Hematite roasting, stage grinding, intermediate magnetic separation, fineness classifying, gravity concentration-magnetic separation technique

A stage grinding and hematite technology, applied in the fields of gravity-magnetic process, hematite roasting, medium magnetism, stage grinding, coarse and fine grading, can solve the problems of unsatisfactory technical indicators, low sorting efficiency, and high index Easy to fluctuate and other problems, to achieve the effect of improved sorting efficiency, improved technical indicators, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

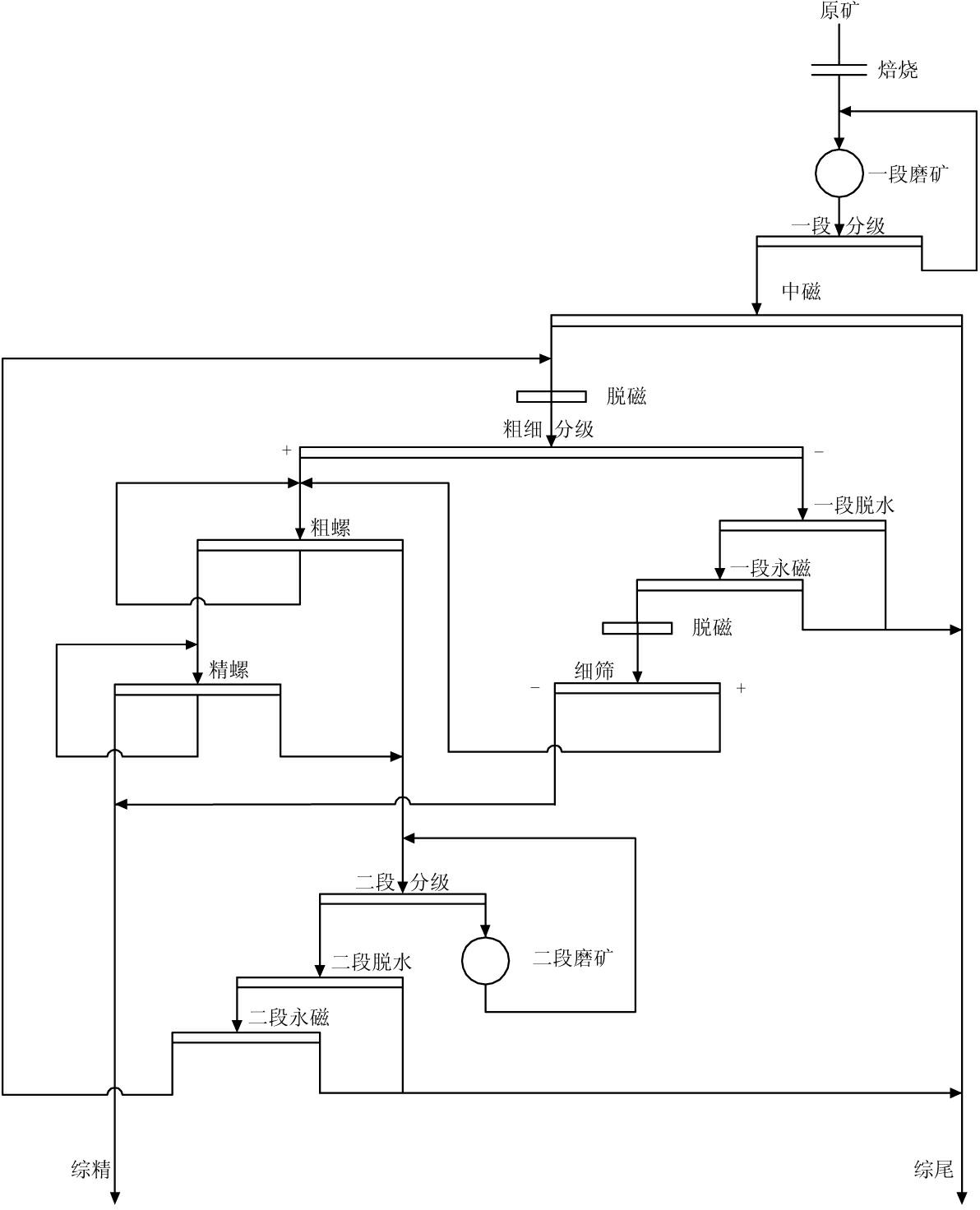

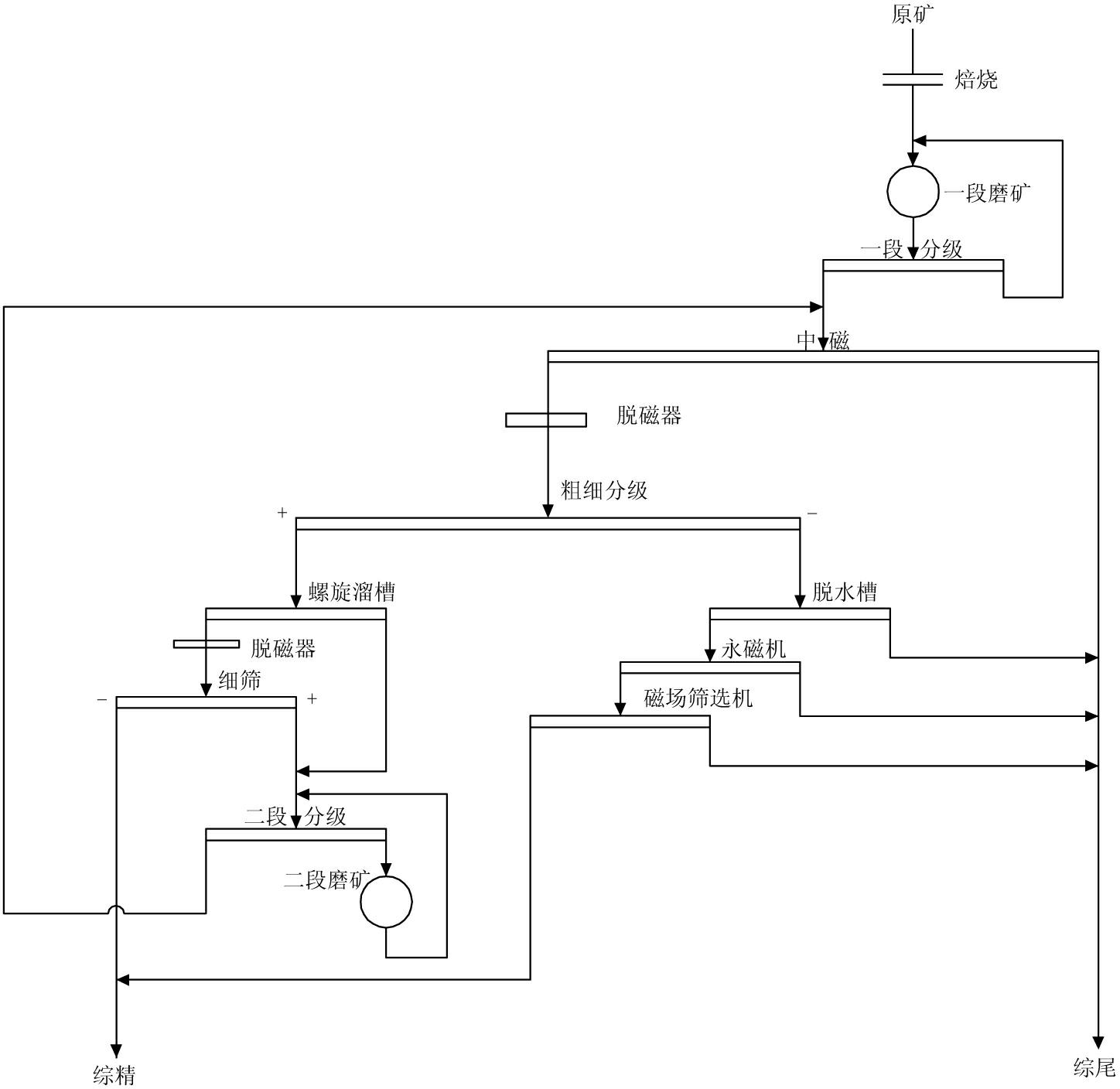

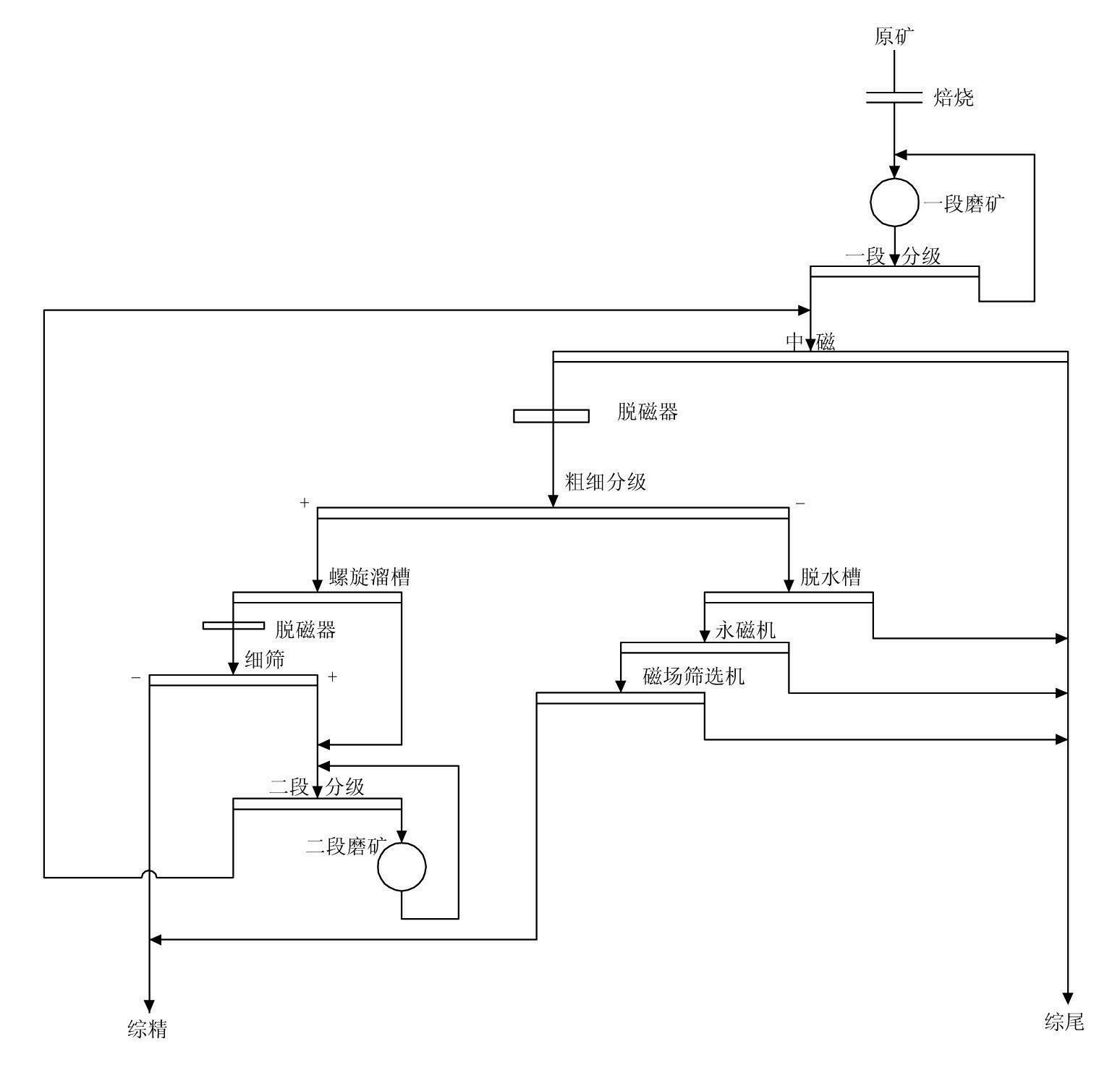

[0020] like figure 2 As shown, a kind of hematite roasting of the present invention, stage grinding, medium magnetic, coarse and fine grading, heavy-magnetic process, including raw ore grade is 25~30% hematite ore through magnetization roasting, magnetic rate reaches 37% Above, feed into a section of closed-circuit grinding, grind until the content of -200 mesh in the first classification overflow reaches 50-70%, one classification and gravity separation-magnetic separation, one classification overflow is fed into the middle magnetic operation to select grade 40 ~45% medium magnetic concentrate and 7~9% medium magnetic tailings gravity separation-magnetic separation, characterized in that:

[0021] 1) The medium magnetic concentrate is fed into the demagnetizer, and the coarse and fine classification is carried out for classification, and the material is classified into two products: coarse-grained and fine-grained;

[0022] 2) Coarse and fine-grained grades of 45-50%, -200 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com