Method for rolling large-size square steel by single machine frame without groove

A single-stand, large-scale technology, applied in the field of steel rolling, can solve the problems affecting the serialization of enterprise product specifications, low roll utilization rate, unfavorable market competition, etc., to achieve flexible product specification changes, high roll utilization rate, good physical and chemical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

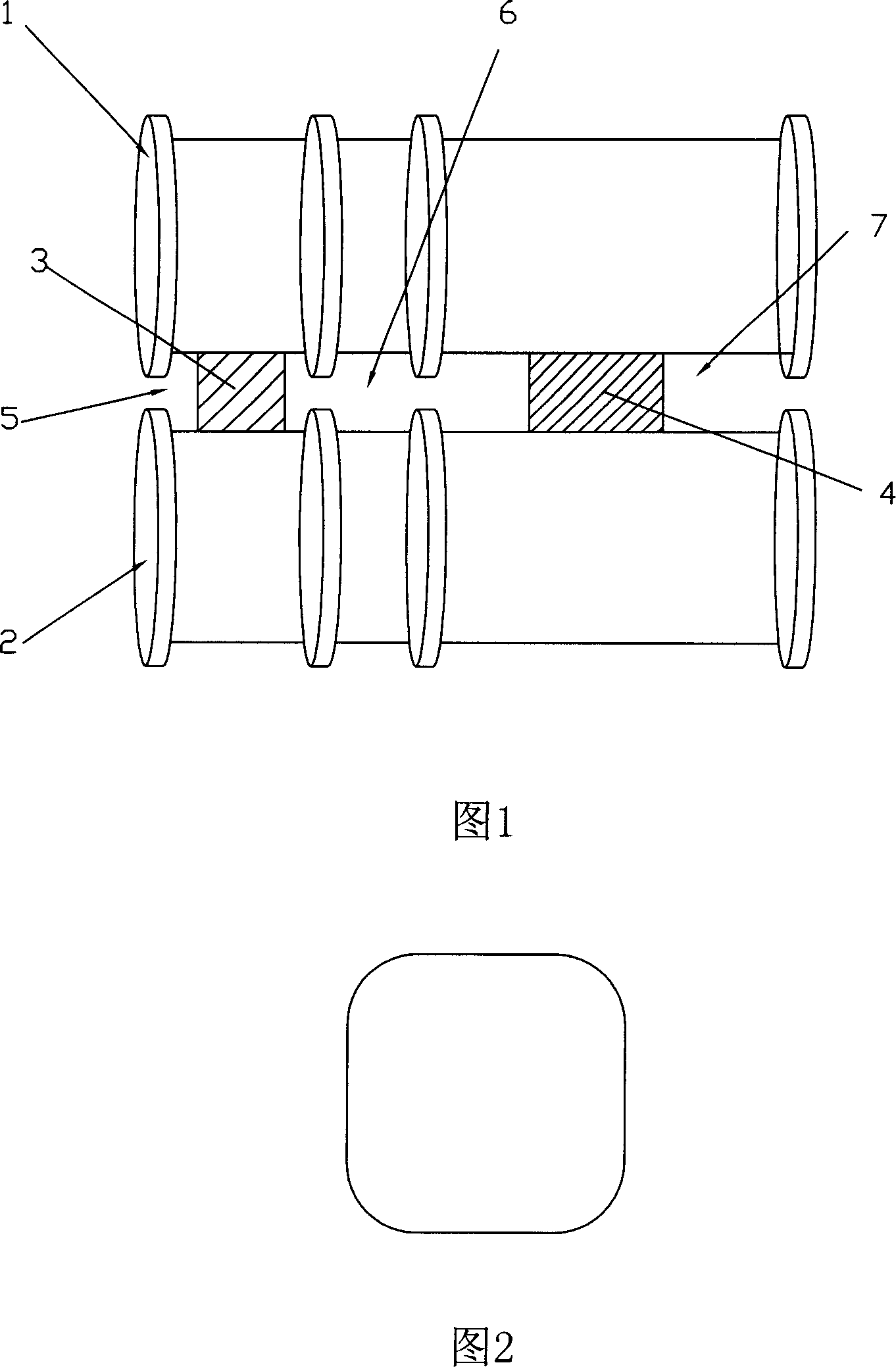

[0077] As shown in Figure 1, the present invention utilizes the flat roll position of the original pass type of a single-stand rolling mill to carry out grooveless rolling, and the rolled piece is rolled between the upper and lower flat rolls 1 and 2. Clamped by the side wall of the pass, the height of the roll gap is the height of the rolled piece, and because there is no effect of the side wall of the pass, the width of the rolled piece is the width of the rolled piece after free expansion. Among them, 5, 6, and 7 are the 2# holes, 3# holes, and 1# holes (flat holes) of the original rolling mill respectively; the left side of the rolling mill is the driving side, and the right side is the working side.

[0078] The 450mm square steel initial rolling grooveless rolling procedure of the present invention is as shown in Table 2, totally 23 passes. The rolling procedure is designed as follows: four passes of rolling without grooves first, then the billet is turned over 90°, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com