Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Improve material removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

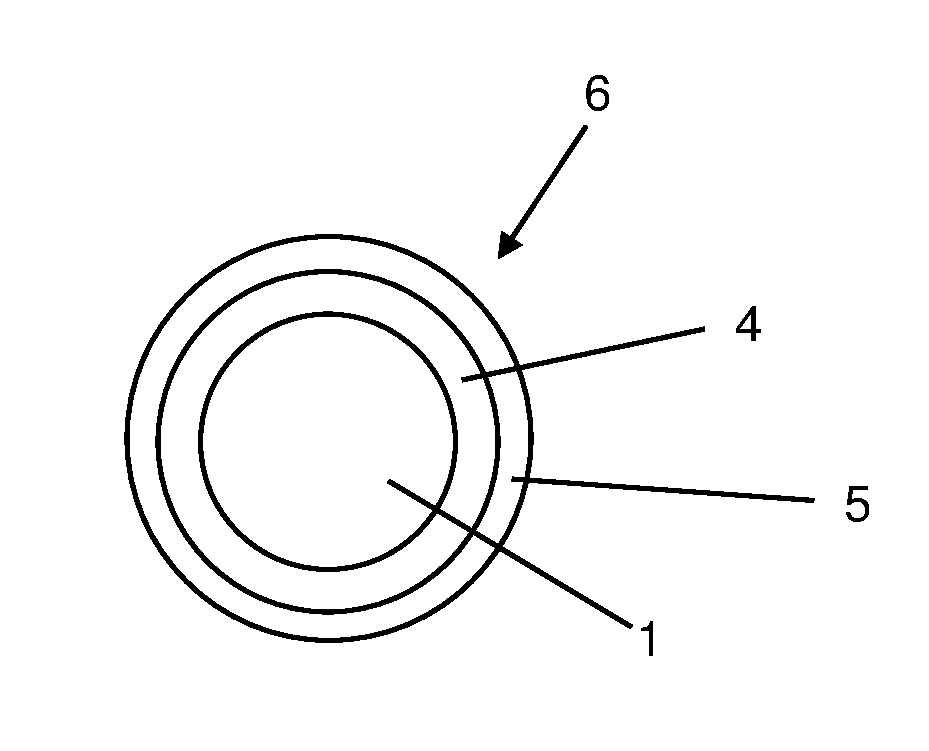

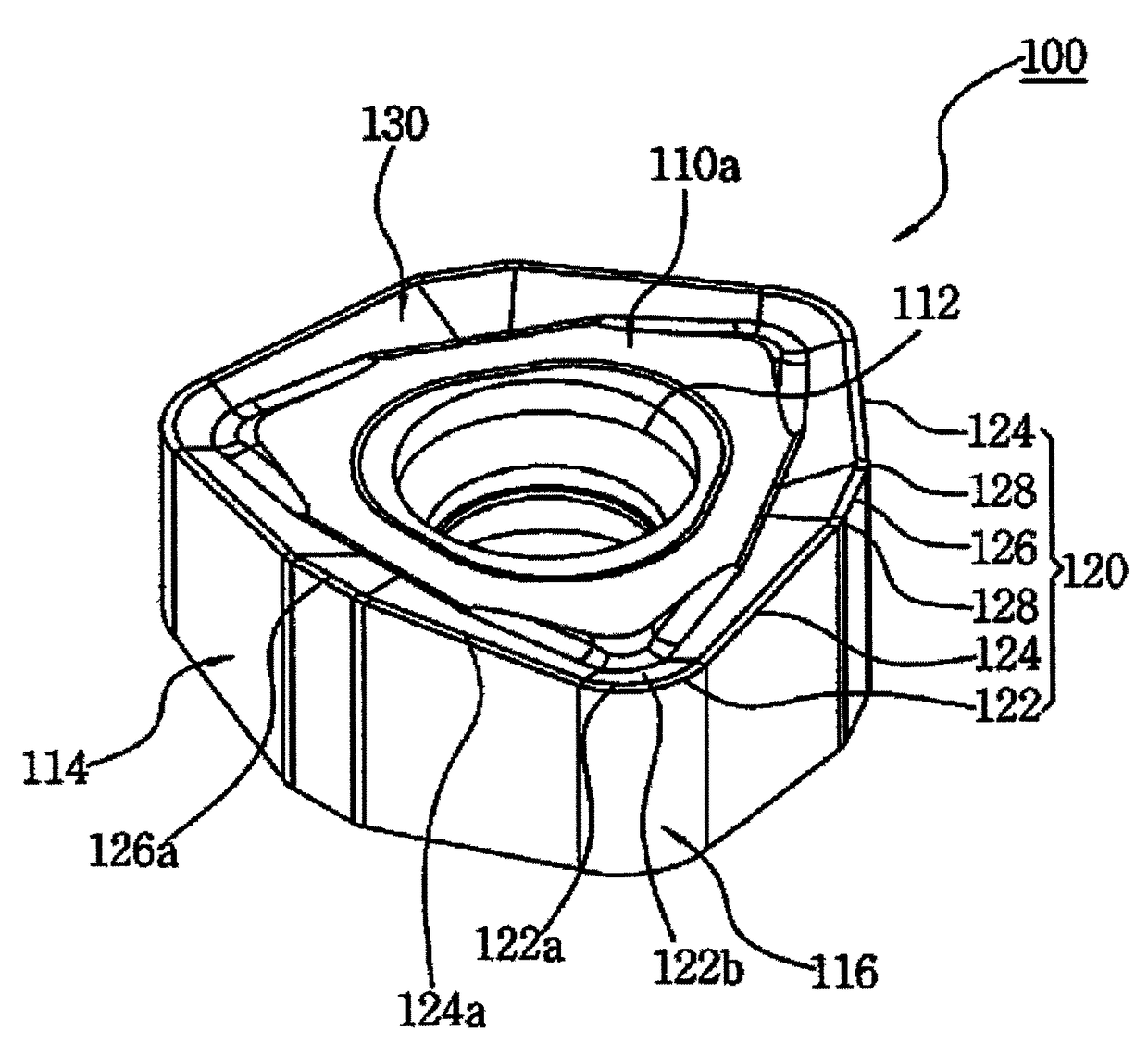

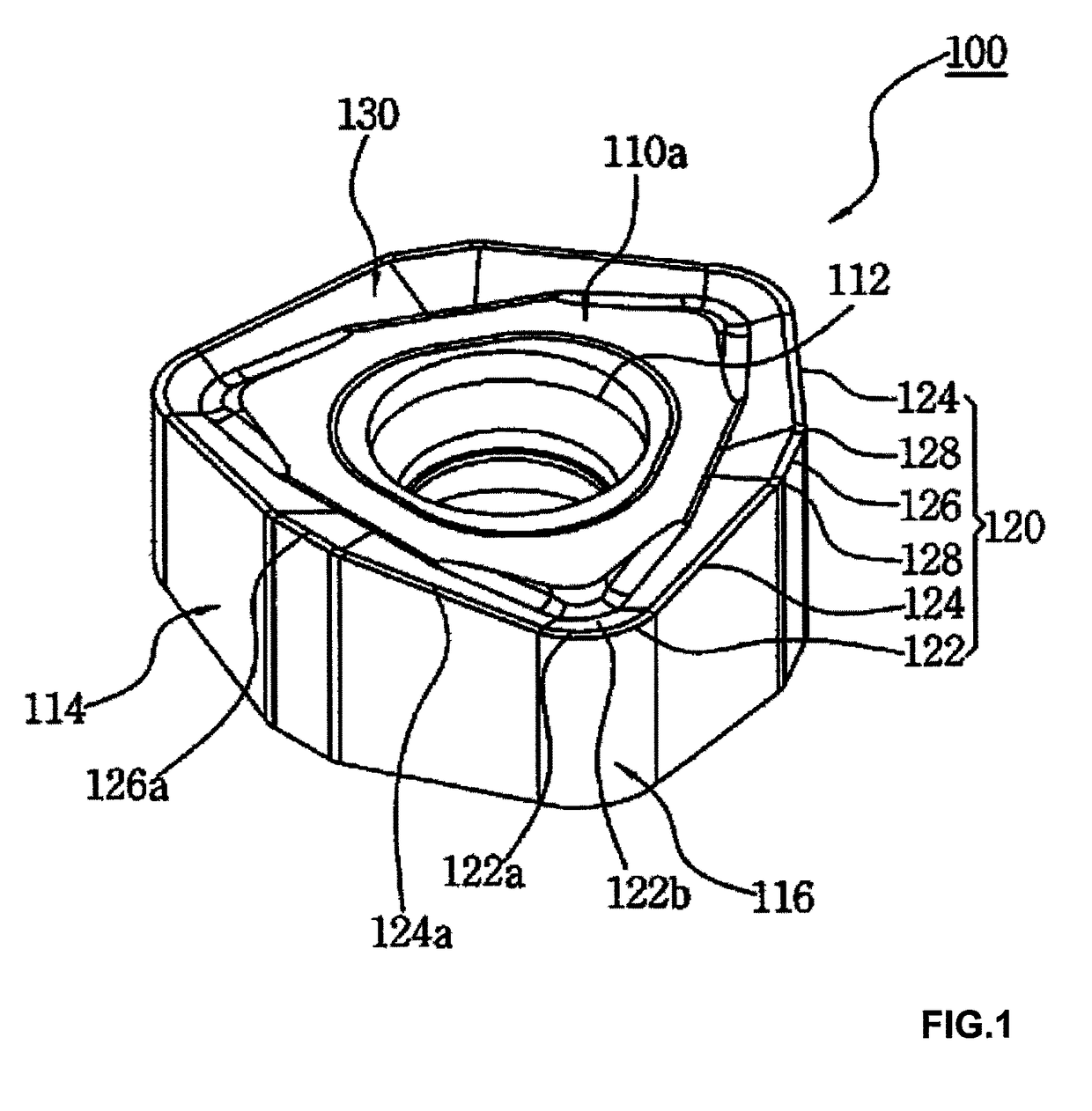

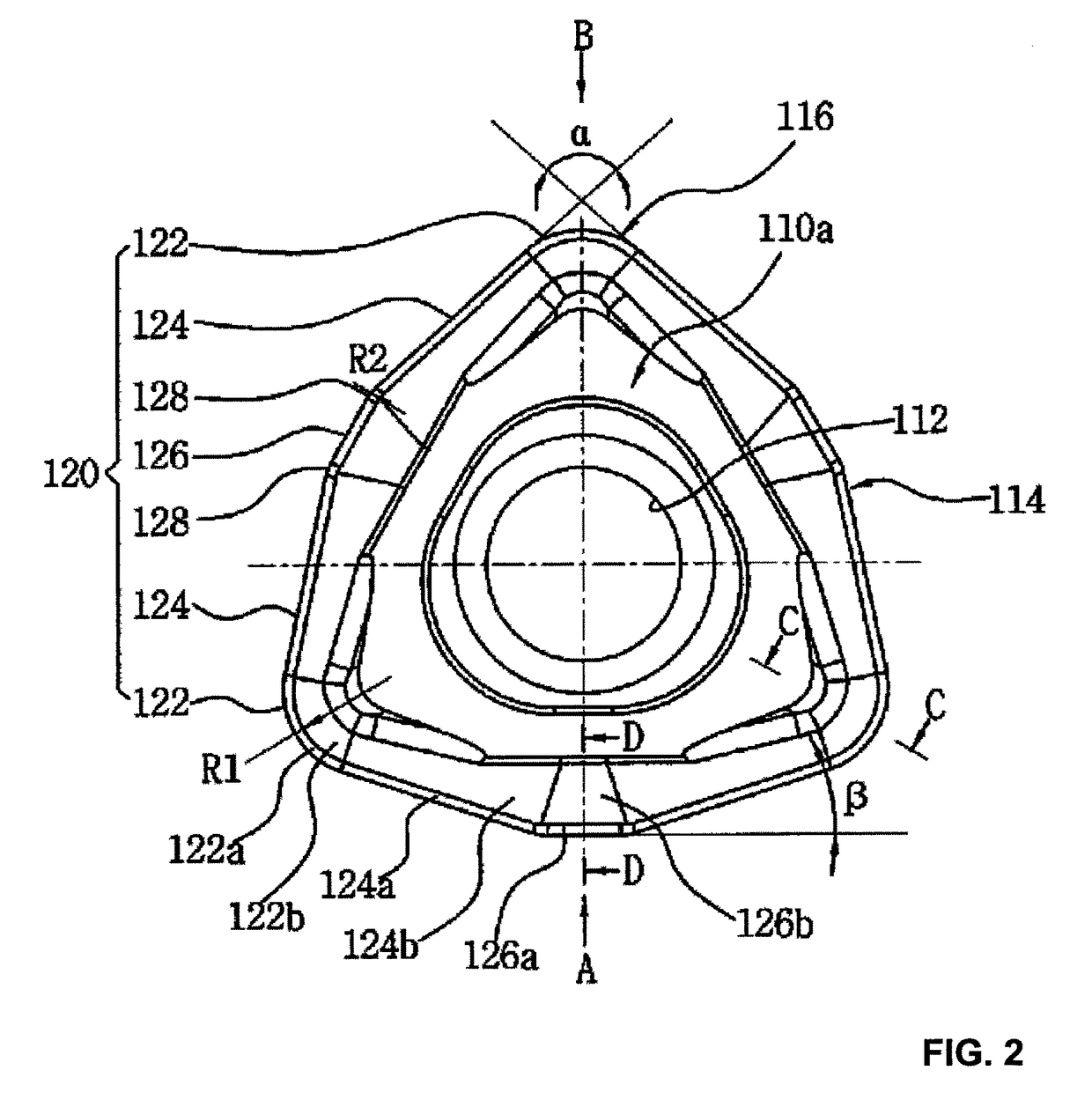

Cutting insert for high-efficient cutting

ActiveUS20100034602A1Increase stiffnessExtended service lifeMilling cuttersCutting insertsEngineeringMechanical engineering

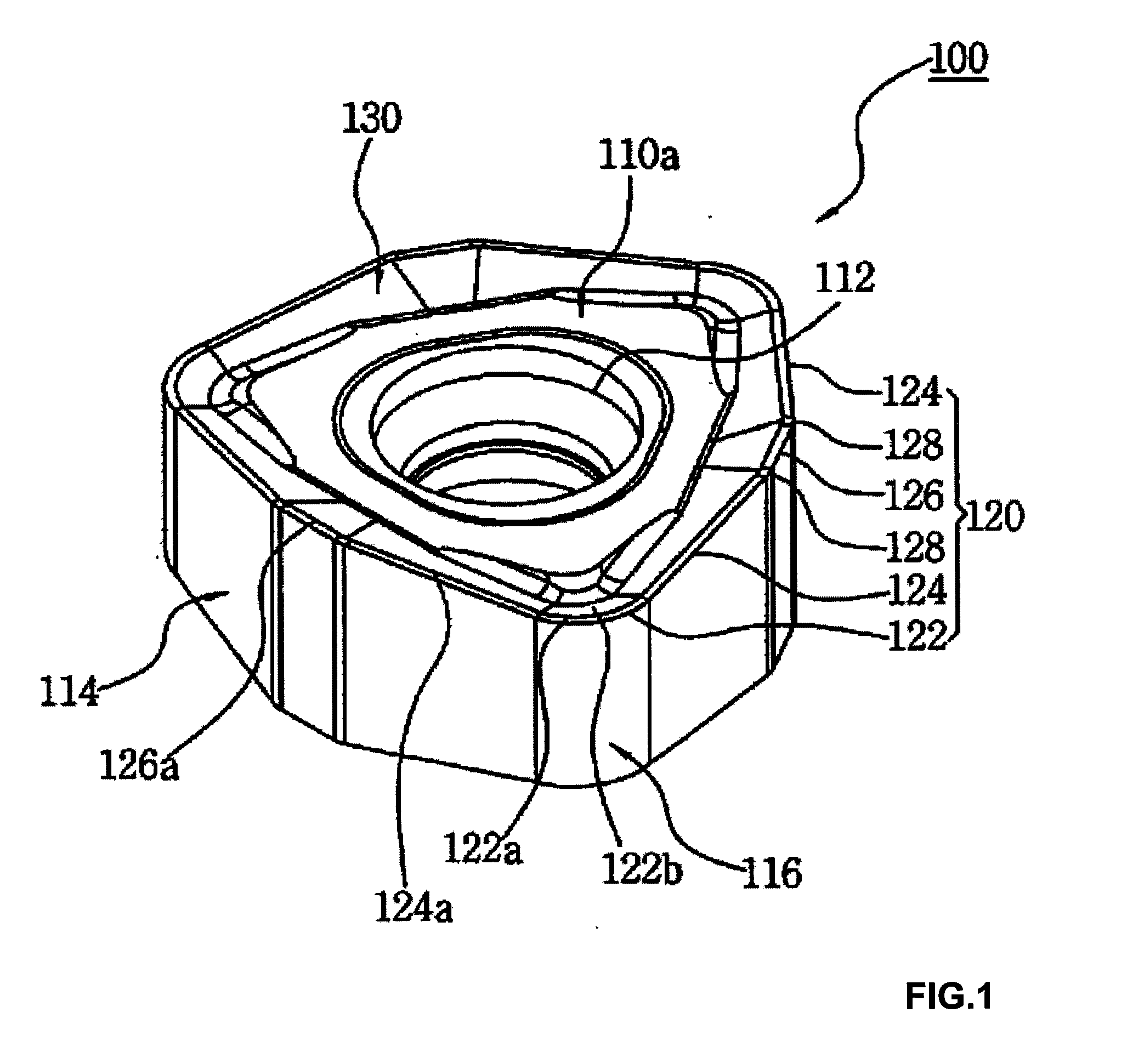

A cutting insert for high-efficiency cutting is disclosed. The cutting insert includes an upper surface (110a), a lower surface (HOb), side surfaces (114) and corner side surfaces (116), which connect the side surfaces to each other. A circular opening is formed through the central portions of the upper and lower surfaces. In the cutting insert, cutting edges are formed by respective junctions between one of the upper and lower surfaces and the side surfaces and between one of the upper and lower surfaces and the corner side surfaces. The cutting edges comprise three corner cutting edges (122), six major cutting edges (124), which extend from opposite ends of the corner cutting edges towards the neighbor corner cutting edges, and three minor cutting edges (126), which are connected between the major cutting edges. Furthermore, the cutting edges may be formed on both the upper surface and the lower surface.

Owner:KORLOY

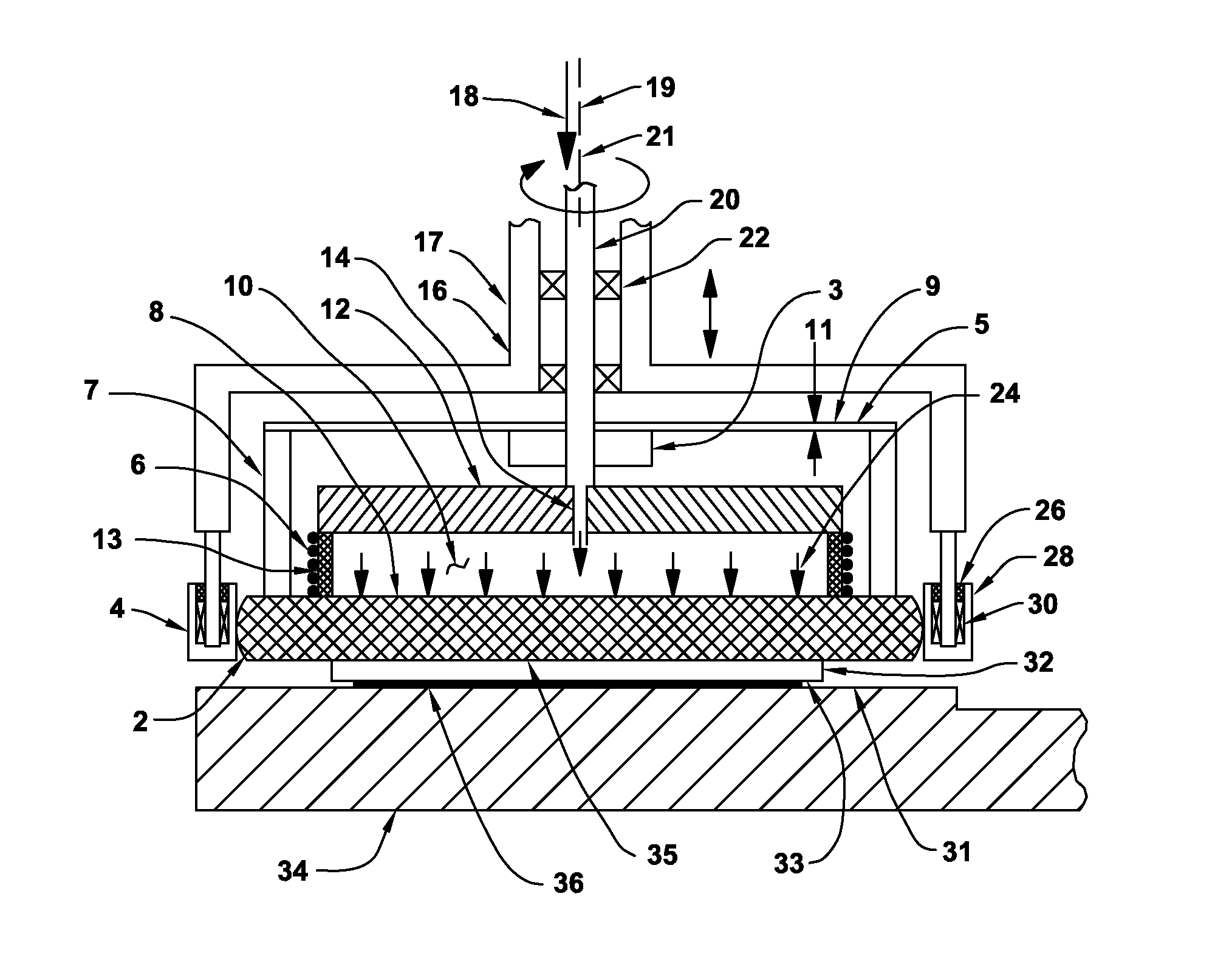

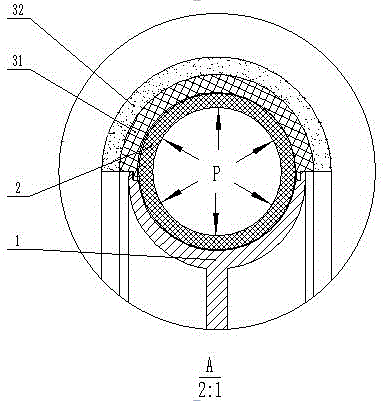

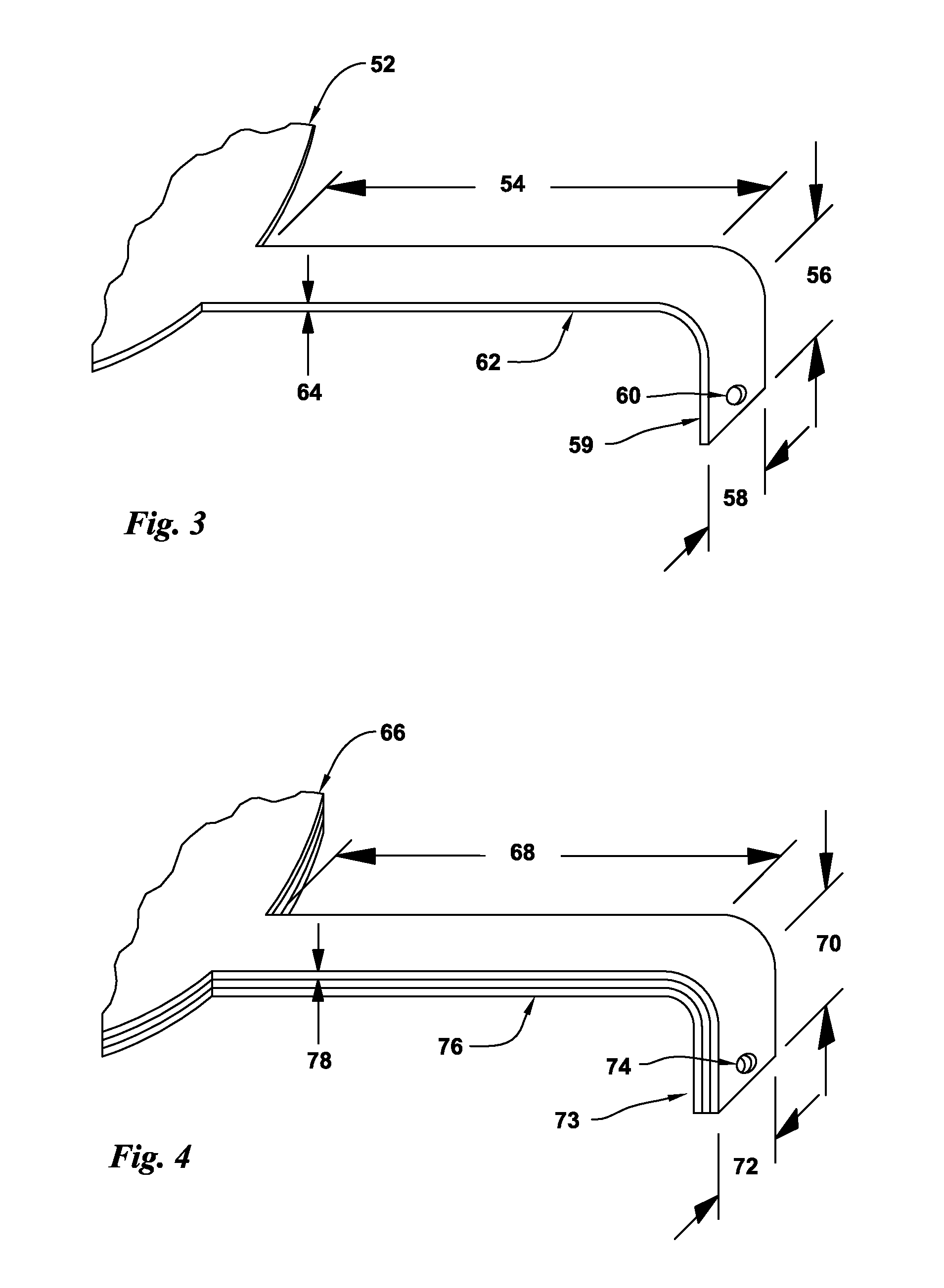

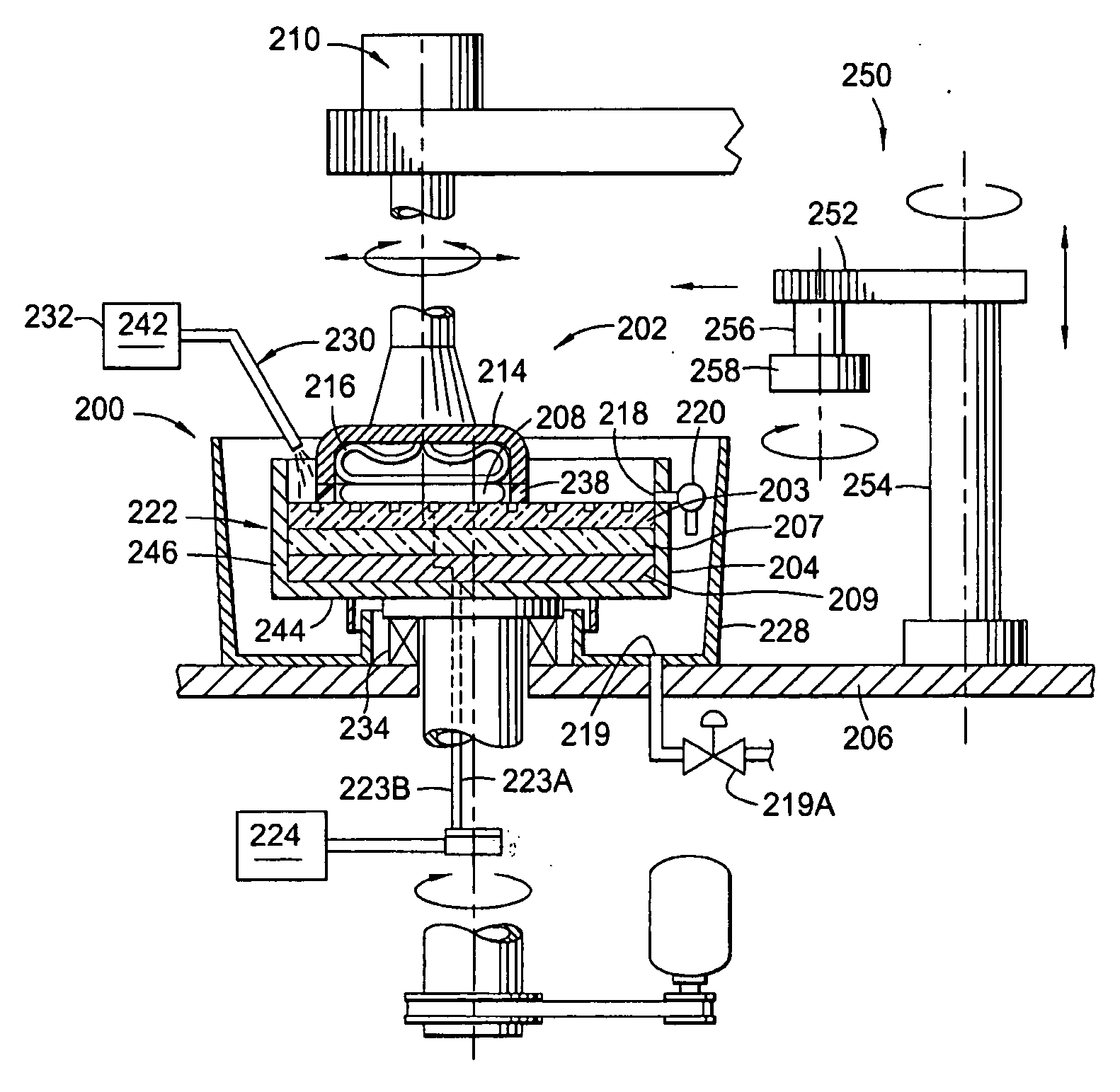

Polishing systems for use with semiconductor substrates including differential pressure application apparatus

InactiveUS6899607B2Reduce rateImprove material removal ratePolishing machinesRevolution surface grinding machinesDifferential pressureEngineering

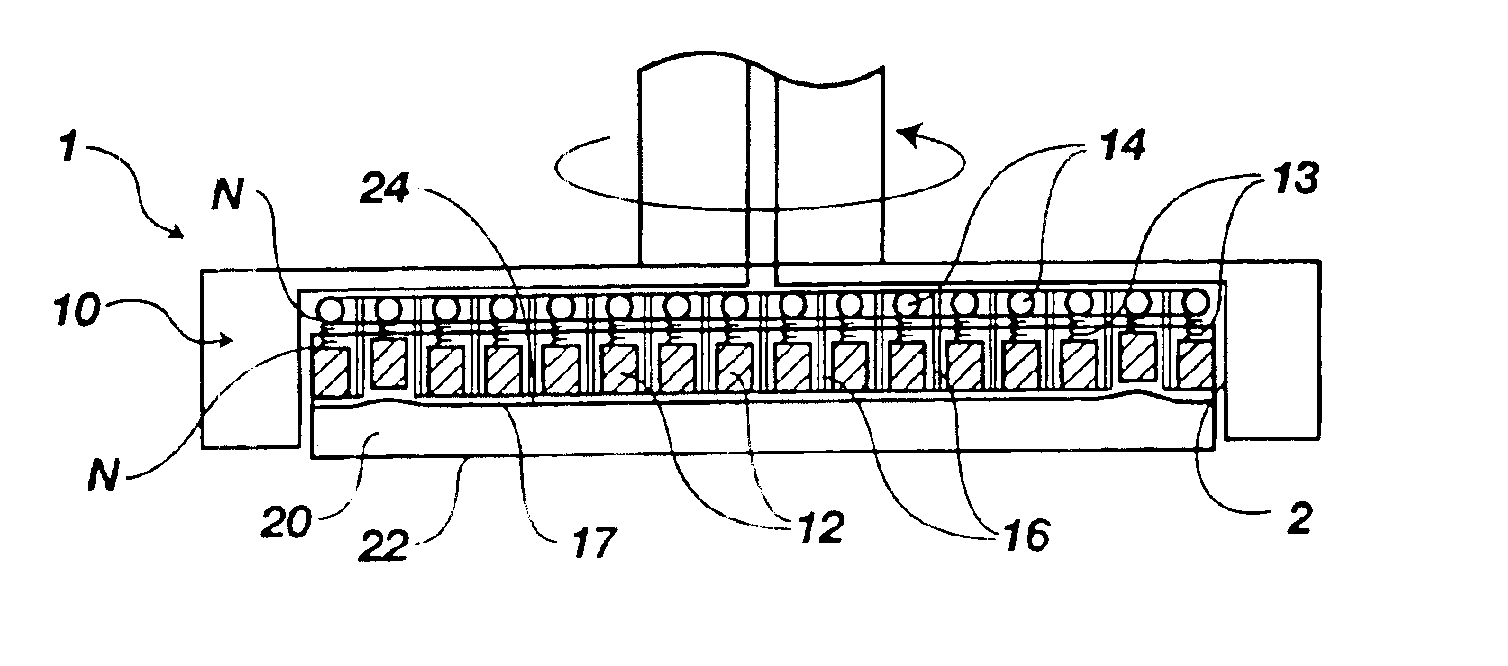

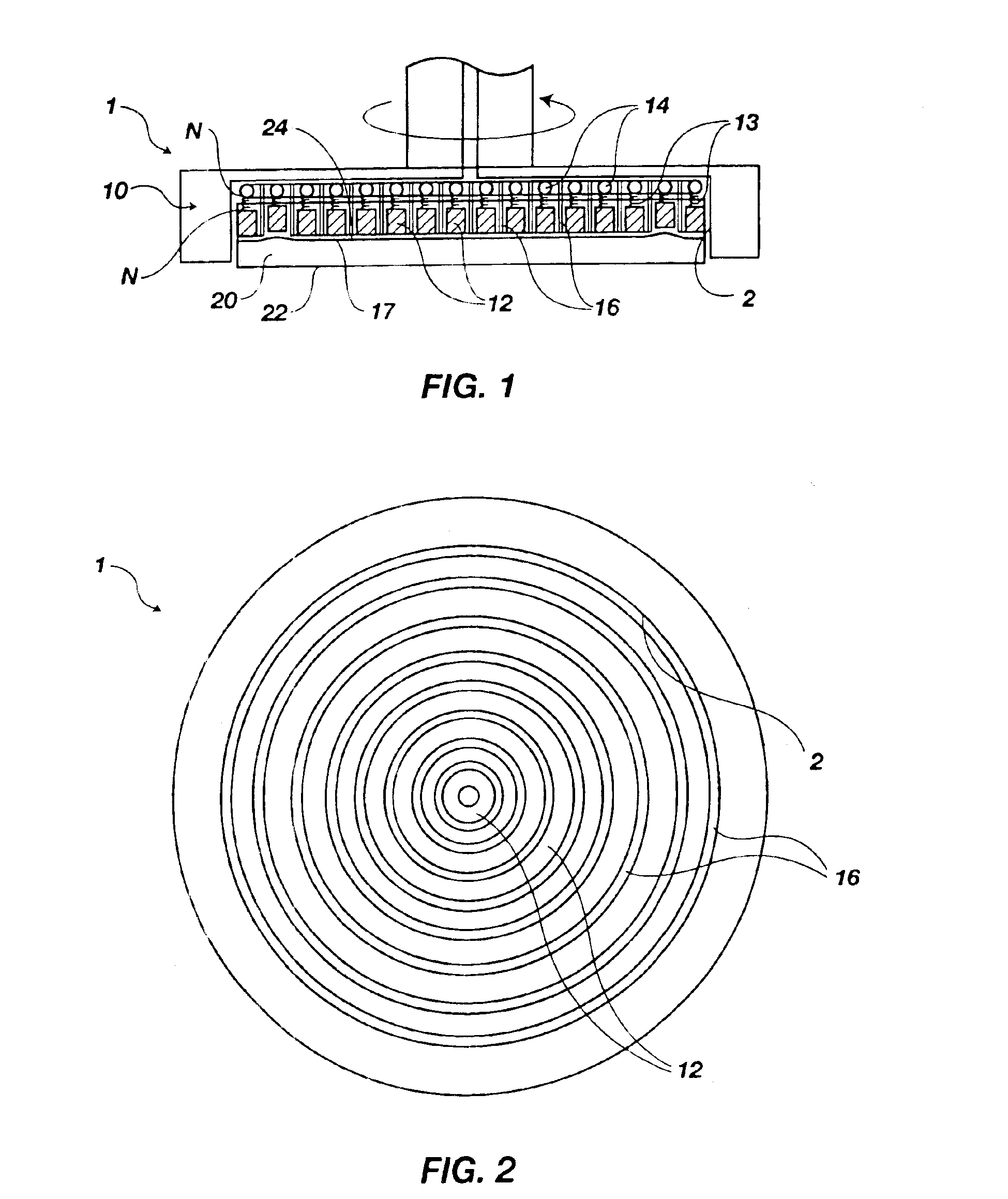

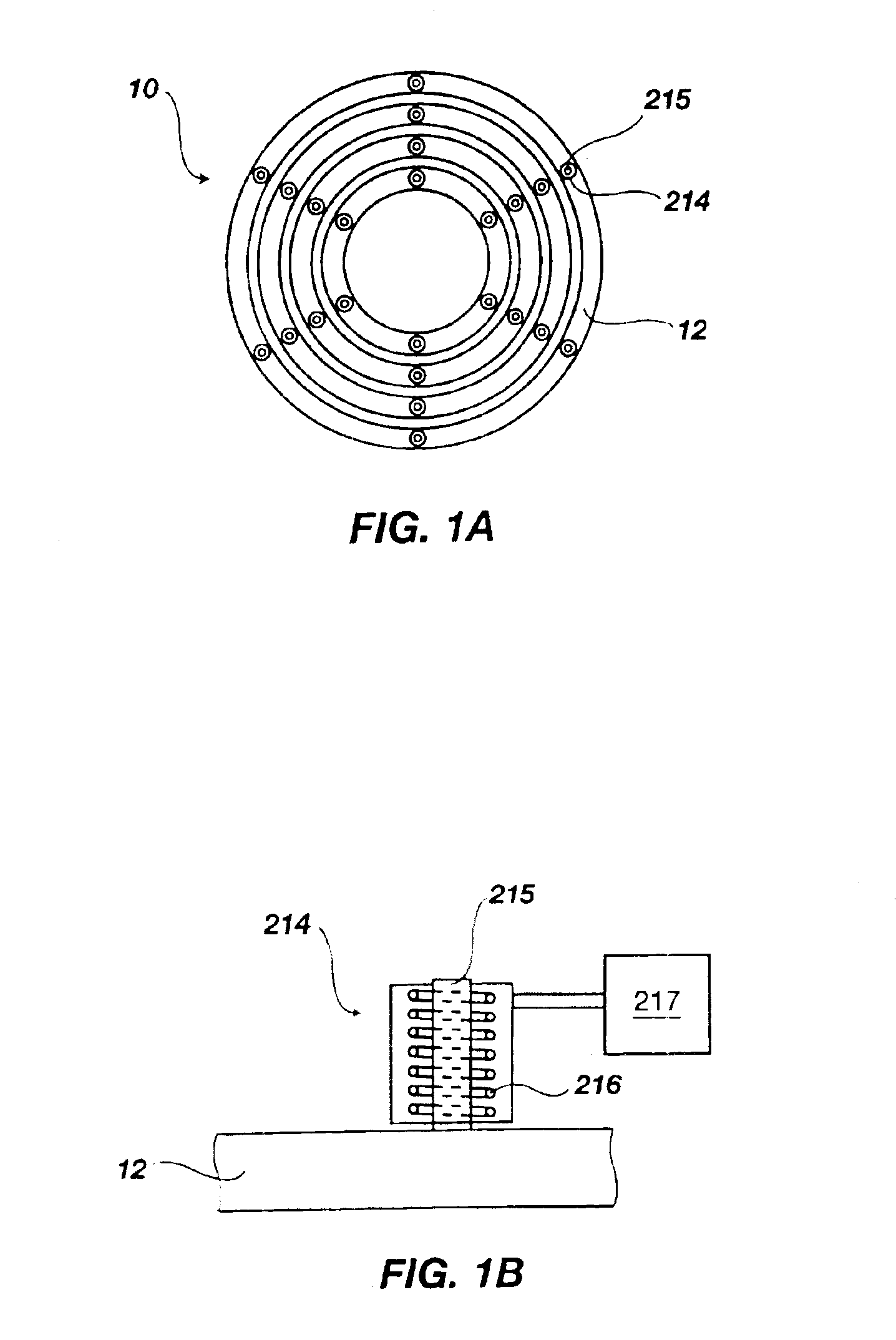

An apparatus for applying different amounts of pressure to different locations of a backside of a semiconductor device structure during polishing thereof. The apparatus is configured to be associated with a wafer carrier of a polishing apparatus and includes pressurization structures configured to be biased against the backside of the semiconductor device structure during polishing thereof. The pressurization structures are independently movable with respect to one another. The amount of force or pressure applied by each pressurization structure to the backside of the semiconductor device structure is controlled by at least one corresponding actuator. The actuator may magnetically facilitate movement of the corresponding pressurization structure toward or away from the backside of the semiconductor device structure. The actuator may alternatively comprise a positive or negative pressure source. Systems including the pressure application apparatus, as well as differential pressure application methods and polishing methods are also disclosed.

Owner:ROUND ROCK RES LLC

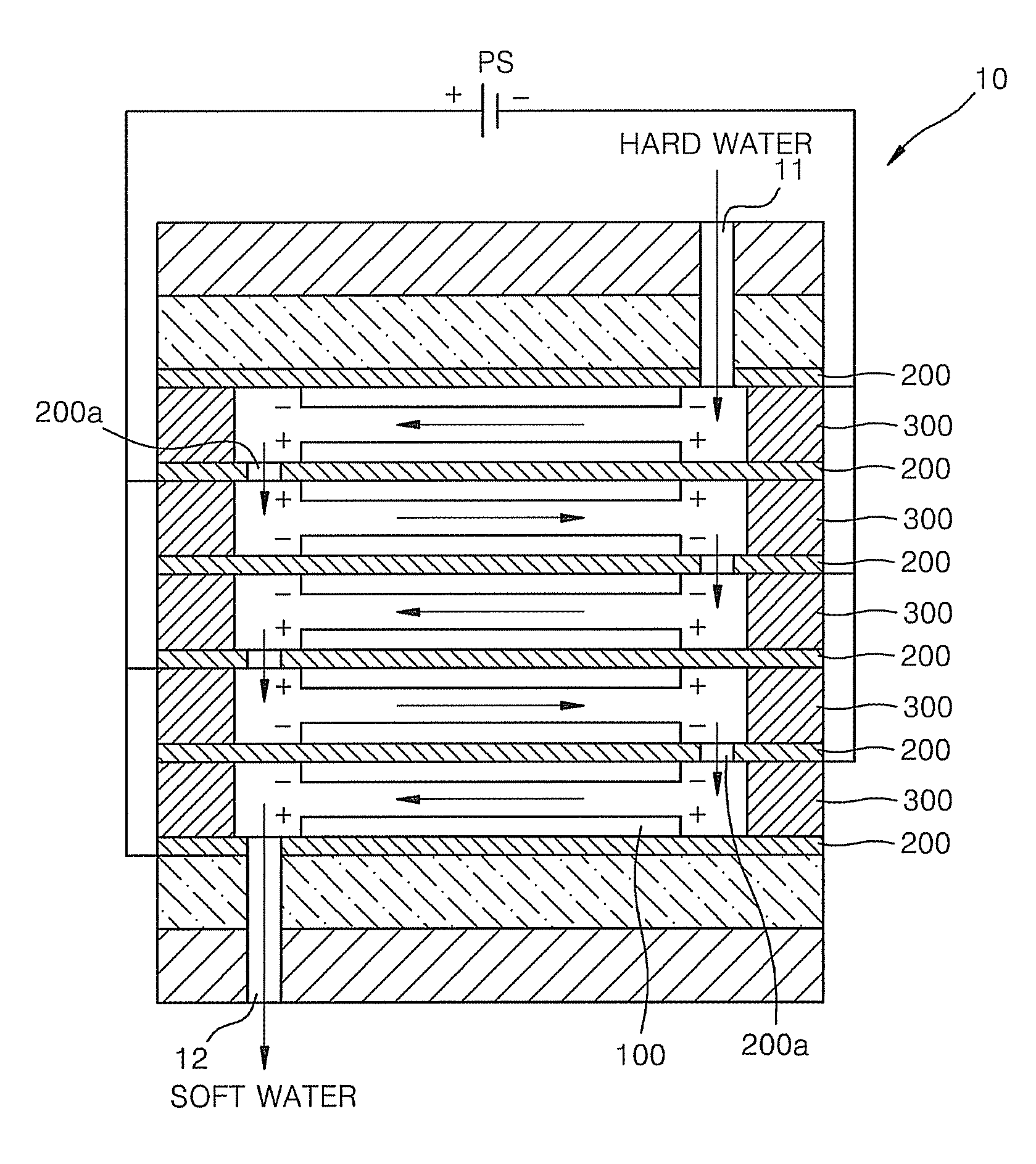

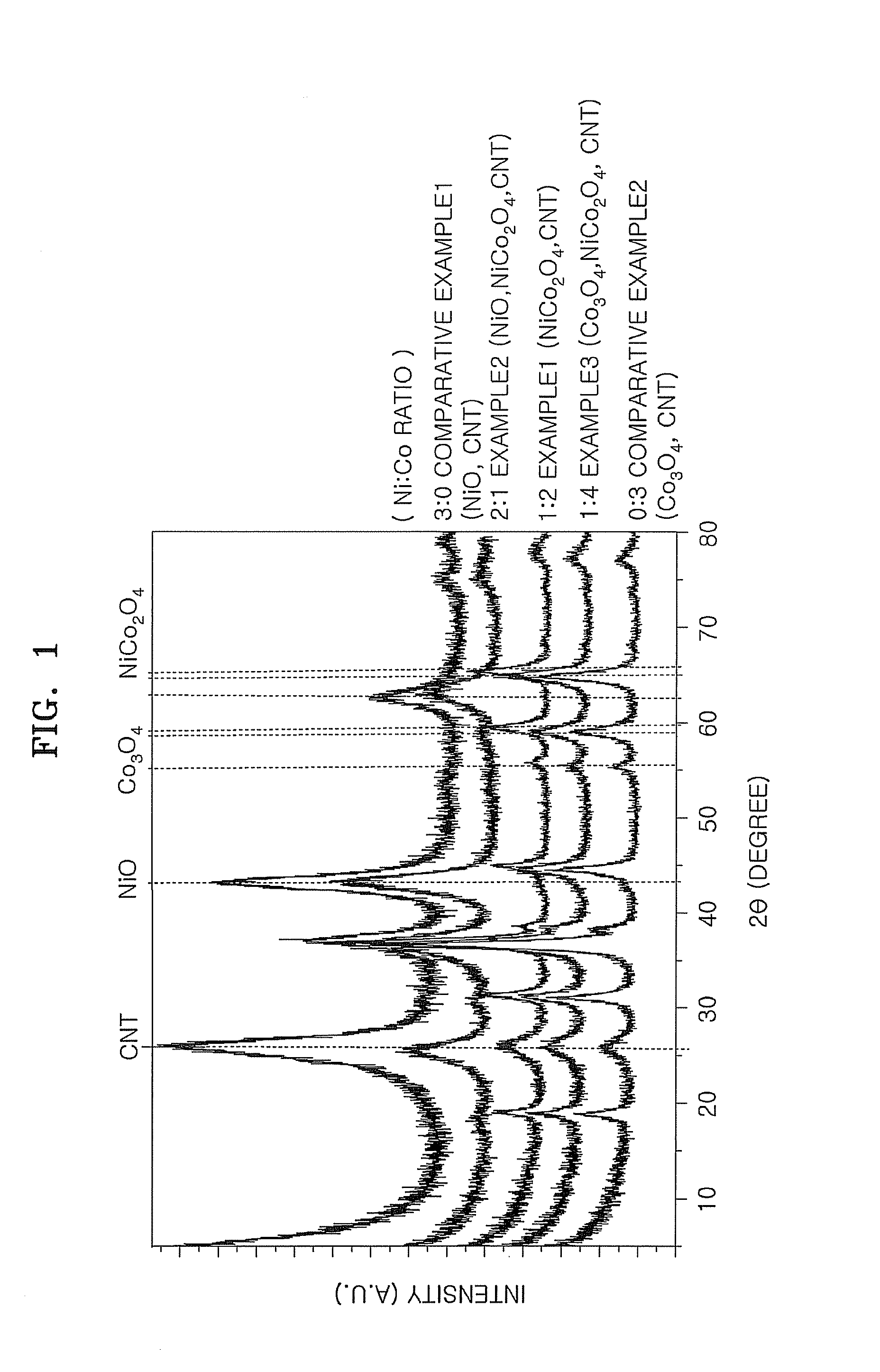

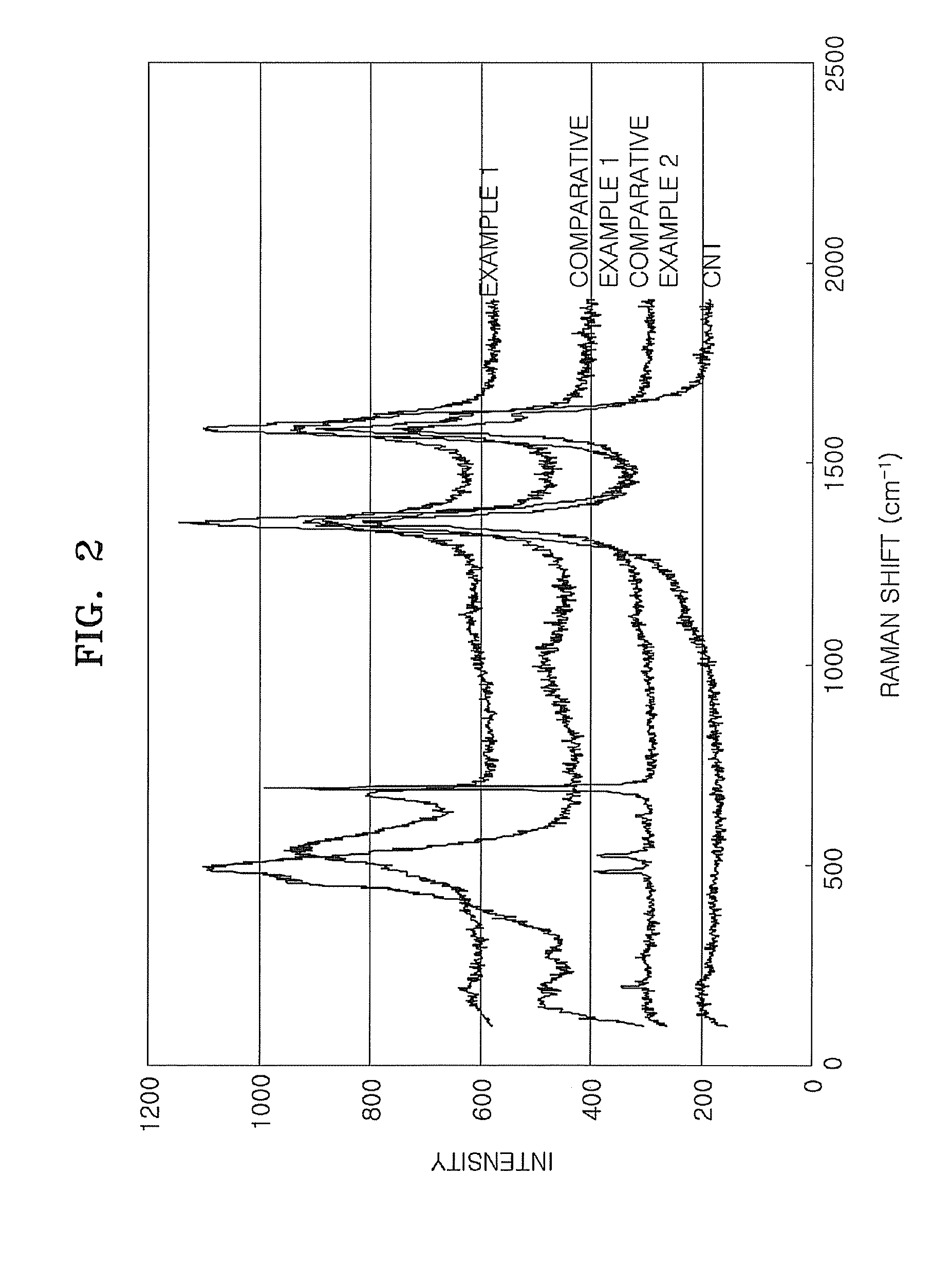

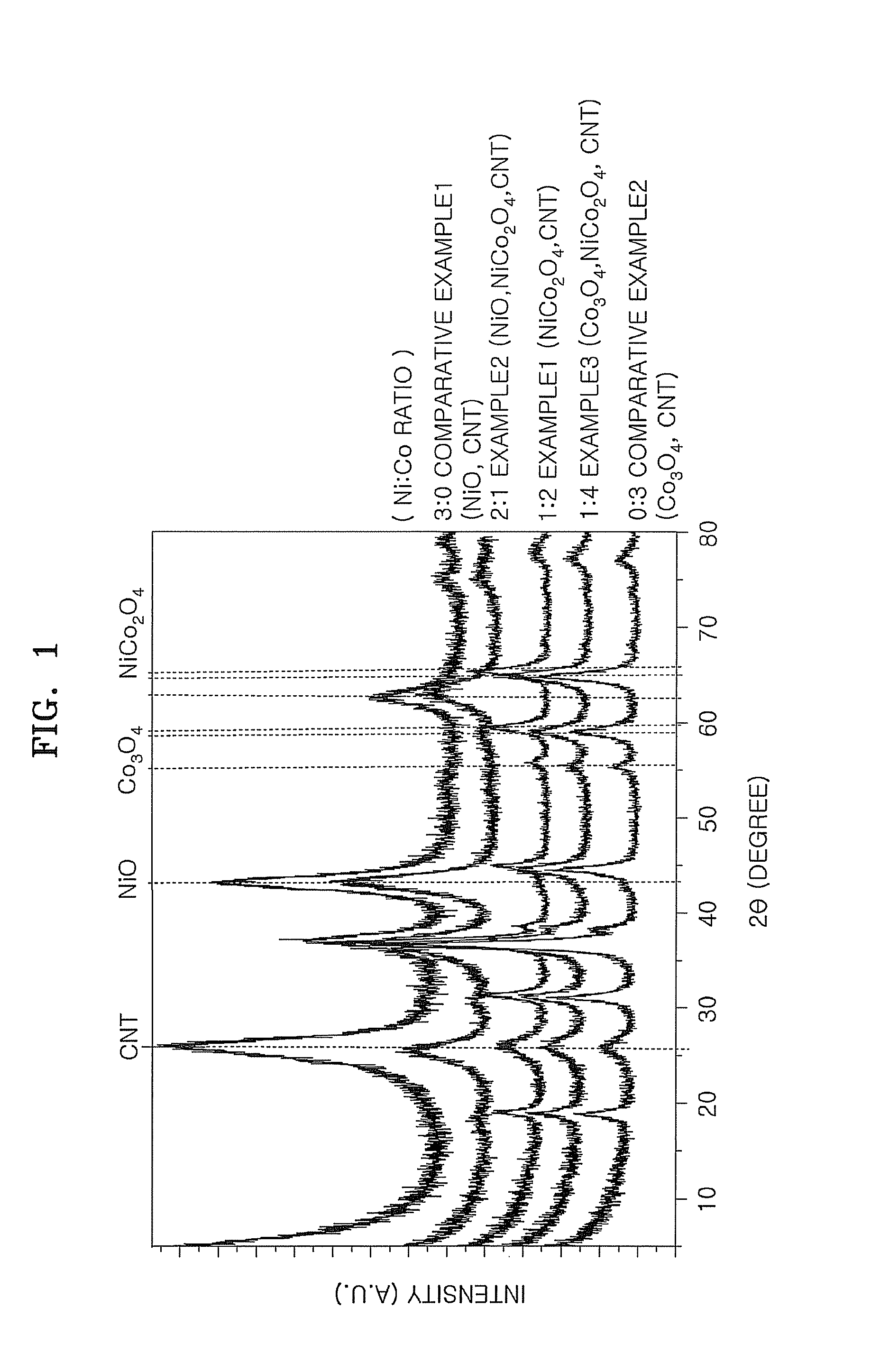

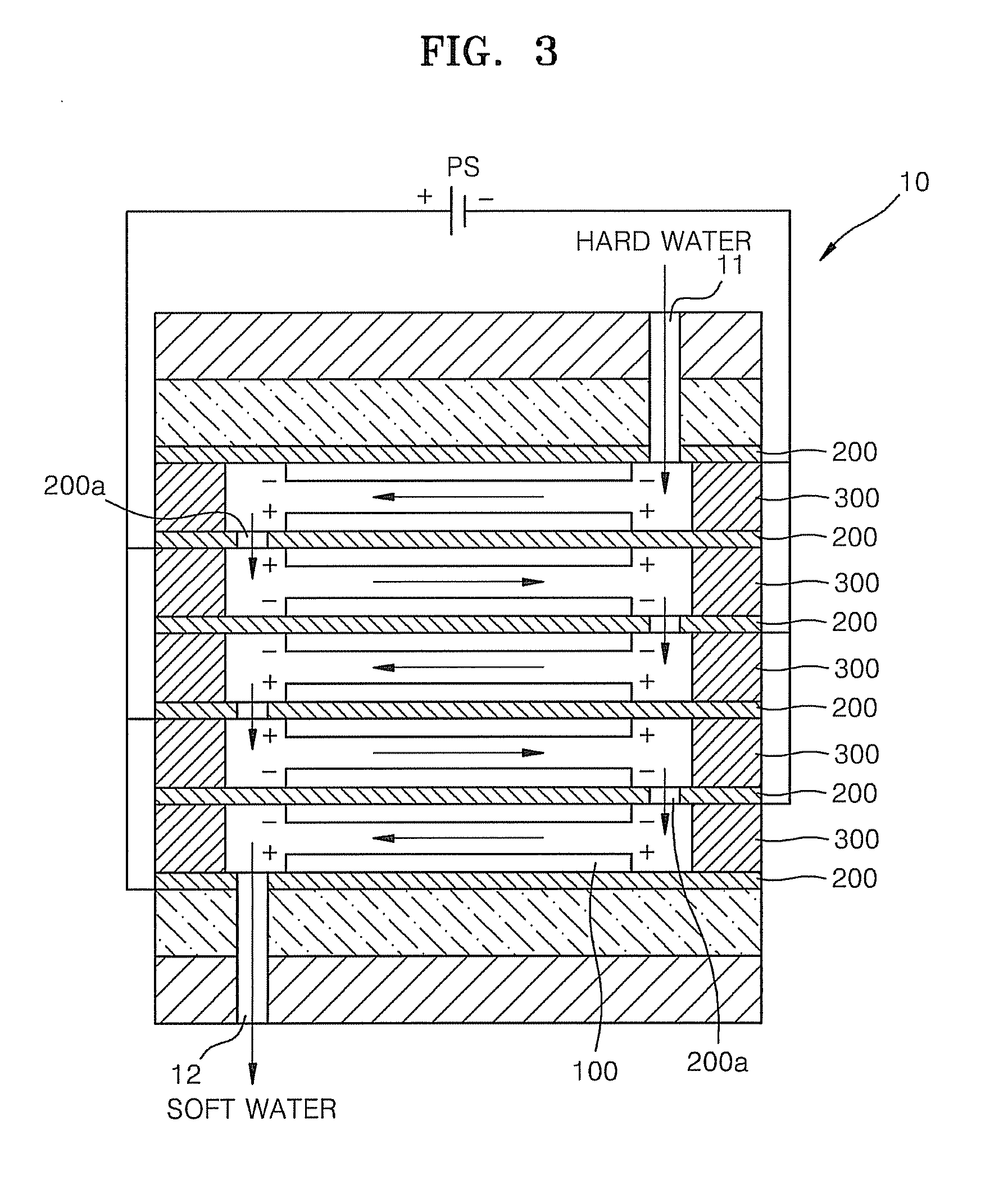

Transition metal/carbon nanotube composite and method of preparing the same

ActiveUS20100181200A1Good capacitance characteristicsImprove material removal rateElectrostatic separatorsMolten spray coatingCarbon nanotubeOxide coating

A transition metal / carbon nanotube composite includes a carbon nanotube and a transition metal oxide coating layer disposed on the carbon nanotube. The transition metal oxide coating layer includes a nickel-cobalt oxide

Owner:SAMSUNG ELECTRONICS CO LTD +1

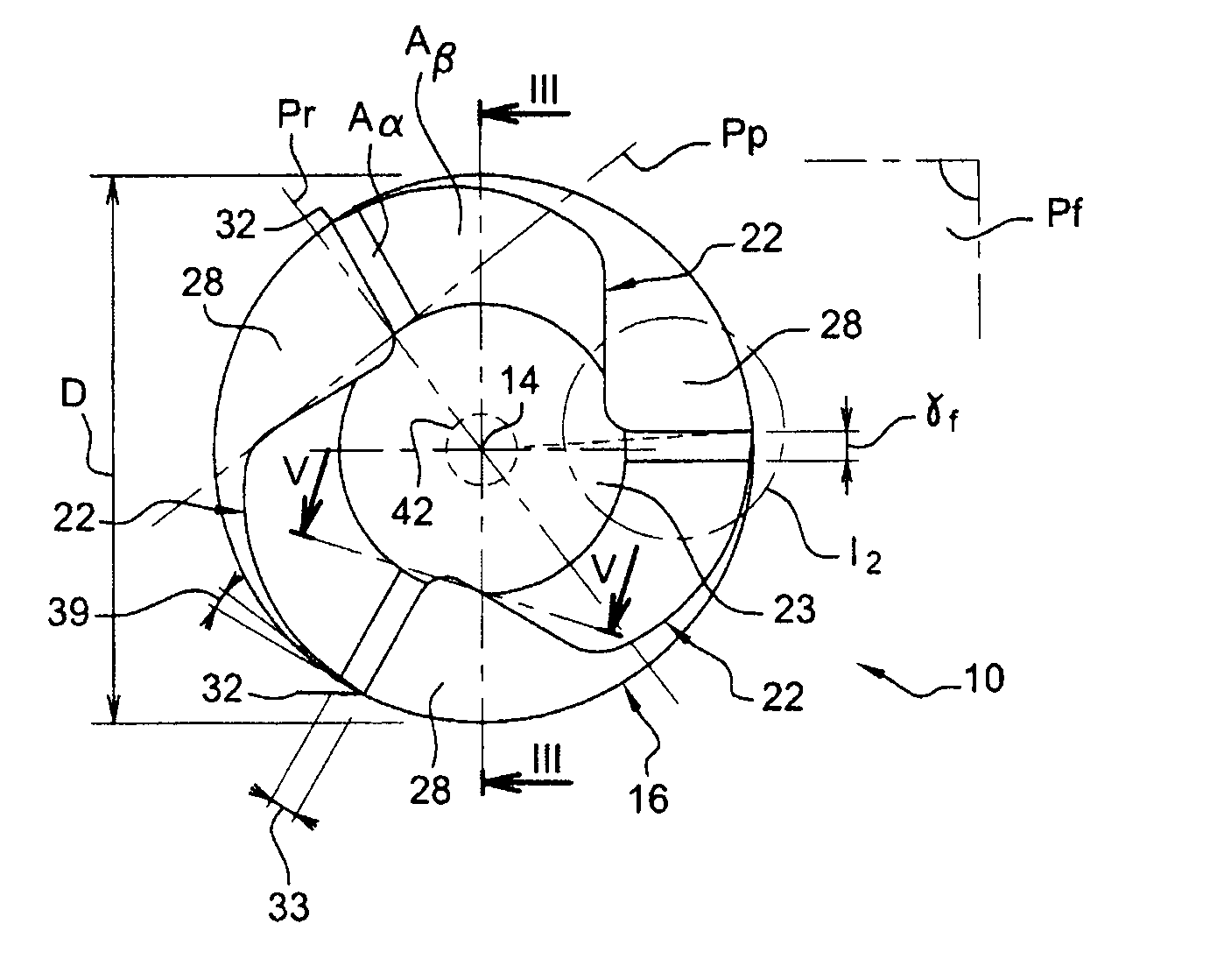

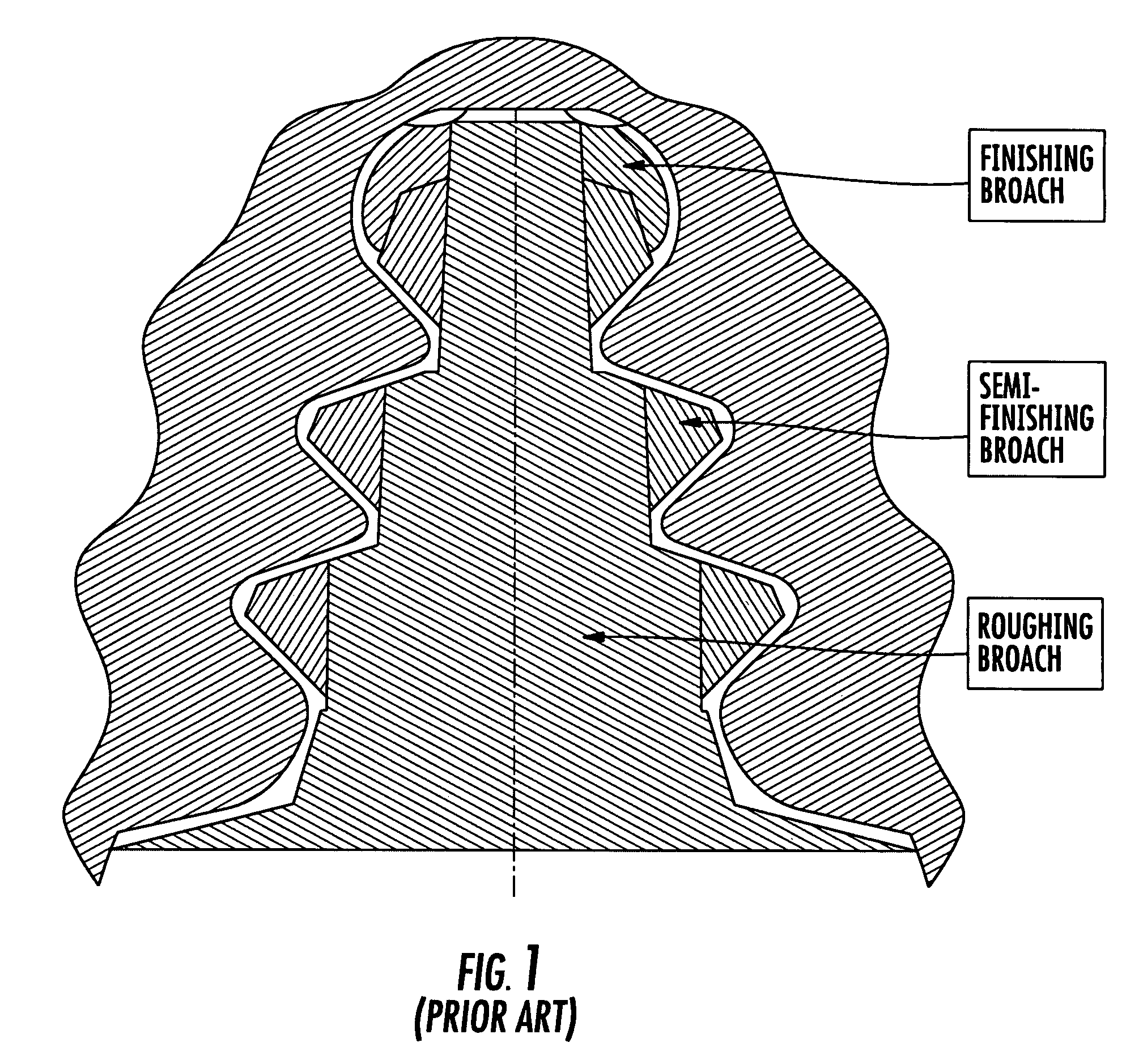

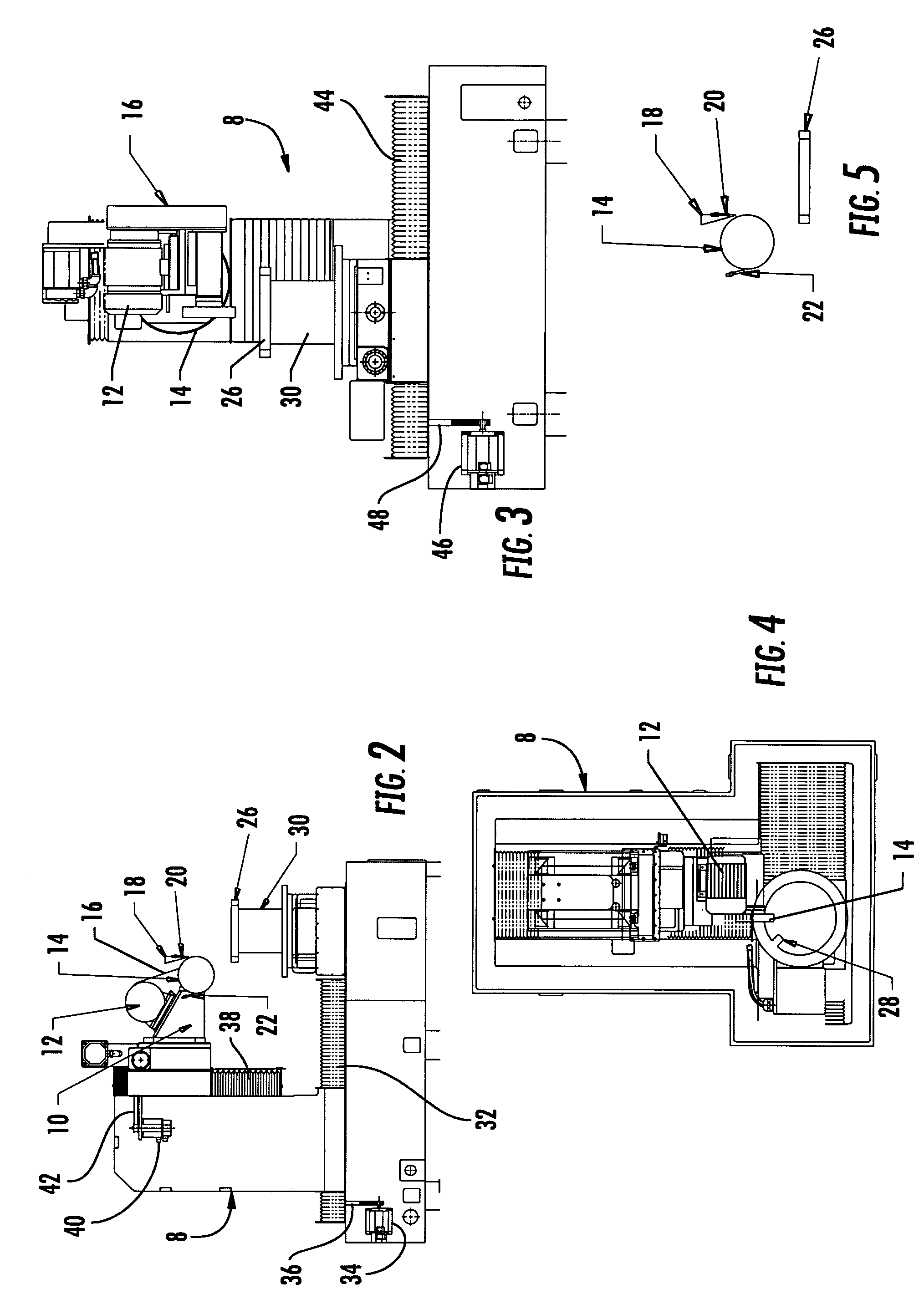

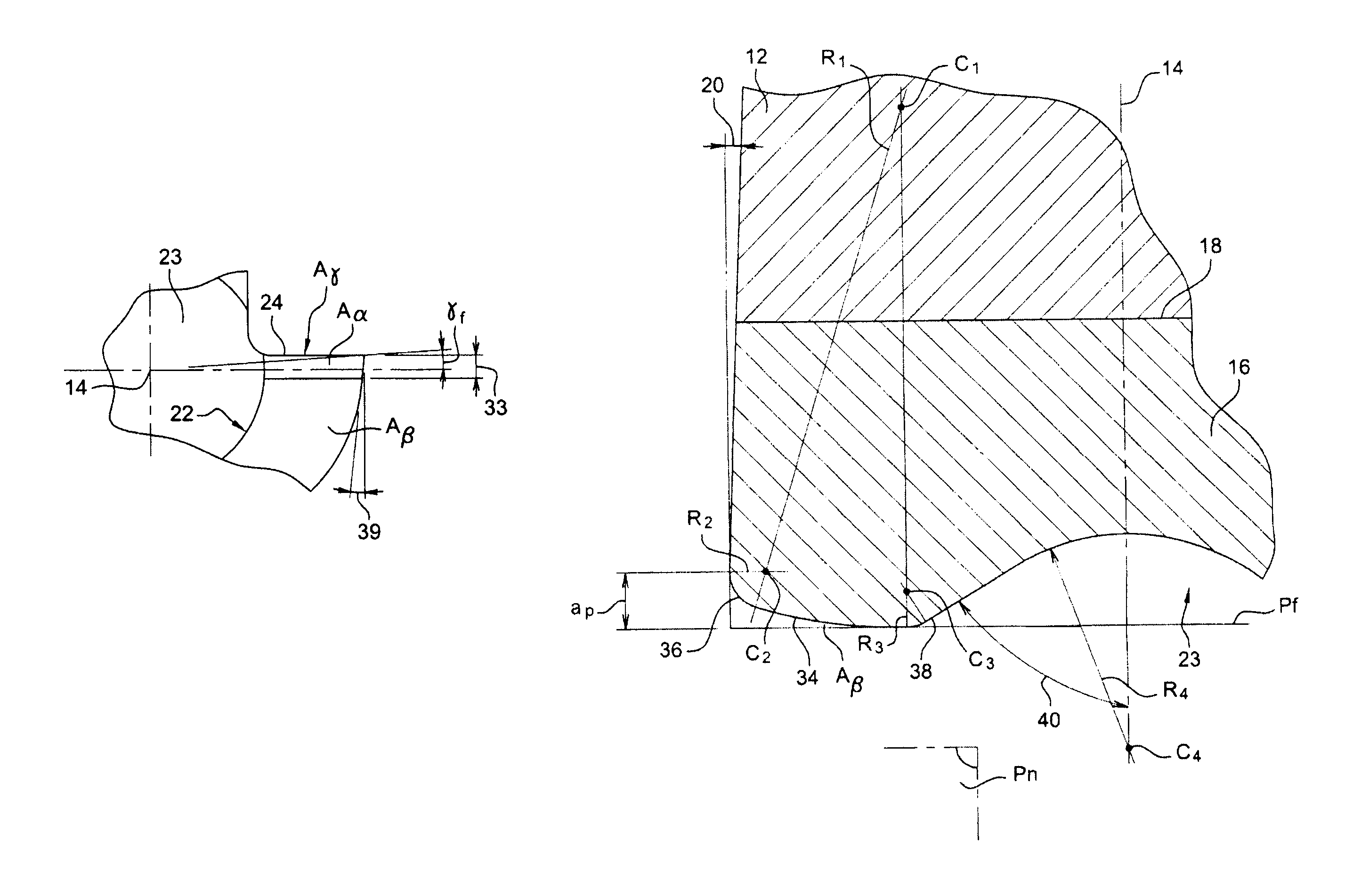

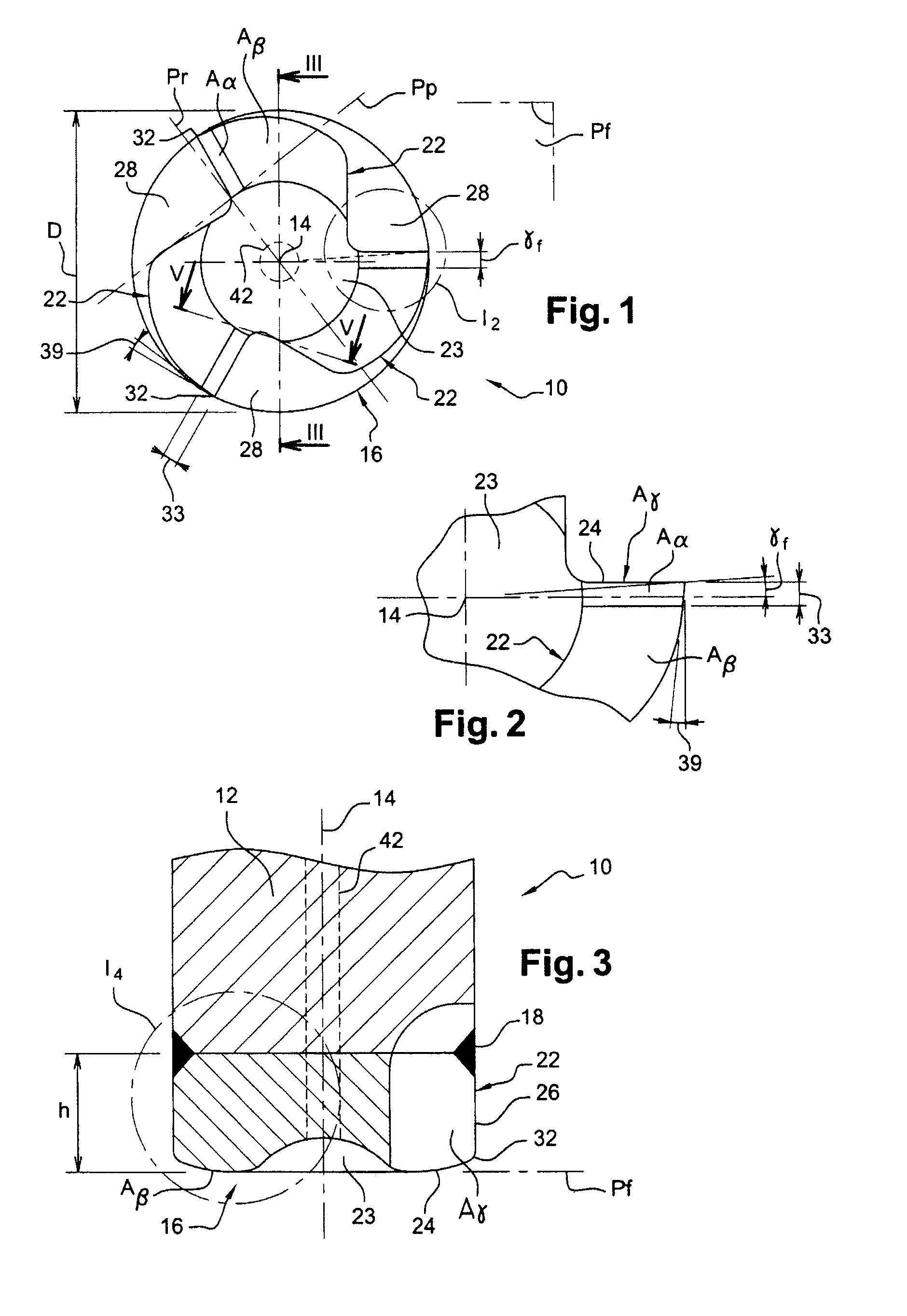

Slotting milling cutter for machining with a high feed and a low pass depth

ActiveUS20090060663A1Reduce shear forceReduce torqueTool workpiece connectionMilling cuttersMilling cutterCarbide

Slotting milling cutter, comprising a carbide body (12) and a ceramic head (16) fixed by brazing to one end of the body, this head having teeth (22), each comprising a cutting edge (24) formed by the intersection between a front cutting face (Aγ) and a lower flank face, in which the milling cutter has a frustoconical general shape, the profile of the flank face, formed by the intersection of the flank face with a plane passing through the axis of the milling cutter, has an outwardly convex rounded shape, and the radial cutting angle is negative.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

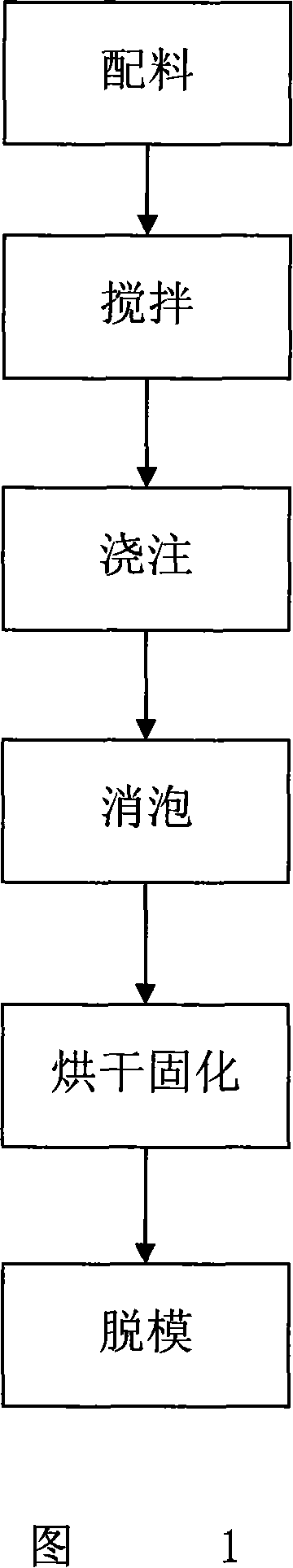

Semi-fixing abrasive grain grinding tool and method of producing the same

InactiveCN101134298AHigh bonding strengthImprove material removal rateAbrasion apparatusGrinding devicesWear particleAdhesive

The present invention is one kind of grinding tool with semi-fixed abrasive particle and its making process. The grinding tool consists of abrasive grain in 80-90 wt%, adhesive 1-10 wt% and additive 5-15 wt%. Its making process includes the following steps: 1. mixing abrasive grain, adhesive and additive, sieving and mixing with water; 2. molding the mixture in a mold; 3. eliminating bubbles from the molded grinding tool; and 4. stoving the grinding toll in a stove for curing and demolding to obtain the grinding tool with semi-fixed abrasive particle. The present invention has high processing precision and high processing efficiency.

Owner:ZHEJIANG UNIV OF TECH +1

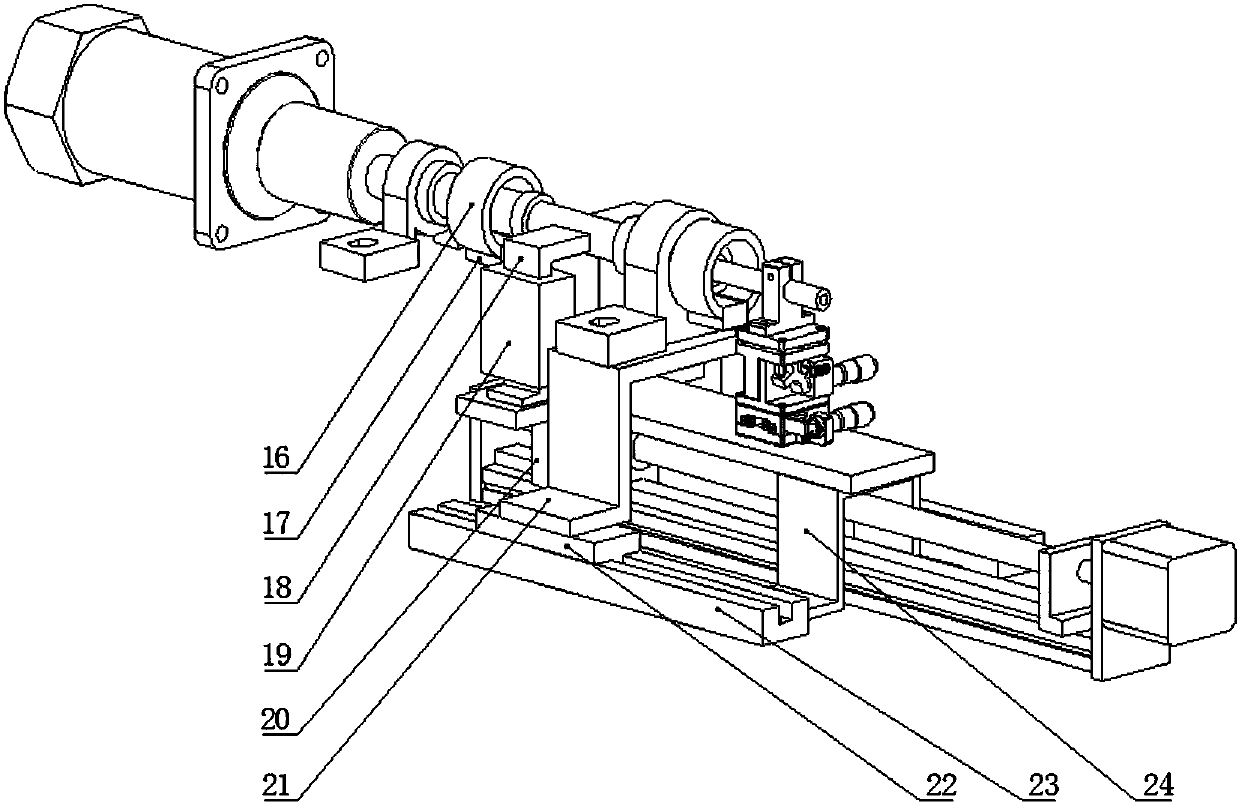

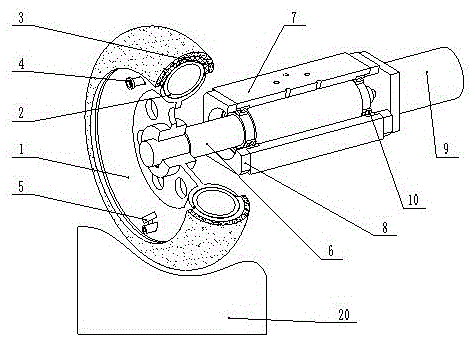

Titanium alloy pipe inner wall magneto-rheological polishing method and device

ActiveCN107791107AGood controllabilityImprove material removal ratePolishing machinesGrinding work supportsApparent viscosityMagnetic current

The invention provides a titanium alloy pipe inner wall magneto-rheological polishing method and device. Magneto-rheological liquid is pumped into a polishing head inner cavity along the inner surfaceof a transmission rod under the effect of a creepage pump, and flows over through rectangular holes around the middle of a polishing head, the liquid flows to the polishing area from the left side and the right side, under the effect of a magnetic field, the apparent viscosity and the shear yield stress of the magneto-rheological liquid are rapidly increased, a Bingham medium with certain viscousplasticity is formed, along with relative motion of the polishing head and the pipe wall, the Bingham medium carries out shear removal on the pipe wall material, the magneto-rheological liquid obtained after polishing is collected through magneto-rheological liquid collecting mechanisms on the two sides of a pipe fitting, through filtering and stirring, the polishing process is continuously carried out, and circular utilization of the magneto-rheological liquid is achieved; in the magneto-rheological liquid circulation process, heat generated in the polishing area is brought away. The inner wall of the titanium alloy pipe can be automatically polished, the beneficial effects of being easy to control, good in polishing uniformity, high in work efficiency and the like are achieved, and themethod and device are particularly suitable for polishing treatment of the inner wall surface of the fine and long titanium alloy pipe.

Owner:NORTHEASTERN UNIV

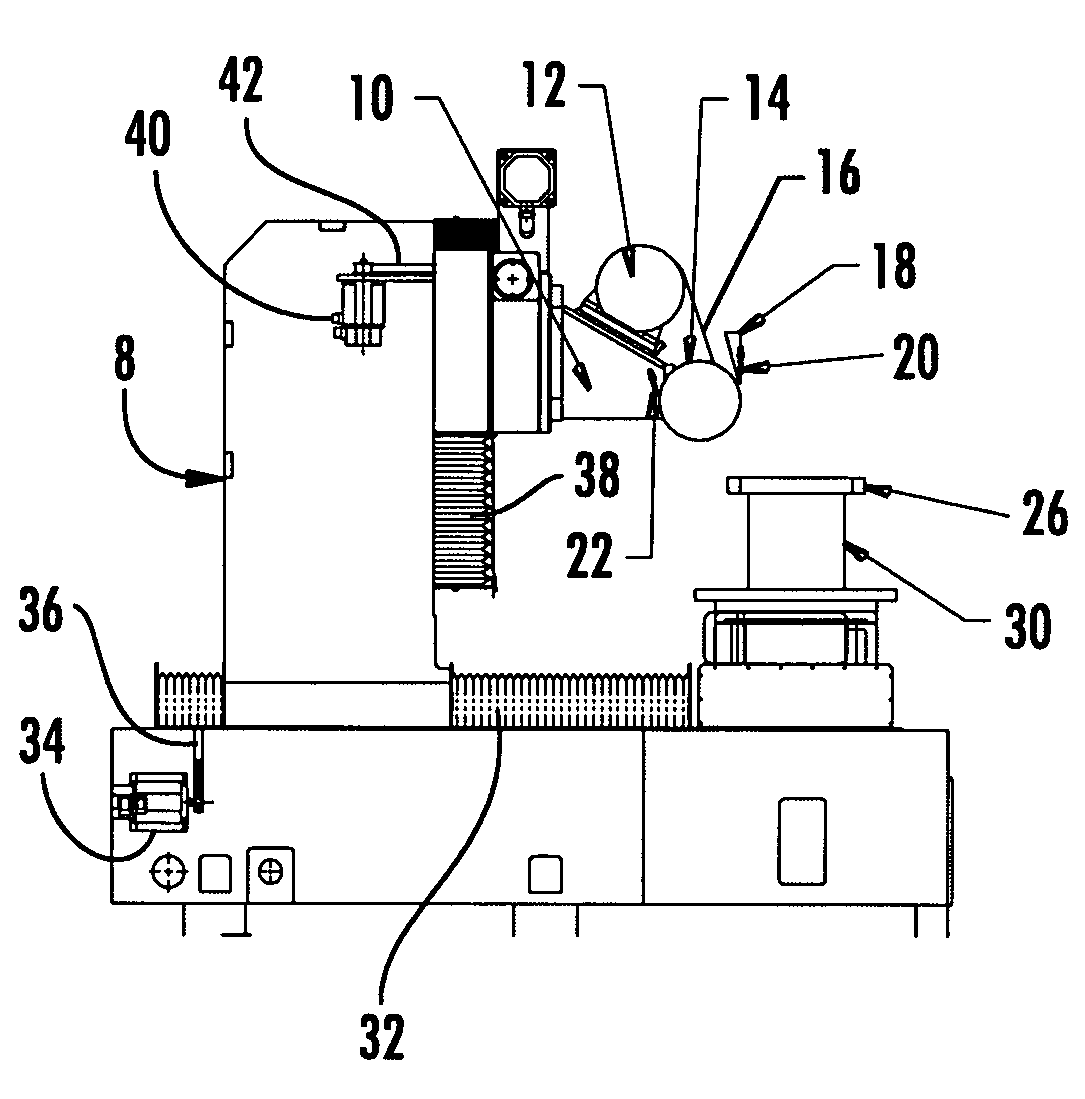

Method and apparatus for grinding a workpiece

ActiveUS7473160B1Avoids disadvantageImprove material removal rateGrinding feed controlAutomatic grinding controlParent materialEngineering

Owner:OPTOMEC INC

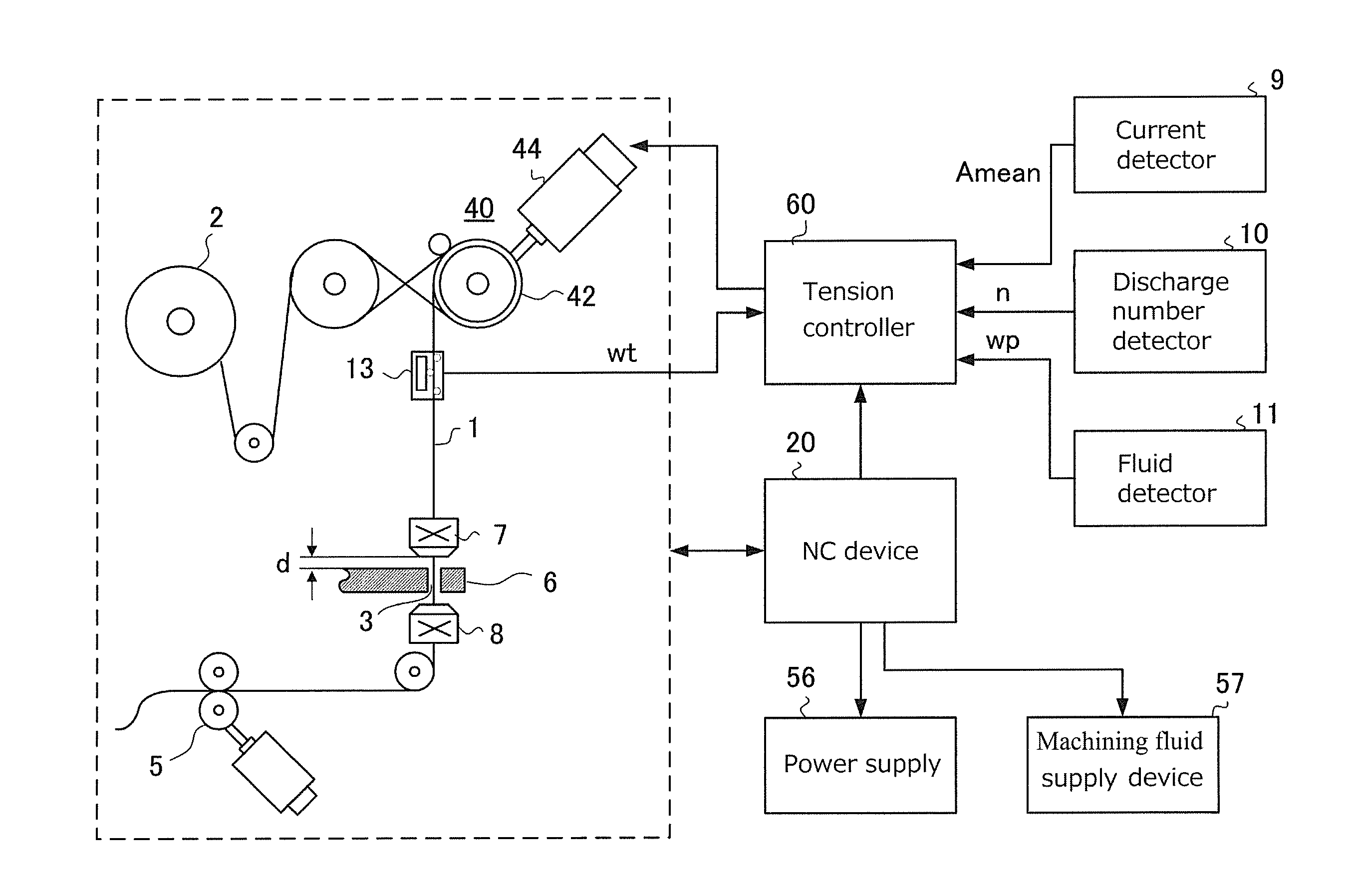

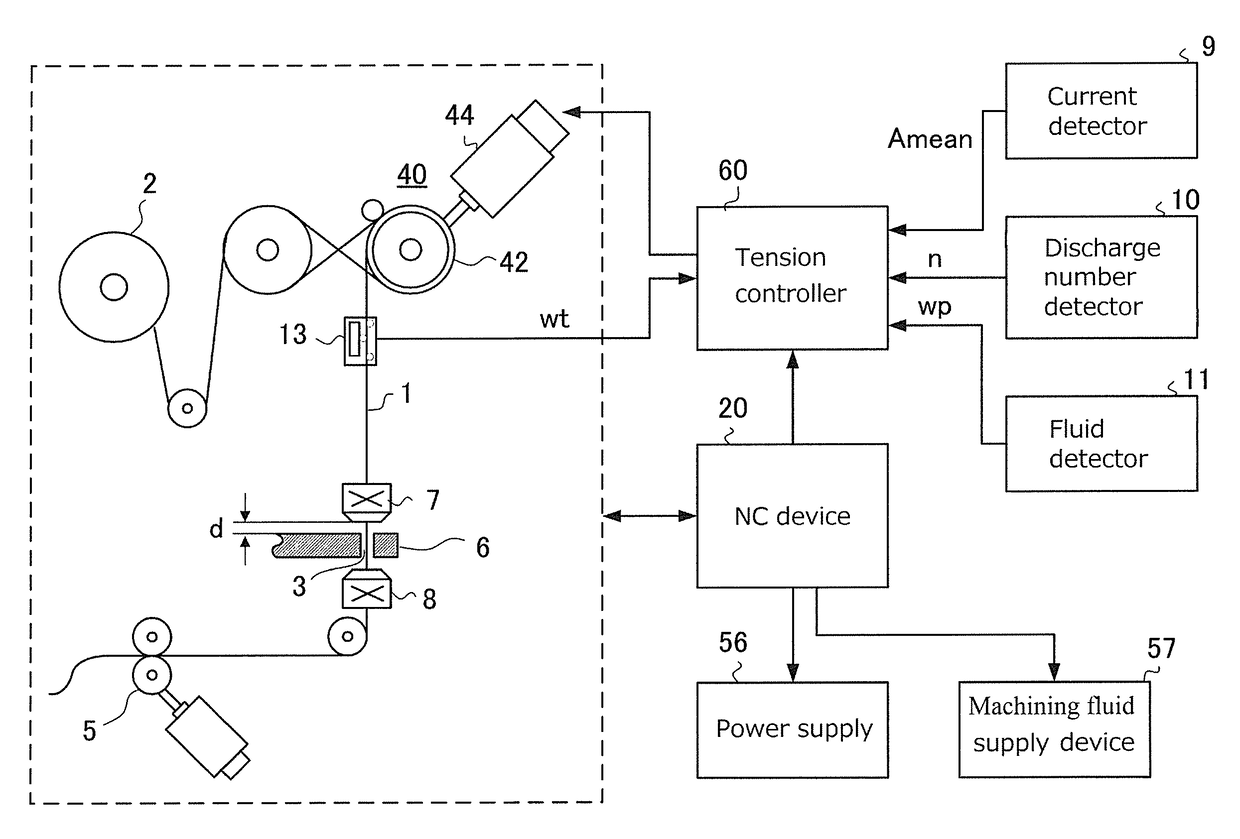

Wire electrical discharge machining device

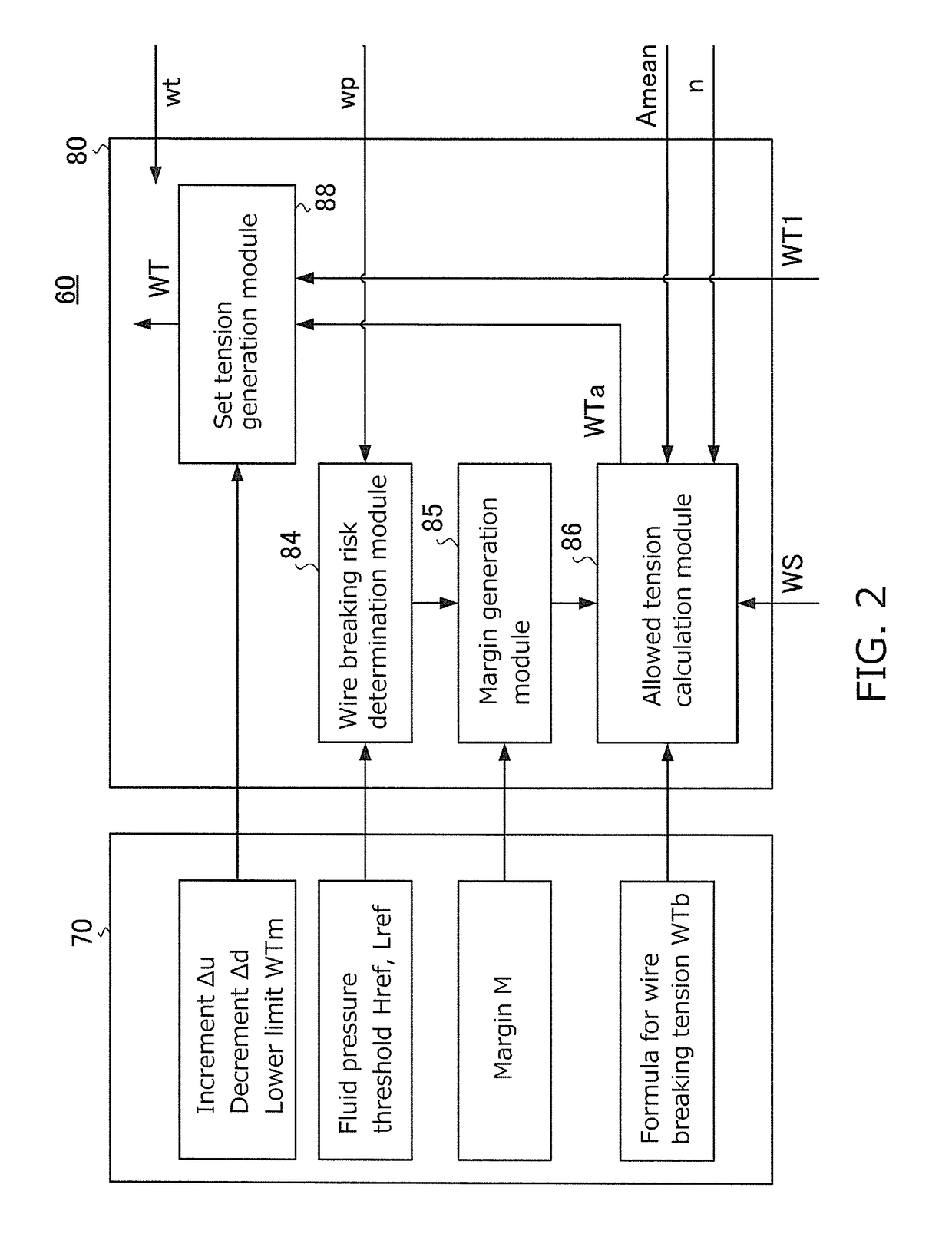

ActiveUS20130240486A1Avoid disconnectionImprove material removal rateElectrical-based machining electrodesElectric circuitsComputer moduleMechanical engineering

Provided is a wire electrical discharge machining device which has a tension controller for maintaining the tension of a traveling wire electrode at a tension. The tension controller includes: an allowed tension calculation module for determining an allowed tension that is less than a wire breaking tension at which the wire electrode breaks; and a set tension generation module for generating the set tension in accordance with the allowed tension. When the set tension is greater than the allowed tension, the set tension generation module reduces the set tension. When the set tension is less than the allowed tension, the set tension generation module increases the set tension in such a way that the set tension does not exceed the allowed tension.

Owner:SODICK CO LTD

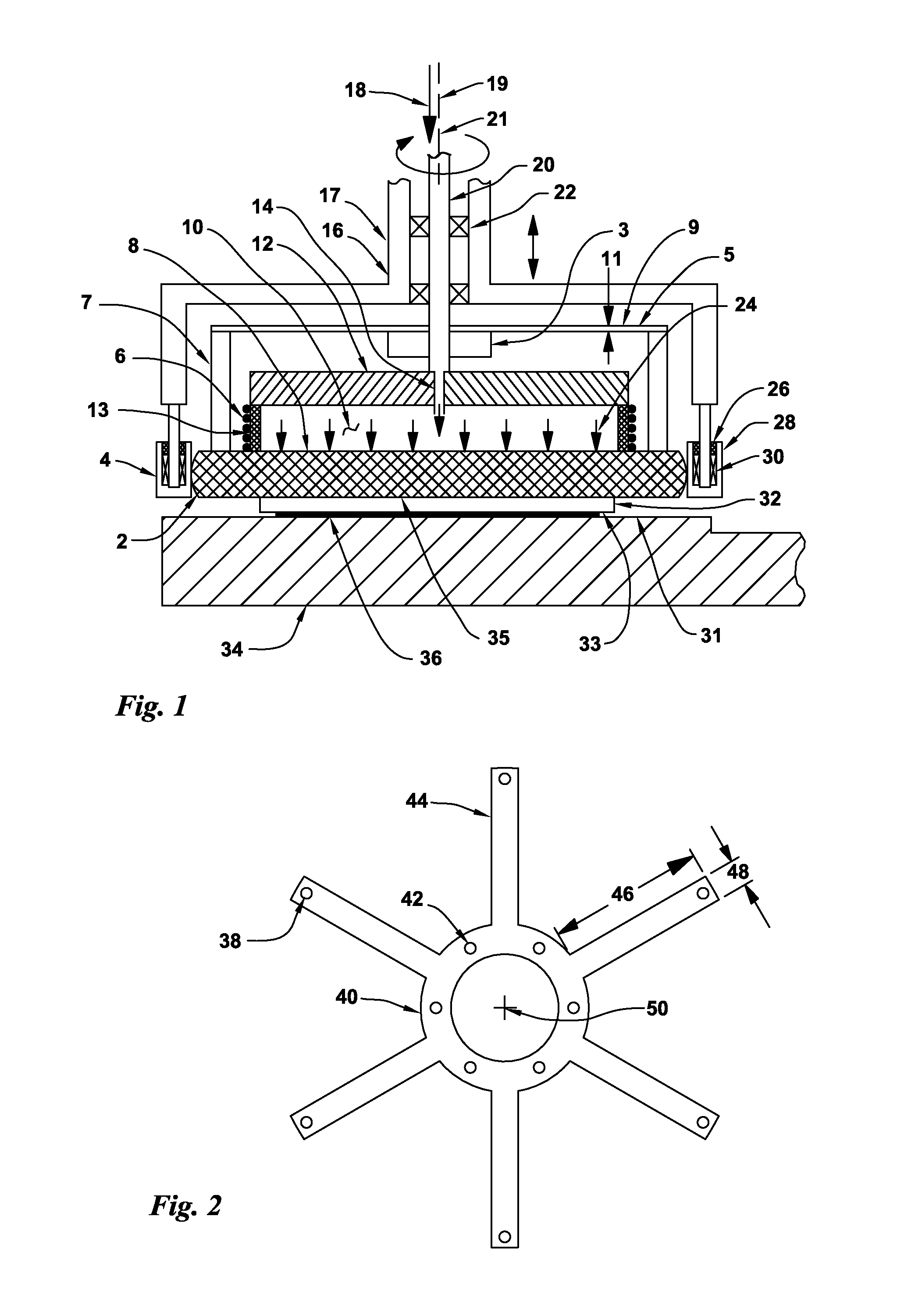

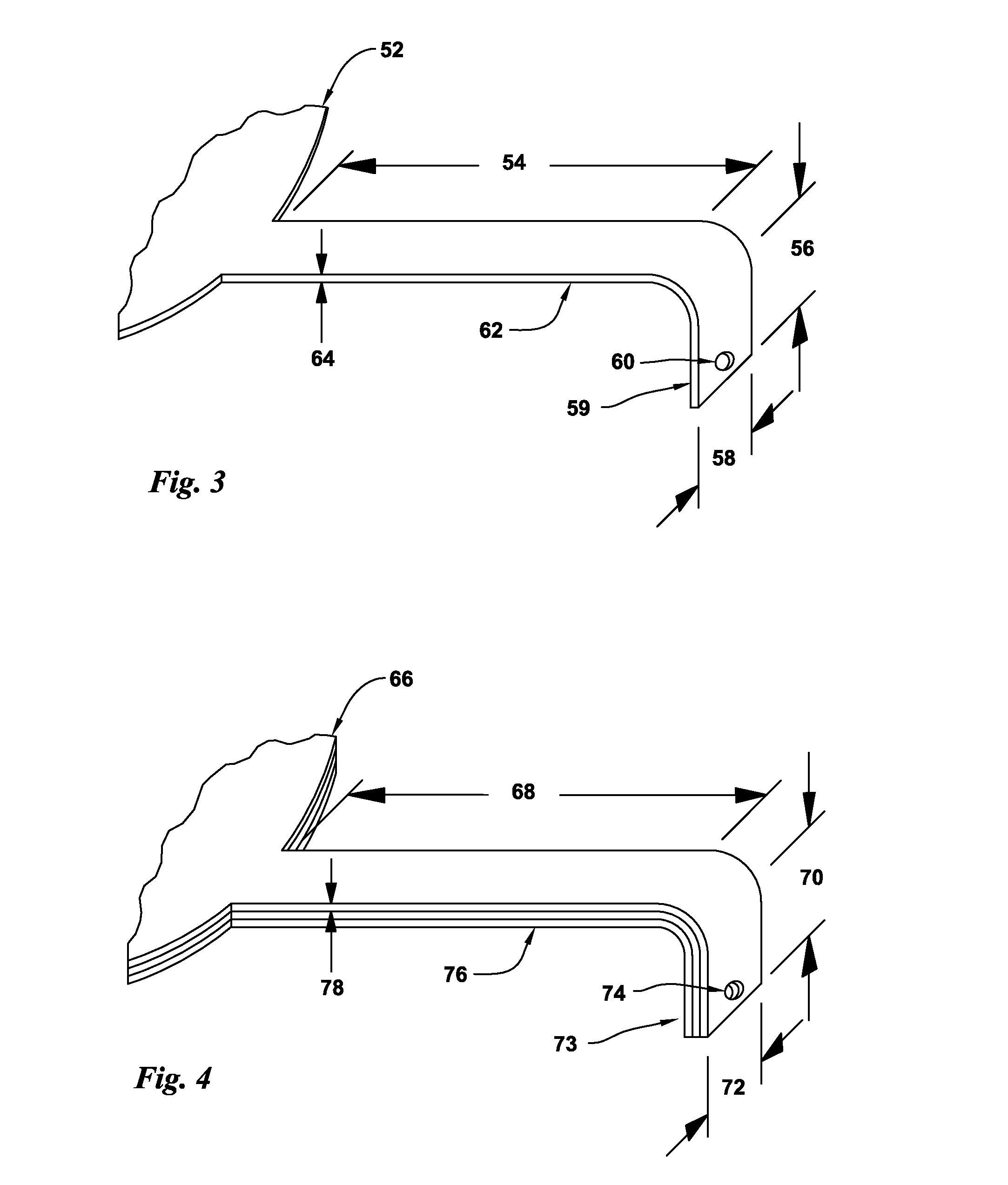

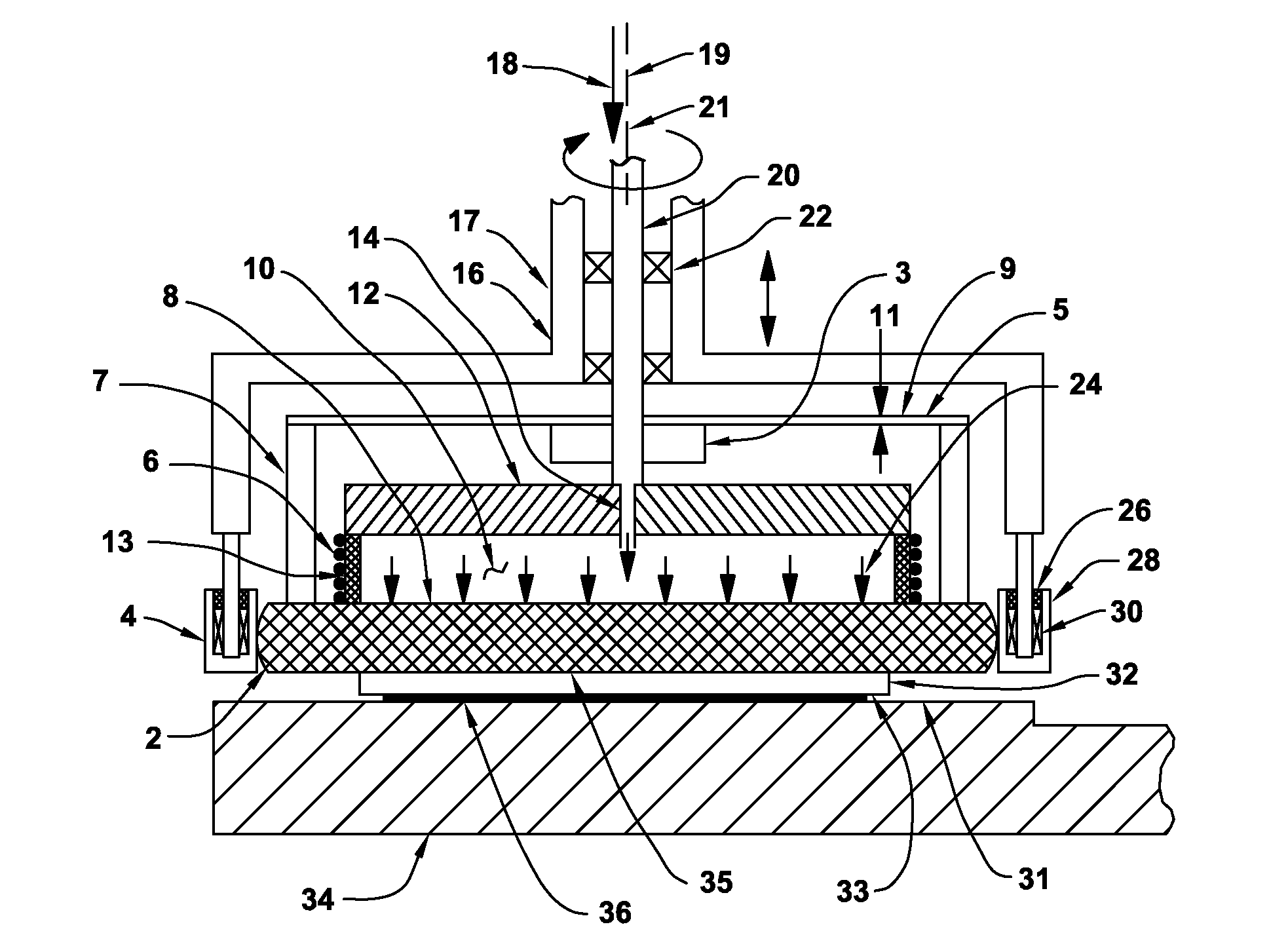

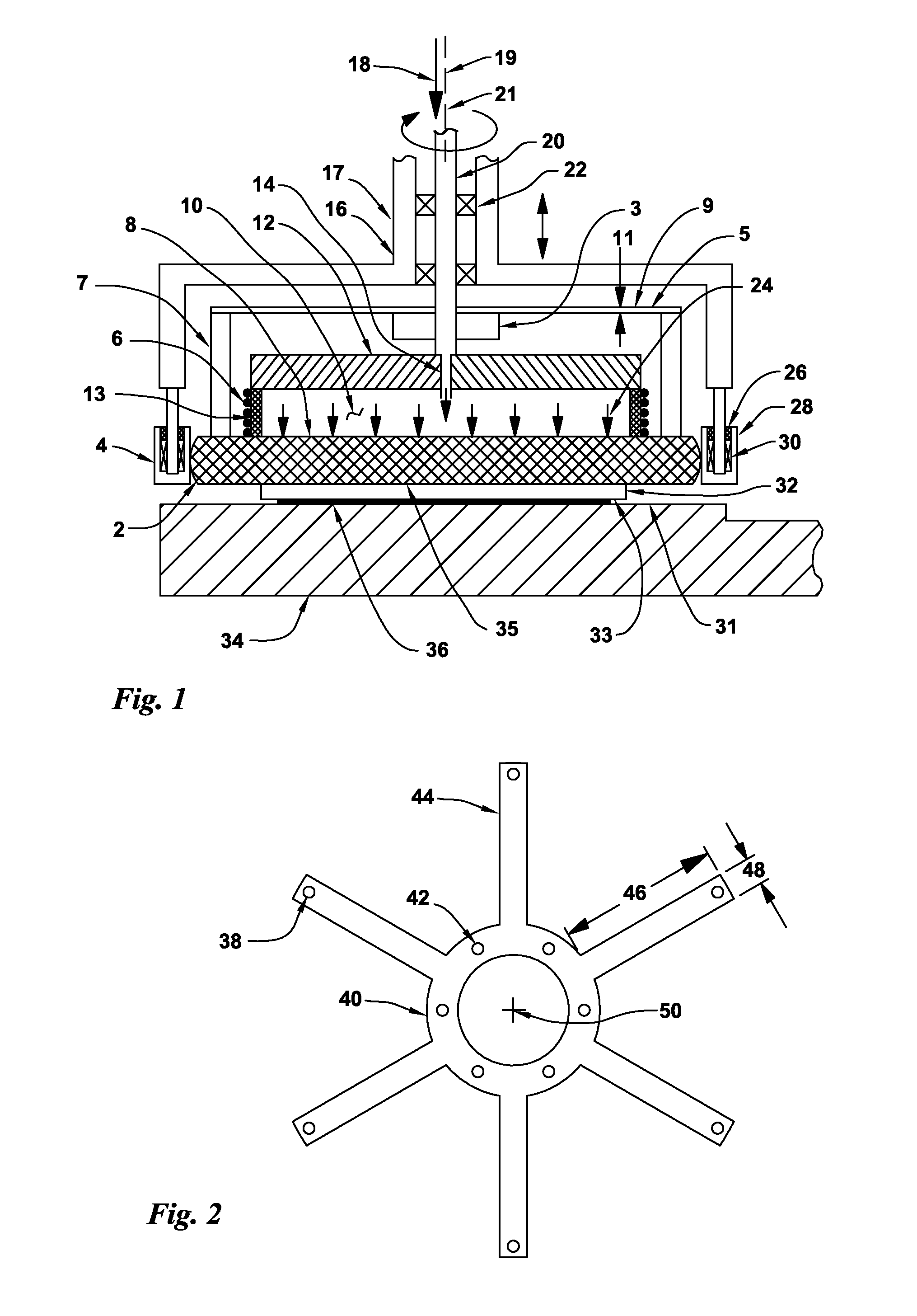

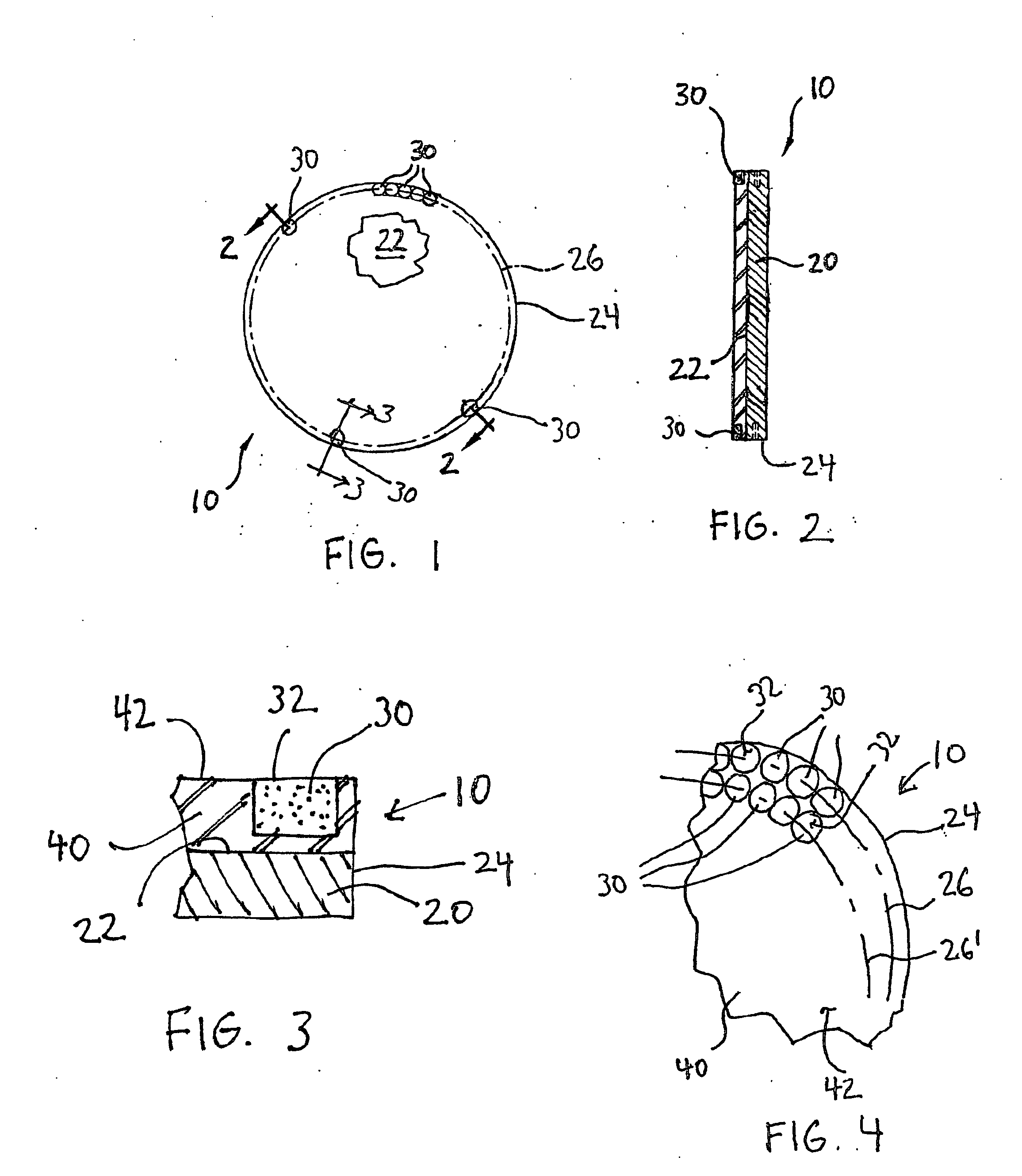

Spider arm driven flexible chamber abrading workholder

InactiveUS20140120806A1Increase vacuumIncrease speedPolishing machinesRevolution surface grinding machinesElastomerEngineering

Flat-surfaced workpieces such as semiconductor wafers or sapphire disks are attached to a rotatable floating workpiece holder carrier that is supported by a pressurized-air flexible elastomer sealed air-chamber device and is rotationally driven by a circular flexible-arm device. The rotating wafer carrier rotor is restrained by a set of idlers that are attached to a stationary housing to provide rigid support against abrading forces. The abrading system can be operated at the very high abrading speeds used in high speed flat lapping with raised-island abrasive disks. The range of abrading pressures is large and the device can provide a wide range of torque to rotate the workholder. Vacuum can also be applied to the elastomer chamber to quickly move the wafer away from the abrading surface. Internal constraints limit the axial and lateral motion of the workholder. Wafers can be quickly attached to the workpiece carrier with vacuum.

Owner:DUESCHER WAYNE O

Ultrasonic spray near drying type electrical discharge machining method and device

InactiveCN104607730AImprove material removal rateImprove processing efficiency and processing effectHigh energyEngineering

The invention provides an ultrasonic spray near drying type electrical discharge machining method. According to the method, electrical discharge machining is conducted on a workpiece through an electrical discharge machining device, and meanwhile auxiliary ultrasonic spray machining is conducted on the workpiece through an ultrasonic spray device. The invention further provides an ultrasonic spray near drying type electrical discharge machining device. The ultrasonic spray near drying type electrical discharge machining method and device have the advantages that electrical discharge machining is conducted while ultrasonic spray is conducted on working liquid, high-energy frog drops with particles being evenly distributed can be obtained through ultrasonic spray, the material removal rate is increased through the ultrasonic cavitation generated in the ultrasonic spray process, and machining efficiency and the machining effect are improved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

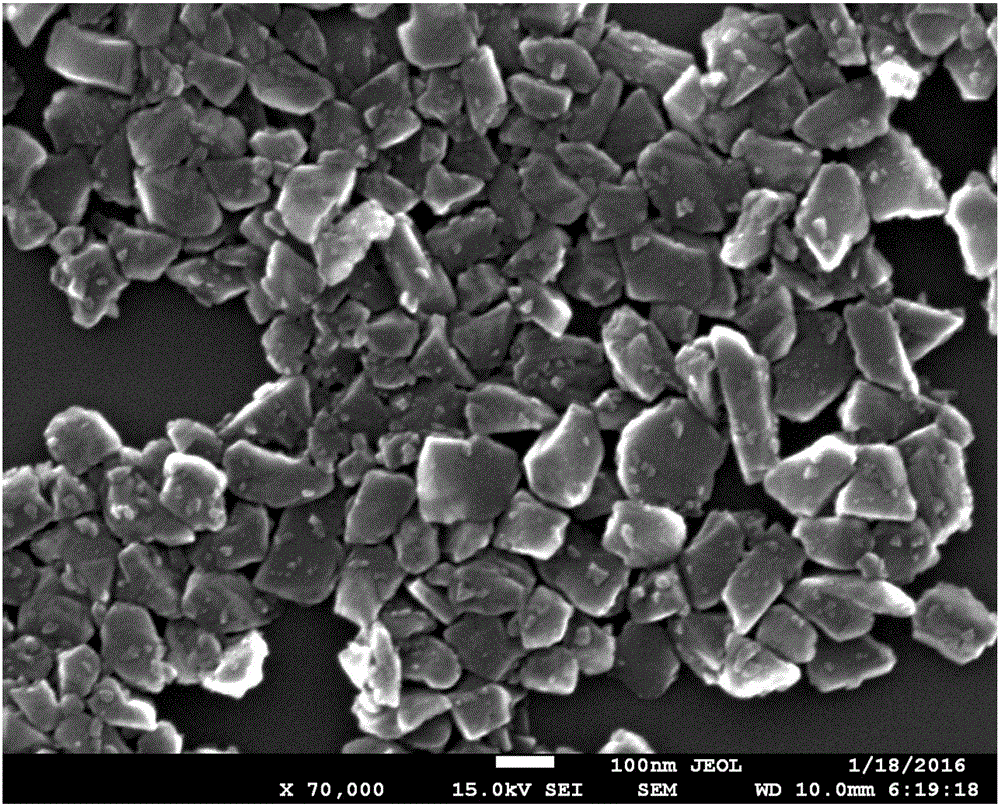

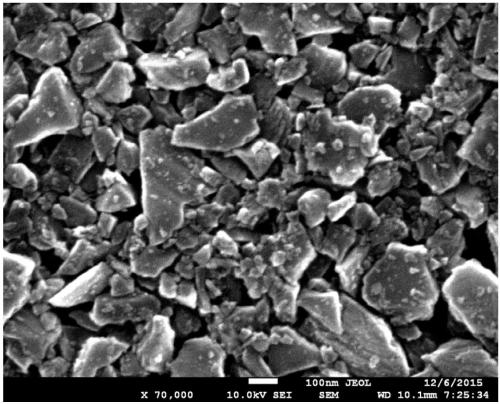

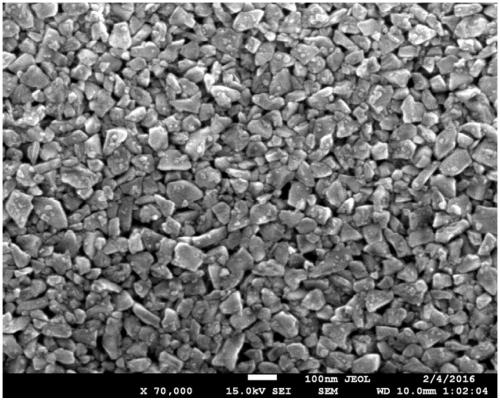

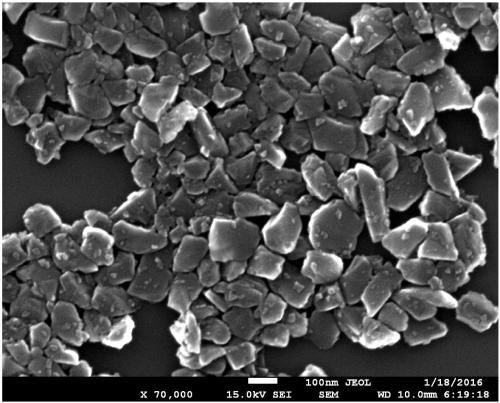

Preparation method of nanoscale diamond micropowder narrow in particle size distribution

ActiveCN106829954AHigh strengthHigh particle size concentrationEdge grinding machinesPolishing machinesSteel ballSlurry

The invention relates to a preparation method of nanoscale diamond micropowder narrow in particle size distribution. The preparation method includes: 1), mixing diamond micropowder with median particle size below 0.3um with water to obtain raw material slurry; 2), adding ultra-hard abrasive particles serving as a grinding medium into the raw material slurry for grinding and shaping, and filtering to obtain shaped slurry, wherein particle size of the grinding medium is larger than that of the diamond micropowder in the step 1); 3), grading the shaped slurry obtained in the step 2) to obtain the nanoscale diamond micropowder. The ultra-hard abrasive particles thicker than the diamond micropowder in particle size and used as the grinding medium and are high in strength, the grinding medium is more effective in friction, collision and shearing when compared with steel balls undergoing contact and collision shaping only on contact points, so that shaping efficiency is improved, and obtaining of nanoscale diamond micropowder products which are regular in shape and high in particle size concentration is facilitated.

Owner:HENAN UNION ABRASIVES

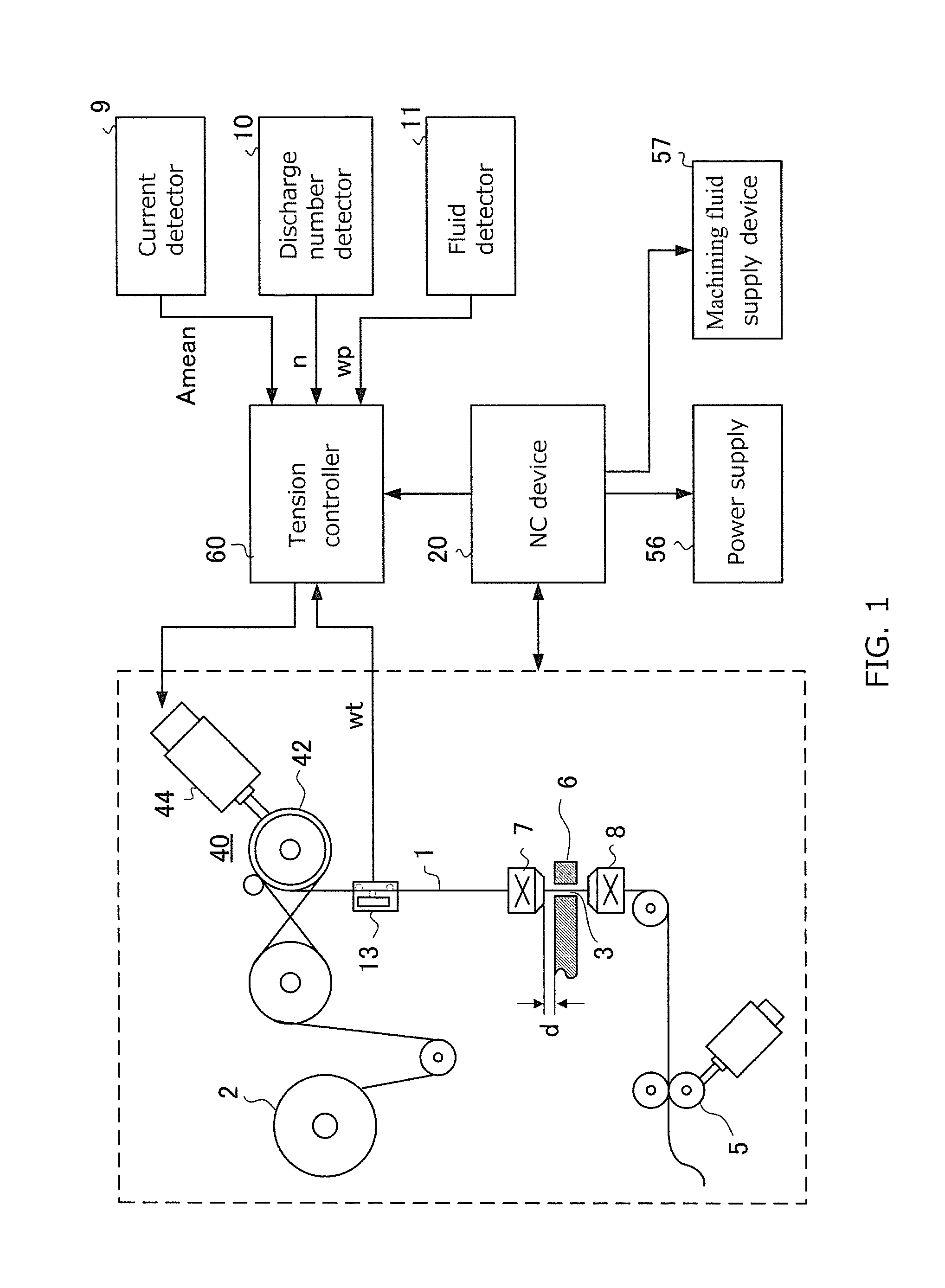

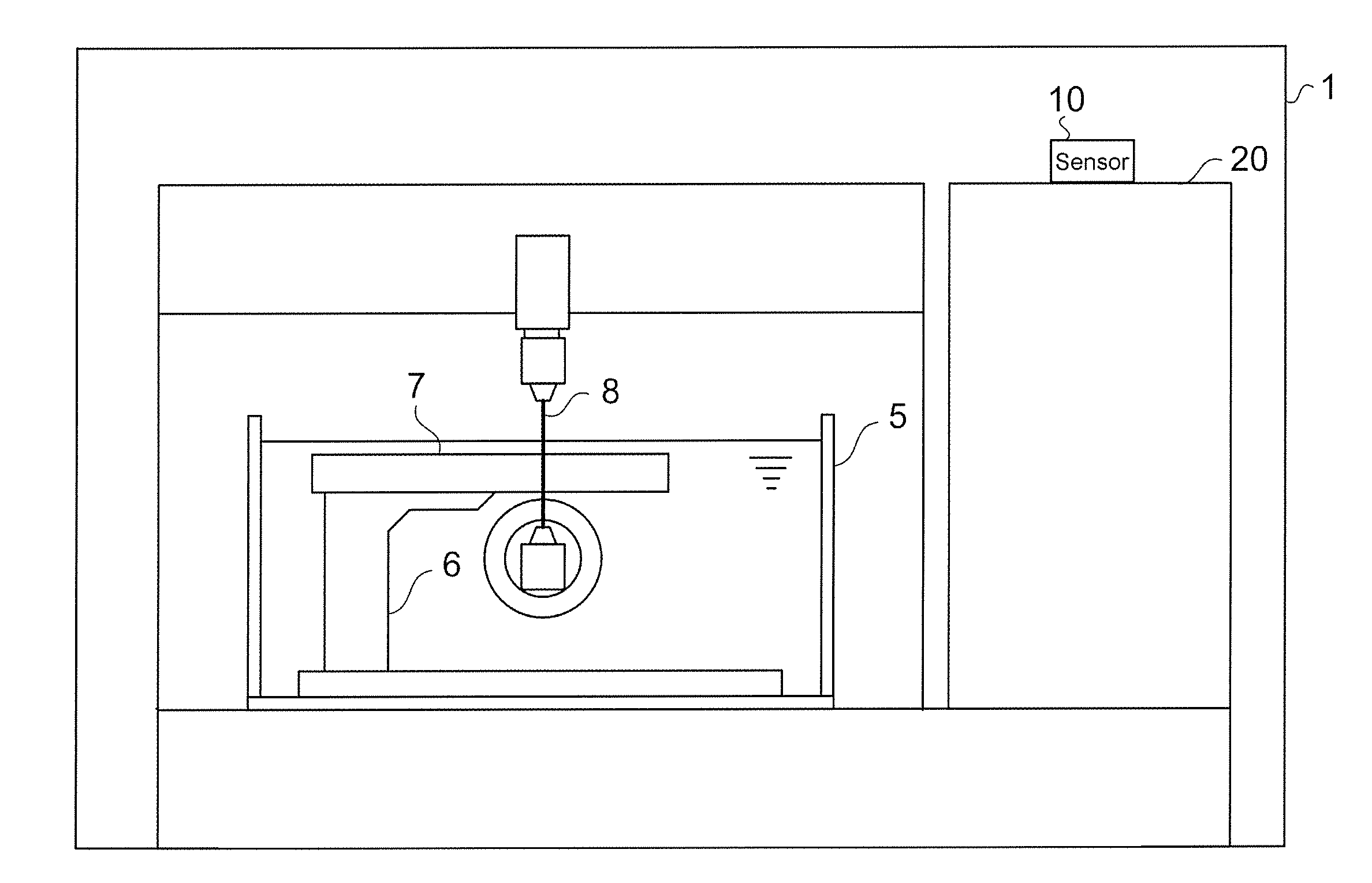

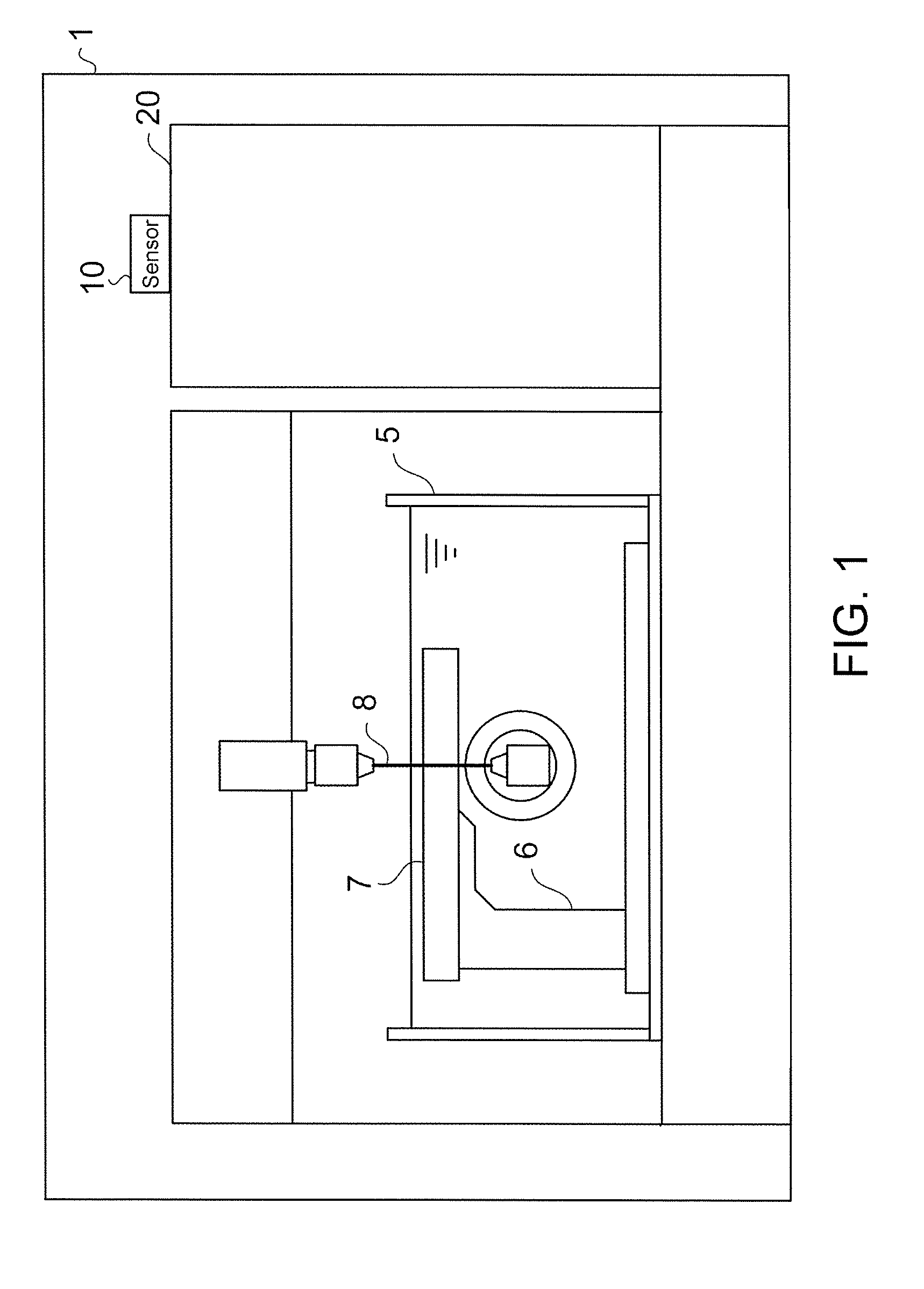

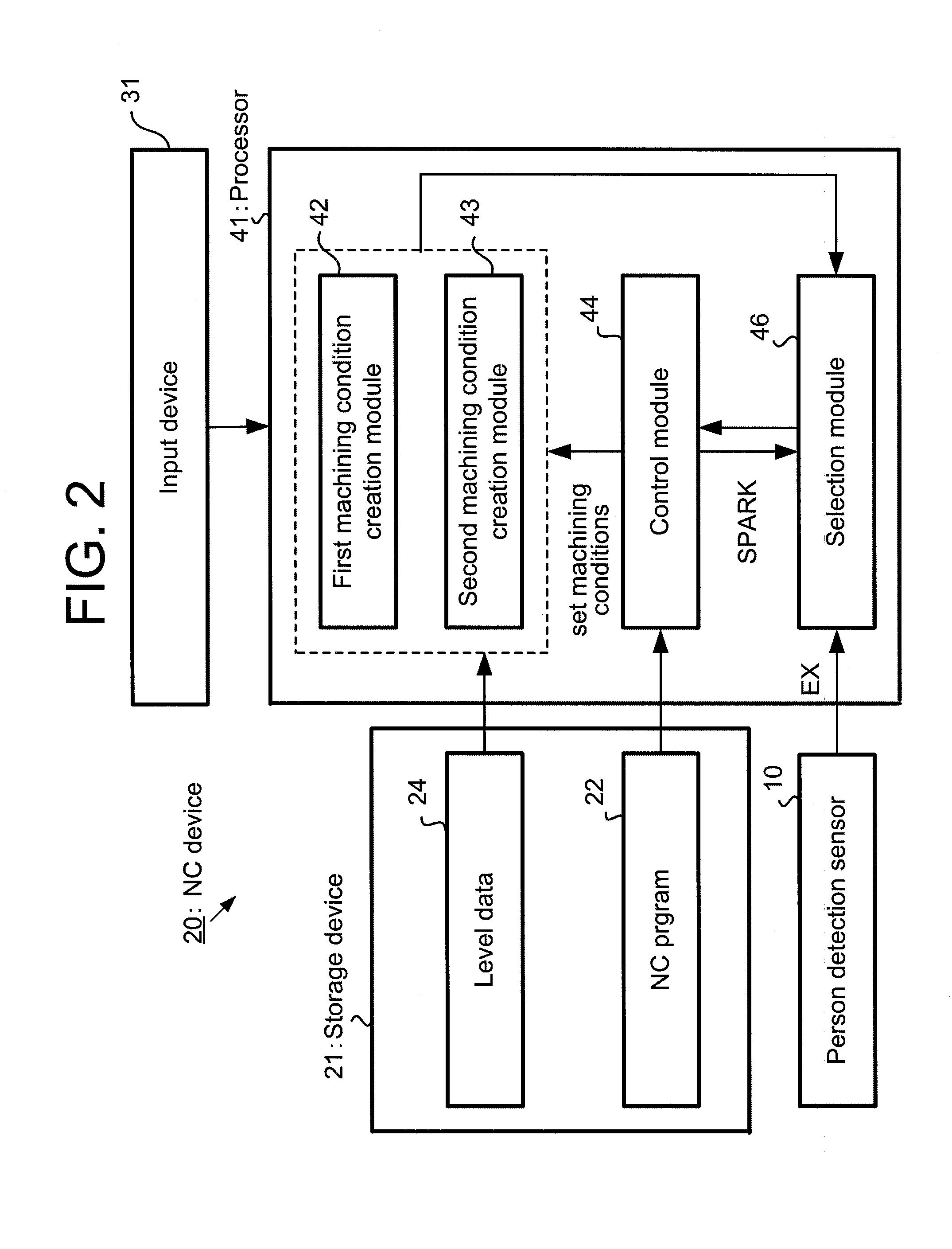

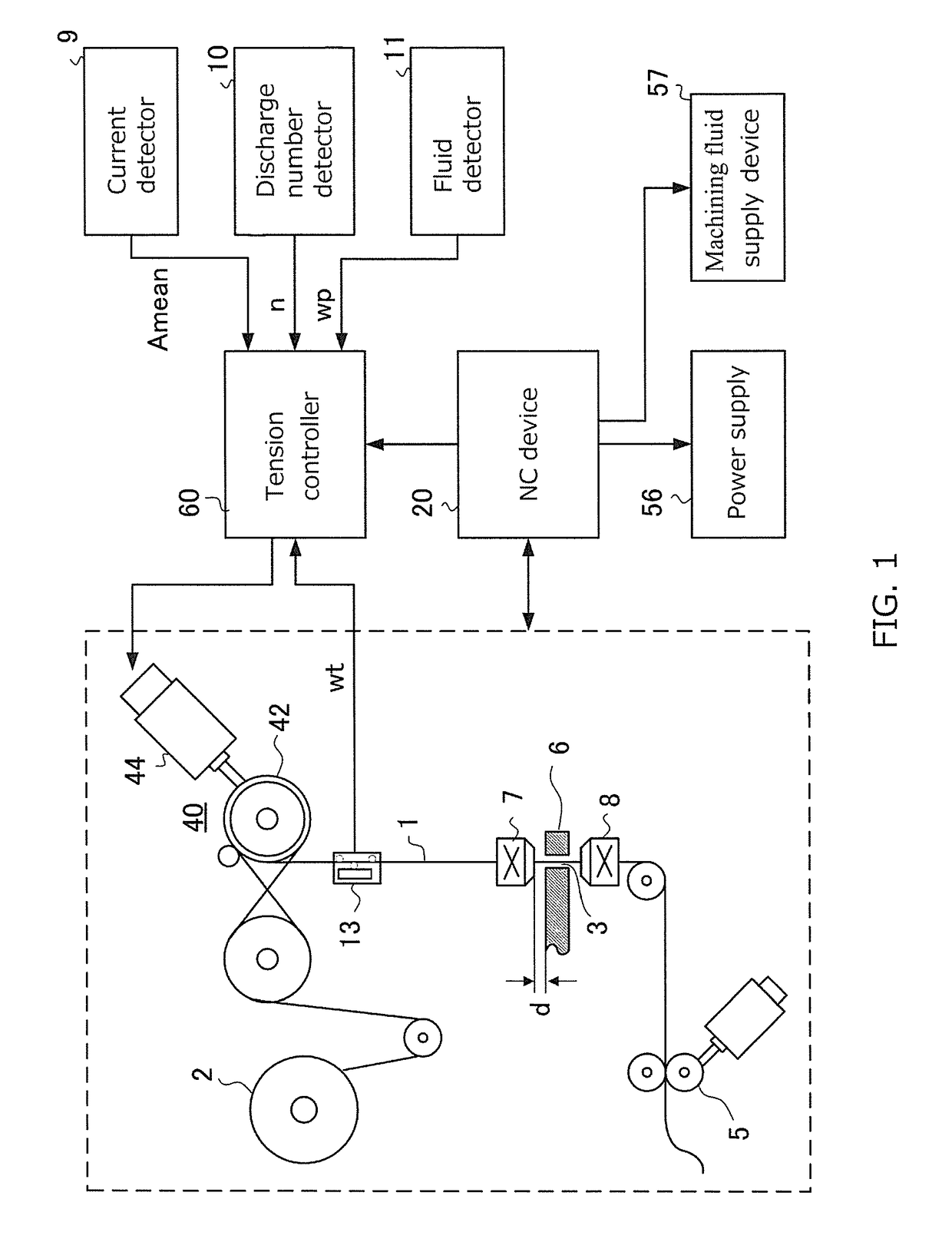

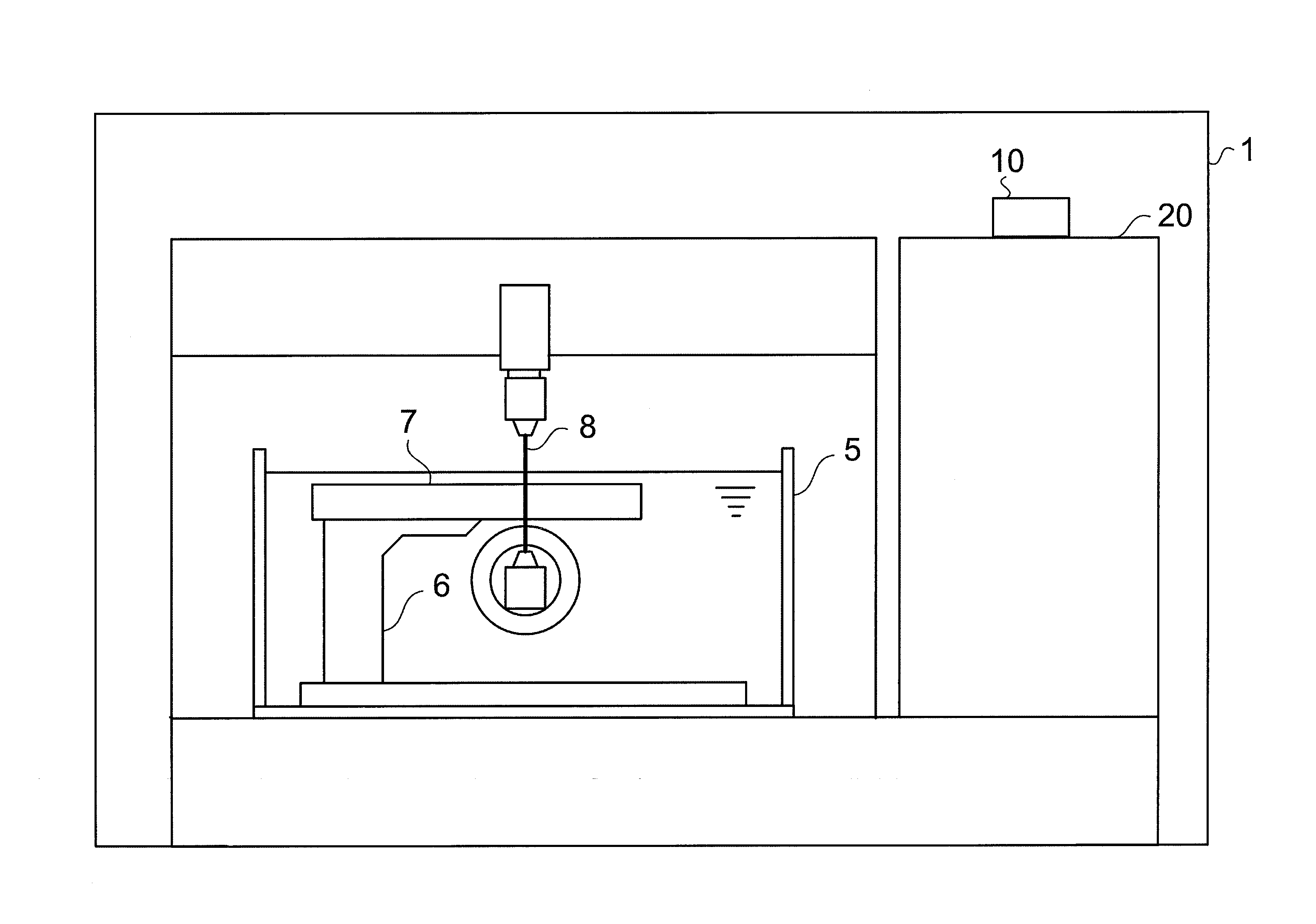

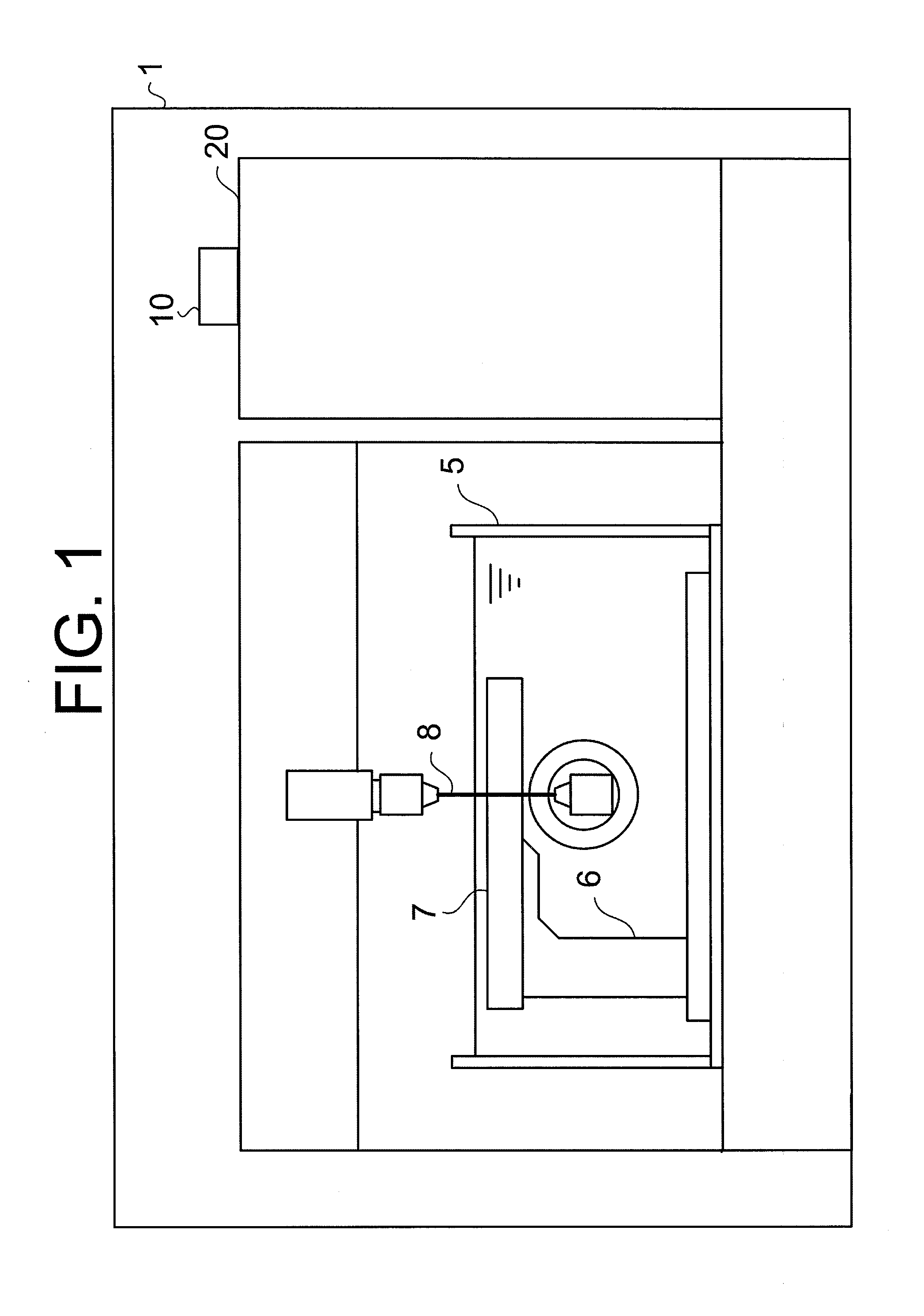

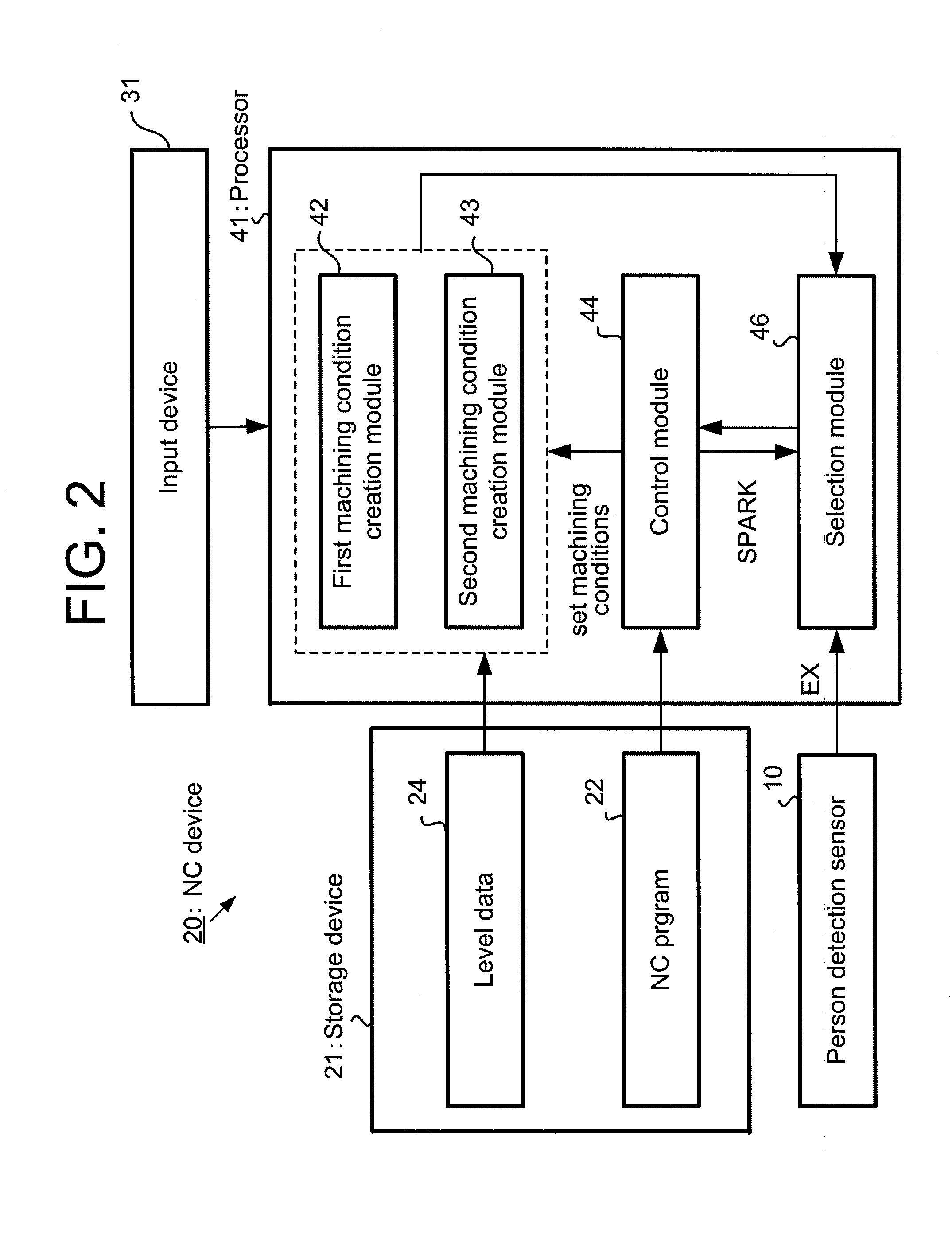

Wire electric discharge machining apparatus

ActiveUS8525063B2Reduce riskImprove material removal rateElectric circuitsSpecial data processing applicationsElectric dischargePerson detection

A wire electric discharge machining apparatus for machining a workpiece (7) by supplying current pulses to a work gap formed between a wire electrode (8) and the workpiece comprises a person detection sensor (10) for generating a person detection signal (EX) when the existence of a person is detected, and an NC device (20) that is configured to receive the person detection signal. When the NC device receives the person detection signal, it selects first machining conditions which improve machining speed. When the NC device does not receive the person detection signal, it selects second machining conditions which reduce the risk of wire breakage.

Owner:SODICK CO LTD

Graphene electrode

InactiveUS20160228964A1Outstanding propertyRequired propertyElectrolytic inorganic material coatingElectrophoretic coatingsGraphene electrodeCvd graphene

Owner:AGIE CHARMILLES

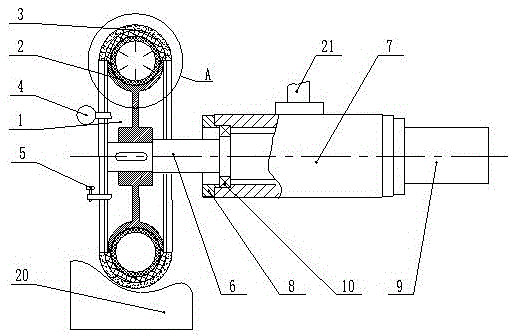

Novel disc type flexible grinding wheel machining tool

InactiveCN105598833AHigh Adaptive Profiling CapabilityImprove material removal rateGrinding headsDrive motorEngineering

The invention discloses a novel disc type flexible grinding wheel machining tool which comprises a grinding wheel disc hub, a pressure maintaining wheel, a flexible rubber base grinding wheel, a pressure monitor, a pressure adjusting valve, a rotating shaft, a connecting base, a bearing end cover, a driving motor and a bearing. The novel disc type flexible grinding wheel machining tool is characterized in that the grinding disc hub is mounted at the output end of the rotating shaft through flat keys; the pressure maintaining wheel is mounted on the grinding wheel disc hub; the flexible rubber base grinding wheel is fixedly mounted on the grinding wheel disc hub through an S-shaped barb; the rotating shaft is mounted inside the connecting base through the bearing and the bearing end cover; the driving motor is connected with the rotating shaft to drive the rotating shaft to rotate; the pressure adjusting valve and the pressure monitor are mounted on the pressure maintaining wheel. The novel disc type flexible grinding wheel machining tool has the advantages of good curved surface profiling property, high air tightness, pressure controllability, high machining efficiency and the like.

Owner:厉志安

Spider arm driven flexible chamber abrading workholder

InactiveUS8998678B2Increase speedQuick changePolishing machinesRevolution surface grinding machinesElastomerEngineering

Flat-surfaced workpieces such as semiconductor wafers or sapphire disks are attached to a rotatable floating workpiece holder carrier that is supported by a pressurized-air flexible elastomer sealed air-chamber device and is rotationally driven by a circular flexible-arm device. The rotating wafer carrier rotor is restrained by a set of idlers that are attached to a stationary housing to provide rigid support against abrading forces. The abrading system can be operated at the very high abrading speeds used in high speed flat lapping with raised-island abrasive disks. The range of abrading pressures is large and the device can provide a wide range of torque to rotate the workholder. Vacuum can also be applied to the elastomer chamber to quickly move the wafer away from the abrading surface. Internal constraints limit the axial and lateral motion of the workholder. Wafers can be quickly attached to the workpiece carrier with vacuum.

Owner:DUESCHER WAYNE O

Transition metal/carbon nanotube composite and method of preparing the same

ActiveUS8192595B2Good capacitance characteristicsImprove material removal rateElectrostatic separatorsMolten spray coatingCarbon nanotubeOxide coating

Owner:SAMSUNG ELECTRONICS CO LTD +1

Slotting milling cutter for machining with a high feed and a low pass depth

ActiveUS8123439B2Reduce shear forceReduce torqueTool workpiece connectionMilling cuttersMilling cutterCarbide

Slotting milling cutter, comprising a carbide body (12) and a ceramic head (16) fixed by brazing to one end of the body, this head having teeth (22), each comprising a cutting edge (24) formed by the intersection between a front cutting face (Aγ) and a lower flank face, in which the milling cutter has a frustoconical general shape, the profile of the flank face, formed by the intersection of the flank face with a plane passing through the axis of the milling cutter, has an outwardly convex rounded shape, and the radial cutting angle is negative.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

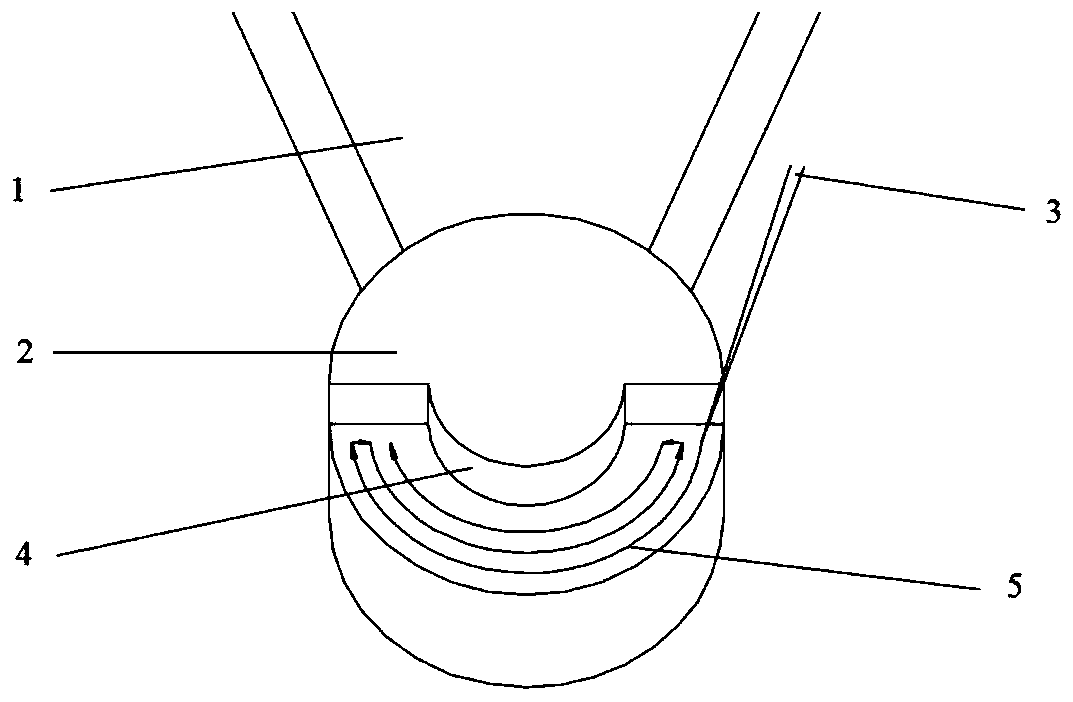

Ultrasonic-electric combined cutting device and method for SiC single crystal wafer.

InactiveCN105033373AShorten finished product processing timeImprove material removal rateUltrasonic generatorElectrochemistry

The invention discloses an ultrasonic-electric combined cutting device for a SiC single crystal wafer. The ultrasonic-electric combined cutting device comprises a glass groove. The glass groove is formed in a machine tool clamp. The bottom in the glass groove is fixedly connected with a resin base. The resin base is provided with a SiC crystal bar. A scroll saw is arranged above the glass groove. An ultrasonic generator is arranged above the scroll saw. The scroll saw is connected with the negative electrode of a direct-current pulse power source to serve as the cathode electrode. The SiC crystal bar is connected with a positive electrode of the direct-current pulse power source to serve as the anode electrode. An electrolytic solution is arranged in the glass groove, and the SiC crystal bar is soaked in the electrolytic solution. Diamond particles are dispersed in the electrolytic solution. The invention further discloses an ultrasonic-electric combined cutting method for the SiC single crystal wafer. According to the ultrasonic-electric combined cutting device and method for the SiC single crystal wafer, through an ultrasonic vibration machining and electrochemical machining combined method, the finished product machining time of the SiC single crystal wafer is shortened, the material removal rate is increased, wafer surface quality is improved, wear of the diamond scroll saw is lowered, waste caused by direct cutting of the scroll saw for precious hard and brittle materials is lowered, and the service life of the cutting device is prolonged.

Owner:XIAN UNIV OF TECH

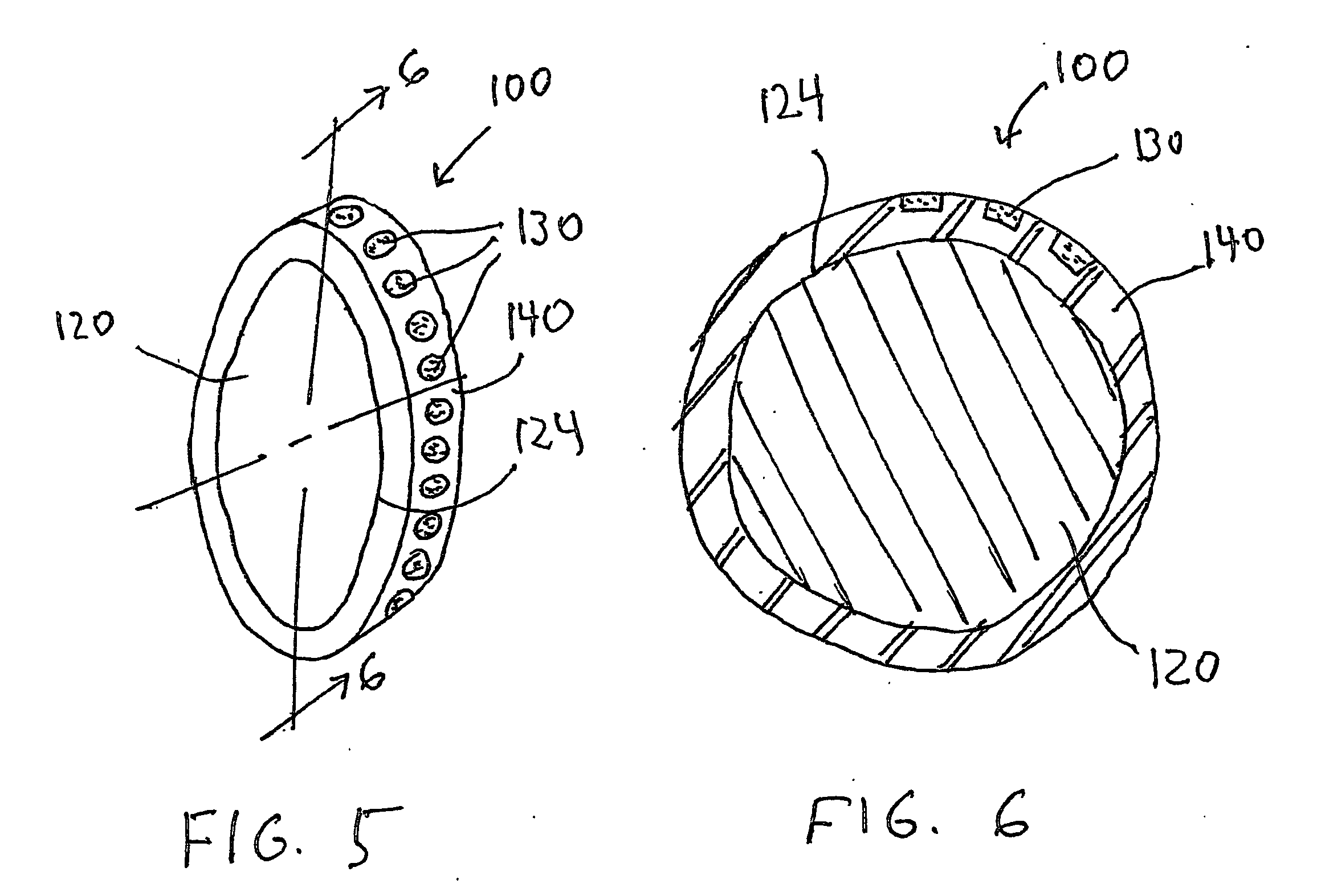

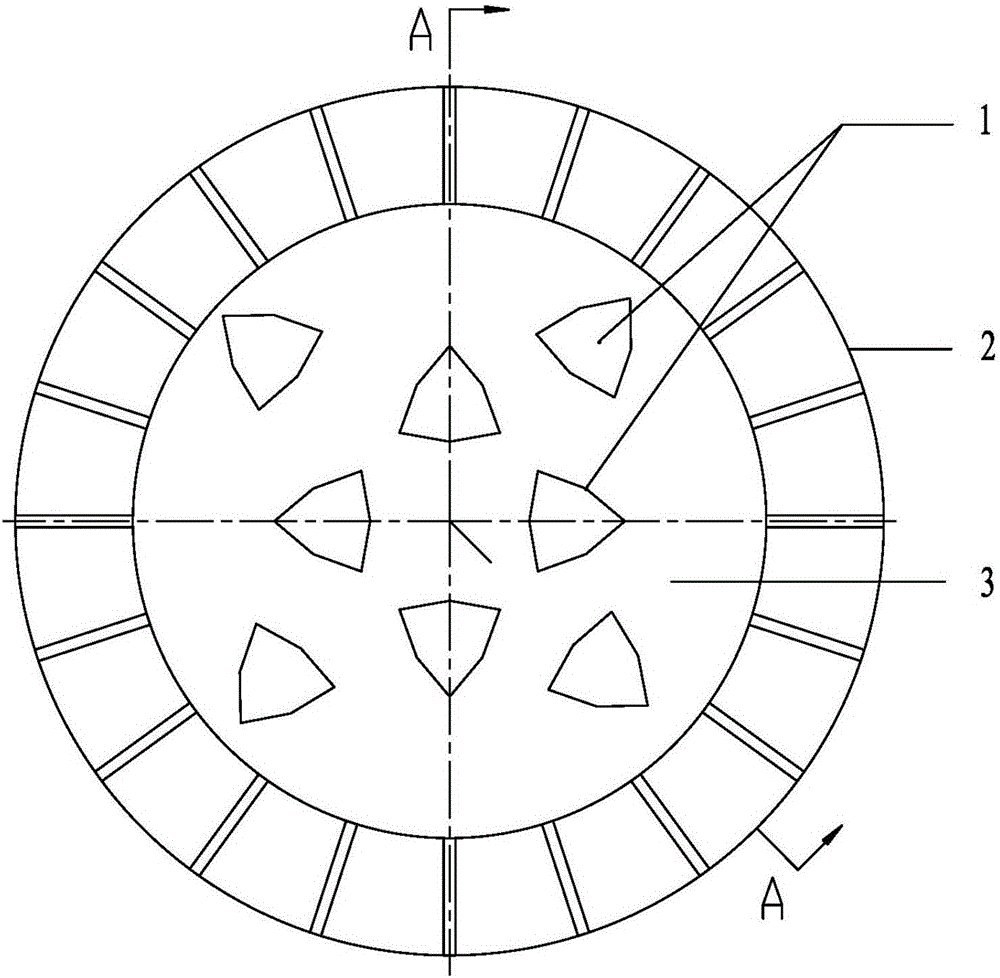

Segmented superabrasive grinding device

InactiveUS20050181715A1Improve cooling effectImprove machine efficiencyRevolution surface grinding machinesOther chemical processesHexagonal boron nitrideBoron nitride

The present invention is for a grinding device, such as a surface grinding disc or an annular grinding wheel, constructed from a plurality of abrasive segments arranged in an array thereon, wherein the plurality of abrasive segments are embedded in a matrix composition, and wherein the device is abapted to perform a “dry machining” operation. The abrasive segments may be resin bonded or vitrified and may include diamond or other superhard or superabrasive particles, such as, for example, cubic boron nitride (“cBN”), dispersed therein. Both the abrasive segments and the matrix composition include a dry lubricant, such as hexagonal boron nitride, molybdenum disulfide or graphite, dispersed therein. The abrasive segments further include a melt phase metal composition, such as bronze or other copper alloys, to aid in heat dissipation.

Owner:FIVES LANDIS

Method and device for preparing polycrystalline silicon solar cell texture

InactiveCN102324447AImprove material removal rateImprove efficiencyFinal product manufactureLaser beam welding apparatusPhysicsPolycrystalline silicon

The invention relates to a method and device for preparing a polycrystalline silicon solar cell texture. The method comprises the following steps of: compositely machining a polycrystalline silicon wafer by using laser and electrochemistry; forming an array light trapping structure on the machined surface of the polycrystalline silicon wafer; meanwhile, generating electrochemical corrosion to thesurface of the polycrystalline silicon wafer by using electrolyte; and carrying out smooth finishing on the machined surface. The device for realizing the method comprises a laser 5 and an electrolysis mechanism 15 as well as a power supply 1 and a workbench 11, wherein the electrolysis mechanism 15 mainly comprises an electrolytic cell base 13, an electrolytic cell cover plate 4, a cathode 8, ananode 12, a workpiece mounting fixture 14, a sealing ring 10 and an optical protective mirror; the polycrystalline silicon wafer is placed in the electrolytic cell and the electrolytic cell is divided into two chambers so that the electrolytic cell is an unique current channel during electrolysis. The invention provides a novel highly efficient texture machining method of the polycrystalline silicon solar cell; and the product has the advantages of high repeatability, good height to width aspect ratio performance and important effect on increasing the photoelectric conversion efficiency; and the reflection reducing effect which is superior to the reflection reducing effect of the texture prepared through pure chemical corrosion can be obtained.

Owner:NANTONG UNIVERSITY

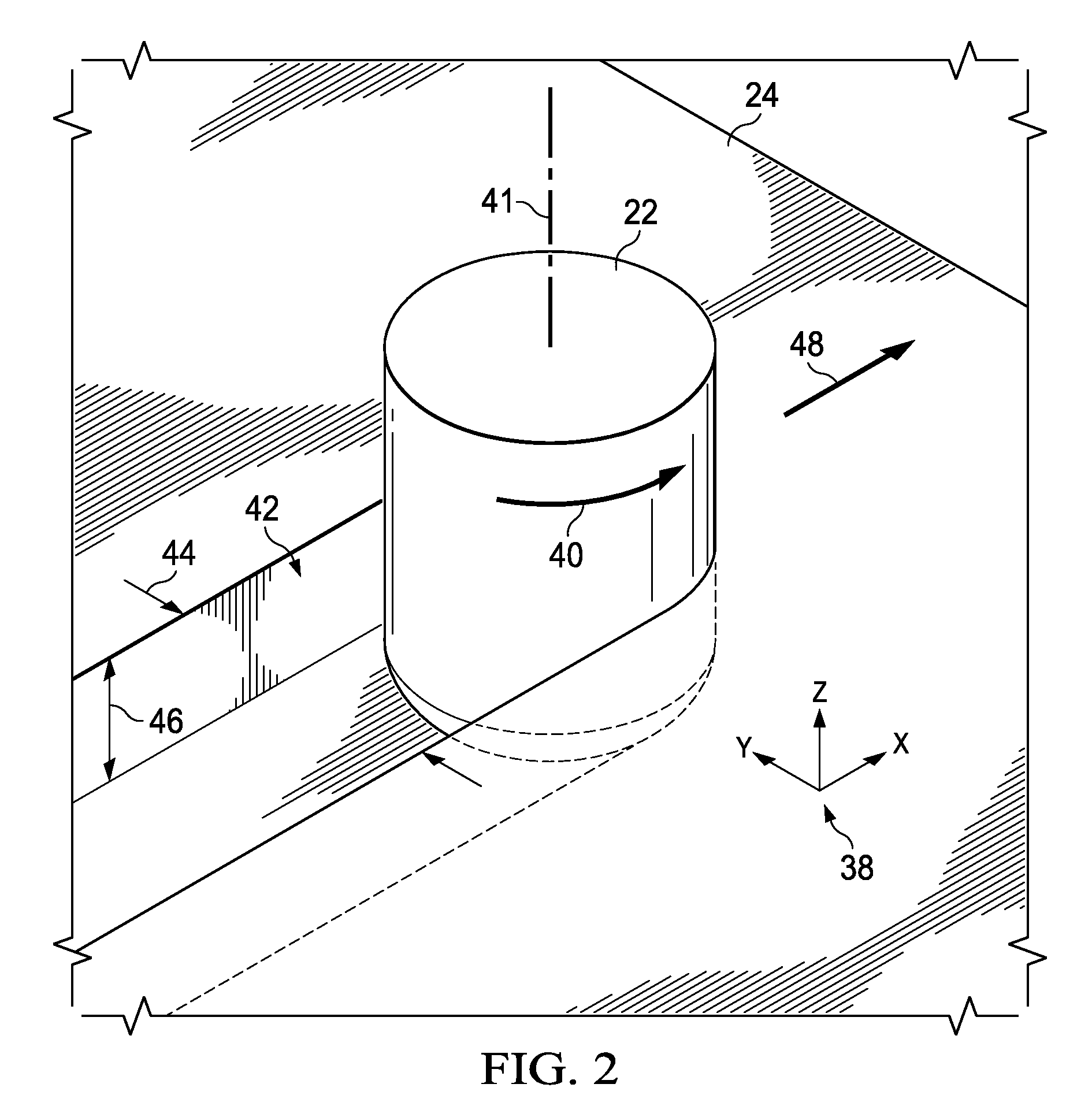

Method of optimizing toolpaths using medial axis transformation

ActiveUS9164503B2Improve material removal rateReduce processing timeComputer controlSimulator controlNumerical controlMaterial removal

Rough machining of a workpiece is performed by a numerically controlled machine tool using an adaptive toolpath technique. Material removal rate and machine efficiency are increased by forming a pre-roughing slot in the workpiece along medial axes, and machining the remainder of the workpiece using a toolpath that begins inside the pre-roughing slot and spirals outwardly in smooth curves.

Owner:THE BOEING CO

Method for conditioning a polishing pad

InactiveUS20080020682A1High removal rateImprove material removal rateAbrasive surface conditioning devicesEngineeringConductive materials

A method of conditioning processing pads increases the removal rate of conductive material from a substrate surface during polishing. In this method, the direction of rotation of the processing pad relative to the conditioning disc during conditioning is opposite the direction of rotation of the processing pad relative to the substrate during polishing.

Owner:APPLIED MATERIALS INC

Methodology of chemical mechanical nanogrinding for ultra precision finishing of workpieces

InactiveUS20060021973A1Minimize magnetic space lossReduce variationDecorative surface effectsGrinding feed controlSurface finishThin membrane

A chemical-mechanical nanogrinding process achieves near-zero pole tip recession (PTR) to minimize magnetic space loss of the head transducer to media spacing loss, alumina recession / trailing edge profile variation, and smooth surface finish with minimal smearing across multi-layers of thin films and the hard substrate to meet the requirements of high areal density head. With a fine lapping plate with a fixed-abrasive nanogrinding process, PTR can be improved to a mean of about 1.0 nm.

Owner:WESTERN DIGITAL TECH INC

Apparatus and method for enhancing plasma etch

InactiveUS20100055920A1Improving manufactory productivityImproving material selectivityElectric discharge tubesSemiconductor/solid-state device manufacturingEtching selectivityMultiple frequency

The present invention discloses a new apparatus and method to enhance the plasma etch rate, etch selectivity and etch uniformity. The present invention will apply sonic waves to the work during plasma etch process. The sonic waves will enhance the plasma etch rate. The applied sonic waves can be of a mixture of multiple frequencies at the same time or at a different time. Applying different sonic frequency for etching different material will further amplify the etch selectivity. Sonic waves with multiple frequencies, especially with some lower frequency components, will further improve the etch uniformity over a large area.

Owner:PENG GANG GRANT

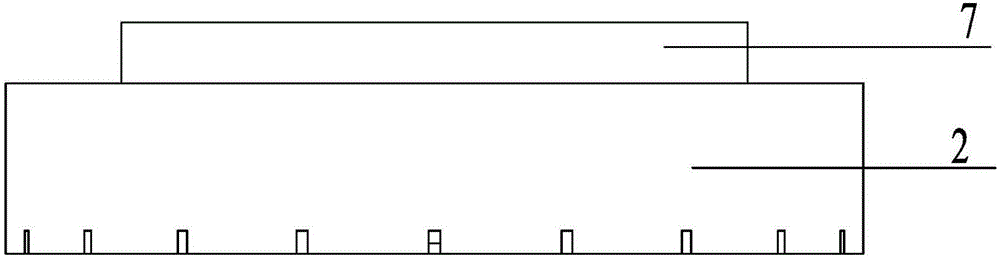

Clamp applied to plane polishing of front blade surfaces of hard alloy blades

The invention relates to a plane polishing clamp and discloses a clamp applied to plane polishing of front blade surfaces of hard alloy blades. The clamp comprises a fixing ring, a blade clamping disc and a magnet, wherein the magnet is fixed in the blade clamping disc; the blade clamping disc is mounted in the fixing ring; blade mounting holes matched with the shape of hard alloy blades are formed in the lower surface of the blade clamping disc; the depth of the blade mounting holes is smaller than the thickness of the hard alloy blades. Through the clamp, the magnet is used for adsorbing and fixing the hard alloy blades mounted in the blade mounting holes in the blade clamping disc; through attraction of the magnet, the clamp is capable of preventing the hard alloy blades from dropping out of the blade clamping disc in the carrying process or the plane polishing process; the hard alloy blades can be rapidly clamped and accurately positioned; the polishing accuracy, the polishing efficiency and the surface quality of the front blade surfaces of the hard alloy blades can be effectively improved, so that the service life of the blades can be prolonged; the part processing quality can be improved; the comprehensive production cost can be reduced.

Owner:XIANGTAN UNIV

Machining method for quickly forming nanometer twin-crystal diamond micro cutter

InactiveCN110480188AImprove material removal rateImprove efficiencyLaser beam welding apparatusGalvanometerRapid prototyping

The invention relates to a machining method for quickly forming a nanometer twin-crystal diamond micro cutter. The machining method comprises the following steps: brazing an ntD block material onto ahard alloy cutter handle, then placing the welded ntD cutter handle on an experimental machining platform with five degrees of freedom, then using femtosecond laser with a galvanometer to carry out parallel rough machining on a rear cutter surface and a front cutter surface of the ntD block material on the experimental machining platform step by step, and then using femtosecond laser without a galvanometer to carry out parallel finish machining on the rear cutter surface and the front cutter surface of the ntD micro cutter formed after machining in the above step according to the sequential order until the nanometer twin-crystal diamond micro cutter meeting the requirement is obtained. The machining method is high in machining quality and high in efficiency.

Owner:YANSHAN UNIV

Wire electrical discharge machining device

ActiveUS9833852B2Improve machining accuracyAvoid disconnectionElectrical-based machining electrodesElectric circuitsElectrical discharge machiningTension control

Provided is a wire electrical discharge machining device which has a tension controller for maintaining the tension of a traveling wire electrode at a tension. The tension controller includes: an allowed tension calculation module for determining an allowed tension that is less than a wire breaking tension at which the wire electrode breaks; and a set tension generation module for generating the set tension in accordance with the allowed tension. When the set tension is greater than the allowed tension, the set tension generation module reduces the set tension. When the set tension is less than the allowed tension, the set tension generation module increases the set tension in such a way that the set tension does not exceed the allowed tension.

Owner:SODICK CO LTD

Cutting insert for high-efficient cutting

ActiveUS10086435B2Increase stiffnessExtended service lifeMilling cuttersCutting insertsMechanical engineering

A cutting insert for high-efficiency cutting is disclosed. The cutting insert includes an upper surface (110a), a lower surface (HOb), side surfaces (114) and corner side surfaces (116), which connect the side surfaces to each other. A circular opening is formed through the central portions of the upper and lower surfaces. In the cutting insert, cutting edges are formed by respective junctions between one of the upper and lower surfaces and the side surfaces and between one of the upper and lower surfaces and the corner side surfaces. The cutting edges comprise three corner cutting edges (122), six major cutting edges (124), which extend from opposite ends of the corner cutting edges towards the neighbor corner cutting edges, and three minor cutting edges (126), which are connected between the major cutting edges. Furthermore, the cutting edges may be formed on both the upper surface and the lower surface.

Owner:KORLOY

Wire electric discharge machining apparatus

ActiveUS20120024821A1Weaken energyReduce riskElectric circuitsSpecial data processing applicationsElectric dischargePower flow

A wire electric discharge machining apparatus for machining a workpiece (7) by supplying current pulses to a work gap formed between a wire electrode (8) and the workpiece comprises a person detection sensor (10) for generating a person detection signal (EX) when the existence of a person is detected, and an NC device (20) that is configured to receive the person detection signal. When the NC device receives the person detection signal, it selects first machining conditions which improve machining speed. When the NC device does not receive the person detection signal, it selects second machining conditions which reduce the risk of wire breakage.

Owner:SODICK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com