Metal-ceramic bond diamond grinding wheel and production method thereof

A vitrified bond and diamond grinding wheel technology, which is applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of low grinding temperature, low grinding calorific value, poor self-sharpening of grinding wheel, etc., and achieve improved Shape retention and wear resistance, improved grinding efficiency, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

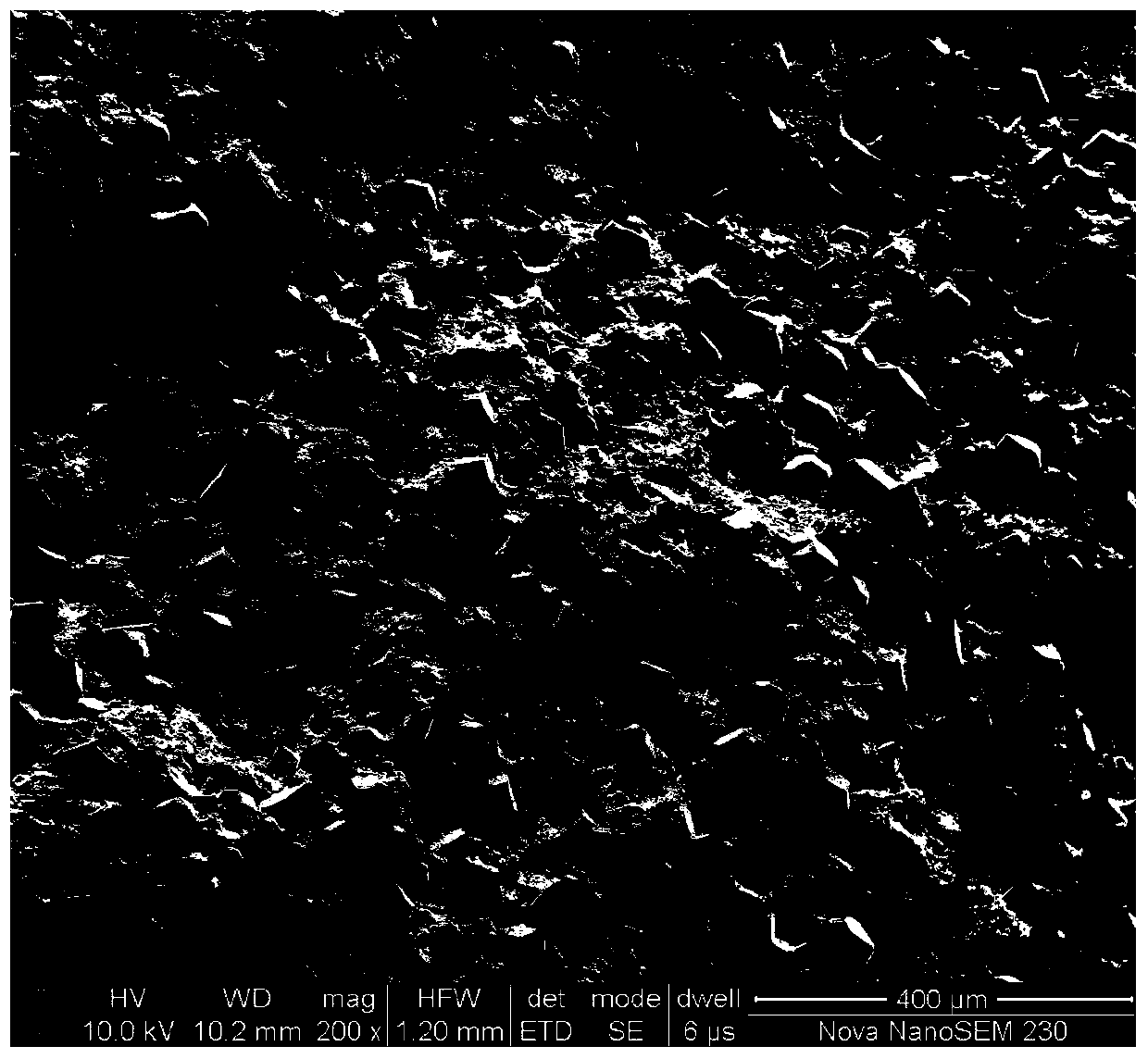

Image

Examples

Embodiment 1

[0037] The steps of the test are:

[0038] 1) Preparation of particles composed of diamond cores and copper coatings coated on the surface of diamond cores

[0039] The diamond particles were successively placed in SnCl 2 solution and PdCl 2 The sensitization and activation treatments were carried out in the solution respectively; the treated diamond particles were uniformly dispersed in CuSO 4 In the mixed solution of the mixed slurry, so as to obtain the mixed slurry; add sodium hypophosphite to the mixed slurry to carry out the electroless plating of Cu on the surface of the diamond particles, to obtain a diamond core and a copper coating coated on the surface of the diamond core. and particles with an average particle size of 10 microns.

[0040] Wherein, the specific operation of preparing particulate matter is as follows:

[0041] A. Place the diamond core in 0.05mol / L SnCl 2 Soak in the solution for 5 minutes, then place in 0.05mol / L PdCl 2 Soak in the solution fo...

Embodiment 2

[0055] The steps of the test are:

[0056] 1) Preparation of particles composed of diamond cores and metal coatings coated on the surface of diamond cores

[0057] The diamond particles were successively placed in SnCl 2 solution and PdCl 2 The sensitization and activation treatments were carried out in the solution respectively; the treated diamond particles were uniformly dispersed in CuSO 4 In the mixed solution of the mixed slurry, so as to obtain the mixed slurry; add sodium hypophosphite to the mixed slurry to carry out the electroless plating of Cu on the surface of the diamond particles, to obtain a diamond core and a copper coating coated on the surface of the diamond core. and particles with an average particle size of 30 microns.

[0058] Wherein, the specific operation of preparing particulate matter is as follows:

[0059] A. Place the diamond core in 0.05mol / L SnCl 2 Soak in the solution for 5 minutes, then place 0.05mol / L in PdCl 2 Soak in the solution for...

Embodiment 3

[0073] The basic steps of the test are:

[0074] 1) Preparation of particles composed of diamond cores and metal coatings coated on the surface of diamond cores

[0075] The diamond particles were successively placed in SnCl 2 solution and PdCl 2 The sensitization and activation treatments were carried out in the solution respectively; the treated diamond particles were uniformly dispersed in CuSO 4 In the mixed solution of the mixed slurry, so as to obtain the mixed slurry; add sodium hypophosphite to the mixed slurry to carry out the electroless plating of Cu on the surface of the diamond particles, to obtain a diamond core and a copper coating coated on the surface of the diamond core. and particles with an average particle size of 50 microns.

[0076] Wherein, the specific operation of preparing particulate matter is as follows:

[0077] A. Place the diamond core in 0.05mol / L SnCl 2 Soak in the solution for 5 minutes, then place 0.05mol / L in PdCl 2 Soak in the soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com