High-speed steel vertical roll ring and its preparation method

A high-speed steel and roll ring technology, applied in the direction of rolls, manufacturing tools, metal rolling, etc., can solve the problems of large wear on the surface of roll rings, poor quality of rail surface products, and small amount of steel passing through, and achieve wear resistance and passing through The effect of increasing the amount of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

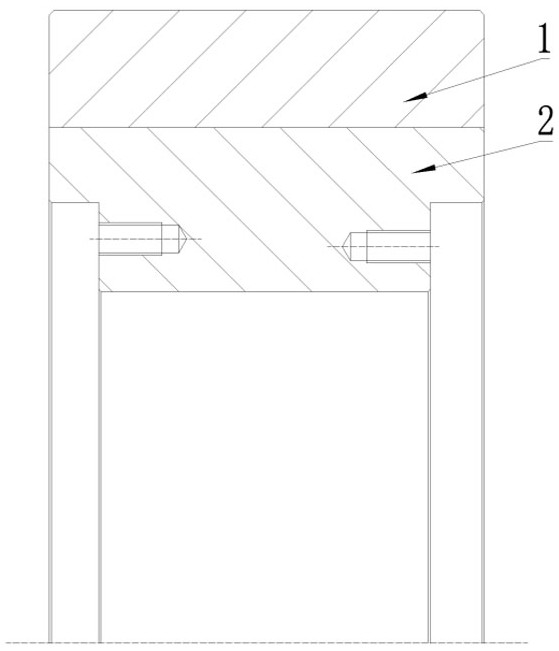

[0025] A method for preparing a high-speed steel vertical roll ring, comprising the following steps: Step 1: Prepare a rolled roll ring 1 by centrifugal casting; Step 2: Prepare a transmission roll ring 2 by static casting; Step 3: Roll the ring The assembly surface of the roll ring 1 and the drive roll ring 2 is finished, and then the rolling roll ring 1 is interference-fitted on the drive roll ring 2 to form a roll ring blank; step 4: process the roll ring blank to a finished product.

[0026] According to an embodiment of the present invention, the step 1 includes the following steps: S10, smelting 1: add a certain proportion of steel scrap, ferrochromium, ferromolybdenum, ferrovanadium, ferrotungsten, and ferrocobalt into the intermediate frequency furnace and melt the molten steel for rolling , heating the rolled molten steel to 1600-1650°C and keeping it warm for 10 minutes; S11, treatment outside the furnace: when the temperature of the rolled molten steel is lowered to ...

Embodiment 1

[0033] Prepare a 550 / 305×220mm hot-rolled 200*100H-shaped steel vertical roll ring, the target content of the rolling roll ring 1: C is 1.2-1.6%, Si is 1.0-1.5%, Mn is 0.3-0.8%, and Cr is 3.5-4.0%, Mo is 4.5-5.0%, V is 1.5-2.0%, W is 4.5-5.0%, Co is 1.5-2.0%, and the rest is Fe and unavoidable impurities. The driving roller ring 2 is obtained by integral static casting of high-toughness ferritic nodular cast iron. The chemical composition and percentage content of the driving roller ring 2 are 2.7-3.0% for C, 2.5-3.0% for Si, and 0.3-3.0% for Mn. 0.8%, Mg is 0.04-0.1%, and the rest is Fe and unavoidable impurities.

[0034] 1) Smelting: Add a certain proportion of steel scrap, ferrochrome, ferromolybdenum, ferrovanadium, ferrotungsten, and ferrocobalt into the intermediate frequency furnace, so that the chemical composition and weight percentage of the rolled molten steel meet the composition requirements before being released from the furnace: C is 1.4% , Si is 1.1%, Mn is 0...

Embodiment 2

[0043] Prepare a 460 / 280×180mm hot-rolled 150*100H-shaped steel vertical roll ring. The target content of the rolled roll ring 1: C is 1.2-1.6%, Si is 1.0-1.5%, Mn is 0.3-0.8%, and Cr is 3.5-4.0%, Mo is 4.5-5.0%, V is 1.5-2.0%, W is 4.5-5.0%, Co is 1.5-2.0%, and the rest is Fe and unavoidable impurities. The driving roller ring 2 is obtained by integral static casting of high-toughness ferritic nodular cast iron. The chemical composition and percentage content of the driving roller ring 2 are 2.7-3.0% for C, 2.5-3.0% for Si, and 0.3-3.0% for Mn. 0.8%, Mg is 0.04-0.1%, and the rest is Fe and unavoidable impurities.

[0044] 1) Smelting: Add a certain proportion of steel scrap, ferrochrome, ferromolybdenum, ferrovanadium, ferrotungsten, and ferrocobalt into the intermediate frequency furnace, so that the chemical composition and weight percentage of the rolled molten steel meet the composition requirements before being released from the furnace: C is 1.55% , Si is 1.11%, Mn is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com