Preparation method of nanoscale diamond micropowder narrow in particle size distribution

A diamond micropowder, narrow particle size distribution technology, applied in diamond, metal processing equipment, manufacturing tools, etc., can solve the problems of easy introduction of impurities and low shaping efficiency, achieve high material removal rate, improve shaping efficiency, and simplify the production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

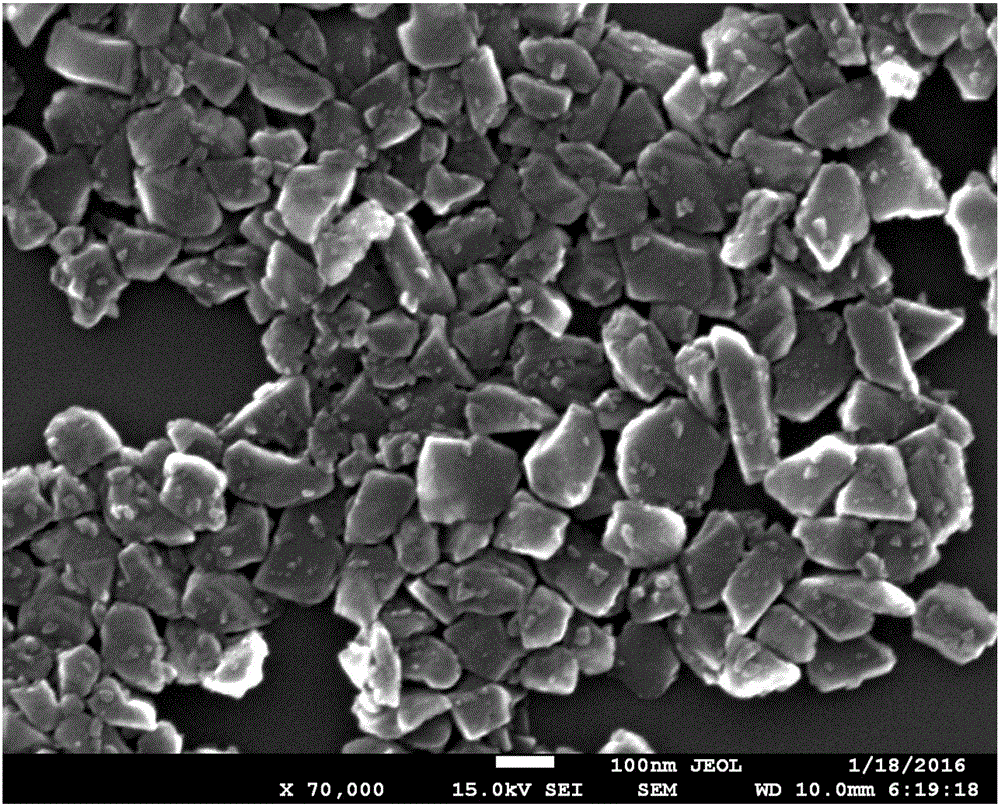

Image

Examples

Embodiment 1

[0037] The preparation method of the nanoscale diamond micropowder of the narrow particle size distribution of the present embodiment, the steps are as follows:

[0038] 1) Take 500 g of ultrafine diamond powder with a median particle size (D50) of 100 nm, disperse it in 8000 ml of deionized water, add 2 g of sodium dodecylbenzenesulfonate, 1.5 g of triethanolamine, and disperse it ultrasonically for 30 minutes to obtain a raw material slurry ;

[0039] 2) Put the raw material slurry into a vertical sand mill with a grinding cylinder volume of 10,000ml, add 10kg of coarse-grained raw sawing grade diamond (Zhongnan Diamond Co., Ltd., 2290 series, specification 16 / 20), and start the sand mill. Grinding and shaping, adjust the linear speed of the grinding disc of the sand mill to 12m / s or the rotating speed at 900-950rpm, run for 6h, release the slurry and filter the mixed coarse-grained grinding medium with a 120 mesh screen to obtain the shaping slurry;

[0040] 3) Centrifuge ...

Embodiment 2

[0043] The preparation method of the nanoscale diamond micropowder of the narrow particle size distribution of the present embodiment, the steps are as follows:

[0044] 1) Take 5000g of ultrafine diamond powder with a median particle size (D50) of 100nm, disperse it in 80000ml of deionized water, add 20g of sodium dodecylbenzenesulfonate, 15g of triethanolamine, and ultrasonically disperse for 30min to obtain a raw material slurry;

[0045] 2) Add the raw material slurry into the external circulation turnover barrel connected with the sand mill, and add 30 kg of coarse-grained primary sawing grade diamond to the vertical sand mill with a grinding cylinder volume of 30000 ml (Zhongnan Diamond Co., Ltd., 2290 series, specification 16 / 20), turn on the diaphragm pump to pump the raw material slurry into the feed inlet of the lower part of the sand mill, adjust the diaphragm pump to make the slurry circulate between the sand mill and the turnover barrel at a flow rate of 4000ml / min...

Embodiment 3

[0049] The preparation method of the nanoscale diamond micropowder of the narrow particle size distribution of the present embodiment, the steps are as follows:

[0050] 1) Take 500 g of ultrafine diamond powder with a median particle size (D50) of 200 nm, disperse it in 6000 ml of deionized water, add 2 g of sodium hexametaphosphate, 1 g of isopropanol, and ultrasonically disperse for 30 minutes to obtain a raw material slurry;

[0051] 2) Put the raw material slurry into a vertical sand mill with a grinding cylinder volume of 10000ml, add 10kg of coarse-grained primary sawing grade diamond (Henan Huanghe Cyclone Co., Ltd., HSD series, specification 18 / 20), and start the sand mill Start grinding and shaping, adjust the linear speed of the grinding disc of the sand mill to 8m / s, run for 6h, release the slurry and filter the mixed coarse-grained grinding medium with a 120 mesh screen to obtain the shaping slurry;

[0052] 3) Centrifuge and dehydrate the shaping slurry obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com