Titanium alloy pipe inner wall magneto-rheological polishing method and device

A technology of titanium alloy tube and magnetorheological fluid, which is applied in the direction of grinding/polishing equipment, surface polishing machine tools, metal processing equipment, etc., can solve the problems of high production cost of abrasive grains, low grinding efficiency, and low service life, and achieve Good uniformity, simple operation and high material removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

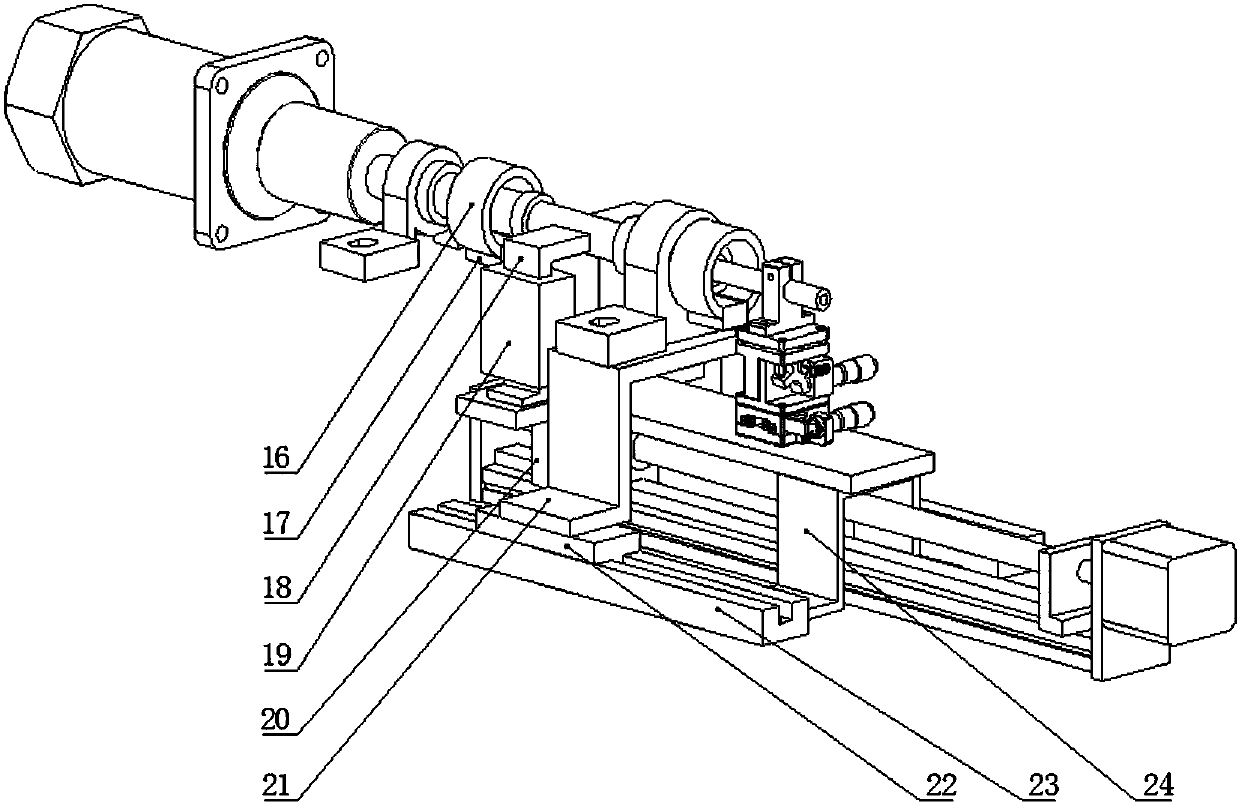

[0034] like figure 1 , figure 2As shown, the magnetorheological polishing device for the inner wall of a titanium alloy tube provided by the present invention includes a frame, a workpiece clamping and rotating mechanism, a polishing mechanism, and a magnetorheological fluid collecting mechanism. The clamping and rotating mechanism of the workpiece comprises a speed-regulating motor 1, a left bearing seat 3, a right bearing seat 7, a left clamp 4, a right clamp 6, and a bearing pad 21. The workpiece 5 is clamped by the left fixture 4 and the right fixture 6. The left fixture 4 is connected with the speed-regulating motor 1 through the coupling 2, and the speed-regulating motor 1 drives the workpiece 5 to perform high-speed rotation. The left fixture 4 and the right fixture 6 are respectively Fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com