Rolling mill laser deviation preventing device

A laser and rolling mill technology, which is applied in the field of laser anti-deviation devices for rolling mills, can solve problems such as deviation, broken belts, damaged rolls, and large losses, and achieve the effects of reducing roll consumption, simple adjustment, and reducing quality loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

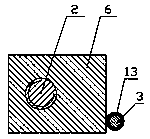

[0015] see figure 1 , figure 2 , the present invention is a laser anti-deviation device for rolling mills, which has a fixed column 9, a base 8 is provided on the fixed column, two supports 1 are arranged side by side on the base, and a horizontally arranged The guide slide bar 3 is provided with a feed screw rod 2 parallel to the guide slide bar, and the two ends of the feed screw rod are respectively erected on two supports through bearings, and the position of the feed screw rod is higher than the guide slide bar Height, one end of the feed screw rod is also provided with a hand wheel 7; the feed screw rod is also threaded with a threaded rod seat 6, and a sliding sleeve 13 is also provided on the outer wall of the screw rod seat, and the sliding sleeve is set on the guide slide rod. and slide adjustment along the guide slide bar, a laser emitter 5 is also housed on the screw mandrel seat, and the laser beam 10 sent by the laser emitter is used to align the strip steel 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com