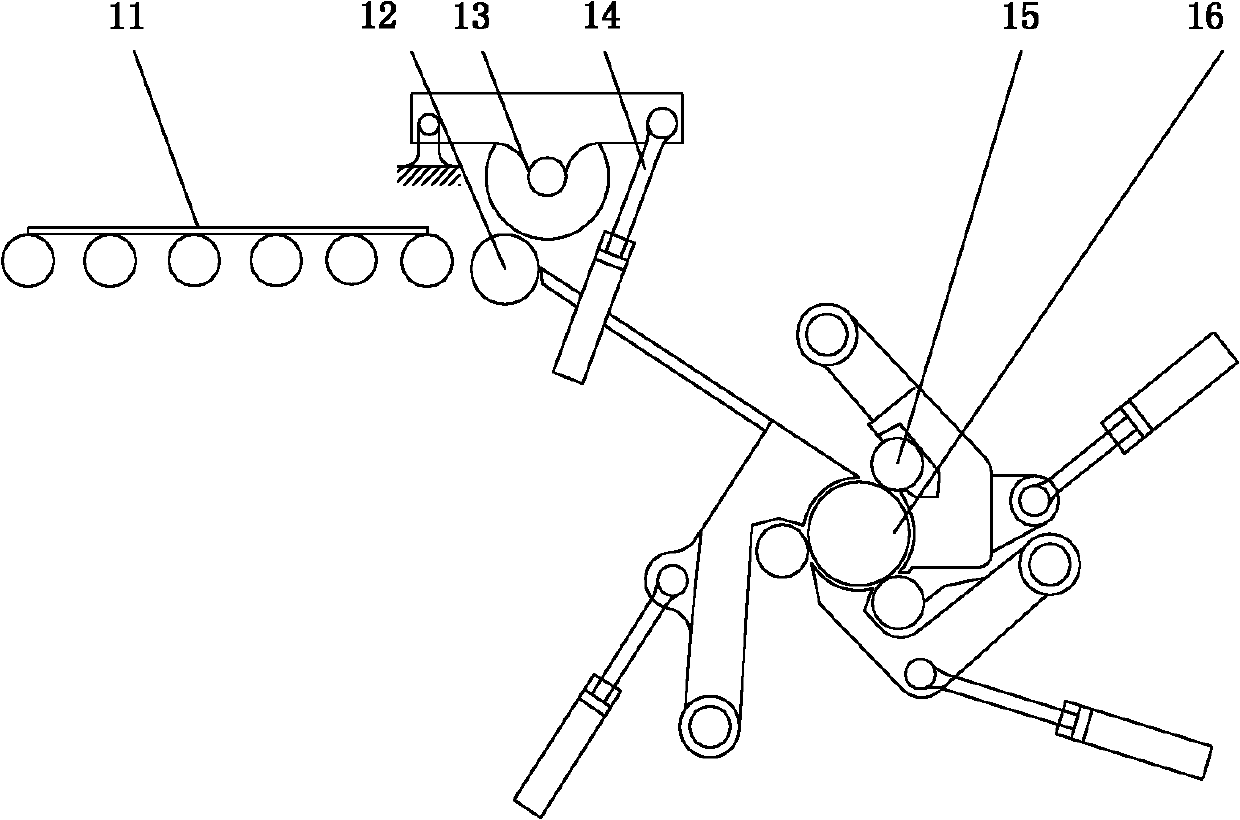

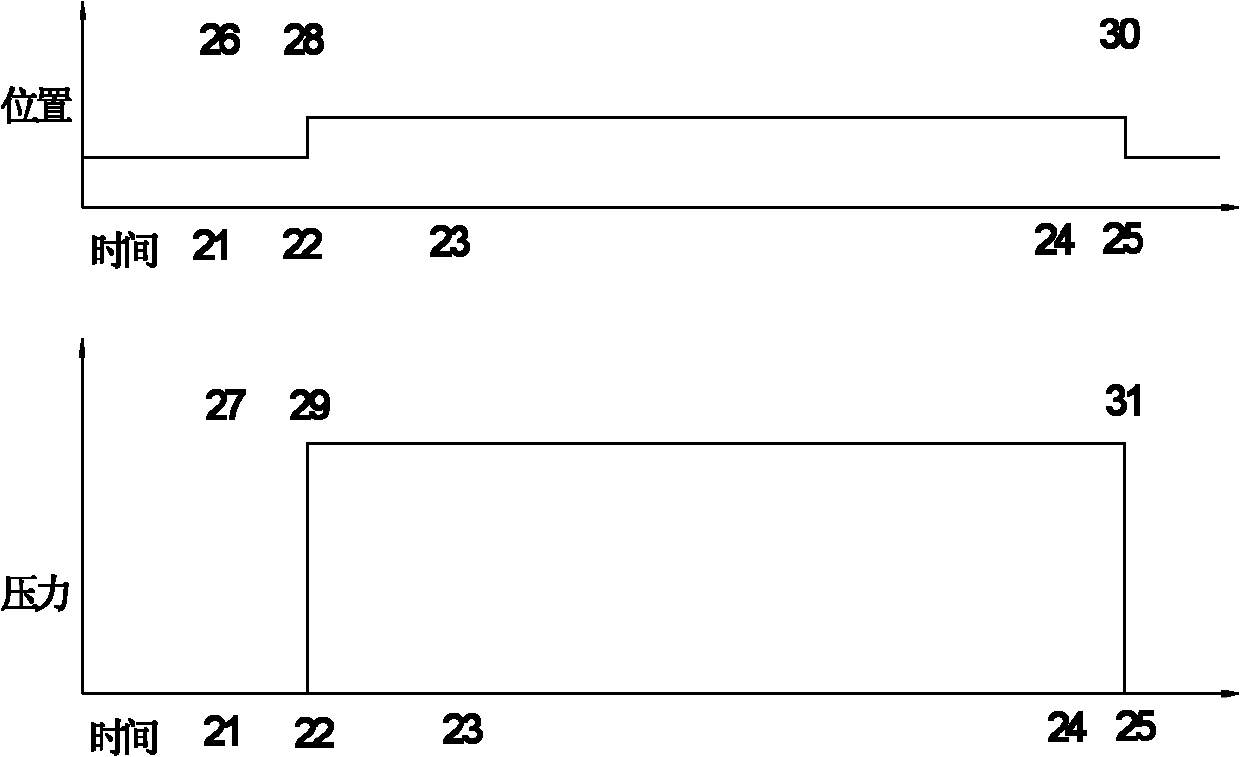

Hot-rolled coiler pinch roll controlling method

The invention relates to a hot-rolled coiler pinch roll controlling method. A pinch roll adopts position control or pressure control. The hot-rolled coiler pinch roll controlling method comprises the following steps that: step 1: before strip steel is gripped, the pinch roll adopts the position control; step 2: at the moment when a head part of the strip steel is gripped, the pinch roll adopts the pressure control; step 3: after the strip steel is wound on a wound roll and tension is formed, the pinch roll adopts the position control or the pressure control; and step 4: after the strip steel is tailed-out by a finishing front stander, the pinch roll adopts the pressure control. Due to adoption of the method, on the premise of the present precision control of roll-gap deviation at two sides of the pinch roll, the coiling quality of the tail part of a thin sheet can be improved, coiling flaws such as creasing, edge damage and surplus edge on the tail part of a steel coil can be reduced, damage on the surface of the pinch roll caused by the rolling cracking of the tail part of the strip steel can also be effectively reduced, the indentation flaw of the pinch roll can be reduced, and the high-strength steel wave-shaped flaw caused by the abrasion of the pinch roll can be improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for configuring shape of supporting roll of four-high mill and shape of working roll thereof

ActiveCN101554635ASolve peelingSolve the large amount of wear and tearCounter-pressure devicesRollsProduction lineStress concentration

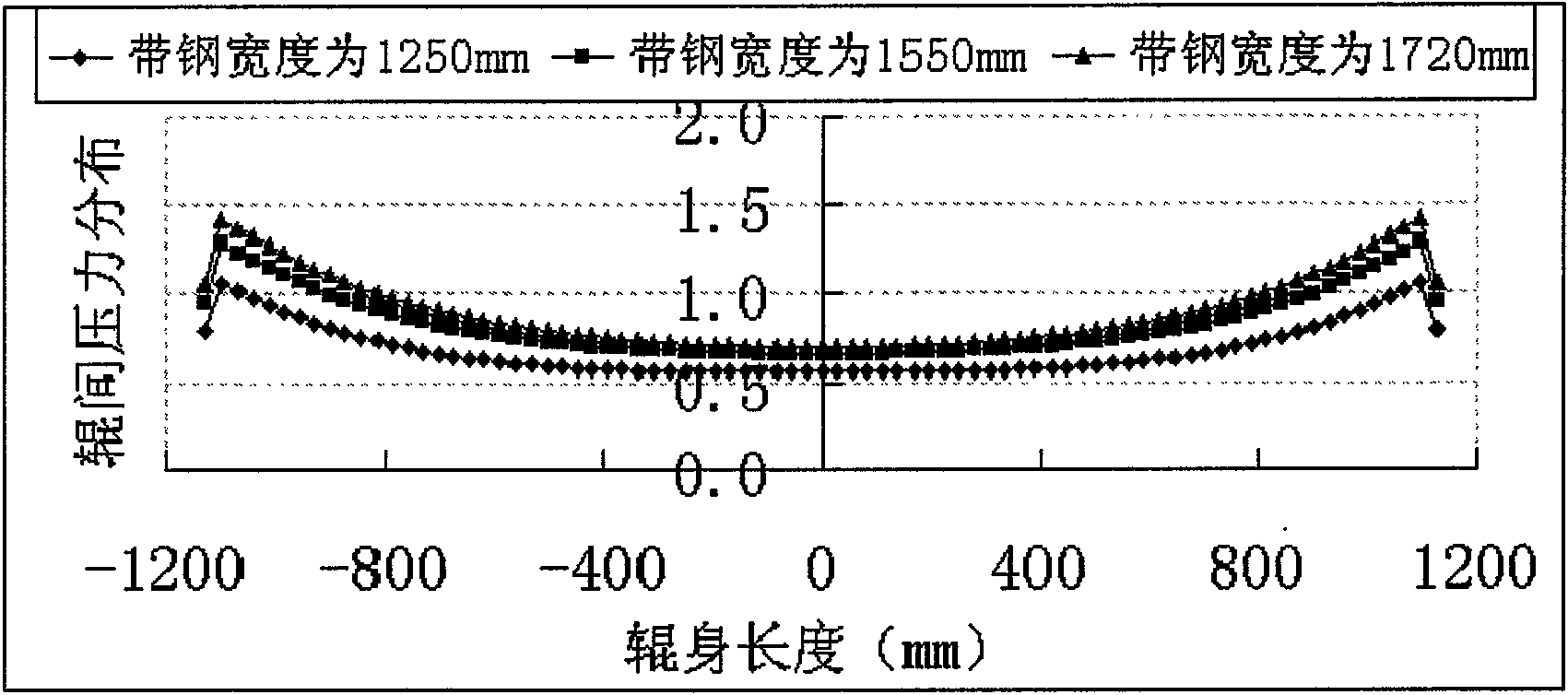

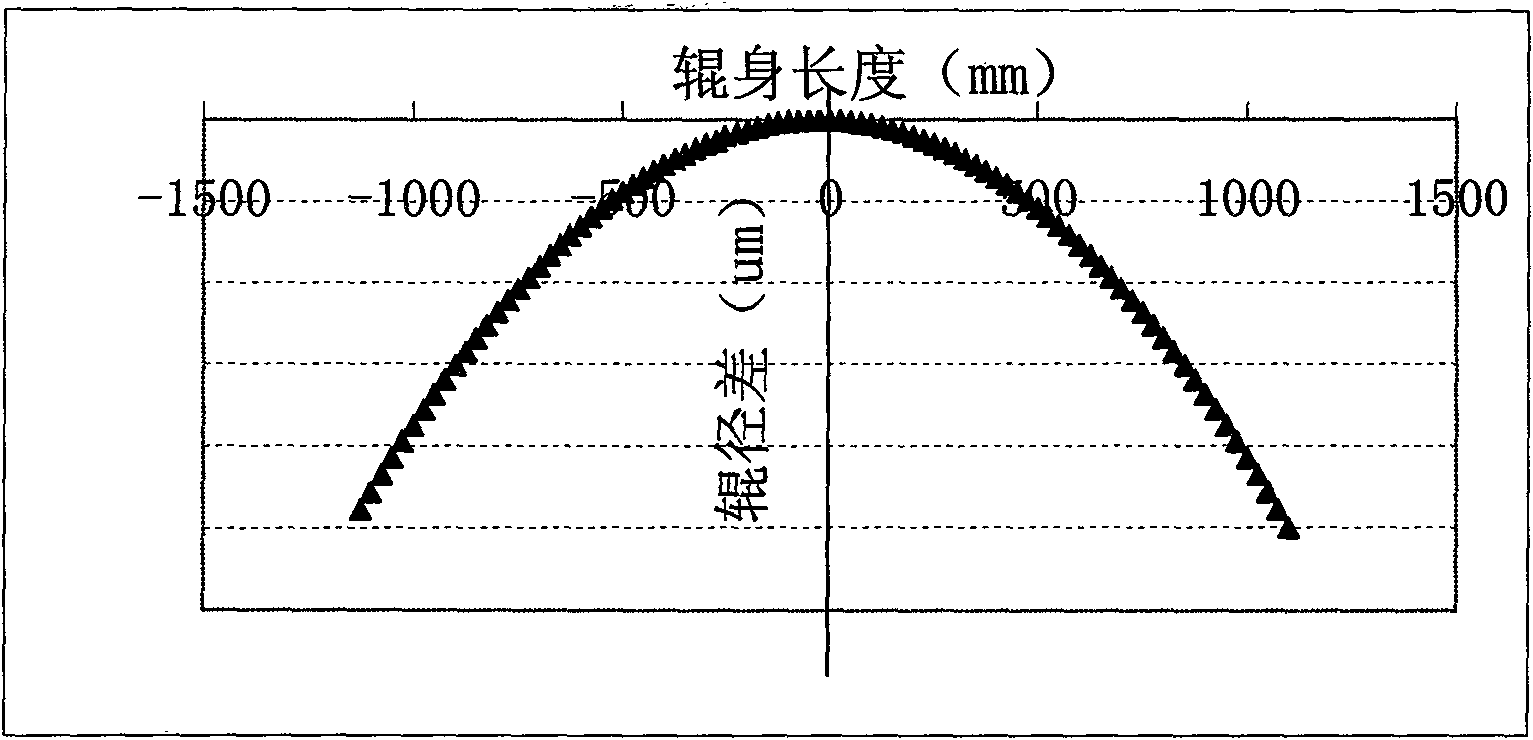

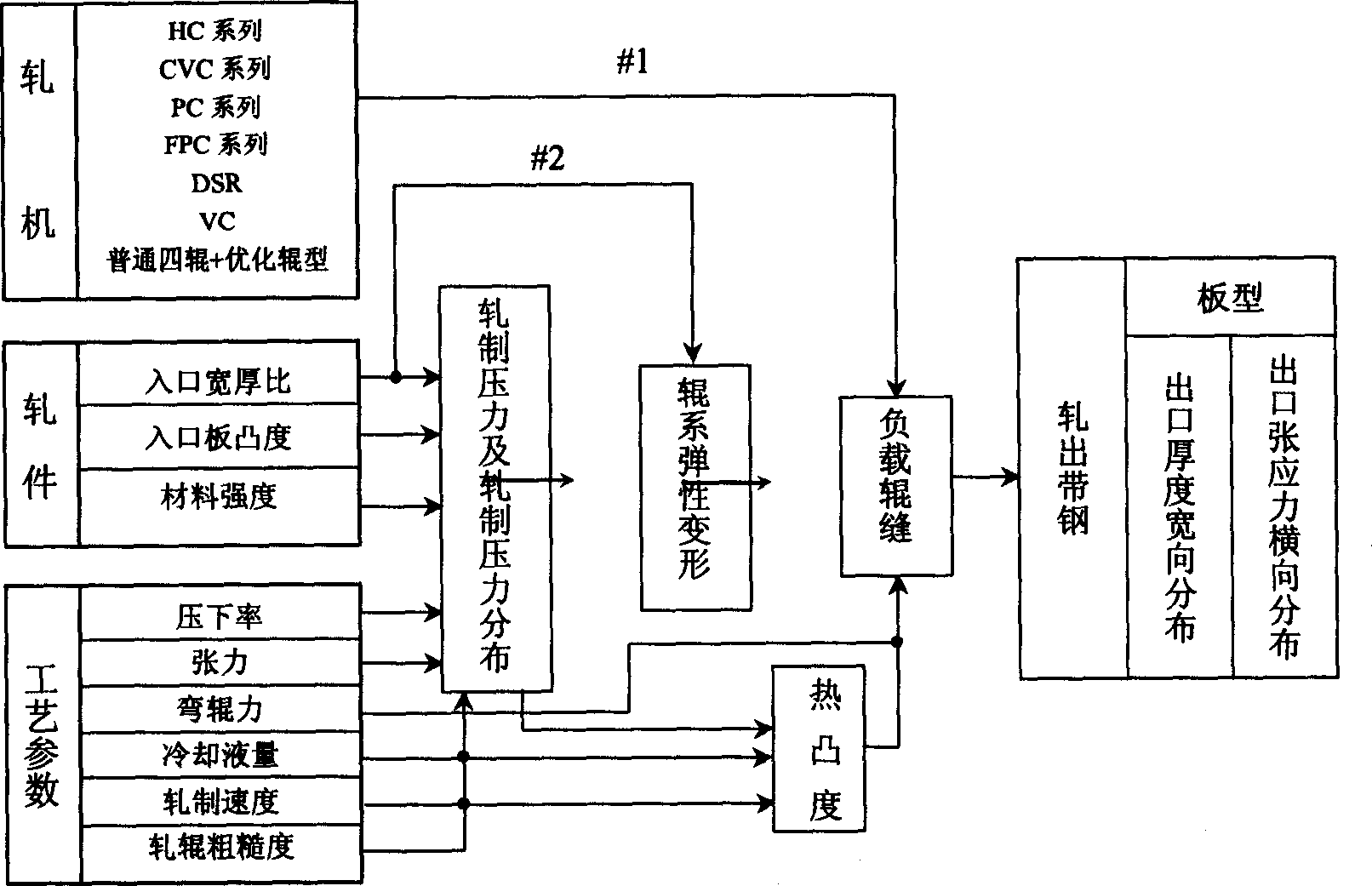

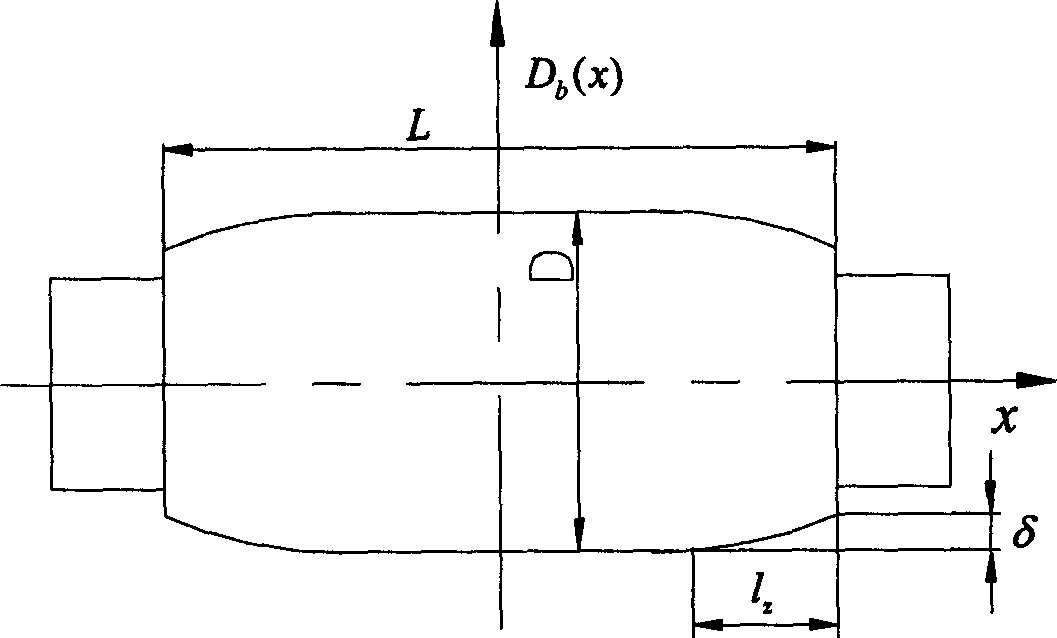

The invention relates to a method for configuring the shape of a supporting roll of a four-high mill and the shape of a working roll thereof, belonging to the technical field of steel rolling. According to three types of width specifications of band steel which are most rolled by hot-rolling band steel production line, sixth-power polynomial supporting roll shape technology and second-power working roll shape curve are used for configuration so as to lead the contact length of the supporting roll and the working roll and the width of the rolled band steel to be fit. The method has the advantages of eliminating hazardous contact areas in which the parts of the two ends of the supporting roll with the flat roll shape and the working roll expand out of the edge of the band steel to generate large deflection and deformation, solving the problems that the stress concentration of the edges of the supporting roll and the working roll in a hot continuous mill for wide band steel causes stripping and the mill roll with the flat roll shape has large wearing capacity and is not even, reducing the consumption of the mill rill, saving energy, reducing consumption and reducing cost for rolling steel; and by the technical configuration of R2 working roll shape and the supporting roll shape, the invention solves the plate-shape problems that the middle blank generates negative convexity and the wedge shape is large, and improves the control precision of the shape of hot-rolled band steel.

Owner:SHOUGANG CORPORATION

Flattening process for steel strip

The invention discloses a belt steel flattening craft, which is comprised the following parts: flattening roll roll-shape optimization design, flattening processing parameter optimization design initialization and elongation and slab-shaped composite optimization control, therein the craft doesn't need to draft flattener, which can guarantee export belt steel board mold and mechanical property on one common planisher; the invention is fit for hot-dip coating zinc units and annealed flattening; the belt steel slab-shaped guarantee value is 4-6T; the hit ratio is more or equal to 97%; the elongation control accuracy is smaller or equal to +-0.1%.

Owner:BAOSHAN IRON & STEEL CO LTD

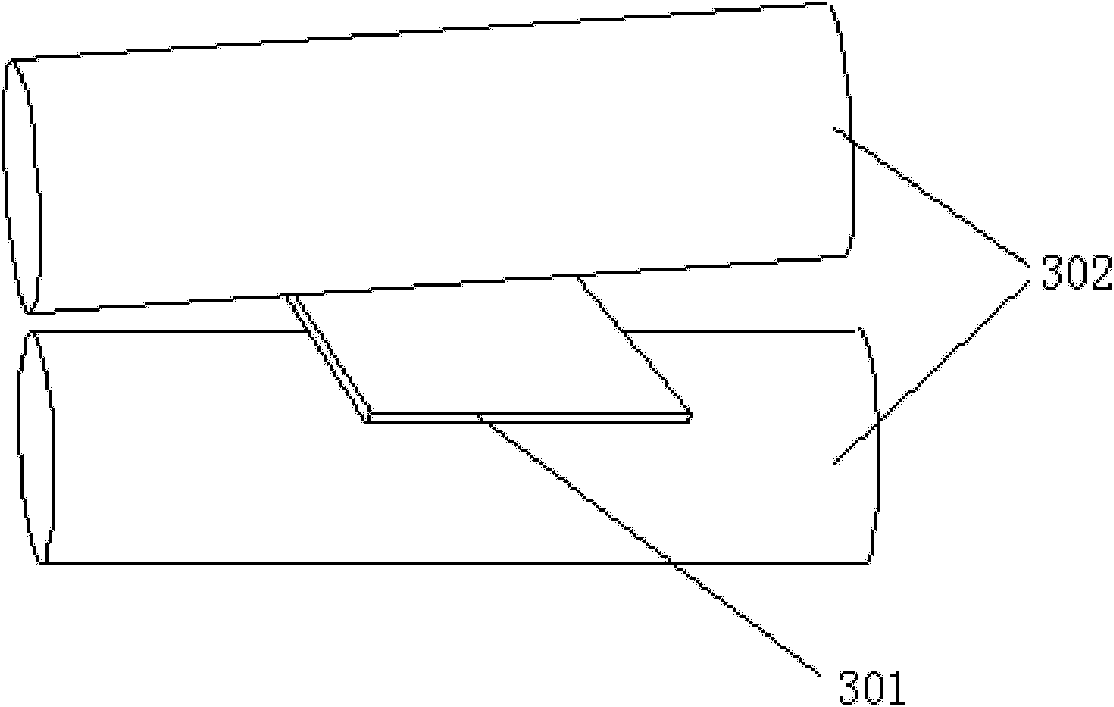

Two-roller reversible mill roller device and technology using continuous casting round billets for carrying out rolling production

ActiveCN103801560AIncrease the amount of steelImprove rolling yieldRollsMetal rolling arrangementsOne passMetallurgy

The invention discloses a two-roller reversible mill roller device and technology using continuous casting round billets for carrying out rolling production. Four types of hole patterns including a transition hole pattern, a supporting hole pattern, a before-finished-product hole pattern and a finished product hole pattern are designed on a pair of rollers. The rolling technology comprises the steps of using the transition hole pattern (1) for rolling the continuous casting round billets, and turning over steel after rolling is accomplished, wherein the rolling reduction ranges from 40 mm to 90 mm per pass; using the supporting hole pattern for continuously rolling the drum-shaped rolled pieces obtained in the previous step to obtain rectangular or square rolled pieces which have regular shapes, and turning over the steel after rolling is accomplished, wherein the rolling reduction ranges from 40 mm 90 mm per pass; using the before-finished-product hole pattern (3) for rolling the rolled pieces to obtain rectangular or oval rolled pieces with reserved rolling reduction and reserved broadening quantity, and turning over the steel billets after rolling is accomplished, wherein the rolling reduction ranges from 20 mm to 90 mm per pass; using the finished product hole pattern for rolling one pass to obtain rolled pieces which are high in dimensional accuracy and product quality, wherein the rolling reduction of square or rectangular steel finished products ranges from 40 mm to 60 mm per pass, and the nominal rolling reduction of round steel ranges from 10 mm to 40 mm per pass.

Owner:HUATIAN ENG & TECH CORP MCC

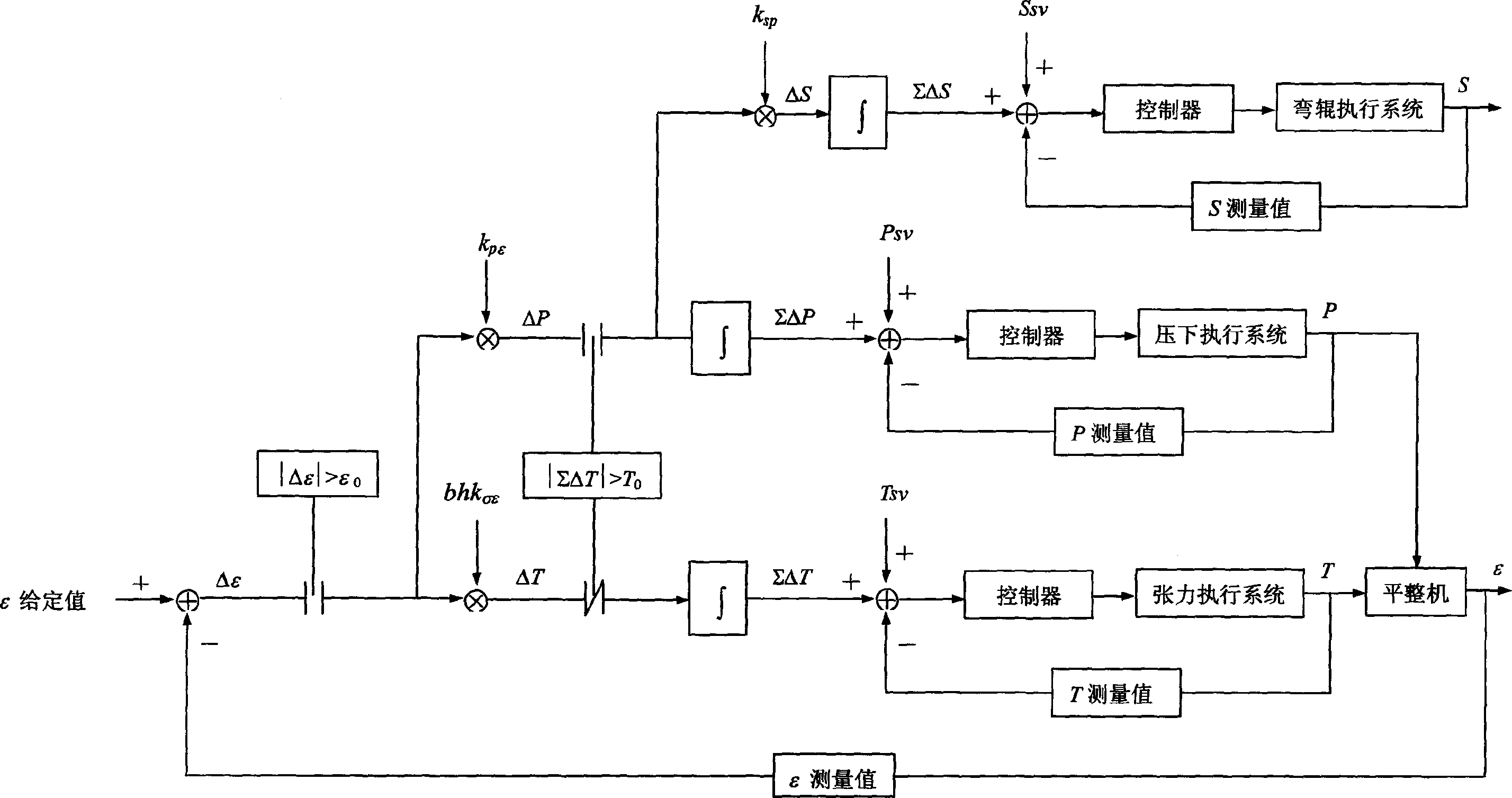

Integrated control method of double-six roller UCM type flattening machine group plate shape

InactiveCN101412043AGuaranteed Coordinated ControlExtended service lifeProfile control deviceNumerical controlWork rollEconomic benefits

The invention discloses a method for comprehensively controlling a plate shape of a double six-roller UCM model temper mill unit. The method is characterized by comprising the following steps: a. collecting equipment parameters of the double six-roller UCM model temper mill unit; b. collecting key rolling technology parameters of a strip material to be comprehensively set; c. calculating optimum setting values of working rolls of 1# frame and 2# frame, ,roll bending of an intermediate roll and movement of the intermediate roll; and d. carrying out comprehensive setting to roll bowing force of the movement of the 1# frame and the 2# frame on the unit according to calculated optimum movement and comprehensive setting value of the roll bowing force. The comprehensively controlling method provided by the invention not only can improve controllability to the plate shape by the roll bending of the working roll and the intermediate roll of the double six-roller UCM model temper mill unit, movement of the intermediate roll and other plate shape control modes, bring full play of roll bending and movement and improve the plate shape quality of a finished product, but also can improve the service life of a roller, and reduce roll consumption, so as to bring significant economic benefit for company.

Owner:YANSHAN UNIV

Repair weld composite leveller roll and its production process

InactiveCN1736627AHigh strengthImprove impact resistanceArc welding apparatusOther manufacturing equipments/toolsChemical compositionWorking life

It relates to a pile-up welding composite straightener roll and the preparation technique, belonging to the art of mechanical device, and it especially relates to a straighter roll for a plate hot straightening machine. The straightener roll uses alloy constructional steel 42CrMo wrought-steel as the base metal to prepare mandrel of roll body, and is built-up an operational layer of 5-15mm by thicken on the surface of the roll body, the chemical composition of the deposited material of the operational layer being: C:0.36-0.45%, Cr: 12.00-14.00%, Ni:2.00-2.50%, Mo: 2.00- 3.00%, W: 2.00- 3.00%, Ti: 0.85-1.25%, Si: <=1.50%, Mn: <= 2.00%, P<= 0.035%, and S: <=0.03%. In the technique it uses 1250 type automatic buried arc building-up device, applies bobbing building-up to build up the operation layer of roll body, and uses the 260 weld flux as the welding material. The straightener roll has a long work life and a high strength of roll body, and it can be repaired and reproduced a plural of times.

Owner:UNIV OF SCI & TECH BEIJING

Method for rolling high-strength IF steel in ferrite area

InactiveCN101693253AEasy to wearReduce roll consumptionTemperature control deviceWork treatment devicesAustenite grainHeating time

The invention relates to a method for rolling a high-strength IF steel in a ferrite area. The high-strength IF steel is formed by adding solid solution strengthening alloy elements such as Mn<=1.8 %, P<=0.1 %, Cr<=0.5 %, Mo<=0.5 % of and the like into common Nb +Ti-IF steel grades so as to improve strength of the IF steel; the high-strength IF steel is produced with a heating temperature<=1150 DEG C, heating time between 0.5 hour and 1 hour and a starting rolling temperature 1100 DEG C; rough rolling is acted in an austenitic area, and screw-down rate of the rough rolling is 80%, thereby austenitic crystal particles are refined after rolled roughly; finish rolling is performed in the ferrite area, finish rolling temperature is <=780 DEG C, and then the IF steel is coiled away after laminar flow cooling is performed. The method substantially decreases oxidized steel loss produced by using the method, improves quality of strip steels, and can produce wider and thinner hot rolled plates and strips by consuming less energy.

Owner:UNIV OF SCI & TECH BEIJING

Technique for rolling figured steel for magnetic suspension train rail

ActiveCN101214494ALow costIncrease productivityRoll force/gap control deviceTemperature control deviceProduction lineThermal treatment

The invention belongs to the technology field of metal thermal treatment, which relates to the rolling technology of deformed steel used for a maglev train rail. The invention comprises the procedures in turn of rough rolling, finishing rolling, coolant-controlling and straightening, which is characterized in that two reversible mills rolling is adopted for rough rolling and the maximum rolling force of a two reversible mill is 8000 to 10000KN. And the rolling deformation should account for 60 to 90 per cent of total deformation. Three-stand universal continuous rolling line with high rolling force and high accuracy is adopted for finishing rolling to realize mixing roll under universal mode. The invention can merely use large H-shaped hot- rolling production line to produce finished products and does not require thermal treatment and machining process, with the result that the cost can be greatly reduced and the requirement of mass production can be fully satisfied.

Owner:LAIWU IRON & STEEL GRP

Improved composite high-chromium iron-cast roller

It is a type of complex high-chromium green roll with strong oxidation resistance and wearable property. Components of its working lining are as follows: 2.5-3.0% C,0.5-1.2% Si,0.6-1.2% Mn,1.0-1.5% Ni,12-20% Cr,0.5-3.5 % Mo,0.05-0.5% V,0.2-1.5% W,0.03-0.3% Al, 0.03-0.1% N ,P <=0.04%,S <=0.04%,iron and impurity the rest. Advantages of this kind of green roll are as follows: wear-resisting property was improved by 50% ,mm rolling quantity increased by 30%,its life-span and rolling output were doubled, draw resistent intensity was reinforced and rigidity asymmetry was lowered effectively.

Owner:JIANGSU GONGCHANG ROLL

Working roll forming technology taking grinding precision and cold-rolled electrical steel edge drop control into consideration

ActiveCN104607468AImprove grinding accuracyImprove grinding efficiencyRollsMetal rolling arrangementsStress concentrationElectrical steel

The invention relates to a working roll forming technology taking grinding precision and efficiency and cold-rolled electrical steel edge drop control into consideration. The sectional roll forming function method is adopted, a special cold-rolled working roll forming curve is formed, and the coefficient of an exponential function curve in the roll forming curve is designed according to the situation of band steel edge drop; a primary straight line is a smooth transition section outside the exponential function curve and prevents stress concentration between rolls caused when a working roll makes contact with an intermediate roll under action of roll bending force; two flat roll sections are provided, wherein the first flat roll section is the section, making contact with a band steel body part, of the roll surface of the working roll, the second flat roll section is located at one end of the roll surface of the working roll, and the purpose is to improve the grinding precision and efficiency of the working roll. After curvilinear functions of all sections are determined, the curvilinear functions are expressed by sections. The working roll forming technology can effectively improve the cold-rolled electrical steel edge drop control level, improve the roll grinding precision and efficiency, reduce the roll consumption, and lower the cold-rolled electrical steel production cost.

Owner:UNIV OF SCI & TECH BEIJING

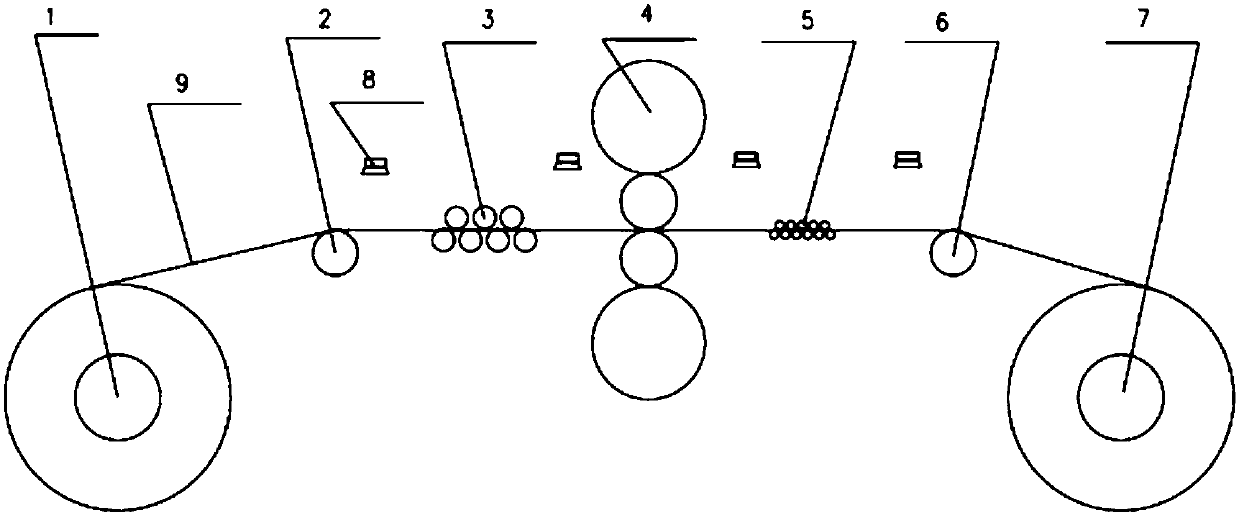

High-strength strip steel straightening, flattening and straightening process

ActiveCN107838199AReduce loadEasy to shapeProfile control deviceMetal rolling arrangementsStrip steelResidual stress

The invention discloses a high-strength strip steel straightening, flattening and straightening process. The high-strength strip steel straightening, flattening and straightening process is characterized in that a hot rolling high-strength steel plate or strip steel sequentially passes through an inlet straightening machine, a temper mill and an outlet straightening machine, and by means of the combined working procedures of straightening, flattening and straightening, the adjustment of the plate shape, the surface quality, the mechanical performance and the residual stress of the strip steelis completed; the inlet straightening machine is used for conducting rough straightening on the strip steel, on the one hand, the plate shape of the supplied material is improved, and on the other hand, the scale on the surface of the strip steel is reduced; the temper mill is used for conducting flattening on the strip steel, the plate shape of the strip steel is improved, the mechanical performance of the strip steel is adjusted, and the surface quality of the strip steel is improved; and the outlet straightening machine is used for conducting precise straightening on the strip steel, the unquenched plate shape problems and newly-generated plate shape problems in the flattening process are solved, and the unquenched residual stress and newly-generated residual stress in the flattening process are eliminated.

Owner:WISDRI ENG & RES INC LTD

Roll gap control method for continuous casting machine by adopting stress as control target

The invention relates to a roll gap control method for a continuous casting machine by adopting stress as a control target, which belongs to the technical field of continuous casting in the metallurgy industry. The technical scheme includes that pressure sensors arranged in segments are used for detecting the stress of the segments, the roll gap of the continuous casting machine is controlled by adopting the stress of each segment as the control target, the stress target value of each segment is set before steel casting, the segment contracts the roll gap when a practical stress value is smaller than the target value during steel casting, and the segment releases the roll gap when the practical stress value is larger than the target value during steel casting. The roll gap control method has the advantages that the method solves the problems of drifting of a displacement sensor and the like which cannot be solved by a traditional roll gap control method adopting displacement as a control target, the internal quality of a casting blank is obviously improved, quality defects such as loosening, segregation and the like are decreased, the quality stability of the casting blank is improved, segregation and loosening of the casting blank can be completely controlled within C-type 2.0, and roll consumption of the segments can be reduced by about 50%.

Owner:HEBEI IRON & STEEL GRP

Cold rolling oil composition and use thereof

The invention relates to a cold rolling oil composition and use thereof, which is mainly used for solving the problems of heavy oil mist in a workshop after rolling as well as poor surface cleanness and poor annealing cleanness after rolling in the prior art. The cold rolling oil composition comprises the following components in parts by weight: a) 1-20 parts of aromatic acid diester, b) 1-25 parts of fatty acid monoester, c) 0.01-5 parts of a fog resistant agent and d) 50-97.99 parts of base oil; and the structural formula of the aromatic acid diester is shown in the specification, wherein R1 and R2 are chosen from alkyl groups with 3-8 carbon atoms. By means of the technical scheme, the problems are better solved; and the cold rolling oil composition can be applied to industrial production of stainless steel thin plates with 2B and BA high-precision grades.

Owner:CHINA PETROLEUM & CHEM CORP

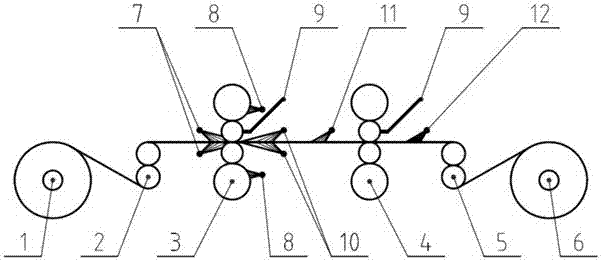

Ultrathin uncoated tinplate base high elongation percentage wet leveling technological equipment and method

PendingCN107309272AImprove deformationFulfil requirementsWork cleaning devicesMetal rolling arrangementsTinningEmulsion

The invention provides ultrathin uncoated tinplate base high elongation percentage wet leveling technological equipment and a method. By arranging a leveling liquid system taking a low-concentration emulsion as a medium in a two-stand leveling unit, the wet leveling elongation percentage of strip steel is raised substantially; by reasonably arranging a splashing prevention device, the splashing of leveling liquid is effectively prevented; equipped with an alkali liquor washing system and a strip steel cleaning system, the surface of the strip steel is subjected to alkali liquor washing and soft water cleaning, so that the leveling liquid remained on the surface of the strip steel is cleaned, and spots of the leveling liquid are effectively controlled; by adopting a curtain wall air knife type air knife blowing system, high-output and low-noise efficient blowing is realized; and equipped with a hot air drying system, surface cleanness and dryness of the strip steel are guaranteed. By adopting the leveling liquid system taking the low-concentration emulsion with the concentration being 0.5-1.5% as the medium, the elongation percentage and the antirust capability of the strip steel are raised and improved significantly, steel plate deformation is improved substantially and the elongation percentage can reach 5-10%, the high elongation percentage wet leveling can repair and cover a part of surface defects, and thus the plate surface quality and the product overall quality are improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

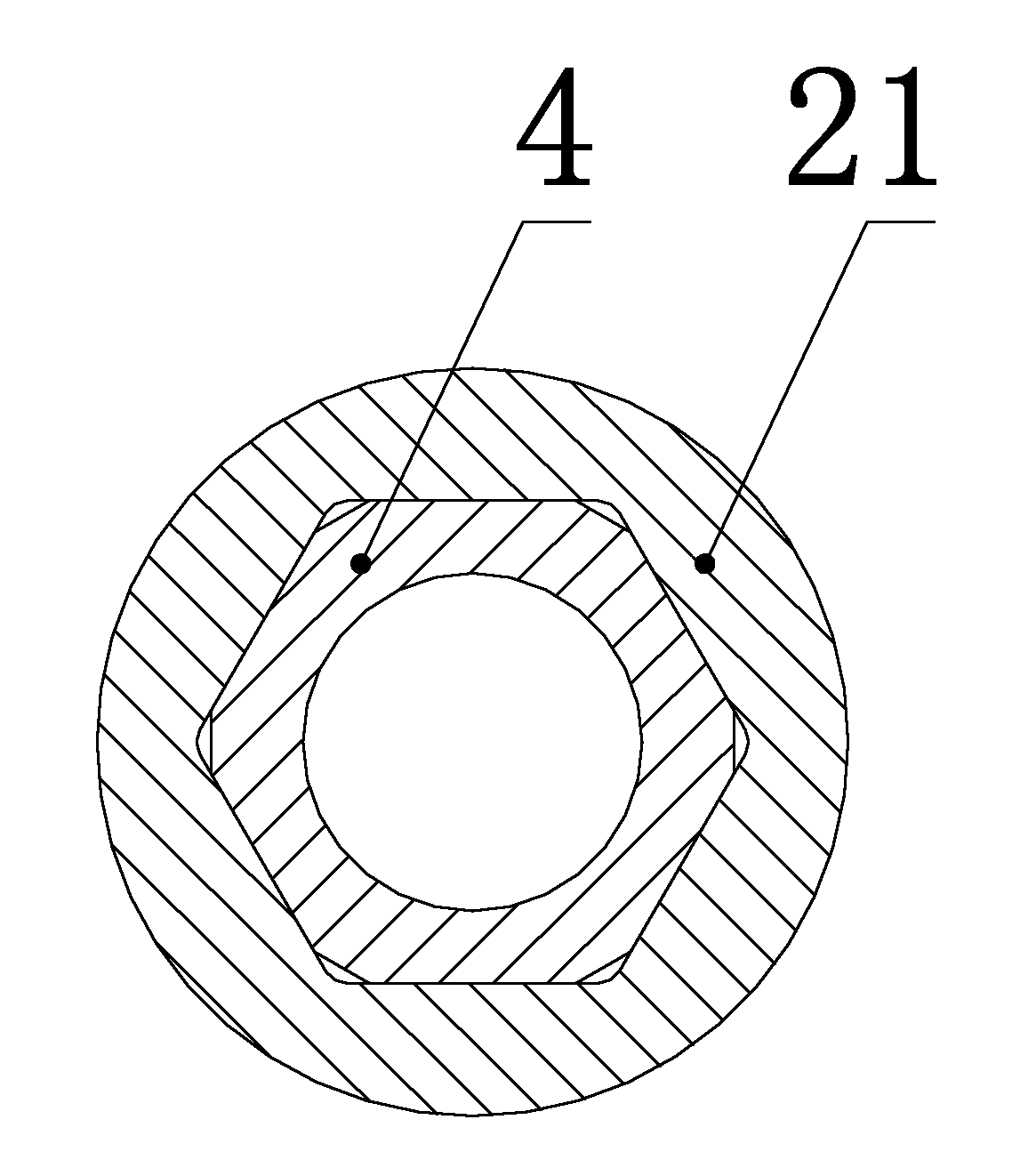

High-speed steel composite roller and production method thereof

ActiveCN106140819AHigh hardnessLow costRollsMetal rolling arrangementsDuctile ironUltimate tensile strength

The invention discloses a high-speed steel composite roller and a production method thereof. The high-speed steel composite roller comprises a roller shell and a mandrel, wherein the roller shell is composed of a high-speed steel layer and a plain carbon steel layer located in the high-speed steel layer in a composite mode, and the mandrel is made of forged steel. The assembling faces of the roller shell and the mandrel are in conical fit with the ratio of 40:1, and the assembling end of the mandrel and the matching face of the roller shell are locked through four to six countersunk bolts used as keys. According to the roller shell, part of high-speed steel is replaced by plain carbon steel, and the production cost of the roller is greatly lowered while the strength and abrasion resistance of the roller shell are guaranteed; the mandrel and the roller shell are detachably connected and can be repeatedly used, so that the production cost of the roller is further lowered; and the mandrel is made of the forged steel instead of nodular cast iron, the strength of the mandrel is improved, and the service life of the roller is prolonged.

Owner:辽宁省亿联盛新材料有限公司

Process for manufacturing large high-chromium medium-carbon alloy forging back-up rolls

The invention relates to a process for manufacturing large high-chromium medium-carbon alloy forging back-up rolls. The process includes the steps: firstly, forging a blank after smelting alloy steel and annealing the forged blank; secondly, performing rough turning, semi-fine turning and fine turning; and thirdly, polishing the forged blank to obtain a finished product. The large back-up rolls are manufactured by means of advanced full-automatic numerical control differential-temperature integral quenching heat treatment process, the hardening depth of each large back-up roll reaches and exceeds 100 millimeters, hardness uniformity of roll bodies is within two Shore hardness units, and the weight of a single roll exceeds that of each large back-up roll of 25 tons. The practical service lift of the rolls is greatly prolonged, roll consumption is reduced, production cost is saved, and high-precision wide strips with even and smooth rolled plate surfaces can be used for automobile manufacture, space shuttle and national defense industry.

Owner:CHANGZHOU ECCO ROLLER

Intermediate roller contour of intermediate roller movable type convexity high-accuracy control temper mill

InactiveCN102107214AReduced contact pressure distributionUniform contact pressure distributionRollsMetal rolling arrangementsContact pressureMovable type

The invention relates to an intermediate roller contour, in particular to an intermediate roller contour of an intermediate roller movable type convexity high-accuracy control temper mill. The intermediate roller contour of the intermediate roller movable type convexity high-accuracy control temper mill consists of three continuous line segments, wherein a polynomial curve equation of a head roller contour is y=A2x<2>+A4x<4>+A6x<6>+A8x<8> by taking a crossing point of a head part and an intermediate segment as an origin of coordinates, axial direction of the intermediate roller as an X axis and radial direction of the intermediate roller as a Y axis; and in the equation, the origin of coordinates is the crossing point of the head roller contour and the intermediate segment, the axial direction of the intermediate roller is the X axis, the radial direction of the intermediate roller is the Y axis, R' is radius difference between roller bodies of two roller-shaped ends of the head, and L1 is more than 0 and less than or equal to L / 3 and the R' is more than 0 and less than R. Through the roller contour, a forced-contact condition is greatly relieved, contact pressure between rollers is uniformly distributed, a peak value of the contact pressure is greatly reduced, the improvement on the service periods of the rollers is facilitated, a set value of rolling force is reduced, the service life of the rollers is prolonged, and the risk of roller spalling is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Method for rolling large-size square steel by single machine frame without groove

ActiveCN101024227AIncrease profitReduce manufacturing costMetal rolling arrangementsEngineeringLarge size

The invention discloses single frame non slot rolling large size square steel method. It adopts big delivery head two-high reversing blooming mill system. Each of blank side is repeatedly made into roller pressing underside and free spread side, processed reciprocating many passes non slot rolling by the horizontal mill to form finished product. It uses critical percent of reduction control method to control the size of the single and double drum ratio in the approved range, control width to height ratio to remove rolling off square. Thus the invention can reduce pass positioning, produce the large square steel product with high quality and flexible size by using non slot rolling technique.

Owner:BAOSHAN IRON & STEEL CO LTD

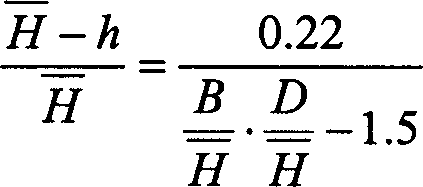

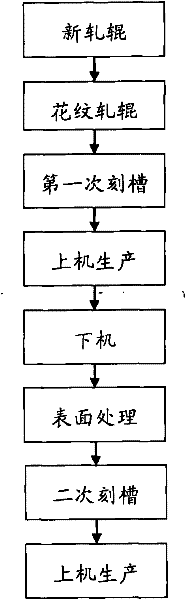

Patterned roller repairing method

The invention provides a patterned roller repairing method. The patterned roller repairing method comprises the following steps of: carrying out surface treatment on the patterned roller; and secondarily indenting the surface-treated patterned roller at the position of the traditional flute of the patterned roller. The patterned roller repairing method can be used for reducing the consumption of the patterned roller and prolonging the service life of the patterned roller, thereby greatly decreasing the production cost.

Owner:攀钢集团西昌钢钒有限公司

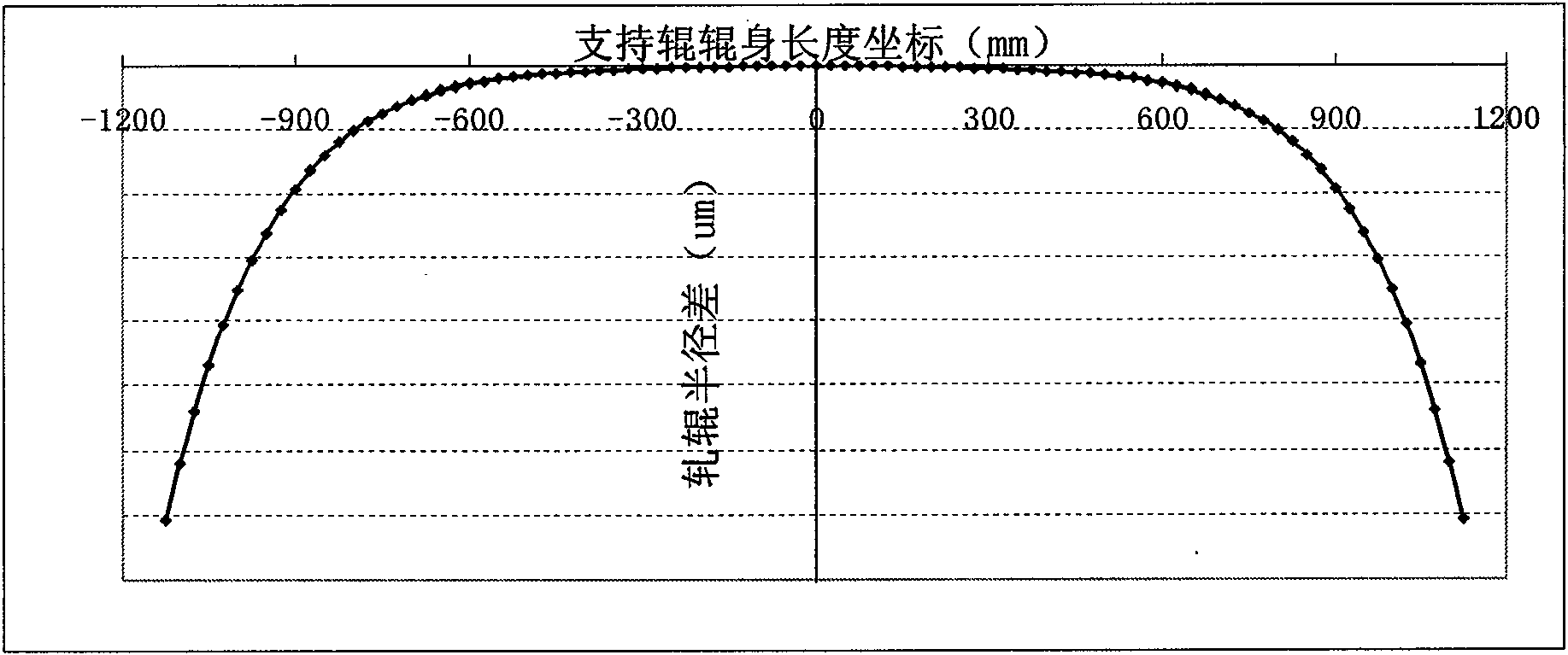

Composite supporting roll for hot-continuous rolling wide-strip-steel four-roll mill

InactiveCN102716911AReduce stress concentrationImproved contact stress distributionCounter-pressure devicesMetal rolling arrangementsStress concentrationStress distribution

The invention discloses a composite supporting roll for a hot-continuous rolling wide-strip-steel four-roll mill, and belongs to the technical field of steel rolling. The roll-shaped curve description equation of the composite supporting roll is as follows: R(x)=b6x6+b5x5+b3x3+b2x2+b1x+b0. The composite supporting roll disclosed by the invention has the advantages that when being matched with a CVC roll-shaped working roll for use, the stress concentration among rolls can be eliminated, contact stress distribution among the rolls is improved, the problems of non-uniform wearing and peeling of the rolls due to stress concentration are solved, and further the quality of the plate shape is improved while reducing the roll consumption.

Owner:SHOUGANG CORPORATION

Functional layer alloy powder and method for repairing finish-rolling descaling box pinch roller through laser cladding

ActiveCN109576603AGuaranteed wear resistanceGuaranteed stabilityMetallic material coating processesThermal fatigueAlloy

The invention provides functional layer alloy powder for repairing a finish-rolling descaling box pinch roller through laser cladding. The functional alloy powder is composed of the components, by mass percentage, of 2-15 % of TiC powder, 0.1-1.1 % of C, 2.0-5.0 % of Si, 3-6 % of B, 5-10 % of Cr, 1-5 % of Ni, and the balance Fe. Meanwhile, the invention provides a method for repairing the finish-rolling descaling box pinch roller through laser cladding, the size of an original roller can be restored by repairing the finish-rolling descaling box pinch roller through the method, properties of the high-temperature wear resistance and the thermal fatigue resistance are improved, the repair cost is reduced, and the service life of the finish-rolling descaling box pinch roller is prolonged, so that the roller consumption is reduced and the production cost of enterprises is reduced.

Owner:沈阳大陆激光工程技术有限公司

Press roll for pressing secondary battery electrode and producing process thereof

InactiveCN102181799AHigh hardnessImprove wear resistanceElectrode manufacturing processesIncreasing energy efficiencyTungstenLanthanum

The invention relates to a press roll for pressing a secondary battery electrode and a producing process thereof, belonging to the technical field of mechanical manufacture and electrochemical power sources. The producing process of the press roll used for pressing the secondary battery electrode comprises the following steps of: performing a molding process on raw materials, namely rare earth alloy containing carbon, molybdenum, chromium, nickel, tungsten, silicon, manganese and lanthanum series and ferrous electroslag remelting steel ingots; heating and then forging and pressing to form a press roll blank by using a hydraulic press; performing balling heat treatment, performing furnace cooling, then raising the temperature, performing homeothermy to constant temperature; and finally performing postprocessing. In the invention, an ultradeep quenching treatment method is adopted, the treatment depth ranges from 10mm to 15mm below the surface of the press roll, thereby the hardness of the press roll is increased, the strength is improved, and high-precision electrode pressing is ensured; and the press roll produced by using the method has the advantages of high hardness, high strength and good wear resistance, can be widely applied to various precision presses, saves use cost, improves product quality and increases production efficiency.

Owner:珠海市光环自动化科技有限公司

Roll allocation method and device for optimization of roll pass system

InactiveCN103586284AReduce in quantityReduce occupancyGuiding/positioning/aligning arrangementsWork treatment devicesEngineeringWorkload

The invention provides a technical scheme of a roll allocation method and device for optimization of a roll pass system. The scheme comprises three types of rolls with the specifications of phi 610*760, phi 770*1000 and phi 860*1200, a guide mechanism used for guiding steel materials and a cooling mechanism used for cooling the steel materials. The roll allocation method and device for optimization of the roll pass system are characterized in that the three specifications of rolls are semi-steel rolls with the carbon content of 1.6%, each of the three specifications of rolls is additionally provided with a roll groove on the premise that the safety factor of roll rings is 0.6-0.9, and the section area of each roll groove is smaller than or equal to the section area of original roll grooves of the three specifications of rolls. Meanwhile, in order to adapt to the variation of the roll grooves of the rolls, the guide mechanism and the cooling mechanism are modified, the single-groove rolling amount of the rolls is largely improved, and the problems of low work efficiency and heavy workloads on technical personnel caused by frequent replacement of the rolls are avoided.

Owner:SHANDONG XIWANG SPECIAL STEEL

Rolling mill laser deviation preventing device

InactiveCN108994093AReduce roll consumptionReduce quality lossGuiding/positioning/aligning arrangementsLaser transmitterEngineering

The invention relates to a rolling mill laser deviation preventing device. The rolling mill laser deviation preventing device is provided with a fixed vertical column. A base is arranged on the fixedvertical column. Two supports are arranged side by side on the base. A horizontally arranged guide slide bar is arranged between the two supports. A feed screw rod is arranged parallel to the guide slide bar. The two ends of the feed screw rod are arranged on the two supports through bearings respectively. The position of the feed screw rod is higher than the height of the guide slide bar. A handwheel is also arranged at one end of the feed screw rod. A screw rod seat is connected to the feed screw rod in a threaded mode. The outer wall of the screw rod seat is also provided with a sliding sleeve. The sliding sleeve sleeves the guide slide bar and slides along the guide slide bar for adjustment. The screw rod seat is also provided with a laser transmitter. A laser beam emitted by the laser transmitter is used for aligning with the side line of strip steel to be rolled. The rolling mill laser deviation preventing device can reduce roller consumption and mass loss, and can realize stripsteel width 700-1260mm free conversion and monitoring, simple overhaul, maintenance and adjustment. The equipment is durable.

Owner:宝钢股份黄石涂镀板有限公司

Control method for reducing transverse thickness difference of hot-rolled strip steel

ActiveCN111389925AImprove the transverse thickness plate shape indexReduce roll consumptionRoll force/gap control deviceRollsStructural engineeringStrip steel

The invention discloses a control method for reducing the transverse thickness difference of hot-rolled strip steel. Rolling control process parameters are designed by control over the thickness of acontinuous casting machine plate blank, configuring of finish rolling high-speed steel, roller cooling, the working roller channeling stroke, the vertical roller side pressure and the oil mass of rolling oil, so that the purpose of reducing the transverse thickness difference of the hot-rolled strip steel is achieved. Transverse thickness plate shape indexes of hot-rolled silicon steel raw materials can be remarkably increased, the silicon steel sheet 7u intra-plate difference precision is improved from 90% to 93%, and the 5u intra-plate difference precision is improved from 40% to 80%. On thepremise of guaranteeing the plate shape indexes, the rolling period is prolonged from 800 tons to 1,800 tons, and the roller consumption during silicon steel rolling is remarkably reduced.

Owner:武汉钢铁有限公司

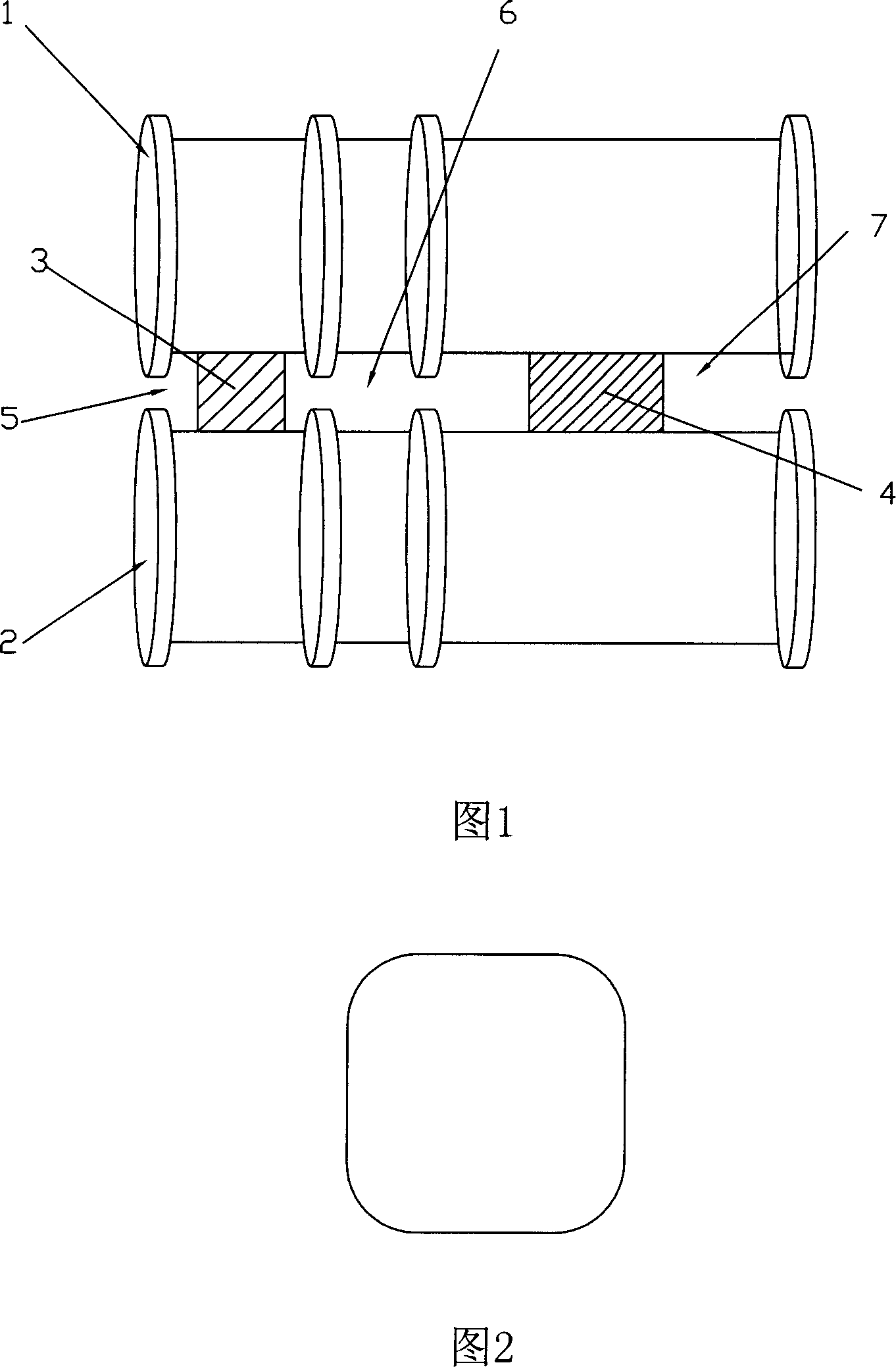

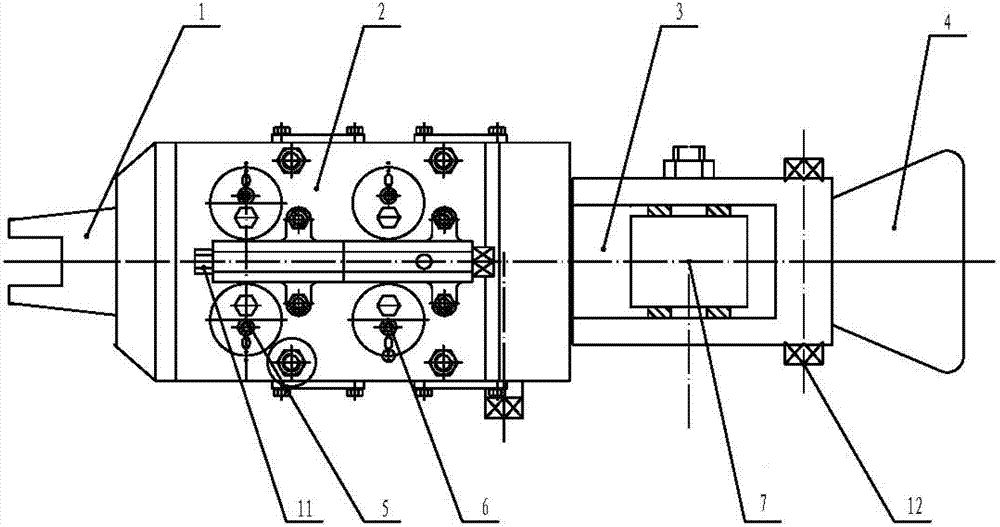

Large-space hole-free rolling device and rolling method of bar production line

ActiveCN102896147AEasy to replaceAvoid shiftingGuiding/positioning/aligning arrangementsCooling bedsProduction lineMetal machining

The invention discloses a large-space hole-free rolling device and a rolling method of a bar production line. The rolling device comprises a box body, wherein the box body is installed on a base; a horizontal roller bracket is arranged at one end of the box body; a guide point is arranged at the other end of the box body; a vertical guide roller is arranged on the box body; a horizontal guide roller is arranged on the horizontal roller bracket; and a horn mouth is connected with the horizontal roller bracket. The rolling method comprises the following steps of: heating, reserving a distance of 38m-45m between a rolling machine group and a fine rolling machine group, cooling and finishing. The rolling production line cn be used for implementing production successfully, adopts a high-technical production technique, breaks through the bottleneck of hole-free rolling, lays basic theories for industrial large-scale production, and improves theories of metal machining deformation in China. The rolling device is high in rolling capacity and low in production cost. Rolling rollers can be repeatedly used, so that the rolling roller consumption is reduced; the production operation efficiency and the production capacity are improved; the power consumption of a motor is reduced; and the market competitiveness of enterprises is improved.

Owner:西安盛日机电科技有限公司

Hollow roll for roller way

InactiveCN101830343AFor quick maintenanceQuality improvementRollersProduction lineMaterials processing

The invention relates to a transportation roller way for sectional material processing, in particular to a hollow roll for a roller way. The hollow roll comprises a roll body (1), a driving side extremity piece (2), a driven side extremity piece (3), a driving side spindle head (6) and a driven side spindle head (8), wherein the driving side extremity piece (2) and the driven side extremity piece (3) are respectively located at two ends of the roll body (1) through grafting type coordination, and the roll body (1), the driving side extremity piece (2) and the driven side extremity piece (3) are detachably and fixedly connected into a whole; the grafting type coordination is formed by a plug (4) and a slot which are coordinated. The invention can realize the rapid maintenance of the roller way, improve the quality of the surface of a rolled piece, reduce the maintenance time, and increase the utilization ratio of a rolling production line and the yield of the sectional material. The replaced roll body is maintained offline and is not influenced by time and fields, which can ensure the quality of the maintained roll body and the surface thereof, thereby the roll consumption is reduced. The invention is suitable for various transportation roller ways.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

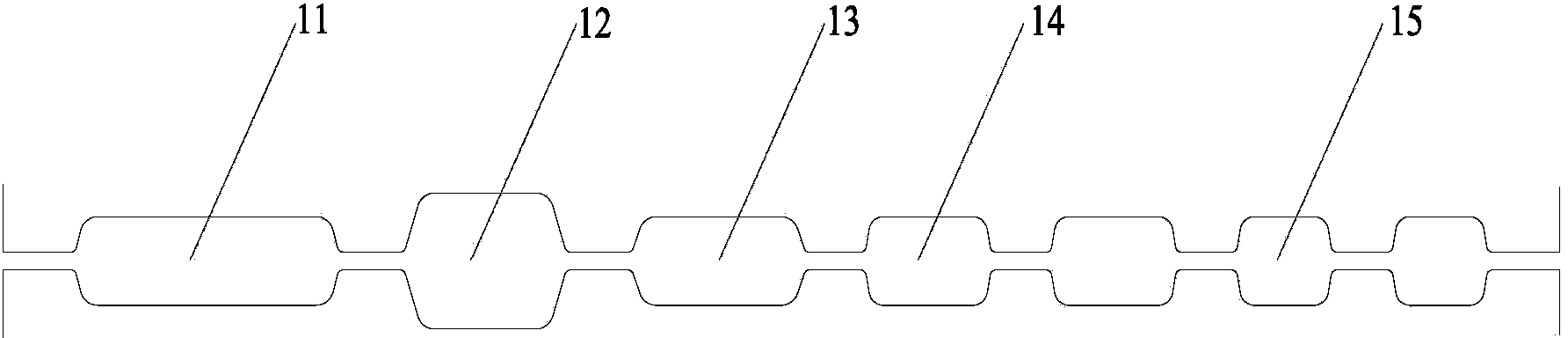

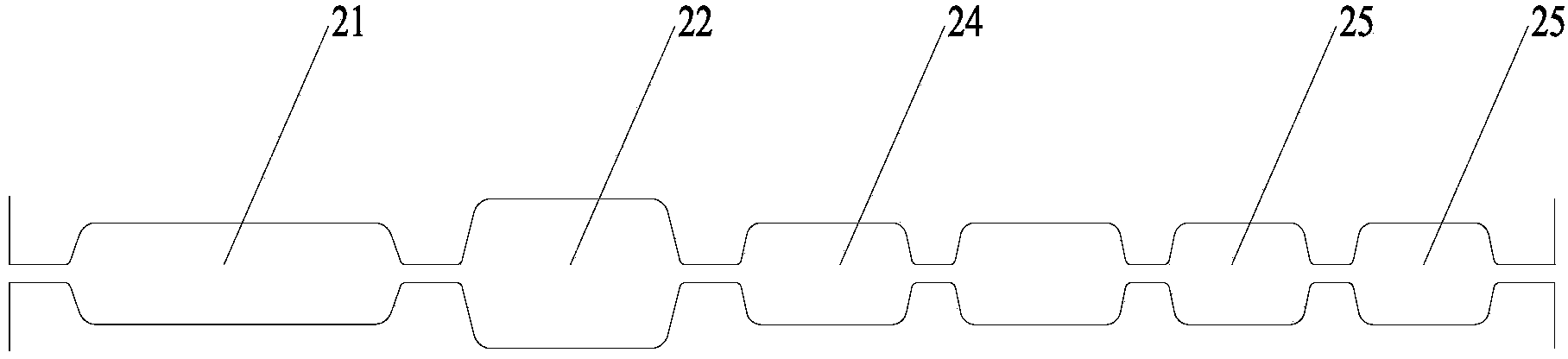

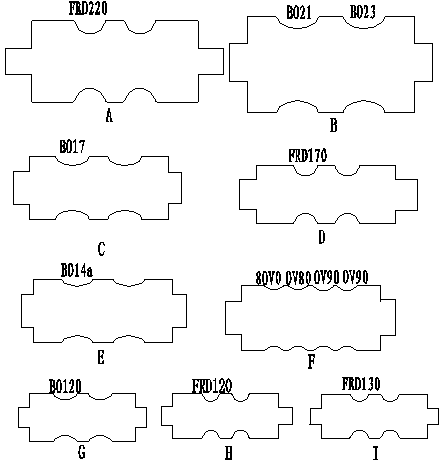

Checkered plate roller and using method thereof

InactiveCN104707886AOptimization parametersAdd depthRollsMetal rolling arrangementsEngineeringLens esculenta

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Method for configuring shape of supporting roll of four-high mill and shape of working roll thereof

ActiveCN101554635BQuality improvementSurface peeling solutionCounter-pressure devicesRollsStress concentrationWork roll

The invention relates to a method for configuring the shape of a supporting roll of a four-high mill and the shape of a working roll thereof, belonging to the technical field of steel rolling. According to three types of width specifications of band steel which are most rolled by hot-rolling band steel production line, sixth-power polynomial supporting roll shape technology and second-power working roll shape curve are used for configuration so as to lead the contact length of the supporting roll and the working roll and the width of the rolled band steel to be fit. The method has the advantages of eliminating hazardous contact areas in which the parts of the two ends of the supporting roll with the flat roll shape and the working roll expand out of the edge of the band steel to generate large deflection and deformation, solving the problems that the stress concentration of the edges of the supporting roll and the working roll in a hot continuous mill for wide band steel causes stripping and the mill roll with the flat roll shape has large wearing capacity and is not even, reducing the consumption of the mill rill, saving energy, reducing consumption and reducing cost for rolling steel; and by the technical configuration of R2 working roll shape and the supporting roll shape, the invention solves the plate-shape problems that the middle blank generates negative convexity and the wedge shape is large, and improves the control precision of the shape of hot-rolled band steel.

Owner:SHOUGANG CORPORATION

Method for processing profiled bar with asymmetrical cross section

InactiveCN103386416AImprove rolling conditionsRolling realizationMetal rolling arrangementsWork in processEngineering

The invention discloses a method for processing a profiled bar with an asymmetrical cross section. The method is characterized in that a to-be-rolled profiled bar with the asymmetrical cross section is subjected to mirror pairing and combining in the direction of a vertical axis (Y axis), converting the asymmetrical cross section into a symmetrical cross section, improving the rolling condition, then rolling the bar with a symmetrical cross section by a four-roll universal mill, and finally dissecting the rolled semi-finished product with the symmetrical cross section by a metal dissecting device, so as to obtain two qualified finished bars which have the asymmetrical cross sections and are the same in size and shape. The method has the advantages that the rolling condition of the profiled bar with the asymmetrical cross section is improved, so the rolling by the four-roll universal mill is realized; and the rolling speed is high, the rolling efficiency is high, and the production capability is greatly improved.

Owner:钱奕峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com