Granulation type pouncing paper, preparation method and application thereof

A granulation and particle technology, applied in abrasives, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult to meet requirements, reduced grinding life, unable to provide high cutting force, etc., to achieve fine polishing surface and high grinding rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation of the granulated grinding paper mentioned in the present invention comprises the following steps:

[0028] (1) Preparation of granulation slurry: Disperse the original abrasive in one or several metal oxide sols, add an appropriate amount of inorganic binder or organic binder as a mixed adhesive, add dispersant and other additives, Evenly dispersed;

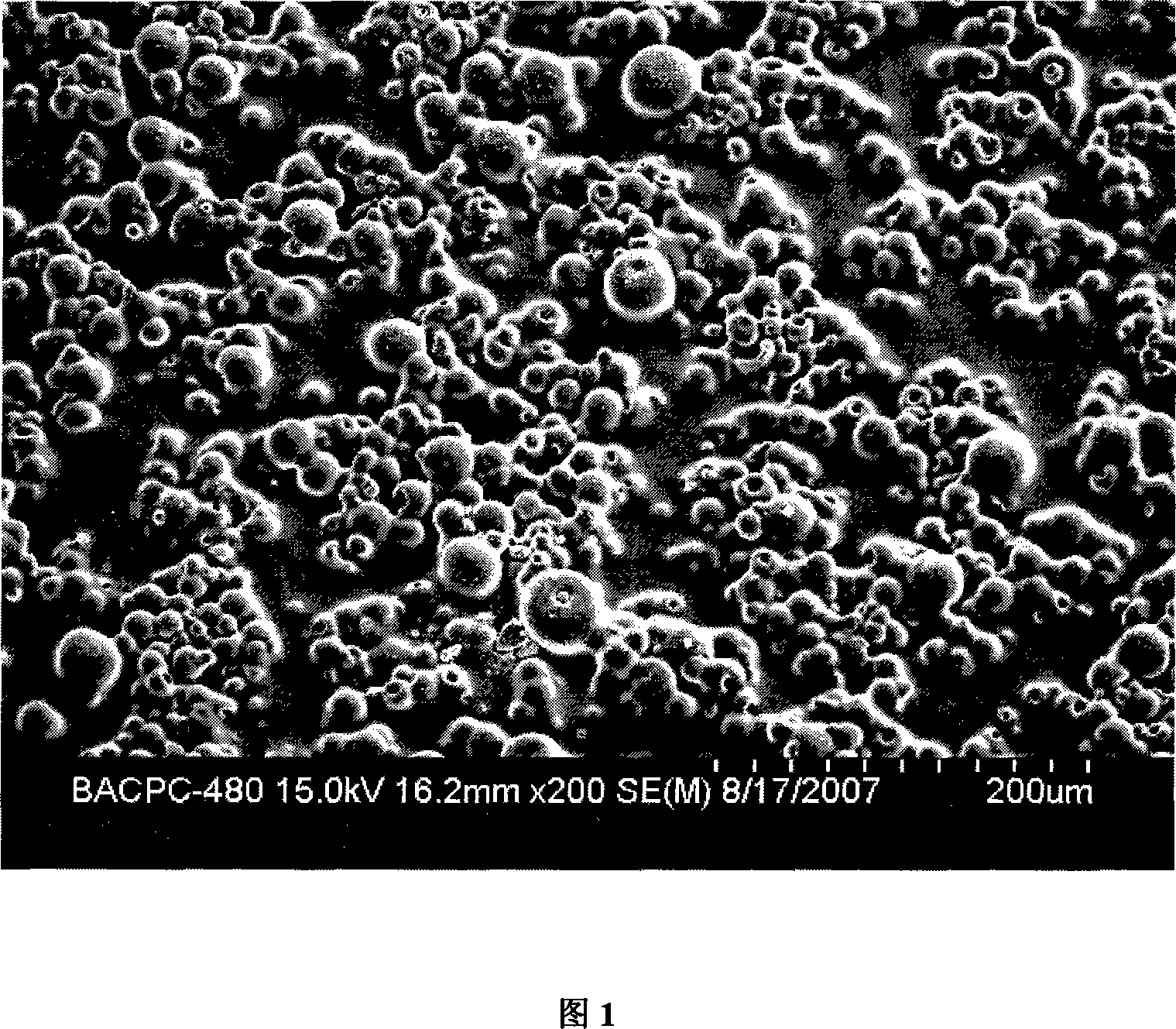

[0029] (2) Spray drying: the prepared slurry is granulated by high-speed rotary spray drying equipment to obtain spherical particle agglomerates with a diameter of 5-50 μm.

[0030] (3) Preparation of abrasive paper: mix the granulated powder with resin glue and solvent to make a coating, then evenly coat the coating on the surface of the substrate, dry and solidify to obtain granulated abrasive paper.

[0031] The specific explanation of the content involved in the preparation process is as follows:

[0032] The abrasive materials are diamond, silicon carbide, alumina, zirconia, modified cerium aluminum...

Embodiment 1

[0042]Take 1Kg of 0.5 μm alumina micropowder, add 5Kg of silica sol (self-made or commercially available) with a concentration of 35%, 150g of dispersant, 100g of PVA aqueous solution and a little defoamer, and disperse the above mixed solution for 24h by using a ball mill; The granulation test was carried out on the dispersed slurry on the rotary spray dryer, the inlet temperature was 220°C, the outlet temperature was 110°C, the atomizer speed was 33000r.p.m, and spherical particles with an average particle size of 20μm were obtained; Granular powder 1.5Kg, add the mixed solution of polyester glue, toluene, methyl ethyl ketone and ethyl acetate, disperse the above mixed solution for 2 hours through a high-speed mixer, apply the coating on the polyester film with a roller coater, and dry it That is, the granulated alumina abrasive paper of the present invention is obtained.

Embodiment 2

[0044] Get 1.5Kg of 1 μm diamond powder, add 8.5Kg of 35% silica sol (self-made or commercially available), 150g of PVA aqueous solution and a little defoamer, and disperse the above mixed solution for 24 hours by using a ball mill; The granulation test is carried out on the dispersed slurry, the inlet temperature is 230°C, the outlet temperature is 110°C, the atomizer speed is 32000r.p.m, and spherical particles with an average particle size of 22μm are obtained; take 1.5Kg of granulated powder , add the mixed solution of polyester glue, toluene, methyl ethyl ketone and ethyl acetate, disperse the above mixed solution for 2h by a high-speed mixer, utilize a roller coater to coat the coating on the polyester film, and obtain the present invention after drying The granulated alumina grinding paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com