Two-roller reversible mill roller device and technology using continuous casting round billets for carrying out rolling production

A technology of continuous casting round billet and roll device, which is applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of less than 40% yield, limited billet size, low production efficiency, etc., and achieves good product quality and performance. , The effect of high dimensional accuracy of products and high dimensional accuracy of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

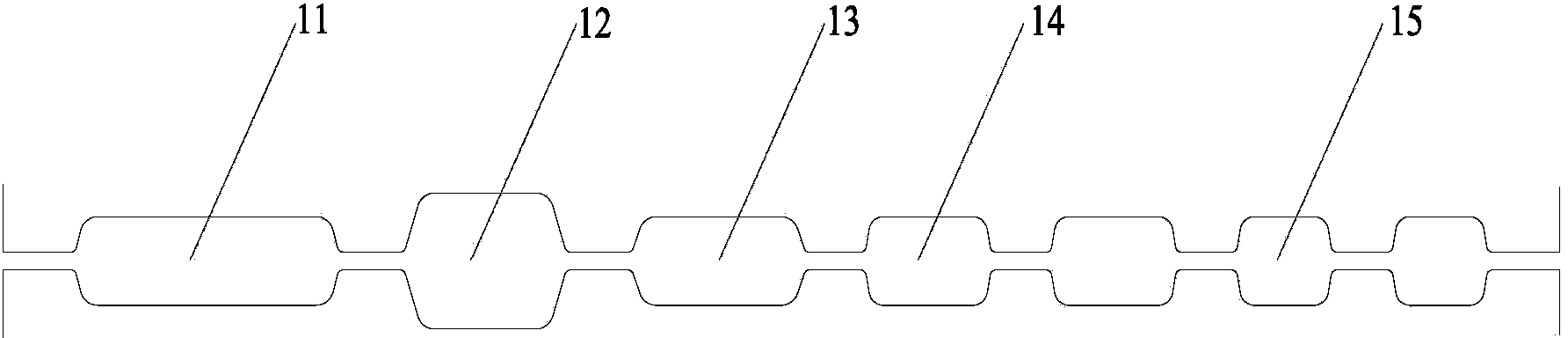

[0033] Such as figure 2 As shown, this embodiment describes the pass design and rolling process for producing 200X200 and 150X150 square steel using Φ380mm continuous casting round billet. The complete process is: billet-heating-high-pressure water dephosphorization-transition pass 1 Rolling-Two-roll reversible rolling mill Front turning steel hook turning steel-Supporting pass 2 Rolling-Two-roll reversing rolling mill Front turning steel hook turning steel-Front pass of finished product 3 Rolling-Two-roll reversing mill Front turning steel hook turning steel - Finished pass 4 rolling - cut to length - cooling - finishing - storage. The material of the billet in this embodiment is 42CrMo, the diameter of the roll used is 1150mm, the length of the roll body is 2600mm, the speed of the roll is 0-50 / 120rpm, and the rolling temperature of the billet is 1150°C. Each pass on the roll is arranged with 7 slots according to the length of the roll body, two 200X200 and 150X150 finishe...

Embodiment 2

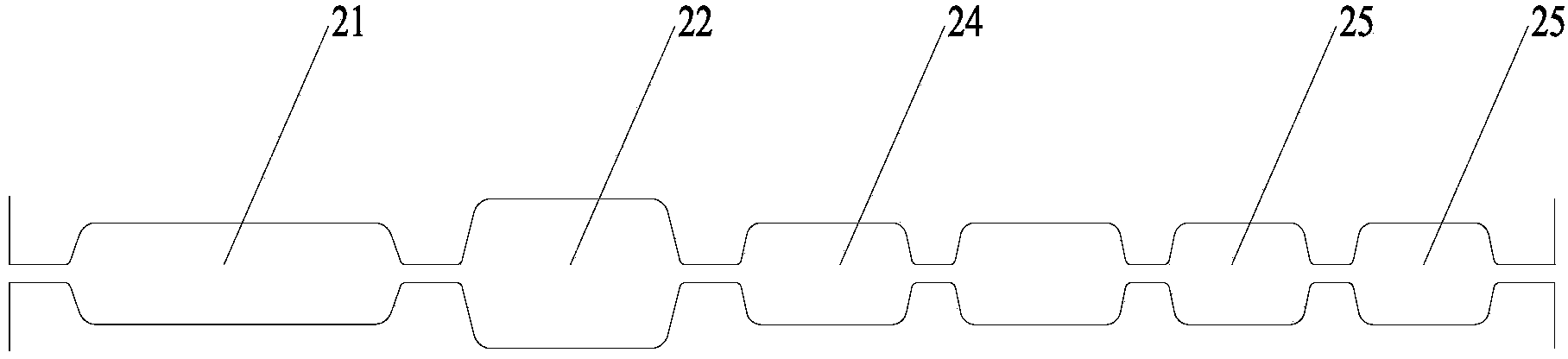

[0050] Such as image 3 As shown, this embodiment describes the pass design and rolling process for producing 270X270 and 220X220 square steel by using Φ500mm continuous casting round billet. The complete process is: billet-heating-high-pressure water dephosphorization-transition pass 21 Rolling-Two-roll reversible rolling mill Front turning hook turning steel-Support pass 22 Rolling-Two-roll reversing mill Front turning steel hook turning steel-Transition pass 1 Rolling-Two-roll reversing mill Front turning steel hook turning steel- Finished pass 4 rolling - cut to length - cooling - finishing - storage. The material of the billet in this embodiment is 40Cr, the diameter of the roll used is 1150 mm, the length of the roll body is 2600 mm, the speed of the roll is 0-50 / 120 rpm, and the rolling temperature of the billet is 1150°C. According to the length of the roll body, 6 slots are arranged on the roll, two 270X270 and 220X220 square steel finished slots, and the 270X270 fin...

Embodiment 3

[0065] Such as Figure 4 As shown, this embodiment describes the pass design and rolling process for producing 320X320 and 270X270 square steel by using Φ600mm continuous casting round billet. The complete process is: billet-heating-high-pressure water dephosphorization-transition pass 1 Rolling-Two-roll reversible rolling mill Front turning steel hook turning steel-Supporting pass 2 Rolling-Two-roll reversing rolling mill Front turning steel hook turning steel-Front pass of finished product 3 Rolling-Two-roll reversing mill Front turning steel hook turning steel - Finished pass 4 rolling - cut to length - cooling - finishing - storage. The material of the billet in this embodiment is 40Cr, the diameter of the roll used is 1150 mm, the length of the roll body is 2600 mm, the speed of the roll is 0-50 / 120 rpm, and the rolling temperature of the billet is 1150°C. According to the length of the roll body, there are 5 hole slots arranged on the roll, two 320X320 finished slots, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com