Hollow roll for roller way

A hollow roller and roller table technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity of operators, large number of welding and repairing rollers, and reducing the yield of steel rails, so as to reduce maintenance time. , Improve the surface quality, reduce the effect of roller consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

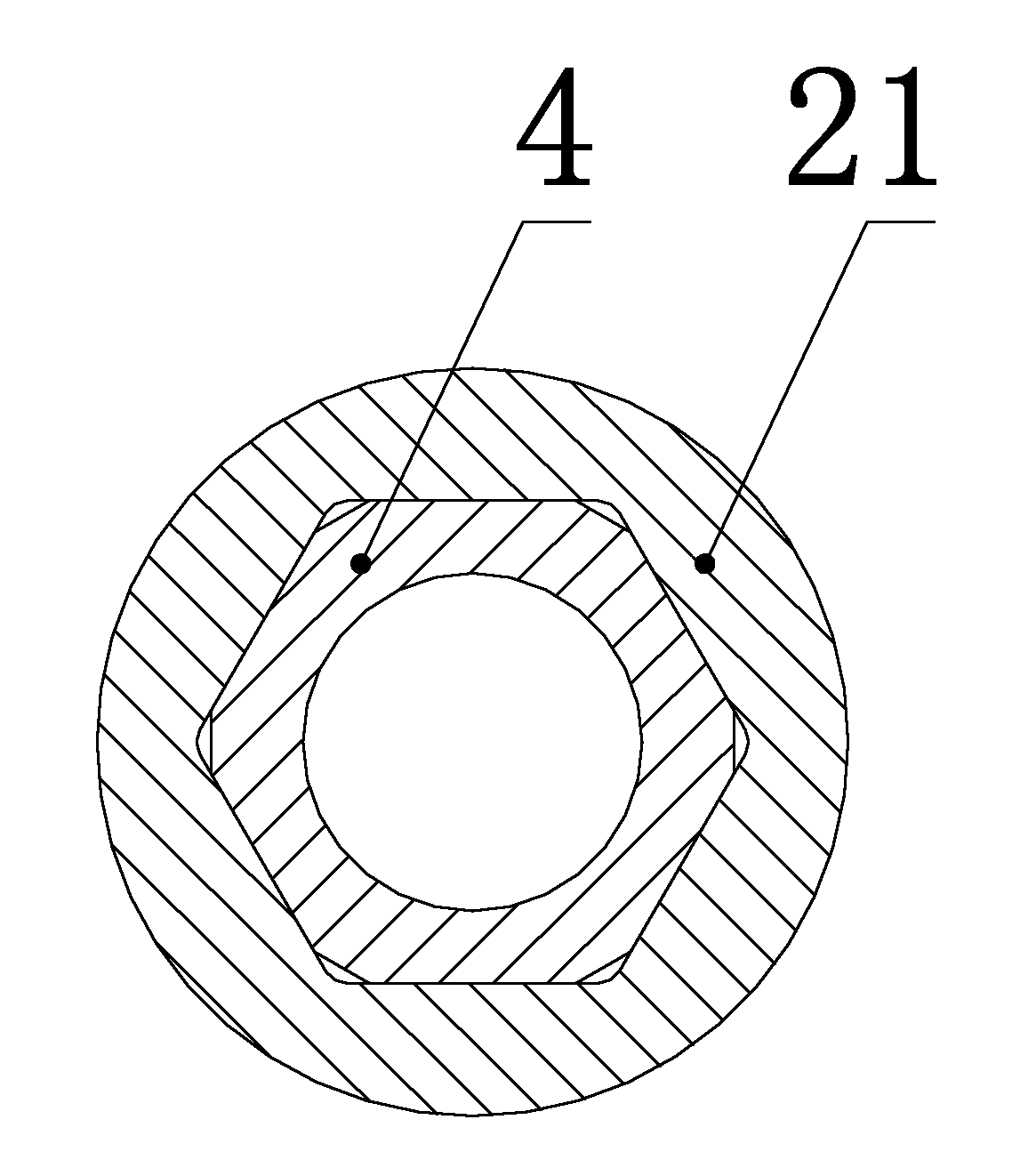

[0021] like figure 1 , figure 2 , image 3 As shown, the hollow roller used for the roller table of the present invention is composed of a roller body 1, a driving side end piece 2, a driven side end piece 3, a driving side shaft head 6, and a driven side shaft head 8. The end piece 2 and the driven-side end piece 3 are respectively positioned at both ends of the roller body 1 through plug-in fit, and the roller body 1, the driving-side end piece 2 and the driven-side end piece 3 are connected as a whole through a detachable fixed connection; The plug fit consists of a mating plug 4 and a socket.

[0022] The wear of the rollers of the roller table is mainly concentrated on the roller body 1, so the transmission side end piece 2, the driven side end piece 3 and the transmission side shaft head 6, the driven side shaft head 8 are still fixed by weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com