Patterned roller repairing method

A repair method and roll technology, applied in the field of pattern roll repair, can solve the problems of large roll consumption, high production cost and low service life of pattern rolls, and achieve the effects of reducing roll consumption, improving service life and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, exemplary embodiments of the present invention are described in detail with reference to the accompanying drawings. This invention may, however, be embodied in many different forms and should not be construed as limited to the exemplary embodiments set forth herein.

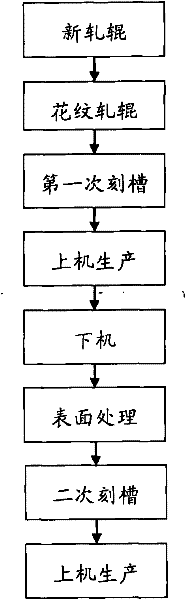

[0021] figure 2 A process flow chart of the repairing method for a patterned roll according to the present invention is shown.

[0022] According to the process flow diagram of pattern roll repair method of the present invention as figure 2 As shown in , specifically, as figure 2 As shown in the dotted line box of , according to the patterned roll repair method of the present invention, before the grooved roll is carried out, the original grooves on the surface of the patterned roll of the lower machine are not completely turned, but the surface of the patterned roll is treated. The roundness and precision of the patterned roll after surface treatment should meet the requirements. After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com