Double-tube fully-hydraulic braking device with closed wet-type multi-disc brakes for coal mine explosion-proof vehicle

A technology for explosion-proof vehicles and braking devices, applied in the direction of hydraulic brake transmission devices, etc., can solve the problems of easy flooding between brake friction pairs, vehicle braking failure, easy heating of the wheel hub, etc., to solve the problems of waterproof and heat explosion, Satisfy the effect of production and transportation, and improve braking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

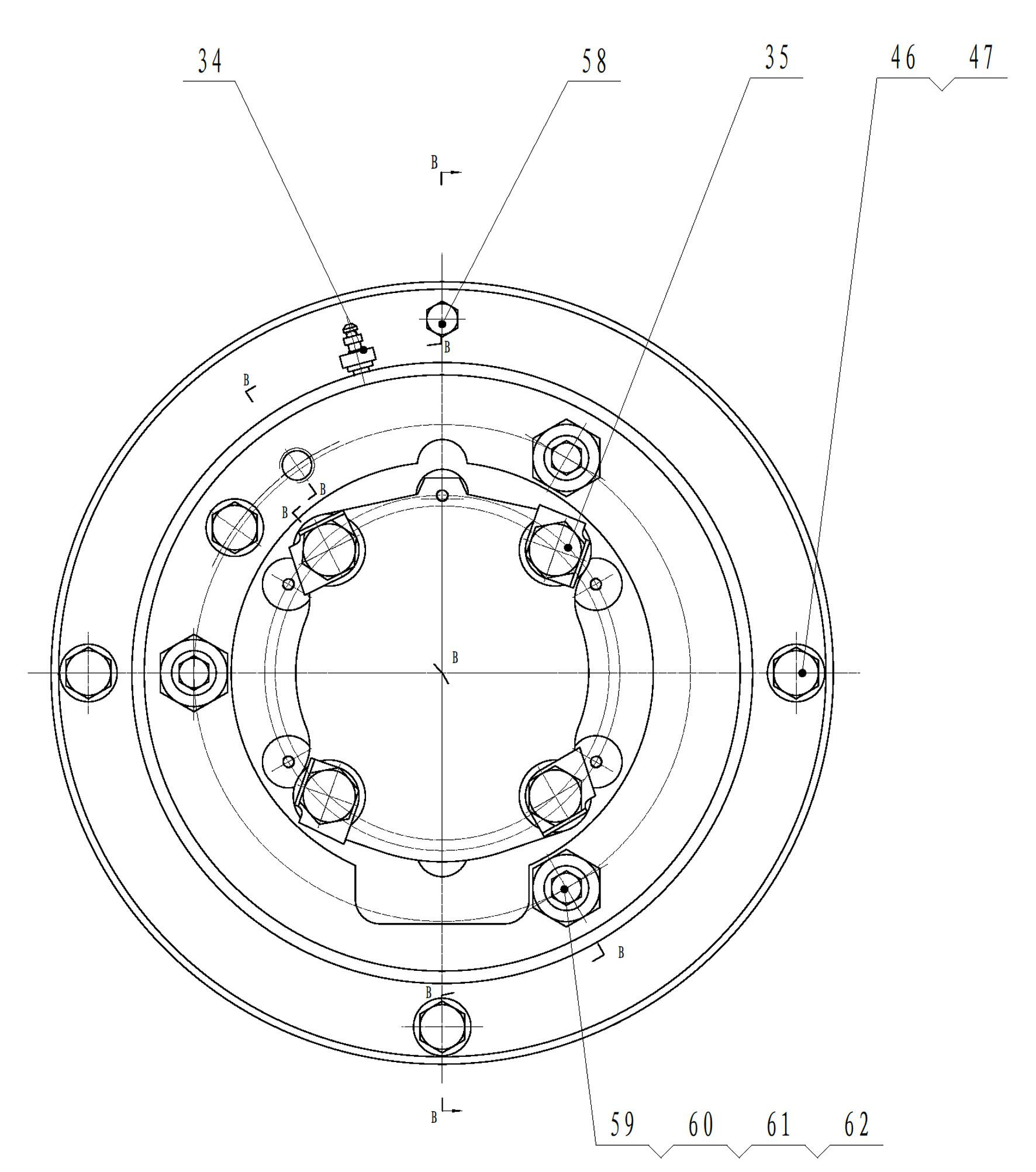

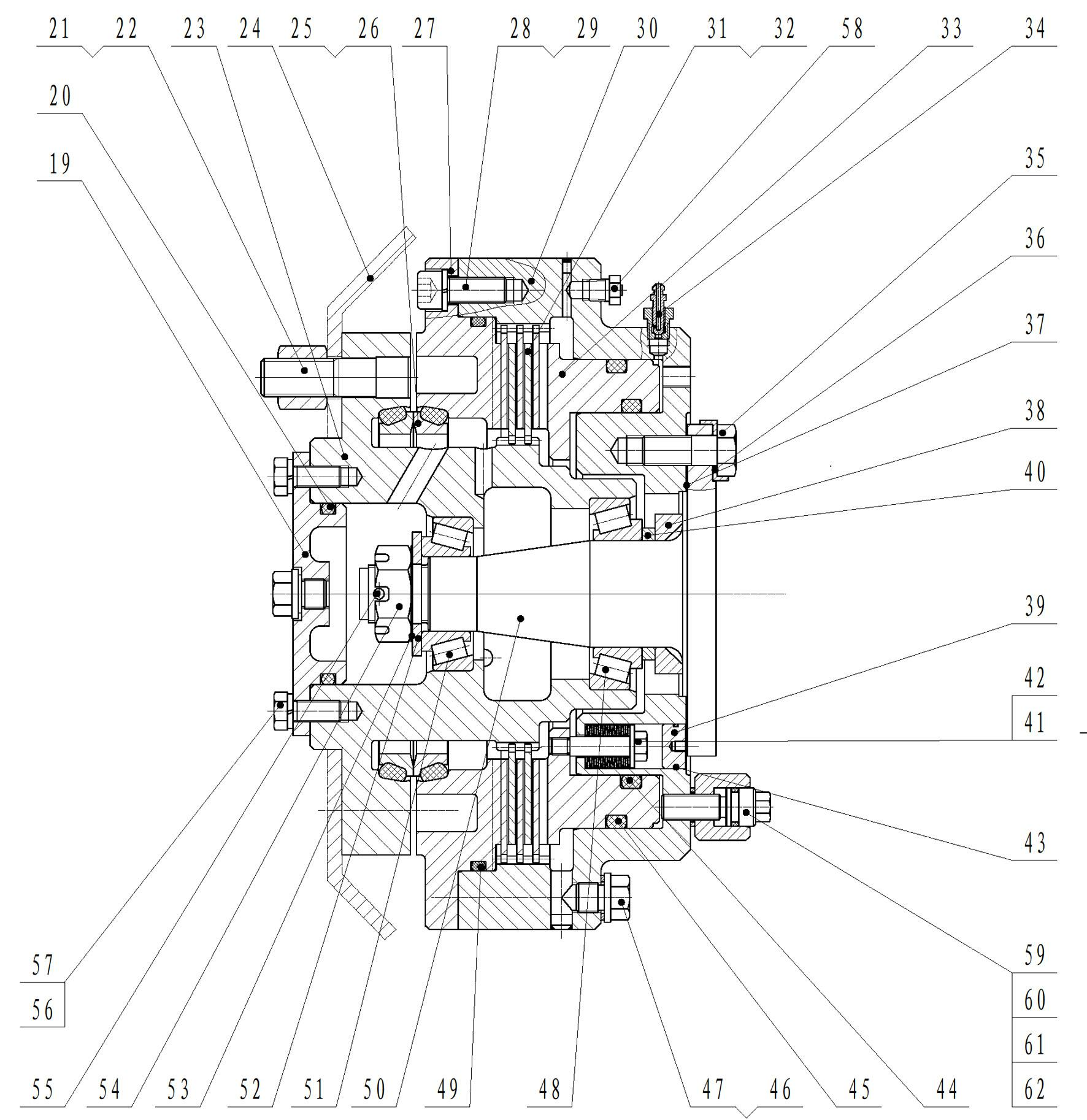

[0025] The specific embodiments of the present invention will be further described with reference to the accompanying drawings.

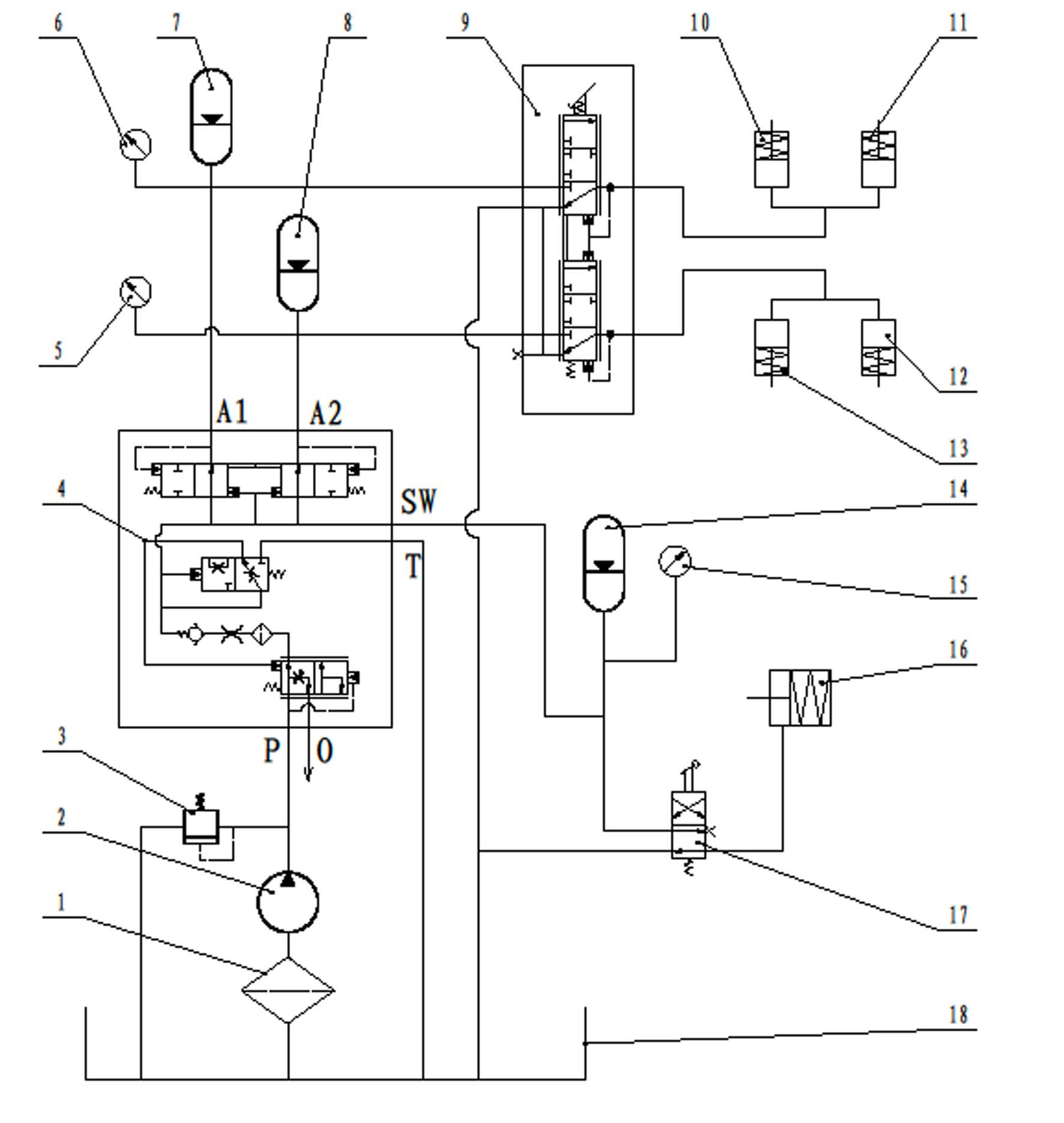

[0026] The structure of the invention is mainly composed of several unit links such as working braking, emergency braking and parking braking system. Mainly consists of hydraulic pump 2, charging valve 4, accumulators 7, 8, 14, pedal brake valve (tandem type) 9, parking brake valve (manual reversing valve) 17, front and rear service brakes 10 , 11, 12 and 13, parking brake 16 and pressure gauges 5, 6, 15 and so on. The working principle of the full hydraulic brake device is as follows: figure 1 shown.

[0027] The hydraulic pump 2 pumps part of the hydraulic oil in the hydraulic oil tank 18 through the filter 1 into the filling valve 4 and the other part into the safety valve 3, and the high-pressure oil overflowing from the safety valve flows back to the oil tank to protect the entire system. The hydraulic oil entering port P of the charging val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com