Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "No subsurface damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical mechanical polishing solution for processing surface of sapphire or carborundum wafer for LED (Light Emitting Diode) substrate slice and preparation method thereof

InactiveCN102888193AAvoid damageNo subsurface damageSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesActive agentSilicon oxide

The invention discloses a chemical mechanical polishing solution for processing a surface of a sapphire or carborundum wafer for an LED (Light Emitting Diode) substrate slice. The chemical mechanical polishing solution comprises the following raw materials by weight: 2 to 30% of grinding material, 0.01 to 5% of chelating agent, 0.01 to 10% of surface active agent, 0.01 to 10% of dispersing agent, 0.1 to 20% of oxidant and the balance of deionized water. The preparation method comprises the steps as follows: preparing a grinding material-silica sol; then, sequentially adding the chelating agent, surface active agent, dispersing agent, oxidant and deionized water to the obtained silica sol along with agitating; and continuously uniformly agitating to obtain the chemical mechanical polishing solution for processing the surface of the sapphire or carborundum wafer for the LED substrate slice. The chemical mechanical polishing solution disclosed by the invention can not bring damage, scratching and corrosive pits to the surface of the LED substrate and has no pollution to the environment; the raw materials are cheap, and the cost is low; and the chemical mechanical polishing solution is suitable for industrial production.

Owner:SHANGHAI INST OF TECH

Method for cleaning sapphire substrate

InactiveCN102632055AImprove product yieldWon't catchCleaning processes and apparatusChemistryNitrogen

The invention relates to a method for cleaning a sapphire substrate. The surface of a sapphire epitaxial substrate has a larger quality difference of the substrate surface and has a difference in defects of an oxidation layer and a subsurface after being cleaned by organic impurities and inorganic metal impurities due to chemical-mechanical polishing (CMP). The sapphire substrate is generally classified according to the cleaning conditions of the substrate surface. And when an imaging (PSS (Poly(sodium-p-styrenesulfonate))) substrate is prepared or heteroepitaxy is directly carried out, the product uniformity is different so that the final yield of the product is decreased. The method provided by the invention is characterized in that the sapphire substrate is cleaned with the organic impurities and the inorganic metal impurities and then is cleaned with hydrogen-nitrogen plasmas. After the cleaning method provided by the invention is carried out, the surface of the sapphire substrate has no oxidation impurities, defection layers and no subsurface defection layers. The surface quality of the substrate is good in consistency. The cleaning method provided by the invention has high yield of the PSS substrate or high crystallization quality of a GaN layer subjected to the heteroepitaxy.

Owner:CHANGZHOU TONGTAI PHOTOELECTRIC

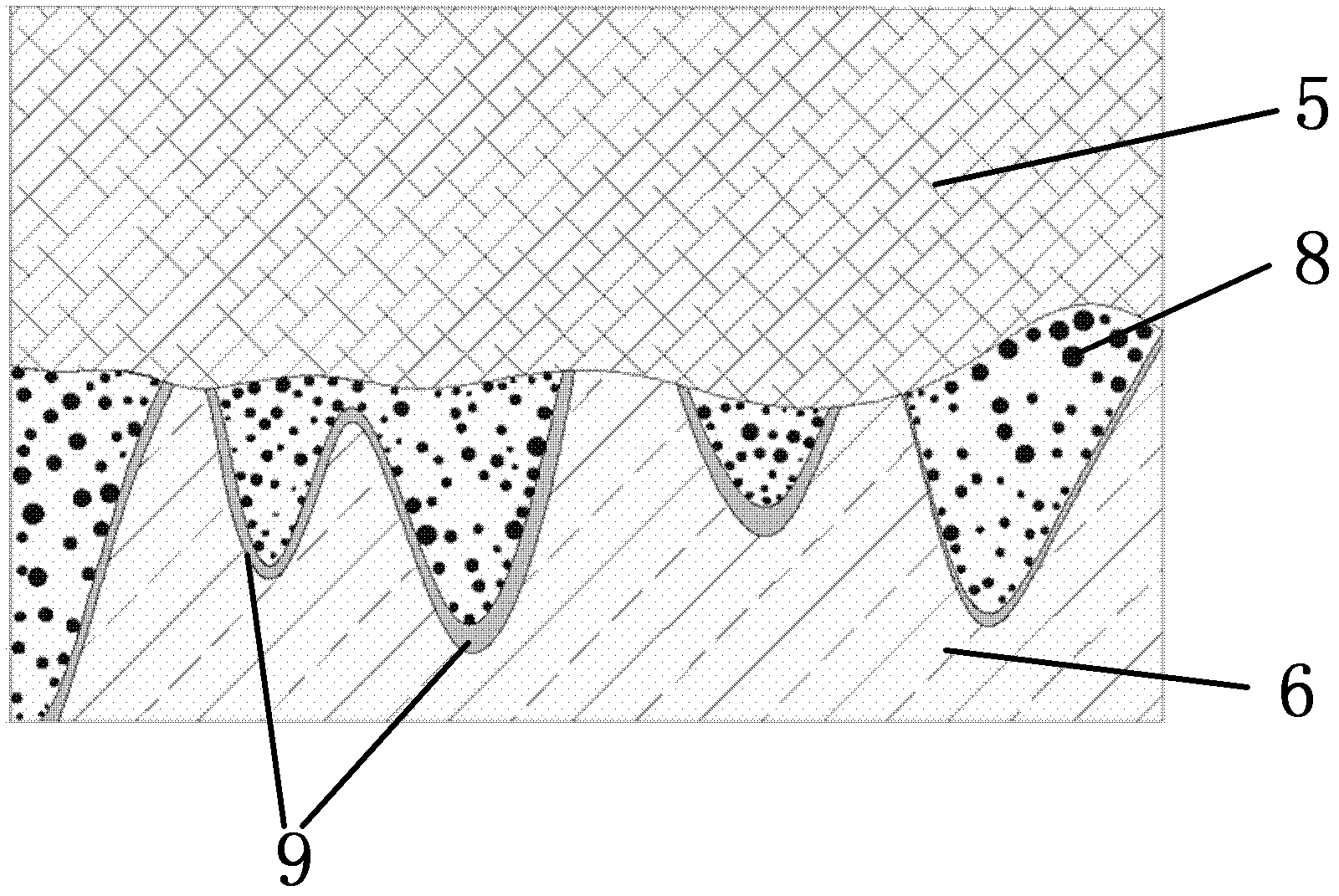

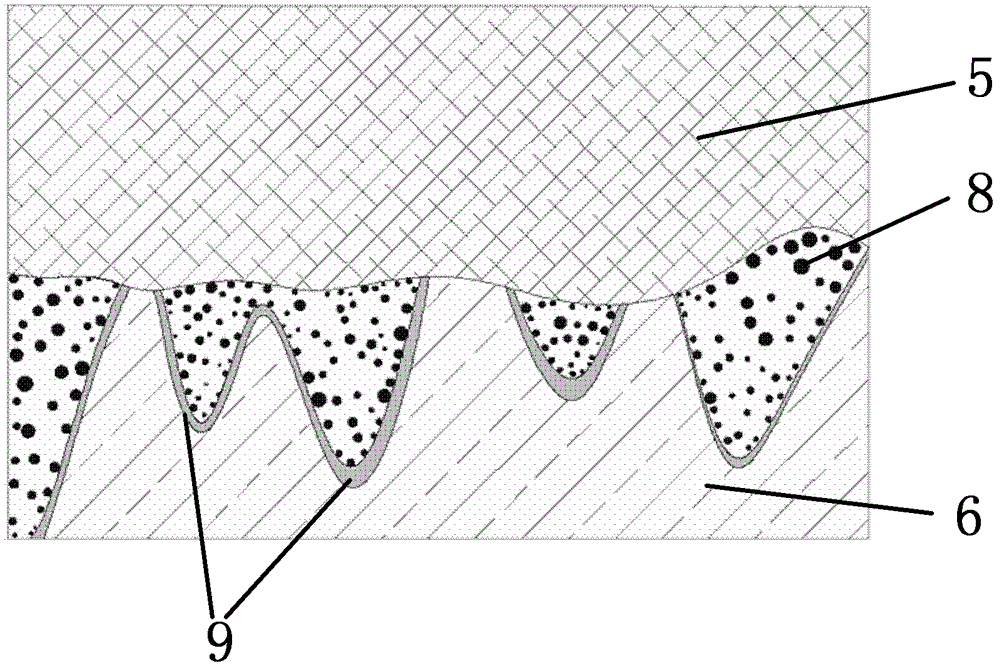

Method for processing soft and crisp LBO crystals based on consolidated abrasive polishing pad

InactiveCN102172879AReduce surface damageImprove surface qualityPolishing machinesPolishing compositionsMicrometerGranularity

The invention discloses a method for processing soft and crisp LBO crystals based on a consolidated abrasive polishing pad, which is characterized by comprising the following steps: firstly, roughly polishing and machining LBO crystals by the polishing pad of diamond consolidated abrasive of which the granularity is less than or equal to 14 micrometers, wherein in the polishing and machining process, the polishing pressure is controlled to 50-600g / cm<2>, the revolving speed of a polisher is controlled to 10-200 rpm, the pH value of a polishing solution adopted by polishing is controlled to 2-6, and the temperature of the polishing solution is 20-30DEG C to roughly polish the LBO crystals; and then, finely polishing and machining the LBO crystals obtained from the rough machining by the polishing pad of cerium oxide consolidated abrasive of which the granularity is not more than 3 micrometers, wherein the polishing pressure is controlled to 50-600g / cm<2> in the fine polishing and machining process, the revolving speed for polishing is controlled to 10-200rpm, the pH value of a polishing solution adopted by polishing is controlled to 2-6, and the temperature of the polishing solution is 20-30DEG C until the surface quality satisfies a set requirement. The method has the advantages of high processing efficiency and high finished product rate and does not cause environmental pollution.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

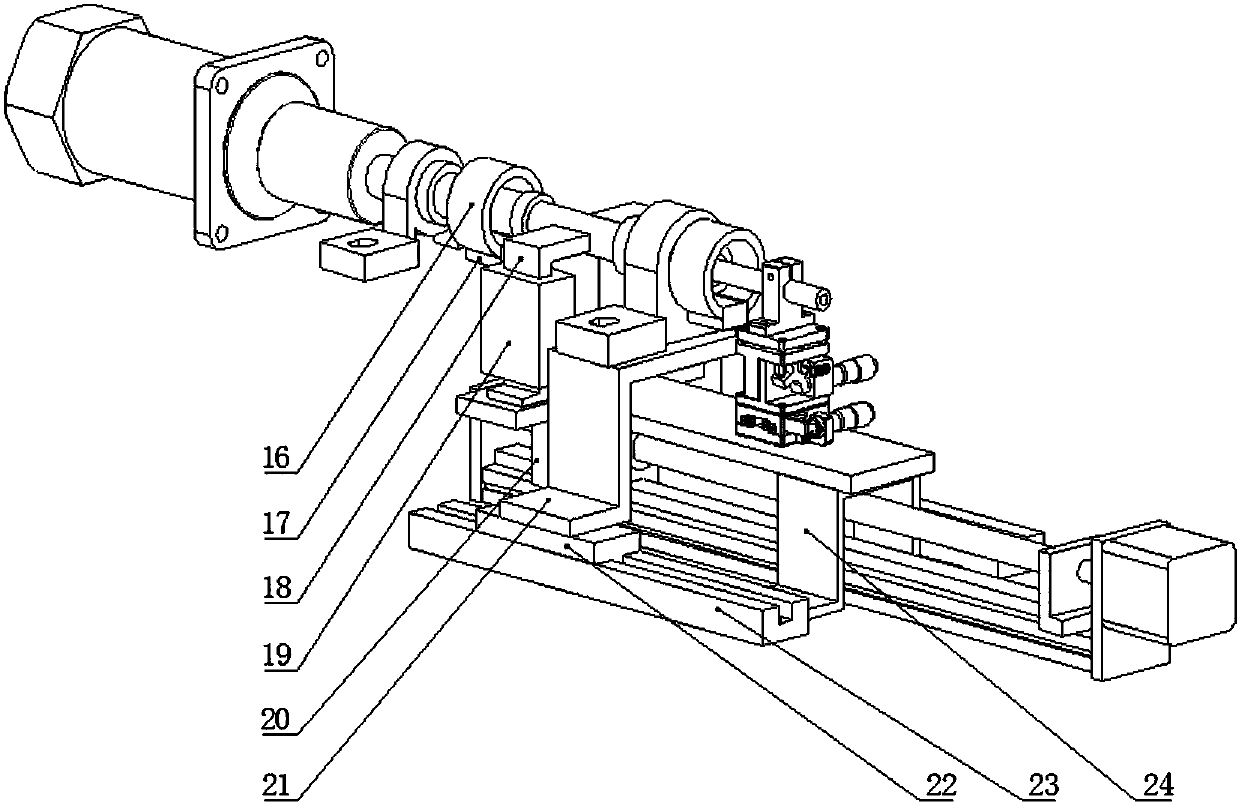

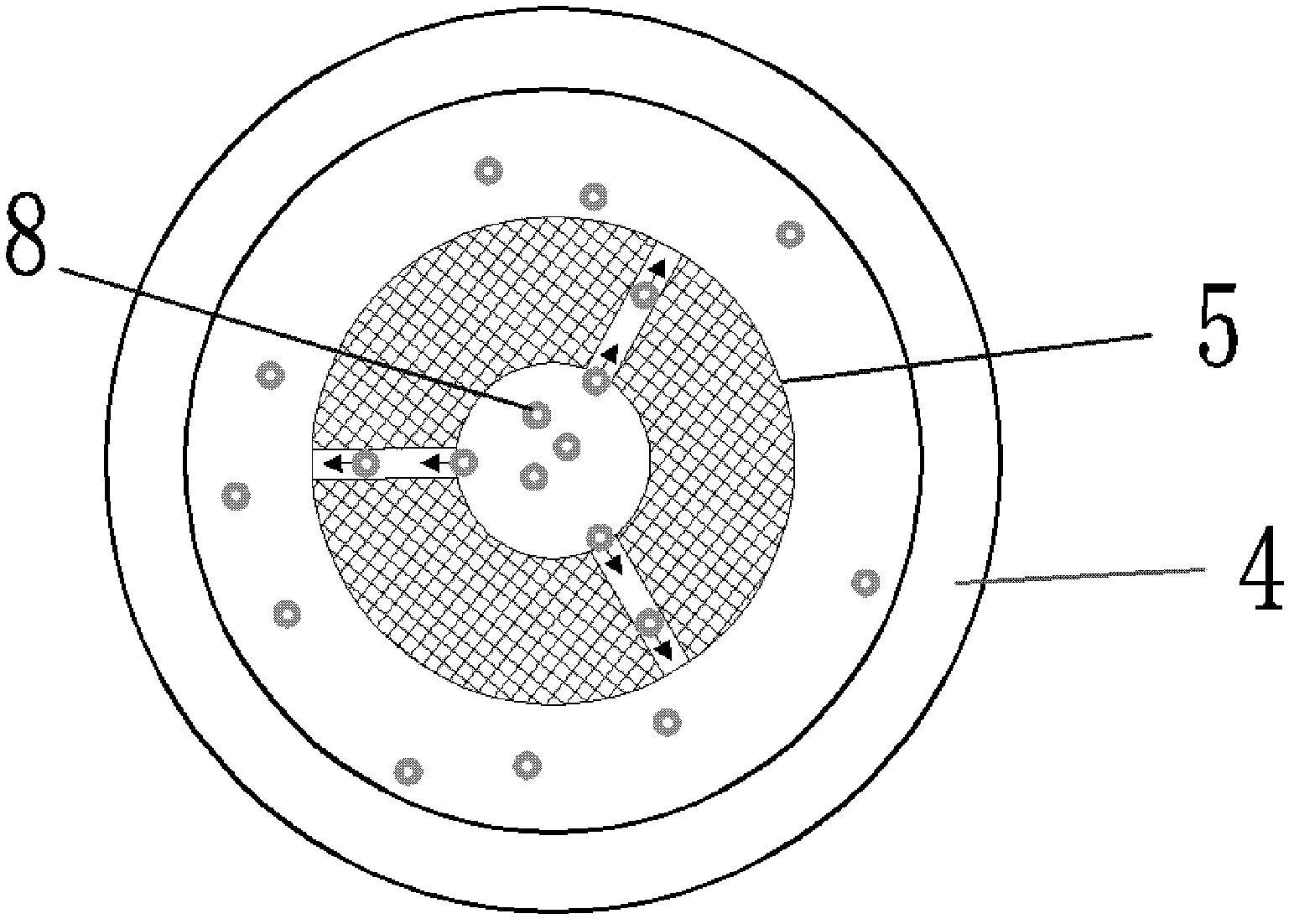

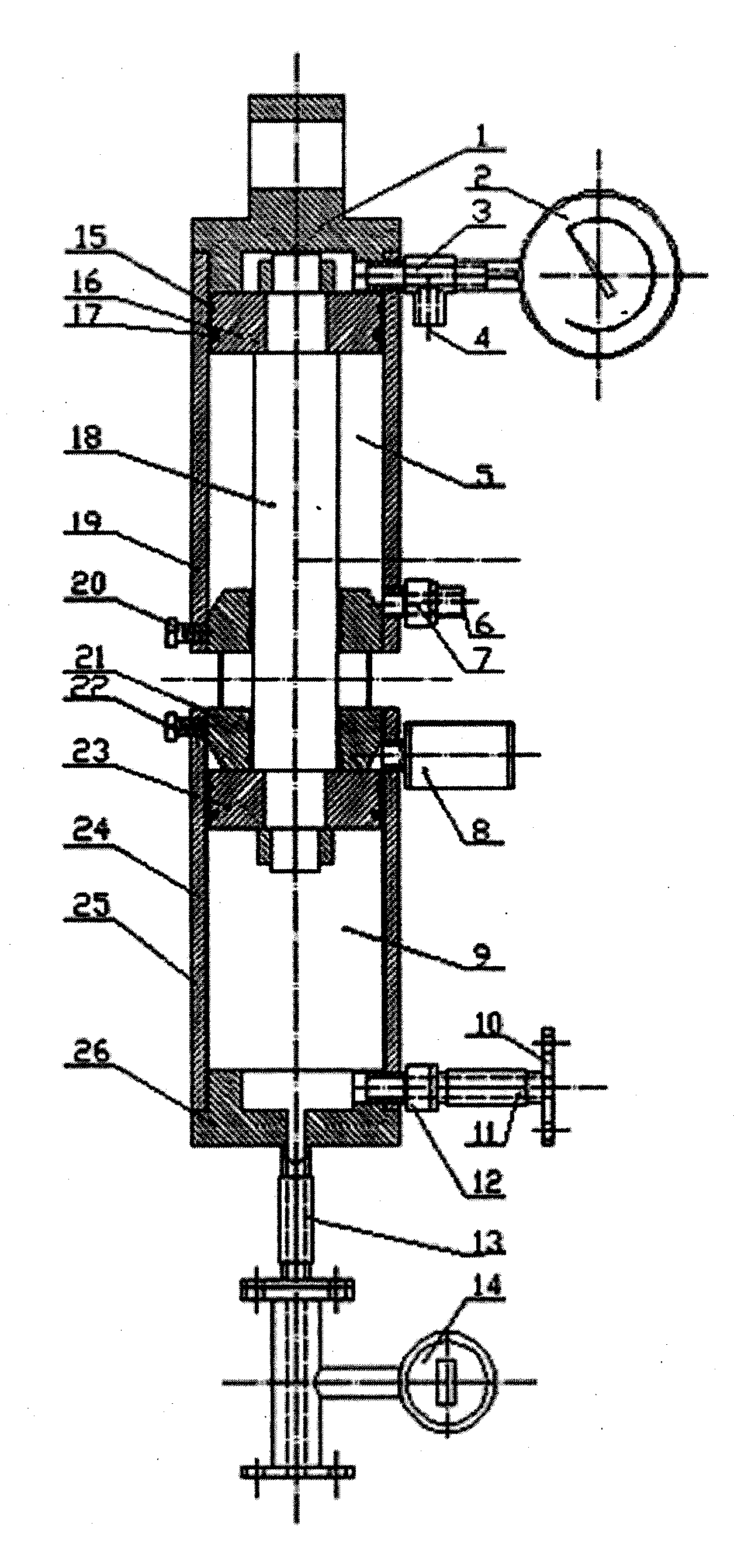

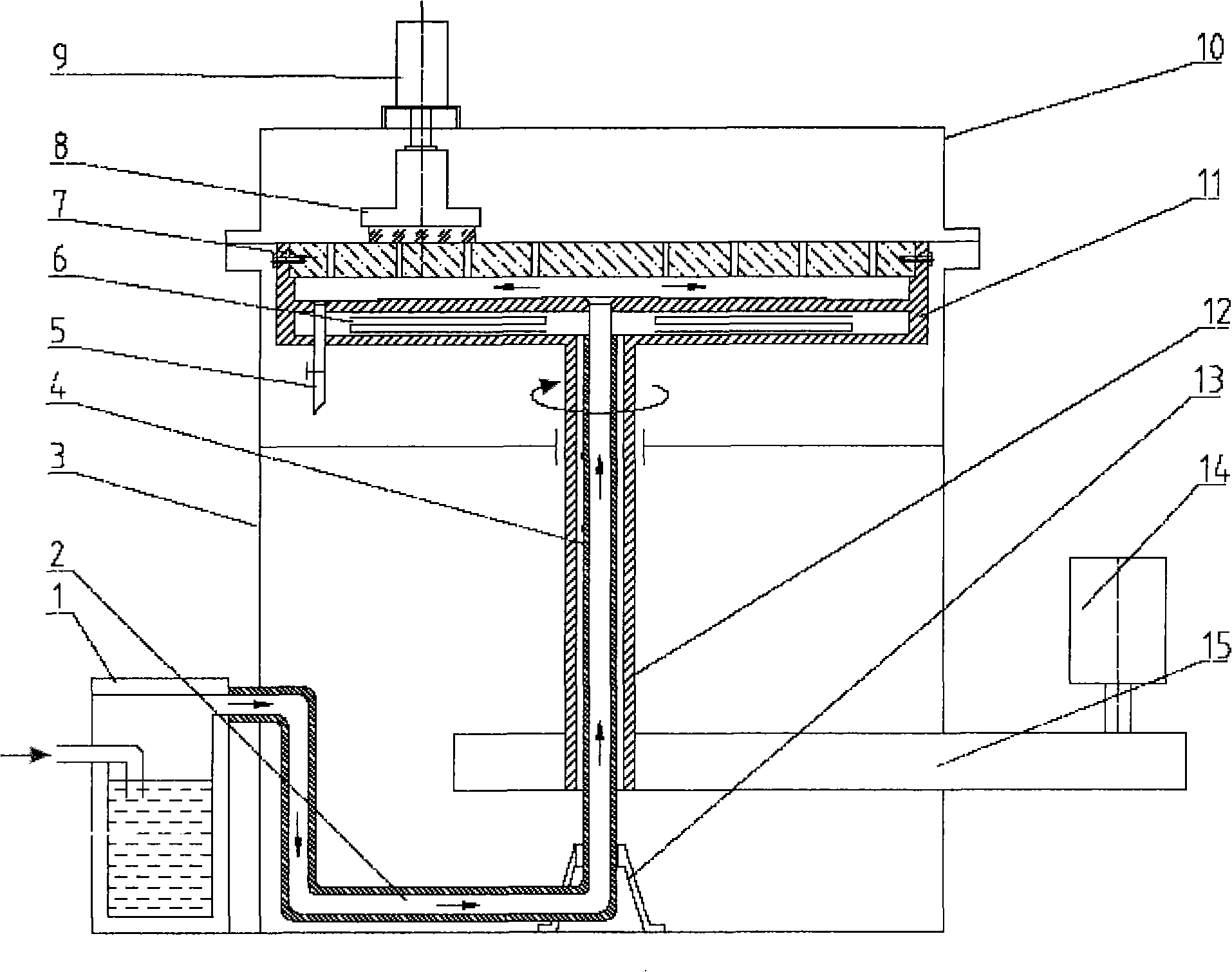

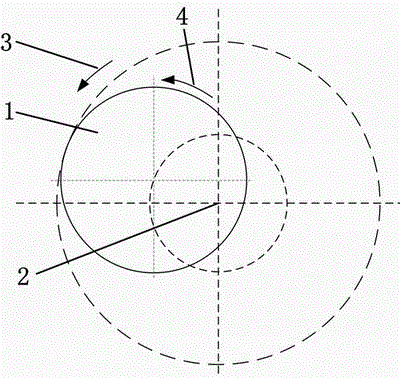

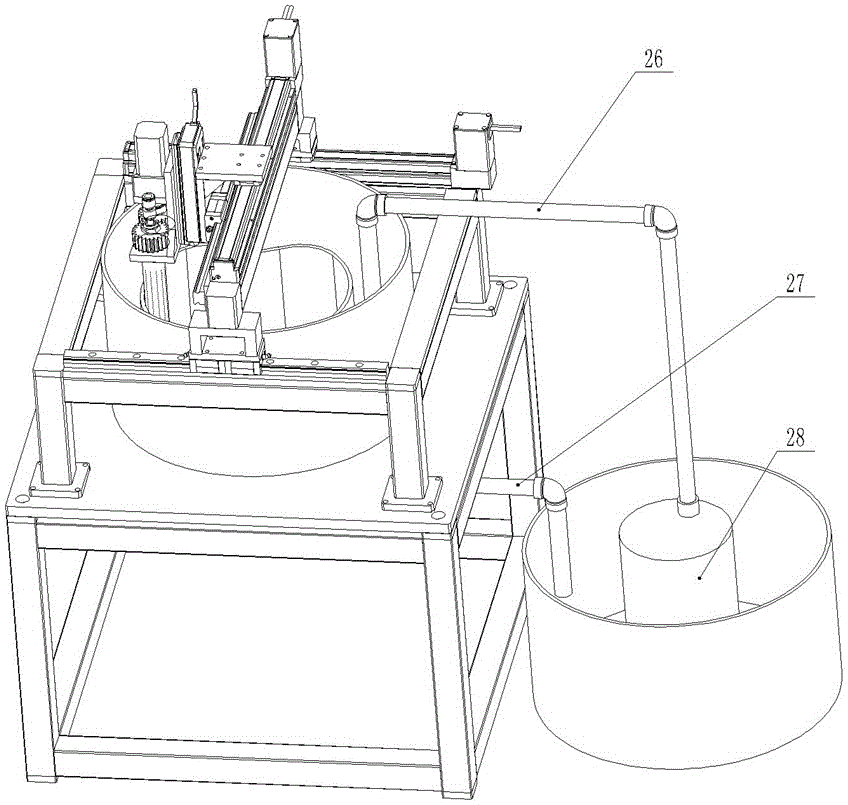

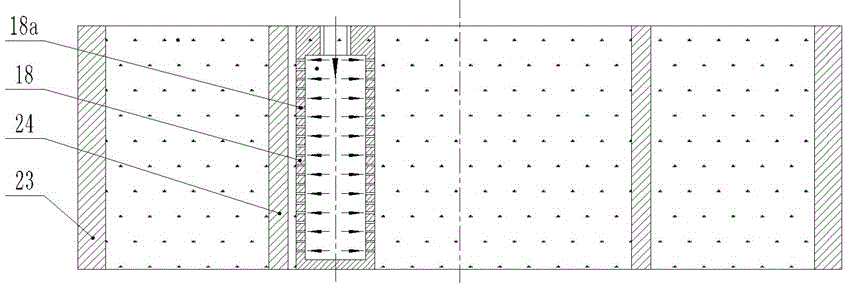

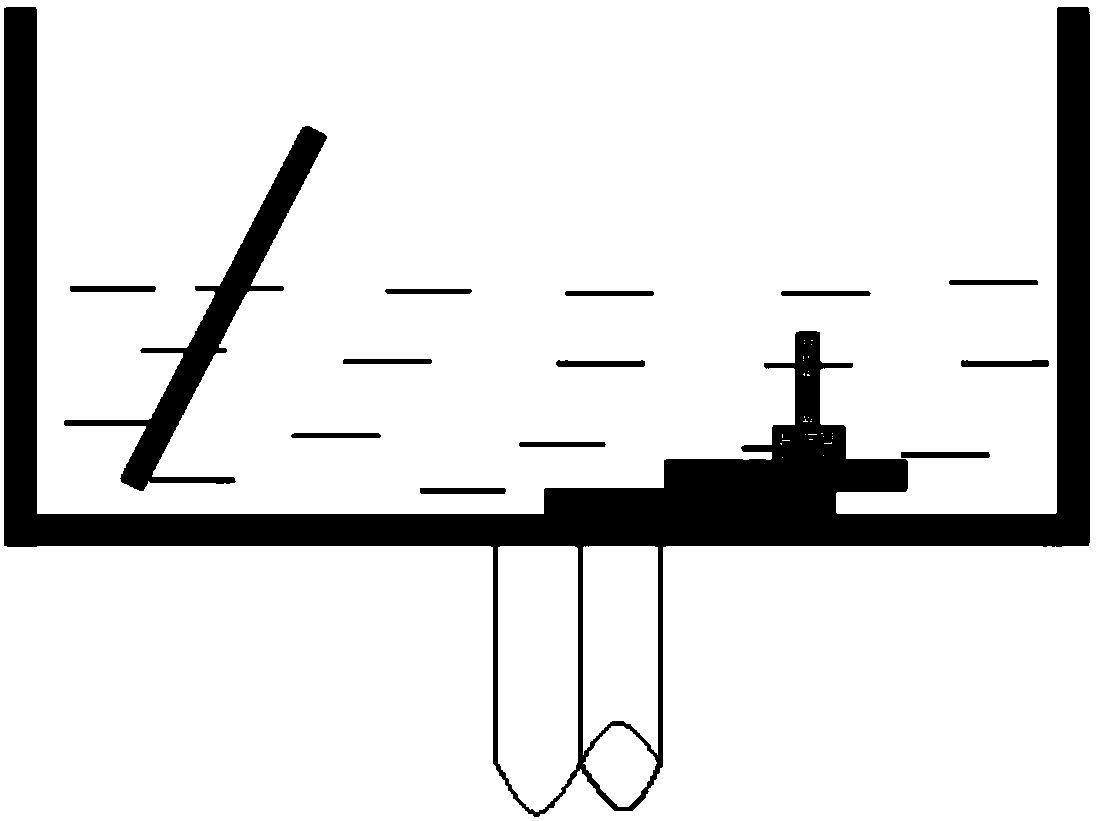

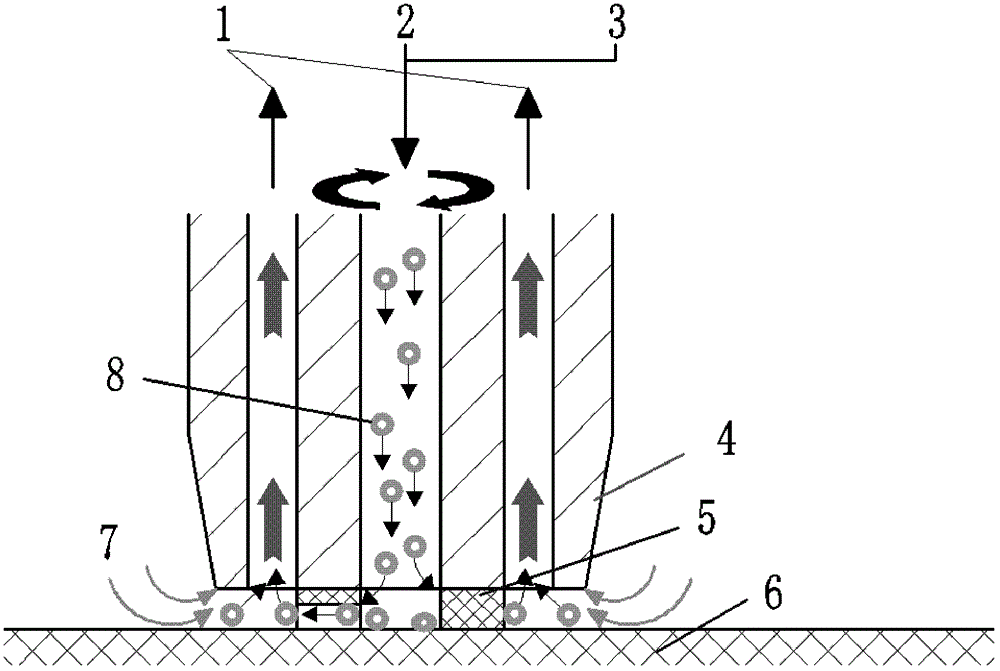

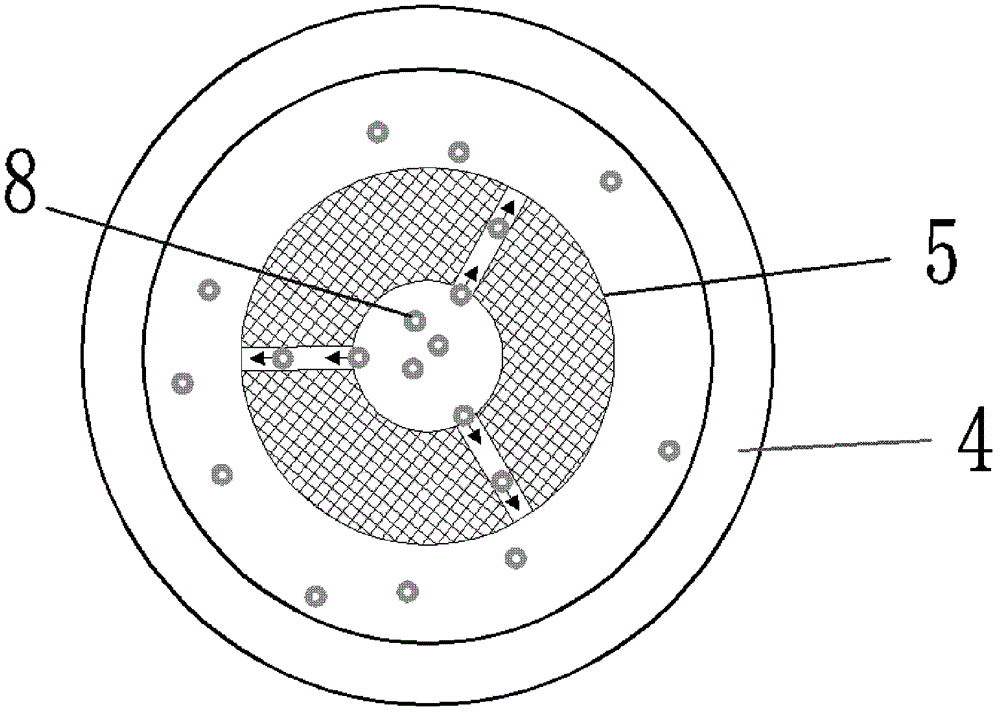

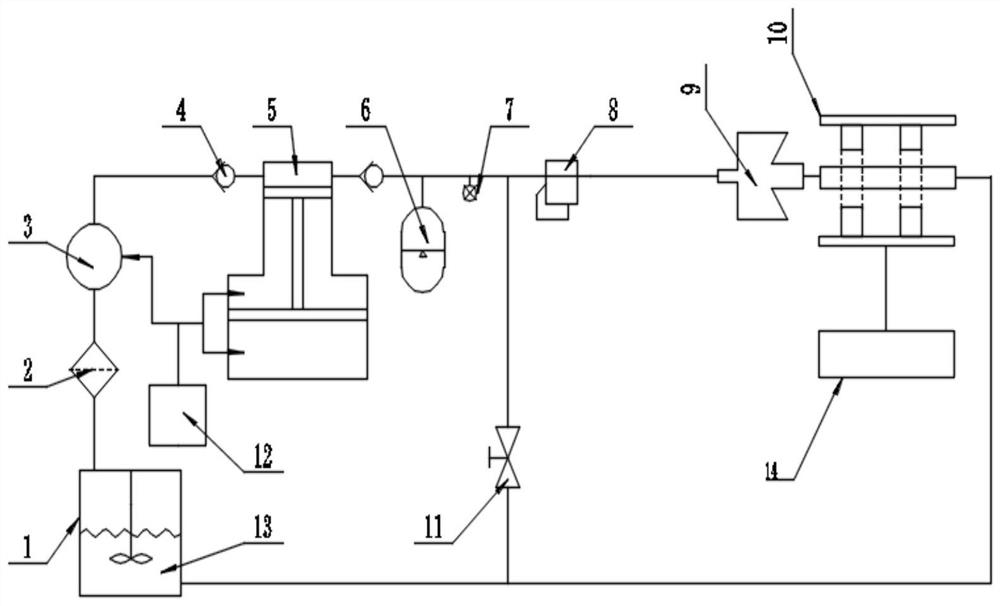

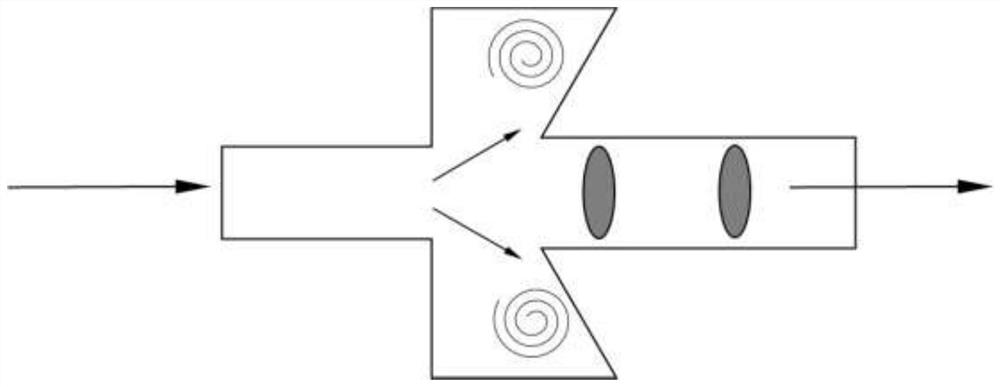

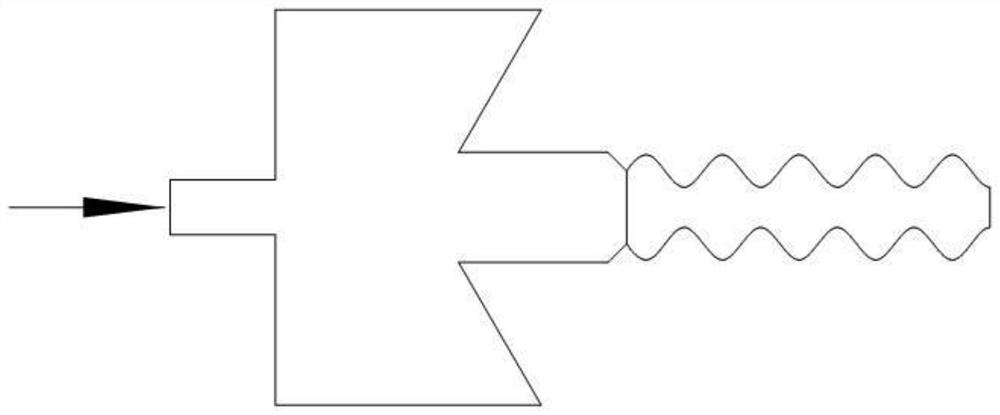

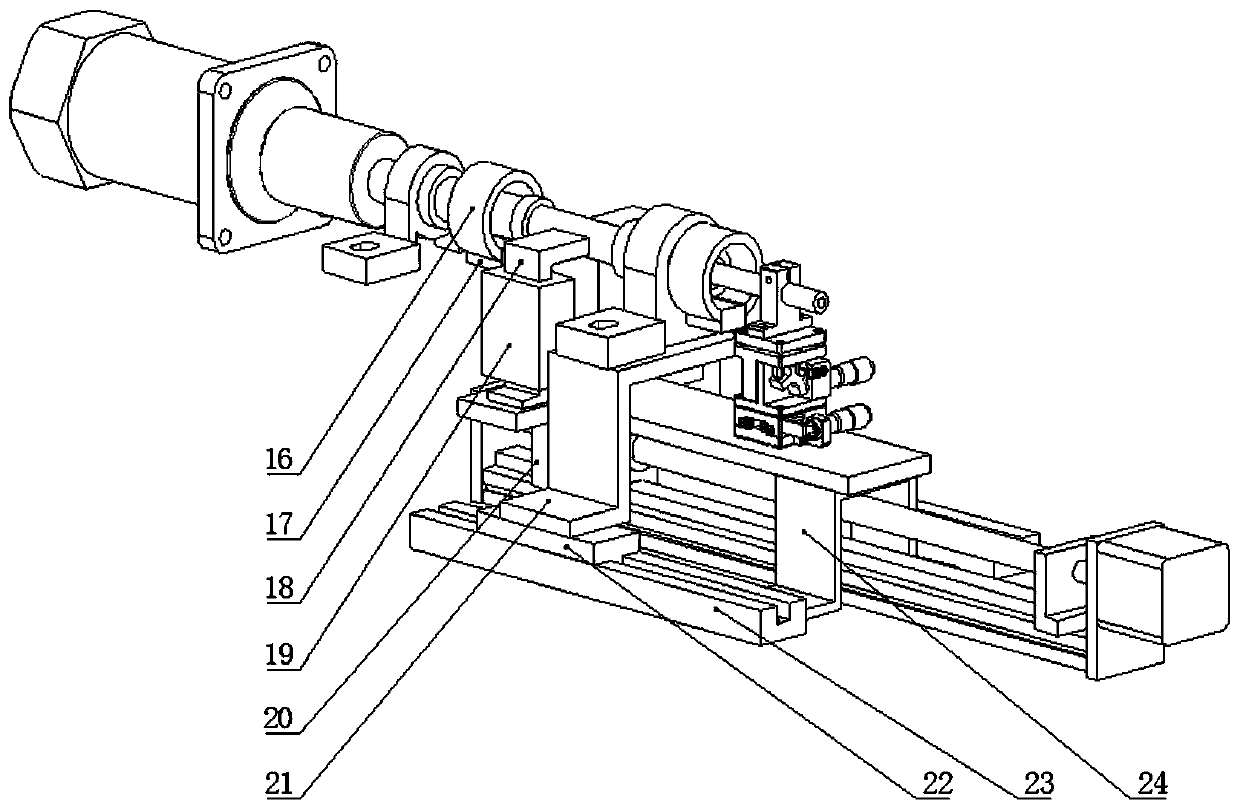

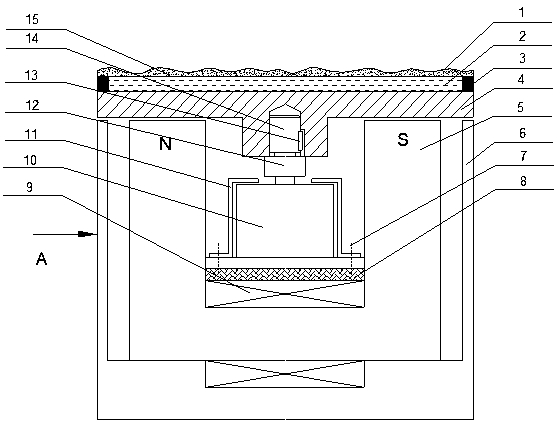

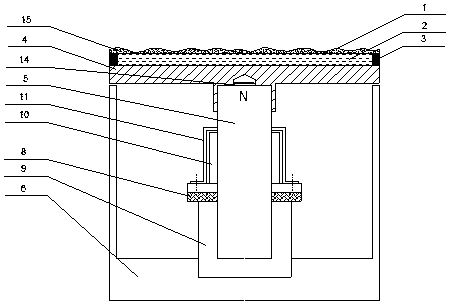

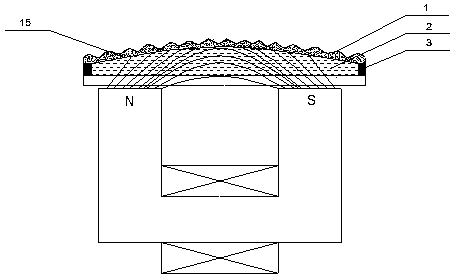

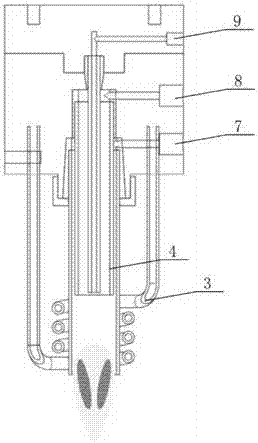

Titanium alloy pipe inner wall magneto-rheological polishing method and device

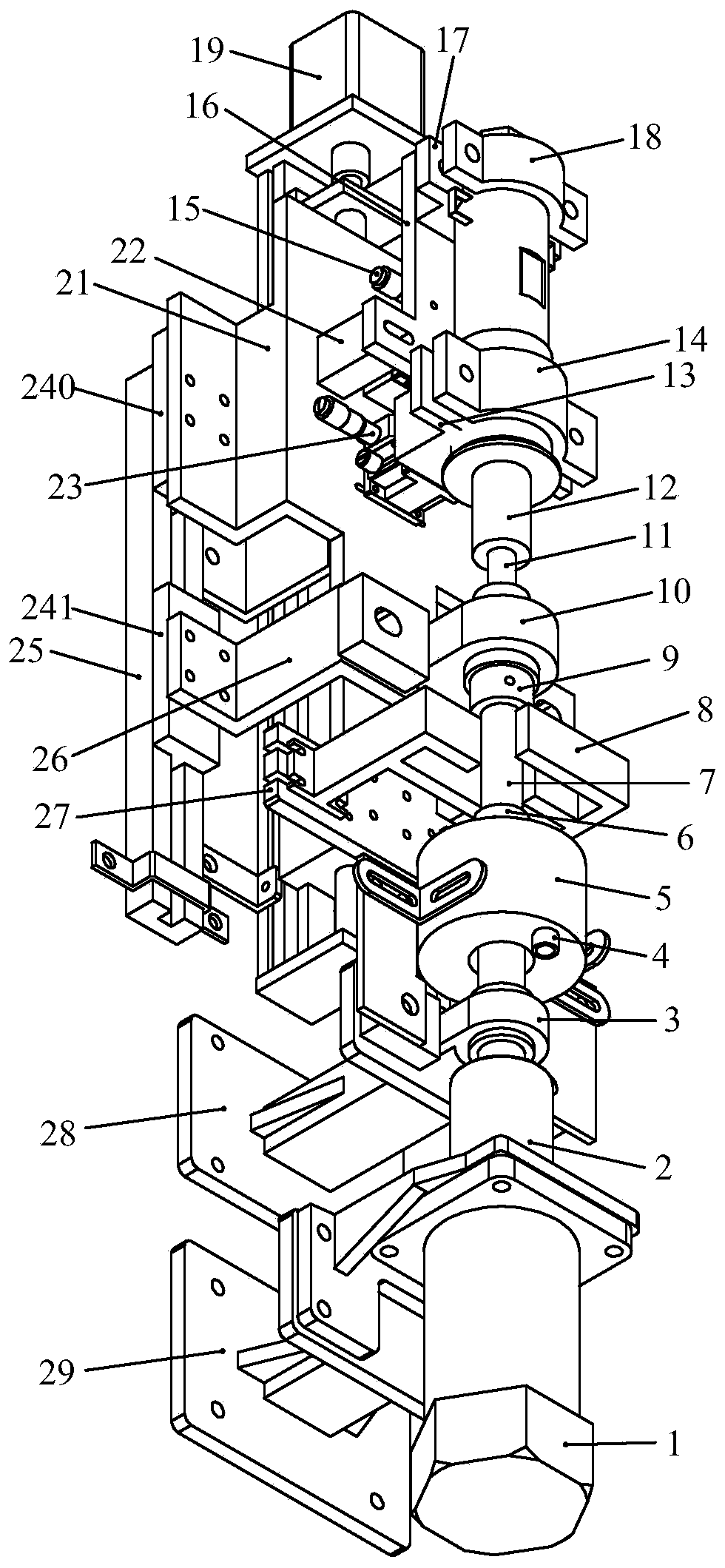

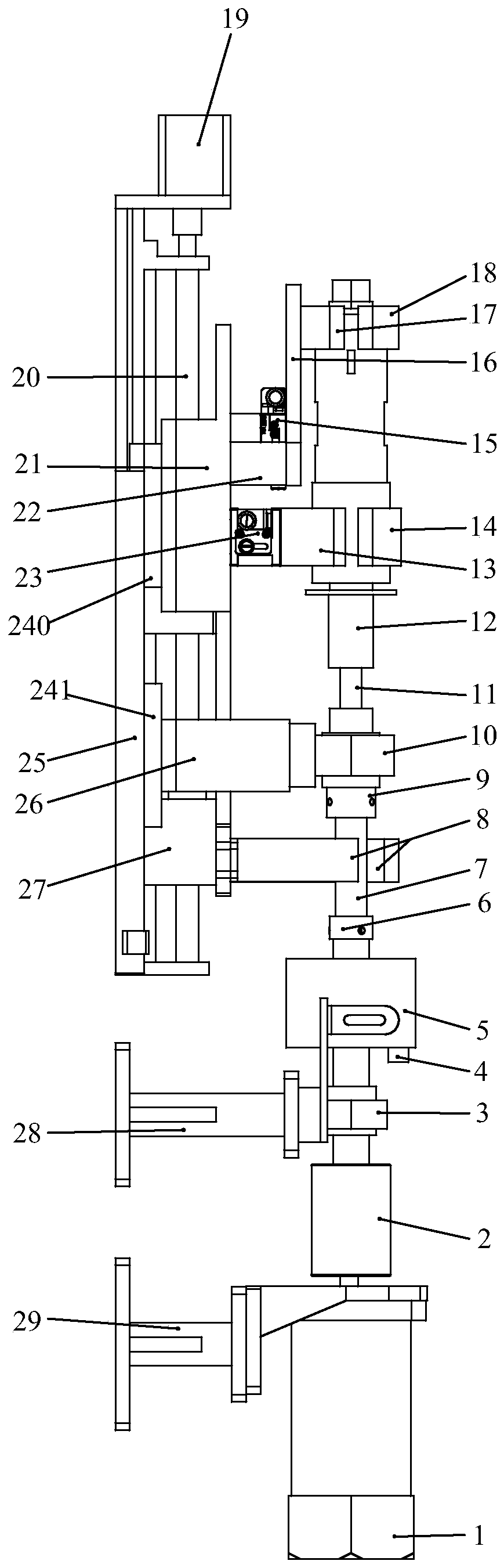

ActiveCN107791107AGood controllabilityImprove material removal ratePolishing machinesGrinding work supportsApparent viscosityMagnetic current

The invention provides a titanium alloy pipe inner wall magneto-rheological polishing method and device. Magneto-rheological liquid is pumped into a polishing head inner cavity along the inner surfaceof a transmission rod under the effect of a creepage pump, and flows over through rectangular holes around the middle of a polishing head, the liquid flows to the polishing area from the left side and the right side, under the effect of a magnetic field, the apparent viscosity and the shear yield stress of the magneto-rheological liquid are rapidly increased, a Bingham medium with certain viscousplasticity is formed, along with relative motion of the polishing head and the pipe wall, the Bingham medium carries out shear removal on the pipe wall material, the magneto-rheological liquid obtained after polishing is collected through magneto-rheological liquid collecting mechanisms on the two sides of a pipe fitting, through filtering and stirring, the polishing process is continuously carried out, and circular utilization of the magneto-rheological liquid is achieved; in the magneto-rheological liquid circulation process, heat generated in the polishing area is brought away. The inner wall of the titanium alloy pipe can be automatically polished, the beneficial effects of being easy to control, good in polishing uniformity, high in work efficiency and the like are achieved, and themethod and device are particularly suitable for polishing treatment of the inner wall surface of the fine and long titanium alloy pipe.

Owner:NORTHEASTERN UNIV

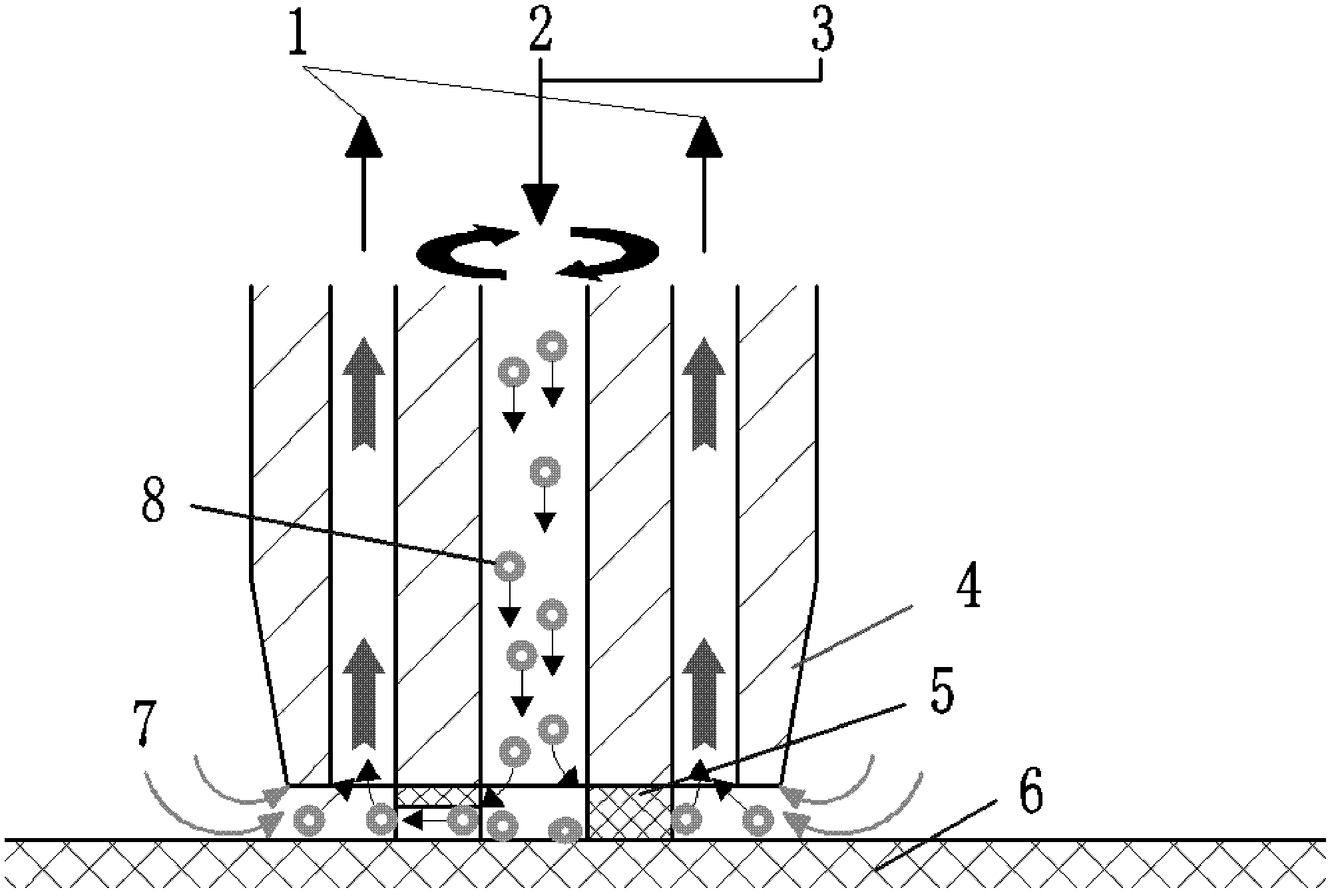

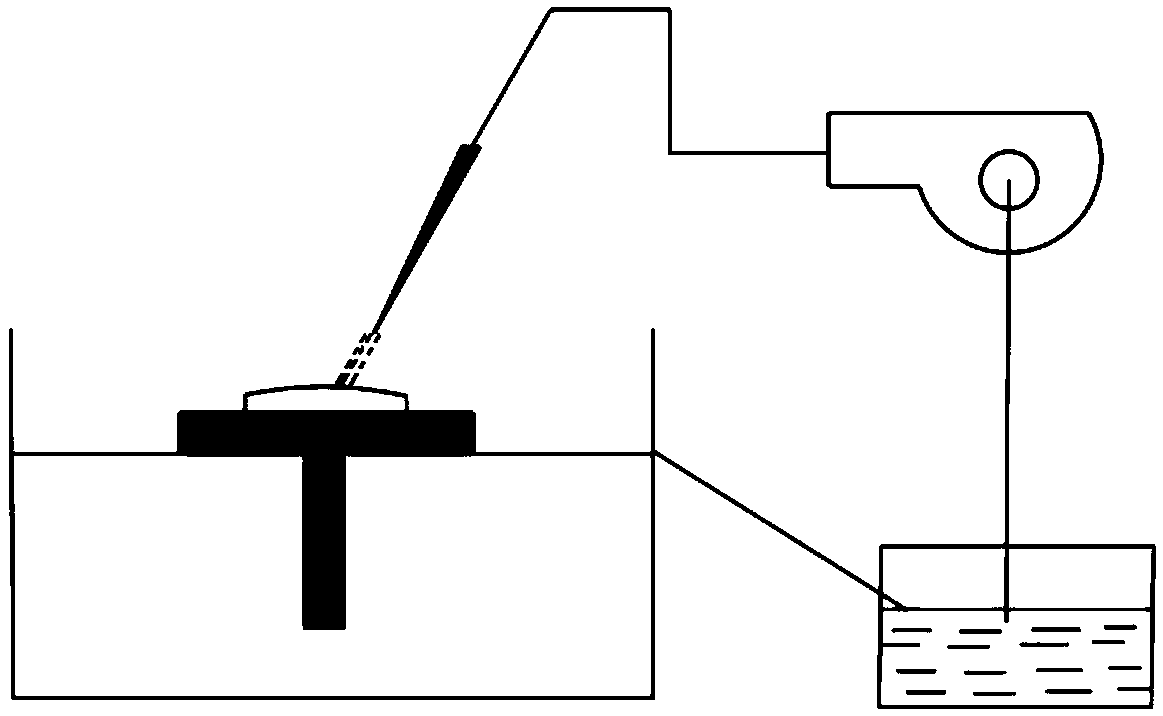

Kindle direct publishing crystal micro-nano hygroscopic ultraprecision polishing method based on ultrasonic atomization moisture

ActiveCN102615555AEnsuring global planarizationEnsuring high profile accuracyMicro nanoRate function

The invention relates to a kindle direct publishing crystal micro-nano hygroscopic ultraprecision polishing method based on ultrasonic atomization moisture, which is characterized by first utilizing ultrasound to product water mist, enabling the water mist to be mixed with dry air to form clean water mist air, pressing a polishing head on the crystal surface, introducing the clean water mist air, conducting micro hydrolysis on the portion of the crystal surface contacted with the moist air to form a dissolution layer, then rotating the polishing head, enabling a polishing mat to remove the high point dissolution layer, enabling a vacuum source to absorb surplus moist air, enabling the polishing head to conduct small area local polishing, ensuring polishing evenness in local areas and finally enabling a polishing tool to polish under control of a computer to achieve crystal surface overall situation planarization according to a dwell time function calculated by a material removing rate function R (r, theta) and removing quantity (x, y) of each point. The method does not use traditional polishing liquid, does not need to washing the crystal surface after polishing is finished and is a real damage-free micro-nano processing method due to the fact that no mechanical processing stress exists in the processing process.

Owner:DALIAN UNIV OF TECH

Fluid magnetic abrasive hole finishing processing device

The invention discloses a fluid magnetic abrasive hole finishing processing device. The device comprises a driving cylinder and a storage cylinder which are connected into a whole through a middle connecting cover, a front end cover is arranged at the upper end of the driving cylinder, a rear end cover is arranged at the lower end of the storage cylinder, a driving cylinder piston is arranged in the driving cylinder, the lower end of the driving cylinder piston is connected with a piston rod, the other end of the piston rod penetrates the middle connecting cover to extend into the storage cylinder and is provided with a storage cylinder piston, and an oil return port communicating with the inside of the driving cylinder is arranged on a driving cylinder shell and adjacent to the middle connecting cover. After a magnetic field is applied, viscosity is increased rapidly under the action of the external magnetic field, so that grinding media with certain shear yield stress are formed along the hole wall surfaces, further processing such as finishing, grinding and deburring of inner walls of various holes is achieved, and surface adaptability and universality are high.

Owner:TAIYUAN UNIV OF TECH

Shear thickening-electrophoresis composite polishing method

PendingCN110026828AImprove polishing efficiencyReduce surface damageGrinding work supportsElectrophoresisMaterial removal

The invention discloses a shear thickening-electrophoresis composite polishing method. The shear thickening-electrophoresis composite polishing method comprises the following steps of 1) selecting a workpiece clamp, and installing the workpiece clamp on a mechanical arm; 2) clamping the workpiece on a workpiece clamp; 3) polishing solution with the shear thickening-electrophoresis composite effect, and the polishing solution is placed in an infusion tube; 4) polishing solution is input to the polishing disk, and the main spindle is started to drive the polishing disk; and 5) starting the shearthickening effect the mechanical arm for controlling, the direct-current power supply for controlling the electrophoresis effect, polishing solution with the shear thickening-electrophoresis composite effect on surface of workpiece under the action of mechanical arm, and is used for providing a load; actively controlling the micro-rotation of the workpiece, meanwhile, electrophoretic effect of abrasive particles generated at two ends of power supply electrode, so that the height matching and material removal of the polishing solution and the surface of the workpiece are formed, and the shearthickening-electrophoresis composite polishing are realized. The invention provides a high-efficiency, and surface-damage-low / free or sub-surface damage shear thickening and the electrophoresis composite ultra-precision polishing method.

Owner:HUNAN UNIV OF SCI & TECH

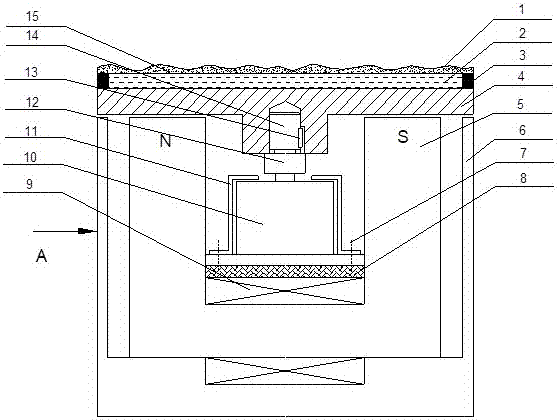

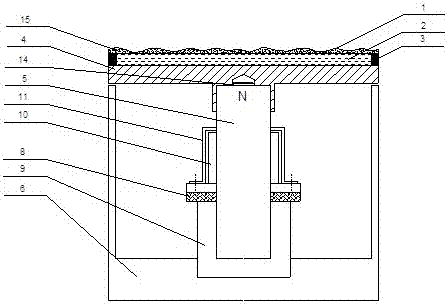

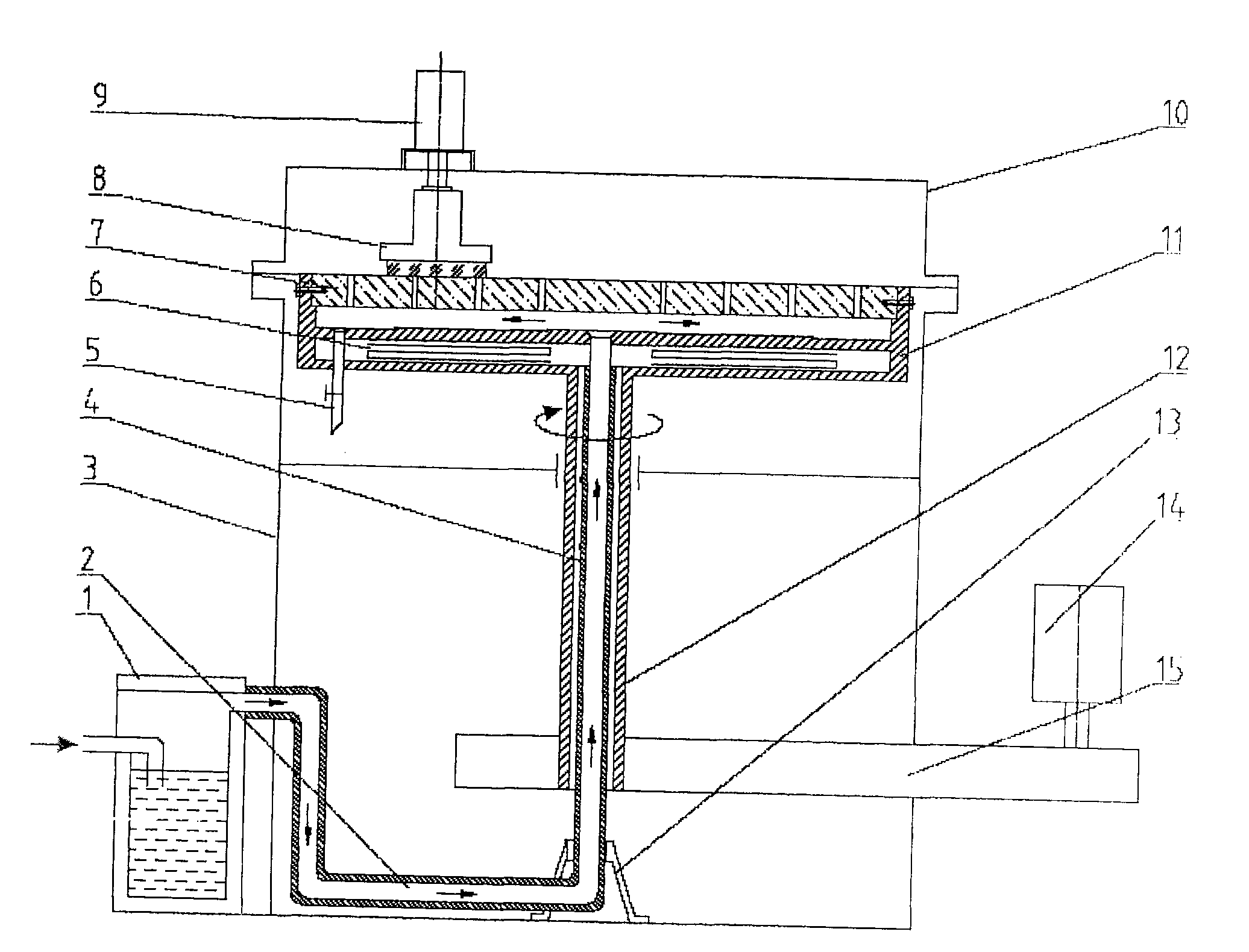

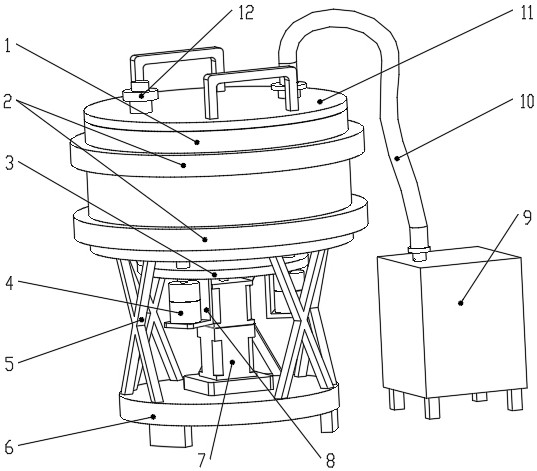

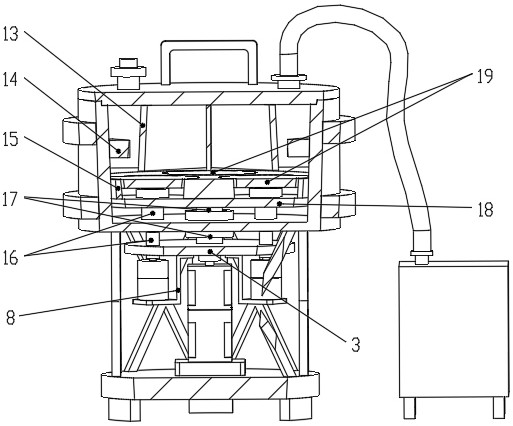

Hydration polisher

InactiveCN101342671AGuaranteed shape accuracyAvoid condensationEdge grinding machinesProcess qualityAgricultural engineering

The invention provides a hydration polishing machine, comprising a frame, a main shaft motor, a main shaft, a polishing disk, a vacuum chuck and a sucker motor. The main shaft motor is connected with the main shaft in a transmission way. The main shaft is arranged inside the frame. The upper end of the main shaft is connected with the polishing disk in a transmission way. The vacuum chuck is located on the upper part of the polishing disk. The vacuum chuck is connected with the sucker motor in a transmission way. The hydration polishing machine also comprises a steam generator, a steam delivery pipe and a basal disk. The outlet of the steam generator is connected with the steam delivery pipe. The inside of the main shaft is provided with a through hole. The steam delivery pipe runs through the through holes from bottom to top. The upper end of the main shaft is fixedly connected with the center of the basal disk. The upper part of the basal disk is fixedly connected with the polishing disk. A transition hollow cavity is arranged between the basal disk and the polishing disk. The steam delivery pipe passes through the basal disk and is communicated with the transition hollow cavity. The bottom of the transition hollow cavity is provided with a drain pipe. The polishing disk is provided with a through hole. When the hydration polishing machine is used for processing the sapphire crystal, the process quality is excellent, the process precision and the process efficiency are high.

Owner:ZHEJIANG UNIV OF TECH

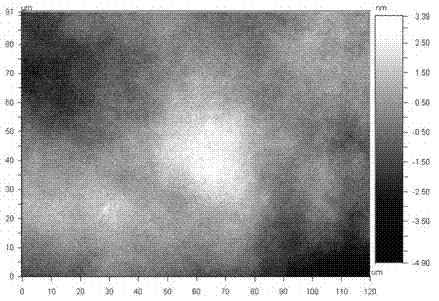

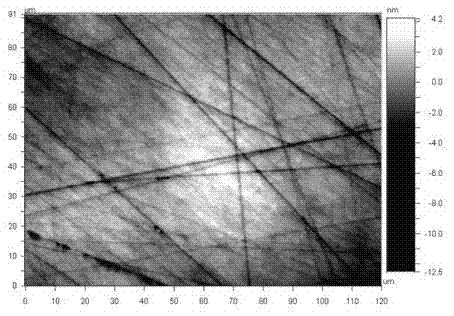

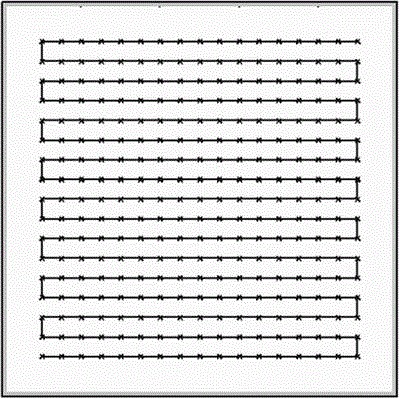

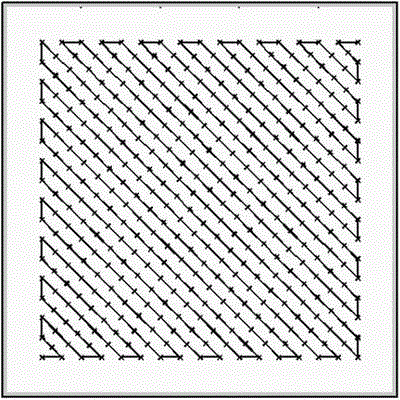

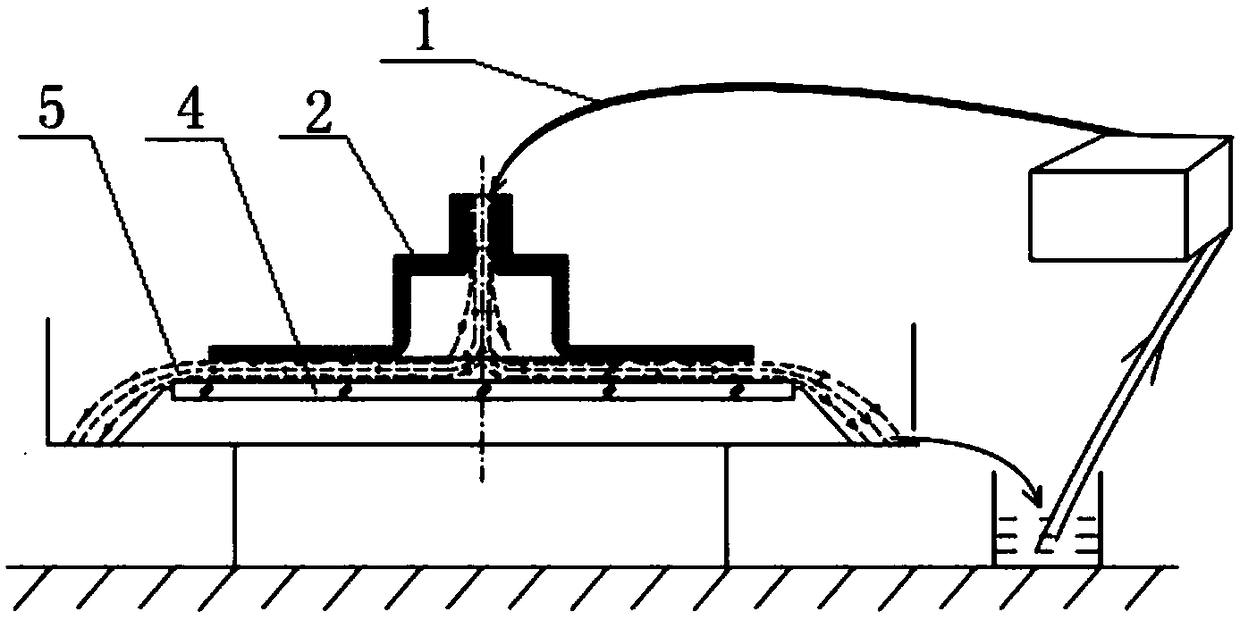

No-damage numerical control water dissolving, polishing and removing method for KDP crystal surface micro-nano texture

ActiveCN105150078ANo subsurface damageImprove surface accuracyPolishing machinesNumerical controlMicro nano

The invention discloses a no-damage numerical control water dissolving, polishing and removing method for KDP crystal surface micro-nano texture, and belongs to a super-precision polishing method. The method comprises the steps that a polishing solution with water is selected for use, a small-size polishing head is used for machining a KDP crystal, a planetary motion revolution center of the polishing head is controlled by a computer to polish the KDP crystal along a preset track, the residence time of all points on the crystal surface is adjusted, and crystal surface figure accuracy is improved; and then the polishing head machines the crystal surface at a constant speed along the polishing track, local residual small-size knife lines are removed, and surface quality is further improved. Removal machining is carried out on materials by means of the physical property that the KDP crystal is soluble in water, subsurface damage caused in a traditional mechanical removing process is avoided, meanwhile, the method can be applied to water-soluble difficult-to-machine materials similar to the KDP crystal, and the problem that small-size waves remaining on the crystal surface after cutting performed by a single-point diamond fly cutter are difficult to remove in existing large-size high-precision KDP crystal element machining is solved.

Owner:DALIAN UNIV OF TECH

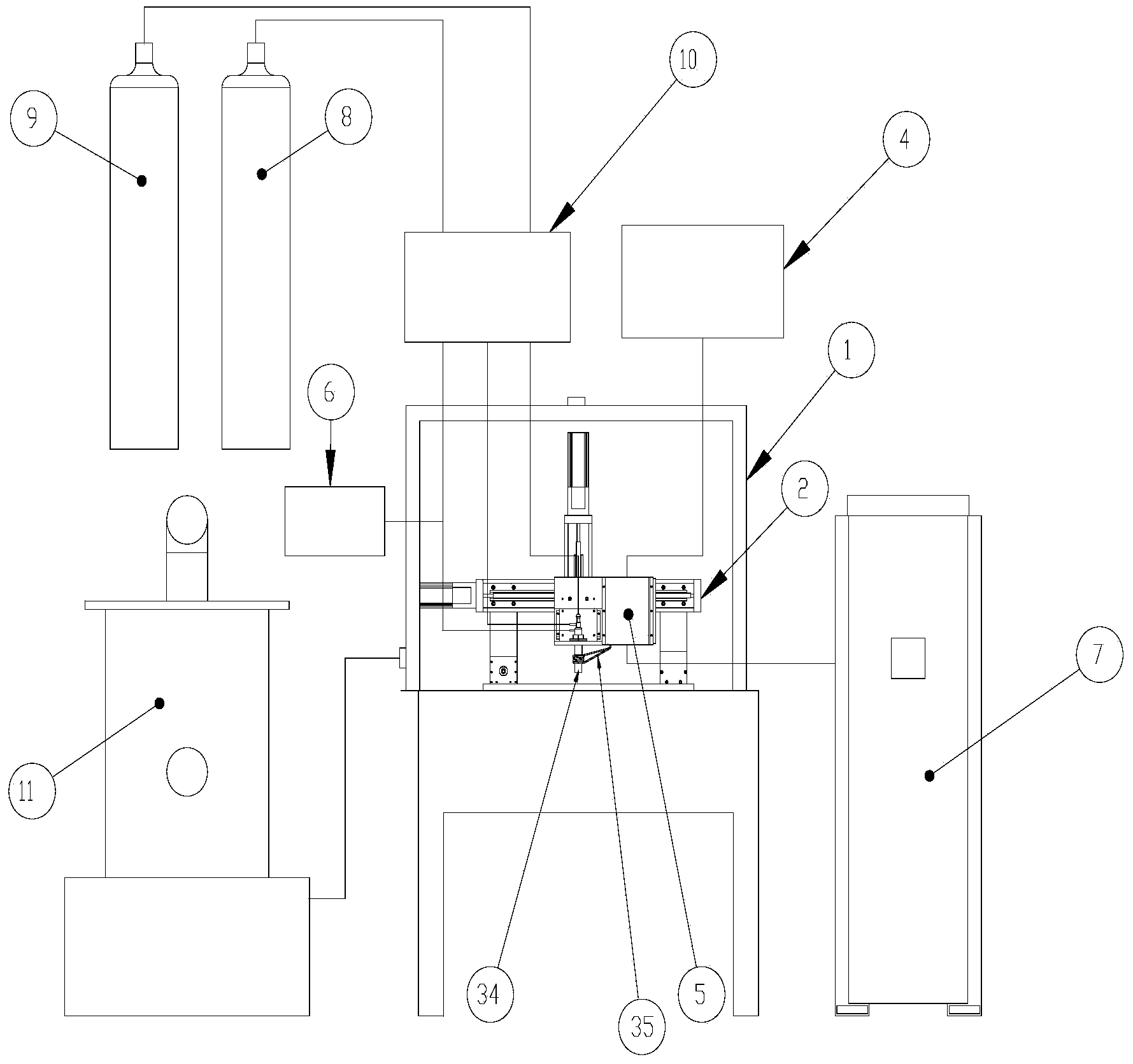

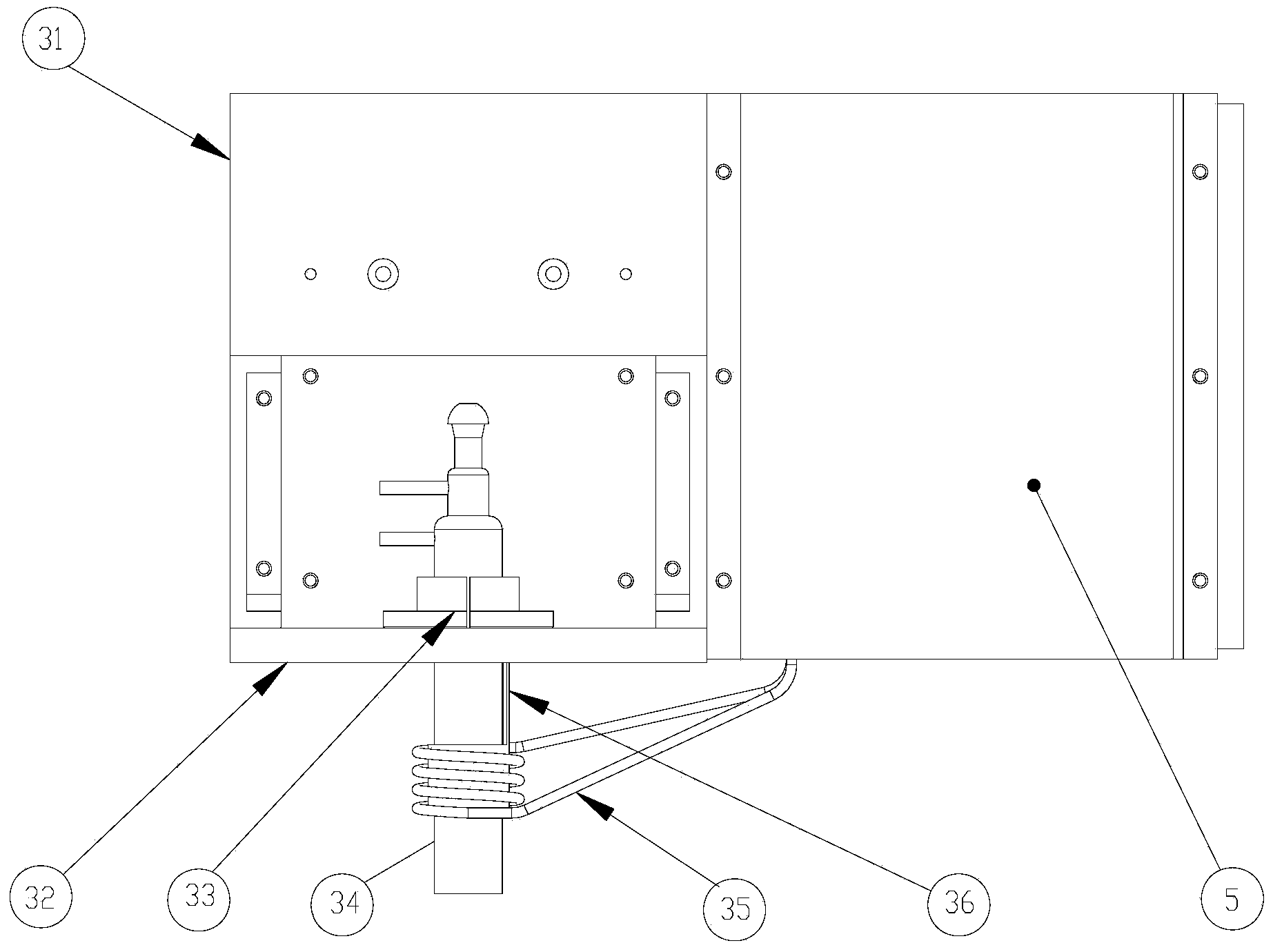

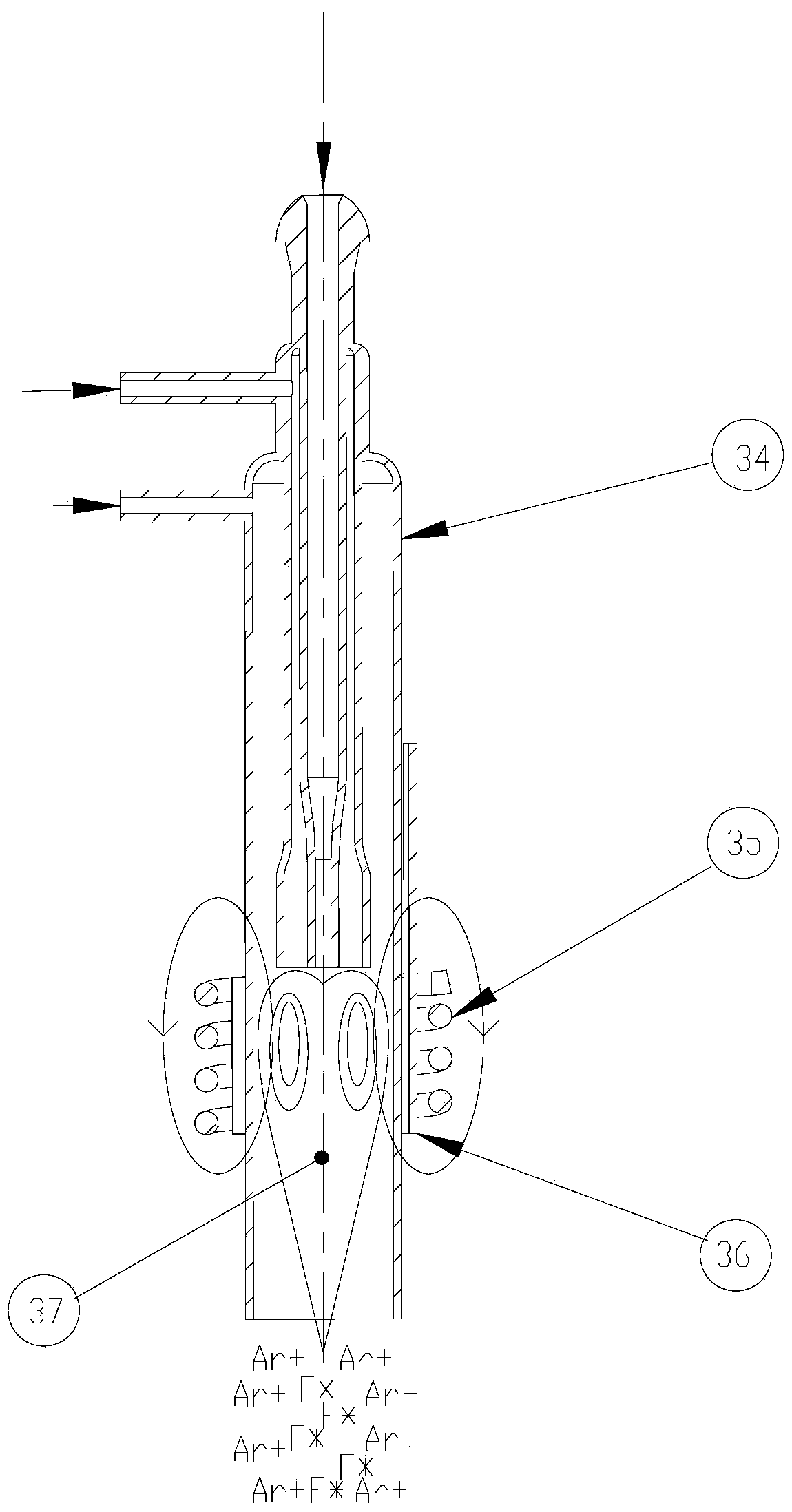

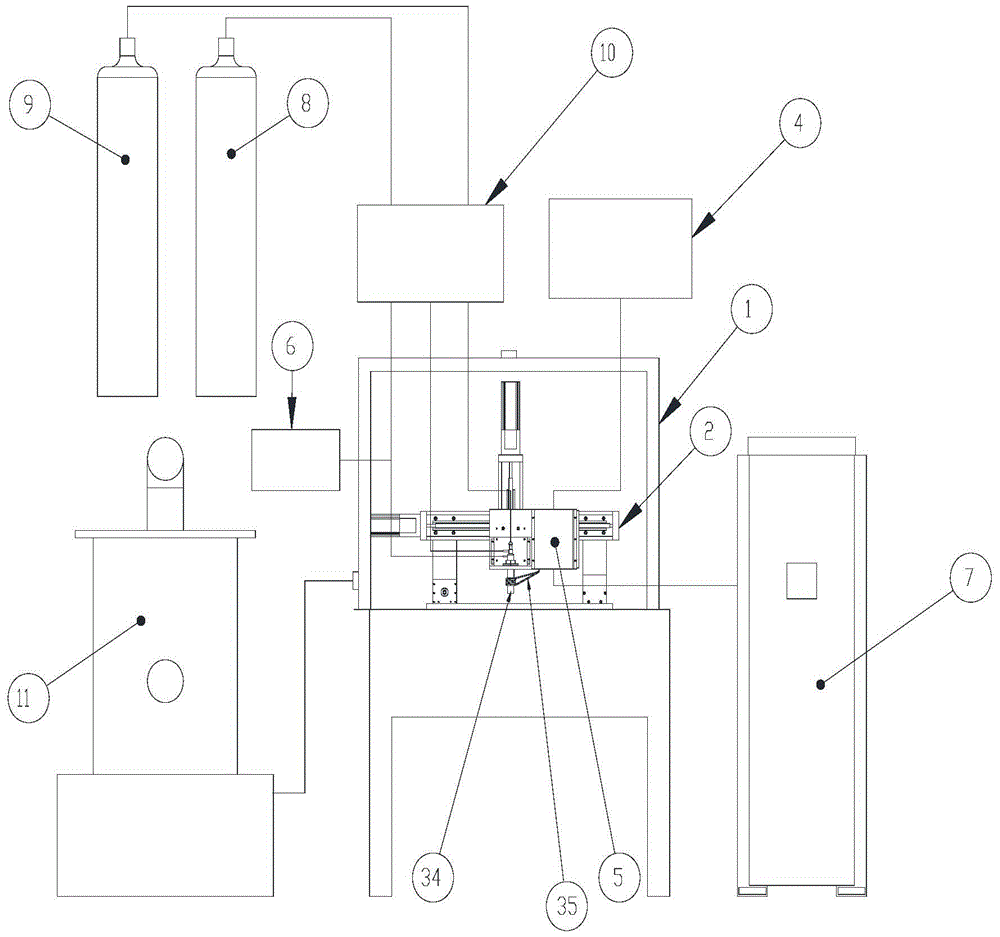

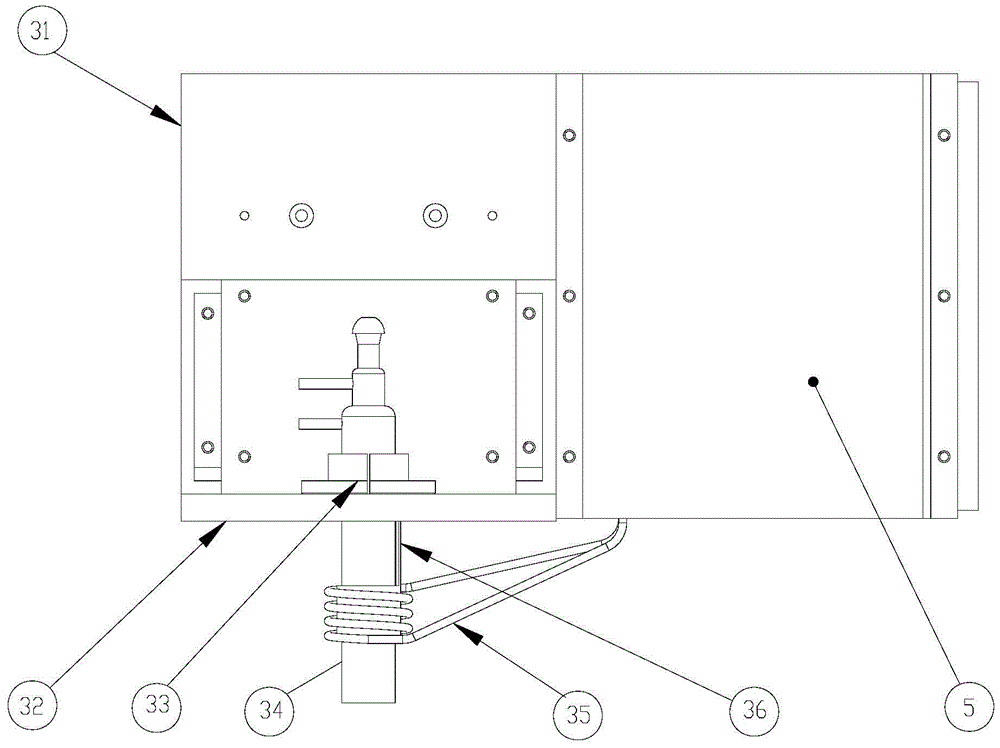

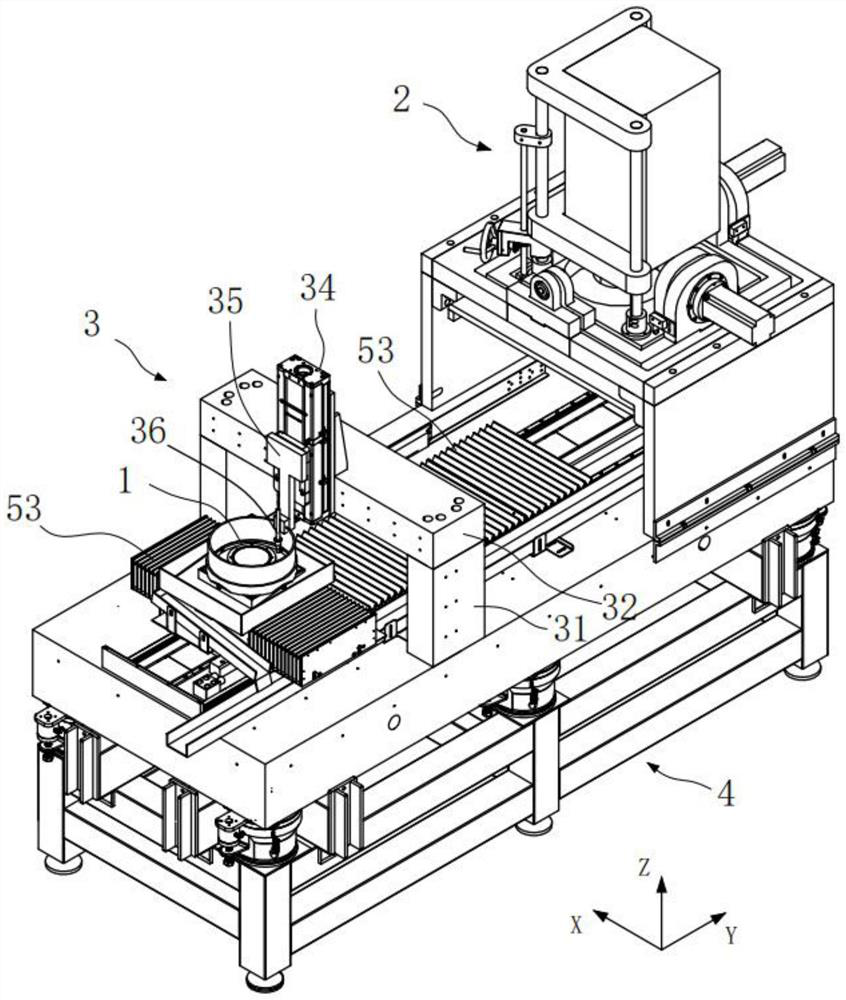

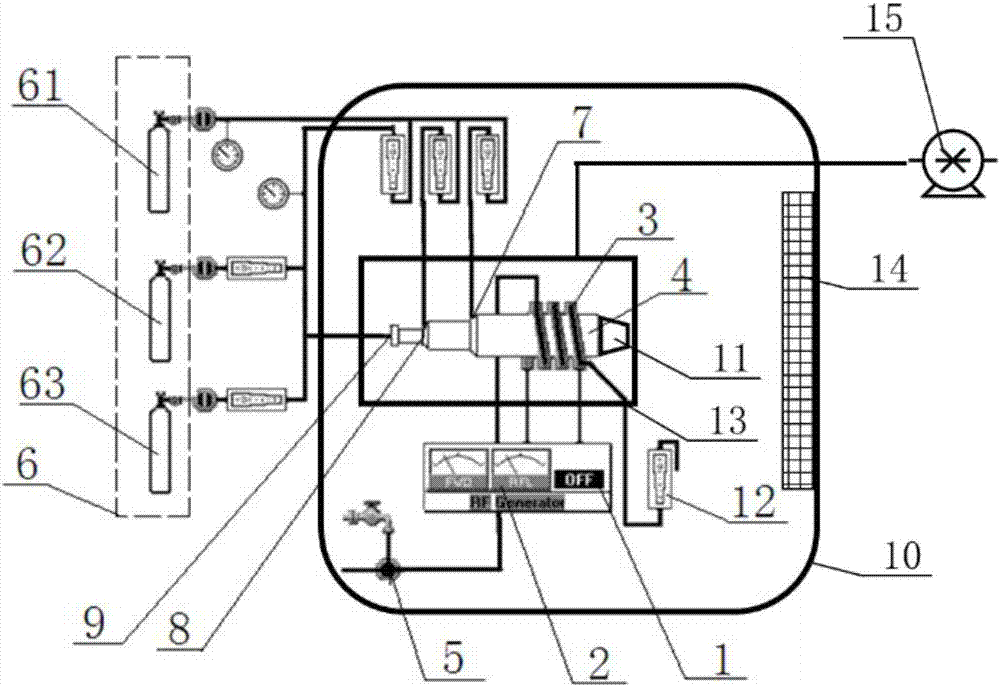

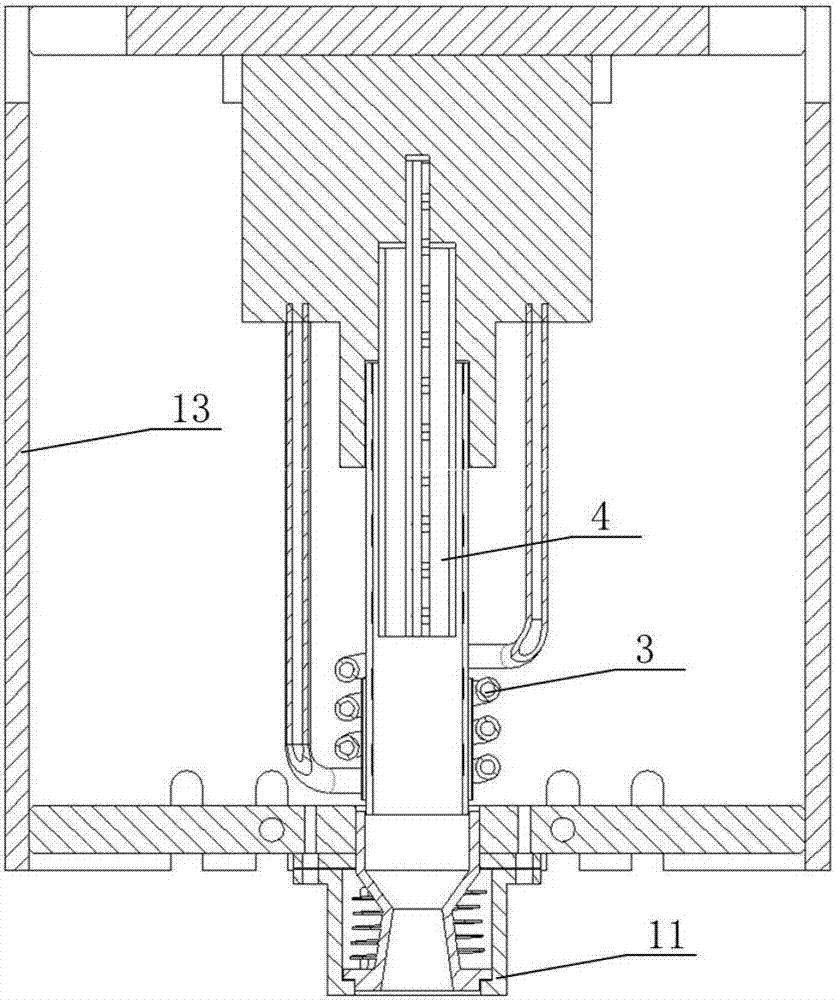

SiC optical material processing device

ActiveCN103456610ASimple structureLow costMirrorsSemiconductor/solid-state device manufacturingChemical reactionEngineering

The invention discloses an SiC optical material processing device which comprises an inductive coupling plasma generation device, a working gas supply source (8) and a reaction gas supply source (9). Reaction gas which can have chemical reaction with SiC after being stimulated by the inductive coupling plasma generation device is placed in the reaction gas supply source (9), the inductive coupling plasma generation device comprises a plasma torch pipe (34) and an induction coil (35), the plasma torch pipe (34) is sleeved with the induction coil (35), the working gas supply source (8) and the reaction gas supply source (9) are connected with the plasma torch pipe (34), one end of the induction coil (35) is connected with a radio-frequency power source (4), and the other end of the induction coil (35) is grounded through an adjustable resistor R1. The SiC optical material processing device has the advantages of being simple in structure and low in cost, producing no subsurface damage or residual stress in a processing procedure, having high processing efficiency and the like.

Owner:NAT UNIV OF DEFENSE TECH

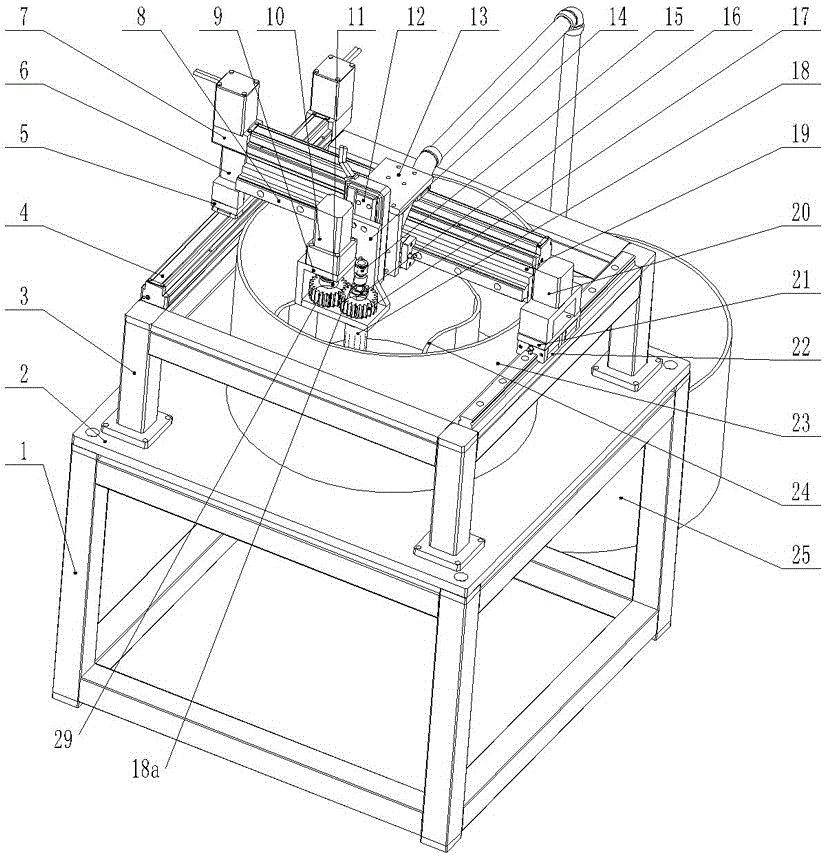

Variable-camber section inner cylindrical surface airflow assisting abrasive flow polishing device

ActiveCN105108631AImprove surface accuracyAchieve precision cutting actionEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

The invention relates to a variable-camber section inner cylindrical surface airflow assisting abrasive flow polishing device. The device comprises an installation frame, wherein a precise three-axis servo driving system, an abrasive flow circulating system and a servo motor driving system are arranged on the installation frame, cylindrical polishing tools are connected with the precise three-axis servo driving system and the servo motor driving system, the cylindrical polishing tools and a variable-camber section tubular workpiece are arranged in the abrasive flow circulating system, the cylindrical polishing tools are arranged in the variable-camber section tubular workpiece and are close to each other, and the cylindrical polishing tools are parallel to the axis of the variable-camber section tubular workpiece. Under the combined action of the precise three-axis servo driving system, the abrasive flow circulating system and the servo motor driving system, the variable-camber section tubular workpiece can be repeatedly polished, the utilization efficiency of abrasive flow can be increased, processing residues can be effectively filtered through a centrifugal pump so as to reduce sewage discharge and achieve clean processing, energy is saved, and the environment is protected.

Owner:沛县度创科技发展有限公司

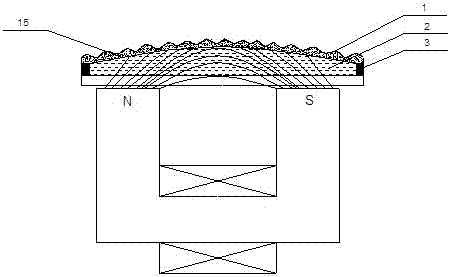

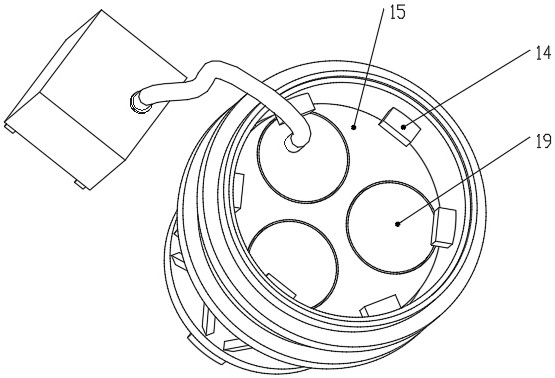

Water-based magneto-rheological closed flexible polishing head based on normal force

The invention discloses a water-based magneto-rheological closed flexible polishing head based on normal force. The polishing head comprises a flexible cutting disc, a magneto-rheological fluid, flexible seal rings, a rotary table, a C-shape magnetic yoke, a shell, baffles, a magnetic coil, a motor, a magnetic shield, shaft couplings, a key, a shaft and abrasive particles. The abrasive particles are evenly distributed on the top surface of the flexible cutting disc; the flexible cutting disc, the flexible seal rings and the rotary table form a seal cavity, and the magneto-rheological fluid is placed in the seal cavity; a rotating shaft is arranged on the center of the bottom surface of the rotary table, blind holes are upwards formed in the center of the rotating shaft, the motor is connected with the shaft through the shaft couplings, and the shaft is connected with the blind holes through the key; the motor is fixed to the top surfaces of the baffles, the motor is separated from the C-shape magnetic yoke through the magnetic shield, the bottom surfaces of the baffles are in contact with the magnetic coil, and the magnetic coil surrounds the closed end of the C-shape magnetic yoke. According to the water-based magneto-rheological closed flexible polishing head based on the normal force, a polishing liquid circulating device is not needed, the size of a flow device is greatly lowered, and the production cost is lowered.

Owner:NANJING UNIV OF SCI & TECH

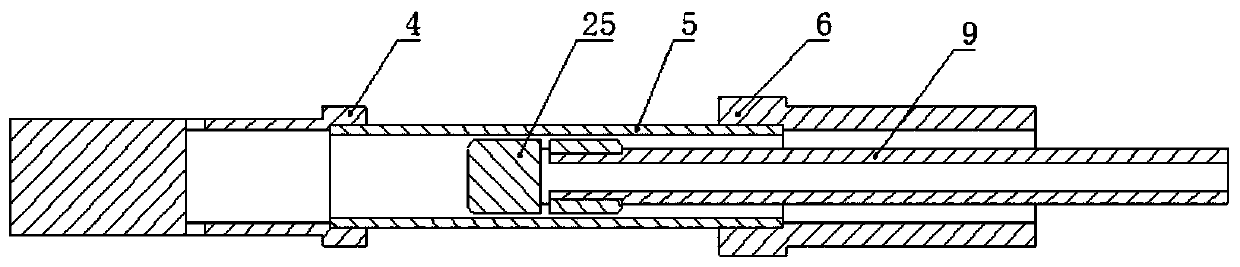

Polishing device and polishing method for ultra-smooth surfaces of optical elements

InactiveCN109015393AAchieve removalImprove processing efficiencyAbrasive machine appurtenancesAbrasive blasting machinesNumerical controlShoot

The invention relates to the technical field of ultra-smooth surface polishing of optical elements, in particular to a polishing device and a polishing method for the ultra-smooth surfaces of the optical elements. The problems of low polishing efficiency, needing of control by a high-precision numerical control machine tool and wave degree error caused by large-area removal in the prior art are solved. The polishing device is of an axisymmetric structure and comprises a pipeline and a grinding head for supplying liquid in the middle, wherein the polishing surface at the lower end of the grinding head is a plane, and a plurality of annular grooves are formed at equal intervals in the polishing surface along the center of a circle; the annular grooves are distributed at the outer circle of the polishing surface, and the pipeline conveys polishing liquid to the center of the grinding head; the polishing liquid is Newtonian fluid, and under the action of pressure, the polishing liquid flows from the center of the grinding head to the periphery to form a liquid film between the polishing surface of the grinding head and a workpiece to separate the grinding head from the workpiece; and the grinding head floats on the surface of the workpiece, the fluid flows through a polishing area to form eddy current at the grooves of the polishing surface and obliquely enters and shoots on the surface of the workpiece, a shearing force is generated on the surface of the workpiece, and material removal is realized.

Owner:XIAN TECHNOLOGICAL UNIV

Kindle direct publishing (KDP) crystal micro-nano hygroscopic ultraprecision polishing method based on ultrasonic atomization moisture

The invention relates to a kindle direct publishing crystal micro-nano hygroscopic ultraprecision polishing method based on ultrasonic atomization moisture, which is characterized by first utilizing ultrasound to product water mist, enabling the water mist to be mixed with dry air to form clean water mist air, pressing a polishing head on the crystal surface, introducing the clean water mist air, conducting micro hydrolysis on the portion of the crystal surface contacted with the moist air to form a dissolution layer, then rotating the polishing head, enabling a polishing mat to remove the high point dissolution layer, enabling a vacuum source to absorb surplus moist air, enabling the polishing head to conduct small area local polishing, ensuring polishing evenness in local areas and finally enabling a polishing tool to polish under control of a computer to achieve crystal surface overall situation planarization according to a dwell time function calculated by a material removing rate function R (r, theta) and removing quantity (x, y) of each point. The method does not use traditional polishing liquid, does not need to washing the crystal surface after polishing is finished and is a real damage-free micro-nano processing method due to the fact that no mechanical processing stress exists in the processing process.

Owner:DALIAN UNIV OF TECH

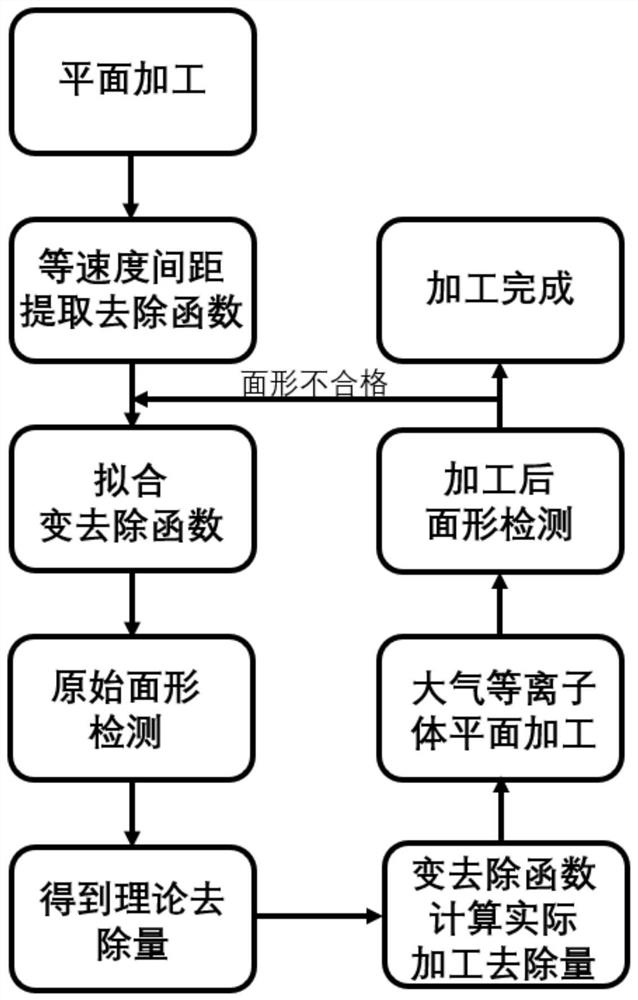

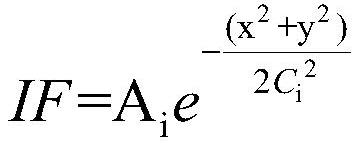

Fused quartz polishing method based on variable removal function atmospheric plasma

PendingCN112456807APrecisely adjust the amount of removalImprove convergence rateComplex mathematical operationsMaterials sciencePlasma processing

The invention relates to the technical field of silicon-based optical element surface ultra-smooth precision processing, and in particular, relates to a fused quartz polishing method based on variableremoval function atmospheric plasma. The problem that in an existing atmospheric plasma processing process, the processing convergence rate is not high due to nonlinear change of a removal function is solved. The method comprises the steps: firstly, carrying out an early-stage variable removal function extraction experiment, then, carrying out operation on a fitted variable removal function and atheoretical removal amount to obtain residence time required by processing, and carrying out fine trimming and polishing by adopting atmospheric plasma equipment, thereby finally finishing high-precision and high-efficiency processing of the fused quartz optical element.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI +1

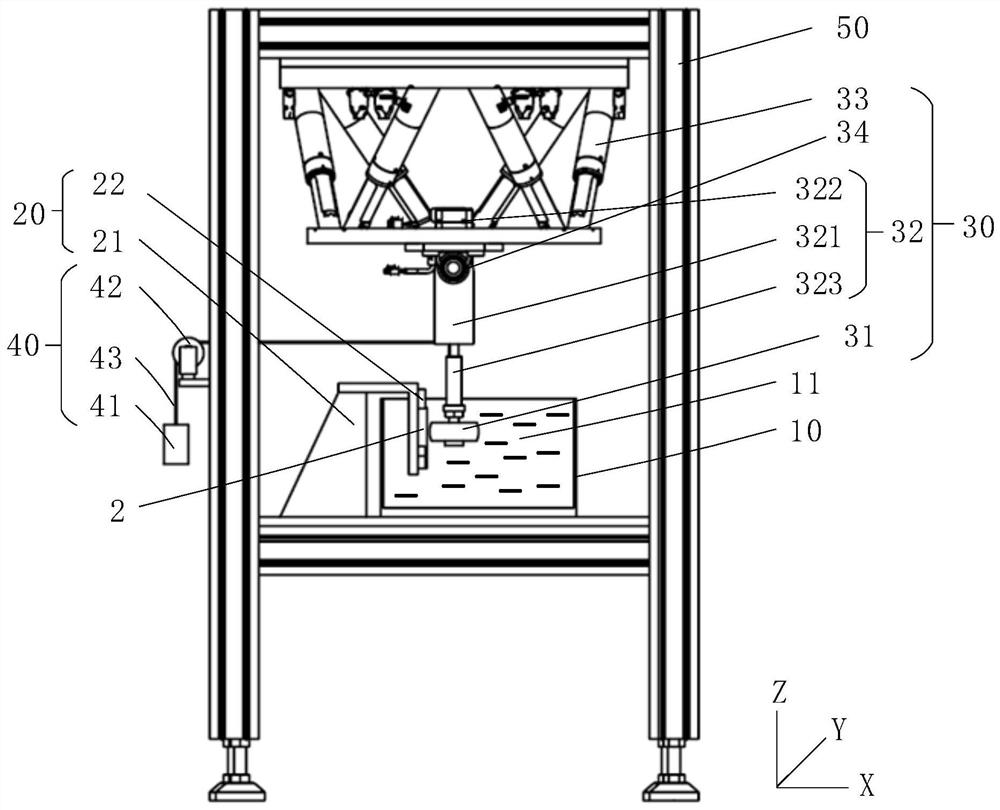

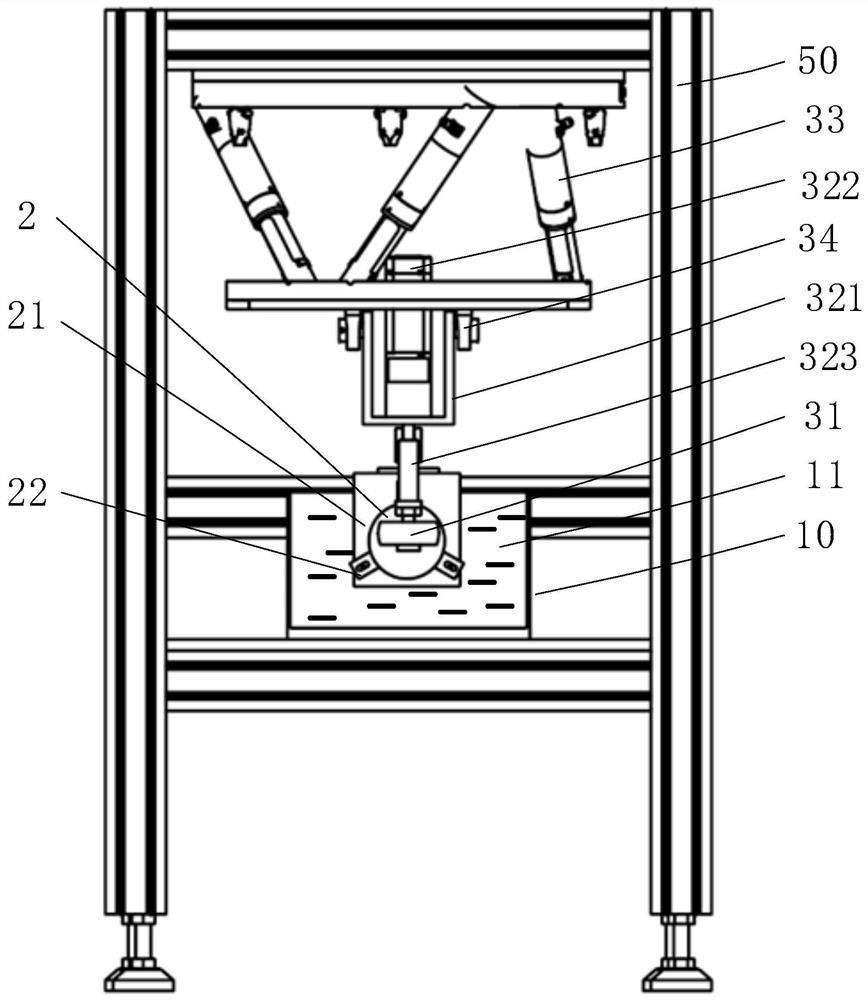

Optical element surface roughness processing device

ActiveCN113263391AImprove surface roughnessNo subsurface damageGrinding carriagesOptical surface grinding machinesPolishingSurface roughness

The invention is applicable to the field of optical element processing, and discloses an optical element surface roughness processing device. The optical element surface roughness processing device comprises a storage tank provided with a polishing solution, a bearing assembly for bearing an optical element to be processed, a polishing assembly for processing the surface roughness of the optical element to be processed, and a pressure applying assembly. The polishing assembly comprises a polishing wheel and a first driving mechanism used for driving the polishing wheel to do rotational motion, the hardness and the elastic modulus of the polishing wheel are far lower than those of the optical element to be processed, the pressure applying assembly is used for applying a load close to the optical element to be processed to the polishing wheel, and the polishing wheel and the optical element to be processed are both arranged in the polishing solution. Under the action of the pressure applying assembly, the contact part of the polishing wheel and the optical element to be processed can deform, a liquid film is formed between the deformation part of the polishing wheel and the optical element to be processed, so that non-contact polishing is performed between the polishing wheel and the optical element to be processed, and the surface roughness of the optical element can be improved; and the surface of the optical element to be processed has no sub-surface damage.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

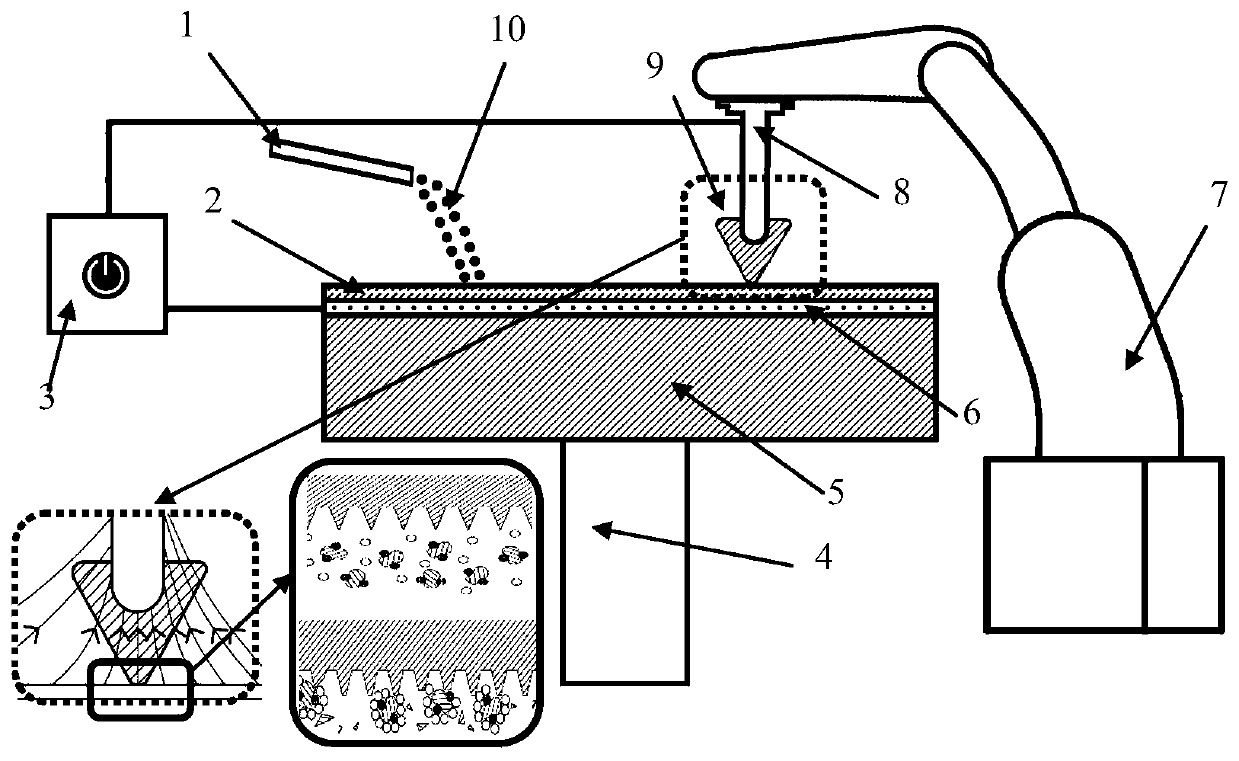

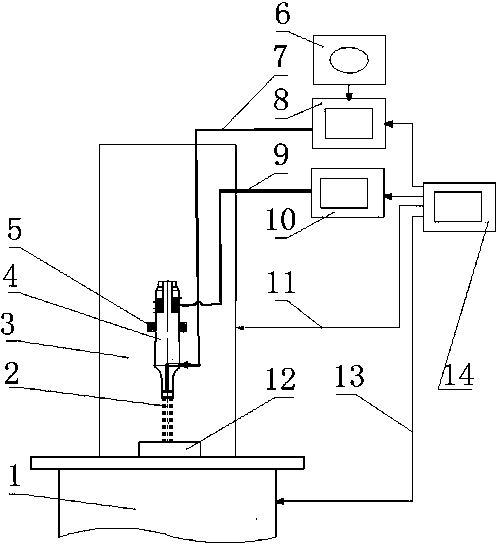

Ultra-precision surface polishing machining device and method

PendingCN107584339AProcessing erosion softUniform surface roughnessGrinding machine componentsSpray nozzleElectricity

The invention discloses an ultra-precision surface polishing machining device and method. The device comprises a precision two-dimensional moving platform, a standing column precisely moving in the Zdirection, an ultrasonic atomizer, an atomizer holder, an intelligent precision micropump, an ultrasonic power supply and a data processing system. According to the device, the intelligent precision micropump is started to run under the control of the data processing system, polishing agent is conveyed to the ultrasonic atomizer through a polishing agent inputting pipe, then the ultrasonic power supply starts an ultrasonic impulse current under the control of the data processing system, a piezoelectric ceramic plate in the ultrasonic atomizer generates ultrasonic vibration by means of the ultrasonic impulse current, and the polishing agent is atomized into polishing aerosol flow to work on the surface of a workpiece. The ultra-precision surface polishing machining device and method have the advantages that the roughness of the machined surface is uniform, subsurface damage to the workpiece does not occur, and the problems of micro powder agglomeration, nozzle blockage and nozzle wear in the flow-jet polishing machining process do not occur.

Owner:SUZHOU UNIV OF SCI & TECH

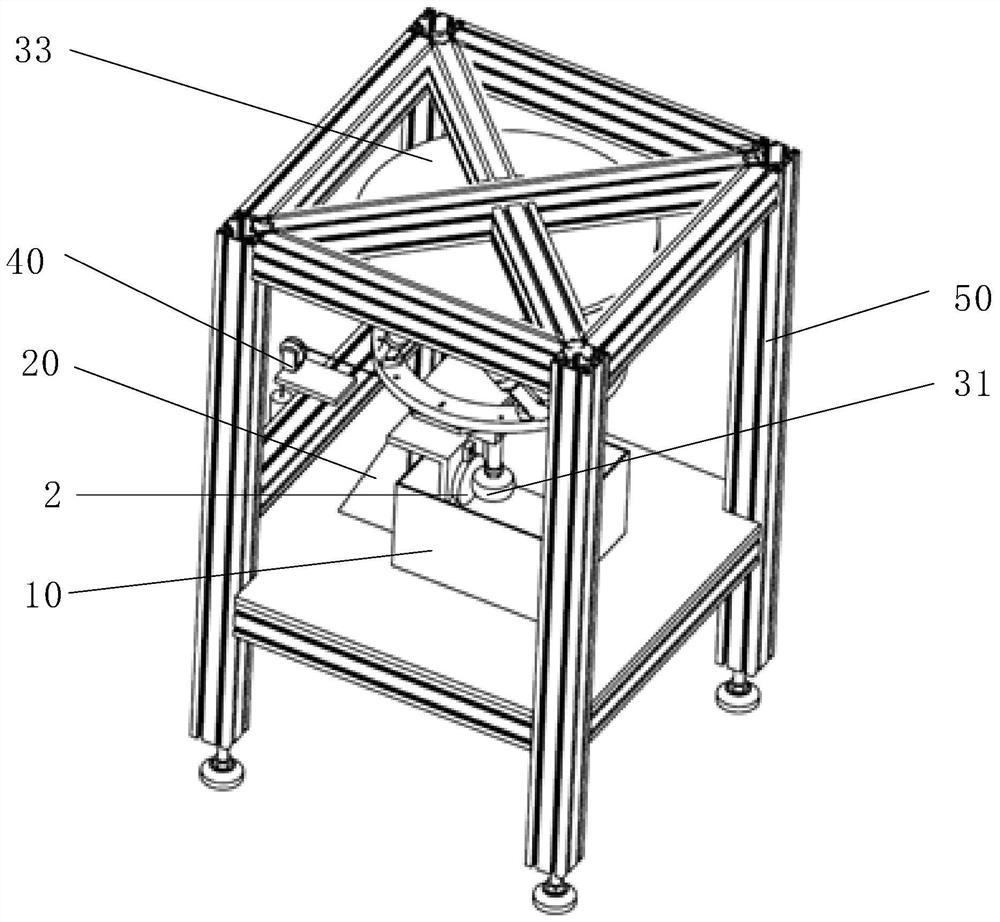

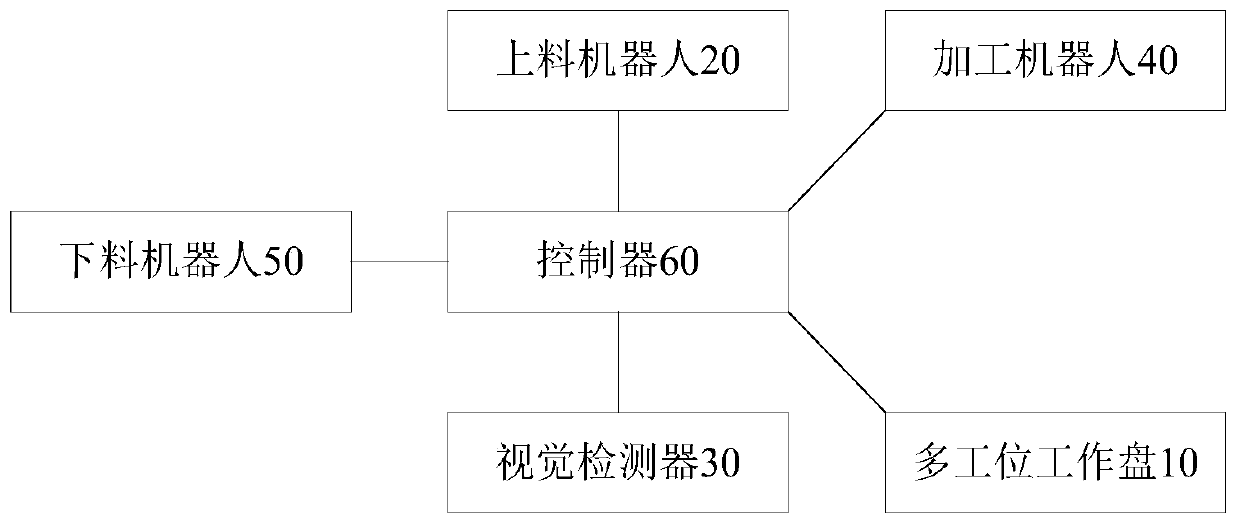

Abrasive water jet deburring system and method based on visual guidance robots

InactiveCN110666706ANo subsurface damageImprove reliabilityAbrasive feedersAbrasive machine appurtenancesVision basedVisually guided

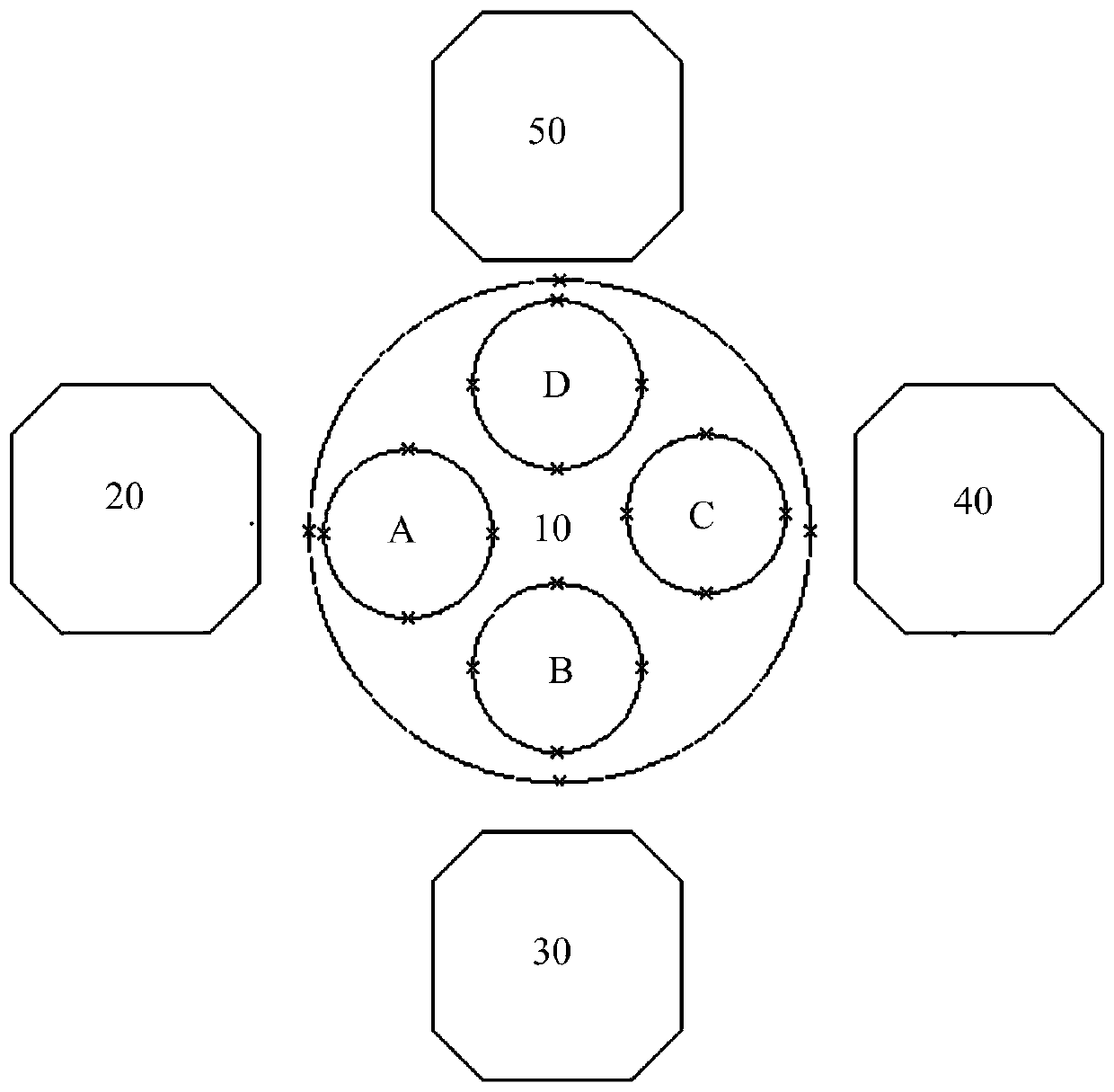

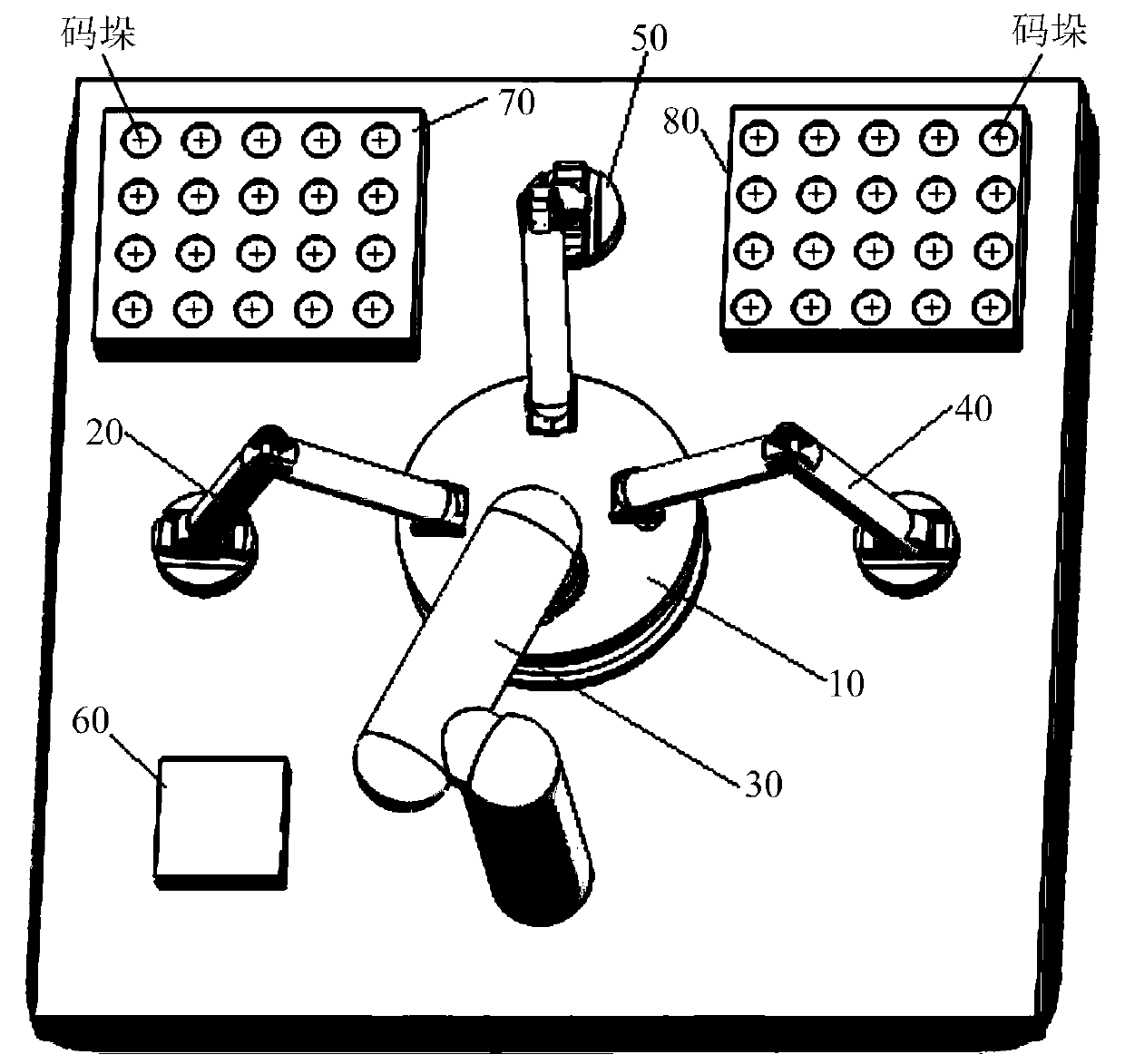

The invention provides an abrasive water jet deburring system and method based on visual guidance robots. The system comprises a multi-station working disc, the feeding robot, a vision detector, the machining robot, the discharging robot and a controller, wherein the multi-station working disc is used for placing a machined product, the vision detector detects a product to be machined in a detection position, and the controller is used for controlling the multi-station working disc to sequentially send the product to be machined to a feeding position, the detection position and a machining position and sent the machined product to a discharging position, and is used for controlling the machining robot to machine the product to be machined through the abrasive water jet according to a detected result. According to the abrasive water jet deburring system and method based on the visual guidance robots, the reliability and the stability of product machining can be improved, the productionefficiency can be improved, the production cost can be reduced, meanwhile, machining of various complex curved surfaces can be achieved, it can be guaranteed that no sub-surface damage occurs to the machined product, the polishing precision can be improved, and the boundary effect is avoided.

Owner:JIANGSU UNIV OF TECH

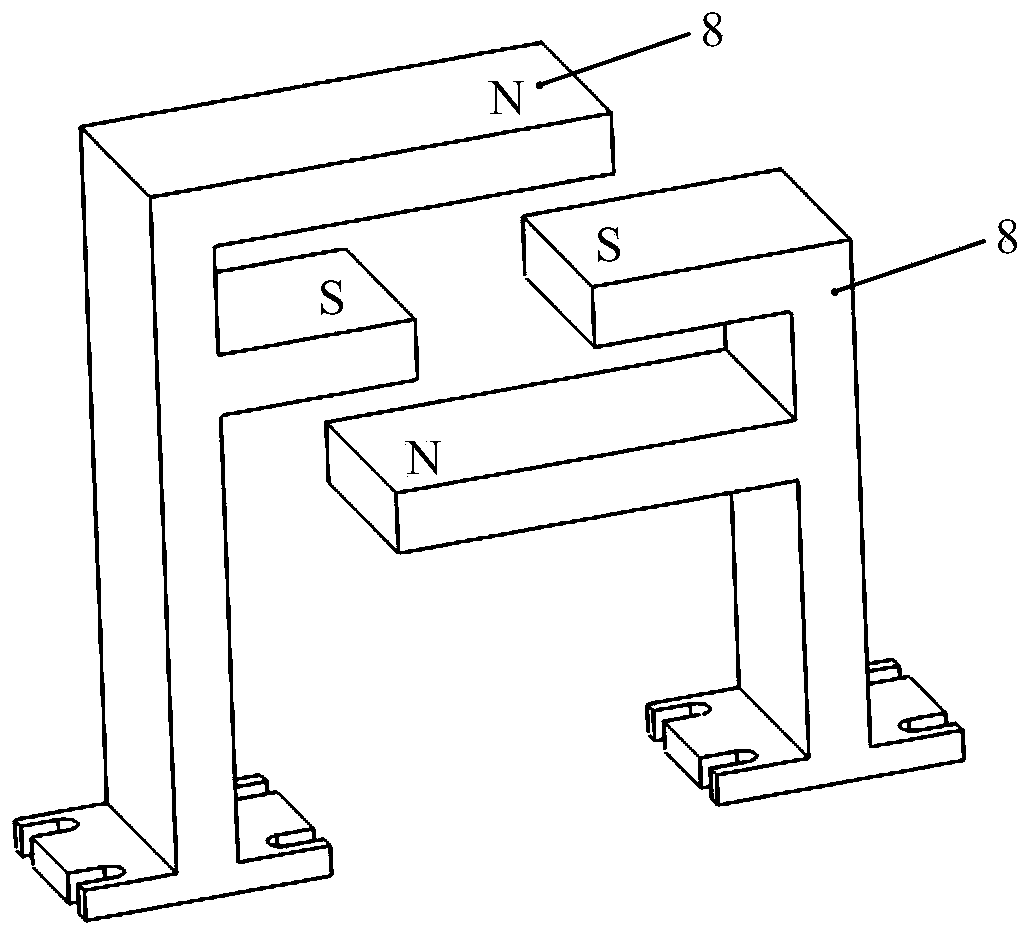

A kind of magnetorheological polishing equipment

ActiveCN110000624BHigh removal rateSimple structureGrinding carriagesGrinding work supportsMaterial removalPolishing

The invention relates to the technical field of mechanical processing, and discloses a magnetorheological polishing equipment. The magnetorheological polishing equipment drives a horn and a magnet to perform synchronous reciprocating linear motion, and combines ultrasonic and magnetorheological polishing on the surface of a workpiece. Polishing has the advantages of good controllability, high material removal rate, and no subsurface damage; ultrasonic waves can cause the horn to vibrate at high frequencies, with a vibration frequency as high as 20Khz. Compared with traditional magnetorheological polishing technology, it has greatly improved Polishing efficiency; the high-frequency vibration of the horn causes the magnetorheological polishing fluid to form a flexible polishing head with certain removal capabilities around the horn. The operation is simple, and the composite motion of the workpiece and the flexible polishing head makes the polishing surface more uniform. . This polishing equipment has the advantages of simple structure, compactness, and uniform polishing.

Owner:NORTHEASTERN UNIV LIAONING

Micro cutter passivation method and device based on flexible abrasive particles and magnetic composite fluid

ActiveCN114131431AHigh passivation precisionImprove consistencyEdge grinding machinesPolishing machinesMetallurgyWear particle

The invention relates to a micro cutter passivation method and device based on flexible abrasive particles and magnetic composite fluid, a cutting edge of a micro cutter is treated by adopting a magnetic composite fluid polishing principle, and a material on the surface of the cutter is slightly removed by utilizing the rheological property of the magnetic composite fluid and the flexible abrasive particles. Cutting edge passivation treatment and surface polishing treatment of the cutter can be achieved at the same time, and the cutter is high in passivation precision and good in consistency; batch passivation of the miniature cutters is achieved through the multi-clamp design, cutter passivation work and disassembly and assembly operation can be carried out at the same time, and the cutter passivation efficiency is improved. According to the micro cutter passivation method and device based on the flexible abrasive particles and the magnetic composite fluid, micro defects of a cutting edge of a micro cutter can be effectively removed, the contour shape of the cutting edge is improved, tiny burrs on the surface of the cutter are eliminated, the surface quality of the cutter is improved, the service life of the cutter is prolonged, and the part machining quality is improved; and high-precision and high-efficiency passivation treatment on the micro cutter is realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A kind of sic optical material processing equipment

ActiveCN103456610BSimple structureLow costMirrorsSemiconductor/solid-state device manufacturingChemical reactionInductively coupled plasma

The invention discloses SiC optical material processing equipment, which comprises an inductively coupled plasma generator, a working gas supply source (8) and a reaction gas supply source (9). The reaction gas supply source (9) is equipped with a The reactive gas that chemically reacts with SiC after being excited by the inductively coupled plasma generating device, the inductively coupled plasma generating device includes a plasma torch (34) and an induction coil (35) sleeved outside the plasma torch (34) ), the working gas supply source (8) and the reaction gas supply source (9) are connected to the plasma torch (34), one end of the induction coil (35) is connected to the radio frequency power supply (4), and the induction coil The other end of (35) is grounded through the adjustable resistor R1. The invention has the advantages of simple structure, low cost, no subsurface damage and no residual stress layer during processing, and high processing efficiency.

Owner:NAT UNIV OF DEFENSE TECH

Hydration polisher

InactiveCN100593455CGuaranteed shape accuracyAvoid condensationEdge grinding machinesProcess qualityAgricultural engineering

The invention provides a hydration polishing machine, comprising a frame, a main shaft motor, a main shaft, a polishing disk, a vacuum chuck and a sucker motor. The main shaft motor is connected withthe main shaft in a transmission way. The main shaft is arranged inside the frame. The upper end of the main shaft is connected with the polishing disk in a transmission way. The vacuum chuck is located on the upper part of the polishing disk. The vacuum chuck is connected with the sucker motor in a transmission way. The hydration polishing machine also comprises a steam generator, a steam delivery pipe and a basal disk. The outlet of the steam generator is connected with the steam delivery pipe. The inside of the main shaft is provided with a through hole. The steam delivery pipe runs throughthe through holes from bottom to top. The upper end of the main shaft is fixedly connected with the center of the basal disk. The upper part of the basal disk is fixedly connected with the polishingdisk. A transition hollow cavity is arranged between the basal disk and the polishing disk. The steam delivery pipe passes through the basal disk and is communicated with the transition hollow cavity.The bottom of the transition hollow cavity is provided with a drain pipe. The polishing disk is provided with a through hole. When the hydration polishing machine is used for processing the sapphirecrystal, the process quality is excellent, the process precision and the process efficiency are high.

Owner:ZHEJIANG UNIV OF TECH

Polishing method based on self-excited oscillation and force rheology composite effect of polishing solution

PendingCN114193242AIncrease transport distanceEnhanced rheological effectComposite effectMaterial removal

A polishing method based on self-excited oscillation of a polishing solution and a force rheology composite effect is used for polishing the inner wall of a pipe fitting, during polishing, the force rheology polishing solution flows through a pipe, the rheology effect is generated due to the shearing effect, a flexible grinding tool is formed on the interface of the force rheology polishing solution and a workpiece, and the inner wall of the pipe fitting is subjected to material removal; during polishing, after the force rheological polishing liquid in the liquid supply pipeline is increased to high pressure, the force rheological polishing liquid passes through the self-excited oscillation device, so that the force rheological polishing liquid has a self-excited oscillation phenomenon and enters a workpiece to be machined, periodic fluctuation of speed and pressure occurs on the inner surface of the workpiece, meanwhile, vibration is applied to the workpiece, and the rheological effect of the force rheological polishing liquid is enhanced. By means of the method, efficient polishing machining of the inner wall of the pipe fitting can be achieved, and the workpiece with low surface roughness and low / no surface damage or subsurface damage is obtained.

Owner:新昌浙江工业大学科学技术研究院

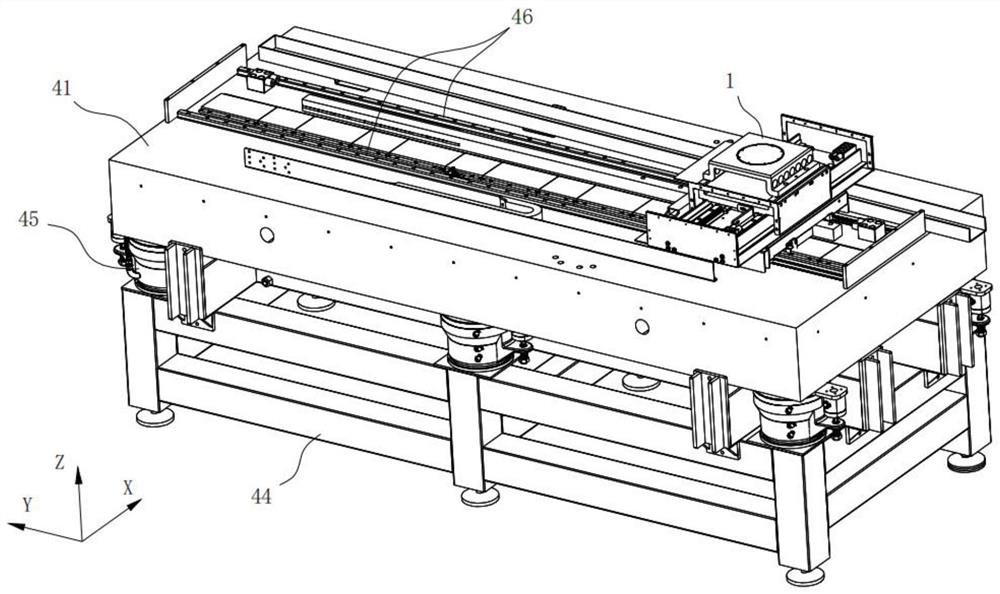

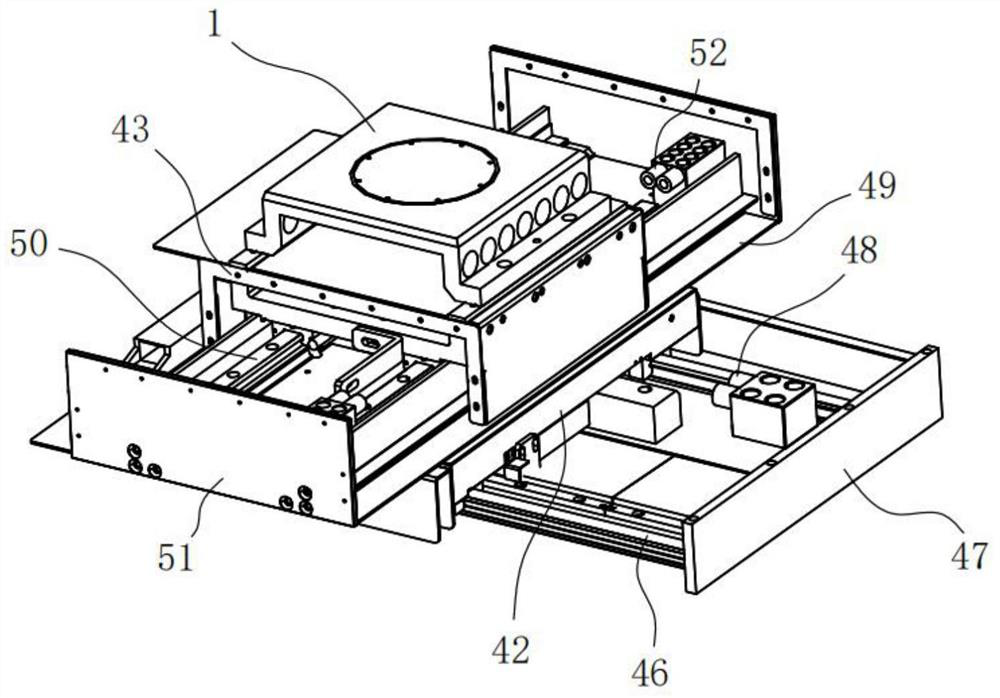

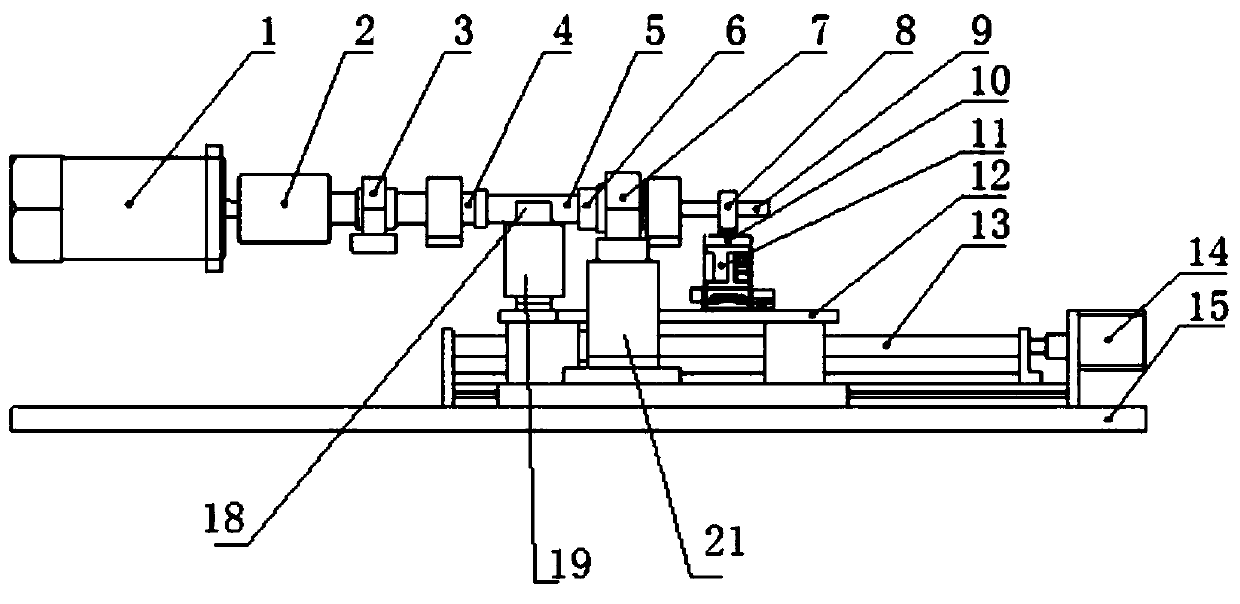

Novel jet machining and detection integrated precision equipment

PendingCN113843716AHigh precisionAchieve nanometer precision manufacturingMaterial analysis by optical meansAbrasive machine appurtenancesEngineeringMachining

The invention discloses novel jet machining and detection integrated precision equipment. The equipment comprises a workbench used for loading a workpiece, a measuring mechanism used for measuring the workpiece, a jet mechanism used for conducting jet machining on the workpiece according to a detection result and a movement mechanism, and the workbench is movably arranged on the movement mechanism. The measuring mechanism and the jet mechanism are arranged at the two ends of the movement mechanism respectively, the movement mechanism drives the workbench to move back and forth to the position below the measuring mechanism and the jet mechanism in a reciprocating mode, and measurement and jet machining are conducted on the workpiece respectively. A detection device and a machining device are integrated, after being measured by a laser interferometer, the workpiece can be directly moved to the position below the jet device to be machined, integrated manufacturing and machining are achieved, and errors caused by multiple times of clamping are reduced.

Owner:GUANGXI UNIV

Novel optical pressurization grinding-tool-free polishing device

The invention provides a novel optical pressurizing grinding-tool-free polishing device which mainly comprises a motor driving module, a sealing tank module and a pressurizing module and is mainly used for polishing optical parts, and the polishing effect is achieved through stable relative movement between a polishing solution and a machined part; specifically, the machined part is driven by a motor to do revolution and rotation movement relative to the polishing solution at the same time, pressure and a magnetic field are applied to the polishing solution with the magneto-rheological property in a sealed tank body, the polishing solution forms a soft grinding disc, and therefore the controllable, stable and strong polishing effect is generated. The novel optical pressurizing grinding-tool-free polishing device has the advantages that traditional grinding tools such as a polishing disc are not needed, the polishing device can adapt to the surfaces of any shapes, polishing is completed through the self-convergence effect generated by stable movement of a machined workpiece relative to a soft grinding disc under the pressurization and magnetic field conditions, the full-coverage and ultra-smooth machining effect on the workpiece can be achieved, surface damage does not exist, and the novel optical pressurizing grinding-tool-free polishing device has the characteristics of high efficiency and controllability.

Owner:徐德富

A processing method for chemical mechanical polishing of tantalum with consolidated abrasive

ActiveCN104400619BSolve the problem of surface planarizationEasy to cleanLapping machinesAqueous dispersionsSurface roughnessMachining process

The invention discloses a processing method for chemically and mechanically polishing tantalum (Ta) by employing a fixed abrasive. The method is characterized by comprising the following steps: carrying out polishing on tantalum or a tantalum film by adopting a cerium oxide fixed abrasive polishing pad, controlling the polishing pressure to be 10-100kpa in the machining process, and controlling the rotating speed of a polishing disk to be 50-150rpm, wherein the polishing solution is composed of deionized water free of an abrasive, a surfactant, a complexing agent and a pH modifier; adjusting the pH value of the polishing solution to be 8 to 11; controlling the temperature of the polishing solution within a range of 20-30 DEG C, wherein the flow rate of the polishing solution is 80-150ml / min, so that the nano-precision surface roughness can be obtained, and the surface quality is excellent. According to the processing method disclosed by the invention, the processing efficiency and the surface quality of tantalum are improved; the qualified rate of the finished product is high; no environmental pollution is caused; the cleaning is easy and the cost is low.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A magnetorheological polishing method and device for the inner wall of a titanium alloy tube

ActiveCN107791107BHigh removal rateImprove controllabilityPolishing machinesGrinding work supportsPeristaltic pumpApparent viscosity

The invention provides a method and device for magnetorheological polishing of the inner wall of a titanium alloy tube. The magnetorheological fluid is pumped into the inner cavity of the polishing head along the inner surface of the transmission rod under the action of a peristaltic pump, and overflows through the rectangular hole around the middle part of the polishing head, respectively. Flows from the left and right sides to the polishing area. Under the action of the magnetic field, the apparent viscosity and shear yield stress of the magnetorheological fluid increase rapidly, forming a Bingham medium with a certain viscoplasticity. With the relative movement of the polishing head and the tube wall, the Bingham medium The medium shears and removes the pipe wall material; the magnetorheological fluid that participates in polishing is collected through the magnetorheological fluid collection mechanisms on both sides of the pipe, and continues to participate in the polishing process after being filtered and stirred, realizing the magnetorheological fluid Recycling; the heat generated in the polishing area is taken away during the circulation of the magnetorheological fluid. The invention can automatically polish the inner wall of titanium alloy pipes, and has the advantages of simple control, good polishing uniformity, and high work efficiency. It is especially suitable for polishing the inner wall surface of slender titanium alloy pipes.

Owner:NORTHEASTERN UNIV LIAONING

Water-based magnetorheological closed flexible polishing head based on normal force

Owner:NANJING UNIV OF SCI & TECH

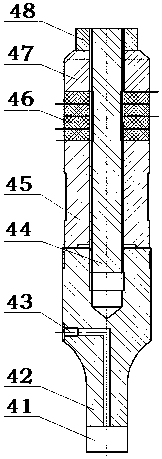

replaceable nozzle icp generator in plasma chemical etching equipment

The invention discloses a replaceable nozzle ICP generating device in plasma chemical etching equipment, and belongs to the technical field of precision processing devices for optical curved surface mirror processing. The ICP generating device includes a nozzle, a plasma torch, an induction coil set outside the plasma torch, a high-voltage Tesla ignition coil, a radio frequency power supply and a matcher, the radio frequency power supply and the matcher supply power to the induction coil, and the high voltage Tesla The ignition coil is powered by an external power supply; the nozzle is detachably fixedly connected to the front end of the plasma torch in the ICP generator, and the size of the removal function can be adjusted by replacing nozzles with different inner diameters. By adopting the ICP generating device of the present invention, the removal function of the ideal size can be obtained for the processing of the optical element, and the convergence of the surface shape error of the whole frequency band can be realized.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Method for processing soft and crisp LBO crystals based on consolidated abrasive polishing pad

InactiveCN102172879BReduce surface damageImprove surface qualityPolishing machinesPolishing compositionsMicrometerGranularity

The invention discloses a method for processing soft and crisp LBO crystals based on a consolidated abrasive polishing pad, which is characterized by comprising the following steps: firstly, roughly polishing and machining LBO crystals by the polishing pad of diamond consolidated abrasive of which the granularity is less than or equal to 14 micrometers, wherein in the polishing and machining process, the polishing pressure is controlled to 50-600g / cm<2>, the revolving speed of a polisher is controlled to 10-200 rpm, the pH value of a polishing solution adopted by polishing is controlled to 2-6, and the temperature of the polishing solution is 20-30DEG C to roughly polish the LBO crystals; and then, finely polishing and machining the LBO crystals obtained from the rough machining by the polishing pad of cerium oxide consolidated abrasive of which the granularity is not more than 3 micrometers, wherein the polishing pressure is controlled to 50-600g / cm<2> in the fine polishing and machining process, the revolving speed for polishing is controlled to 10-200rpm, the pH value of a polishing solution adopted by polishing is controlled to 2-6, and the temperature of the polishing solution is 20-30DEG C until the surface quality satisfies a set requirement. The method has the advantages of high processing efficiency and high finished product rate and does not cause environmental pollution.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com