Fused quartz polishing method based on variable removal function atmospheric plasma

A plasma and fused silica technology, applied in the ultra-smooth and precise processing field of fused silica glass surface, can solve the problems of affecting the etching process and low processing convergence rate, and achieve the effect of high convergence rate and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with the example polished fused quartz (SiO 2 ) to further illustrate the present invention, but should not limit the protection scope of the present invention with this.

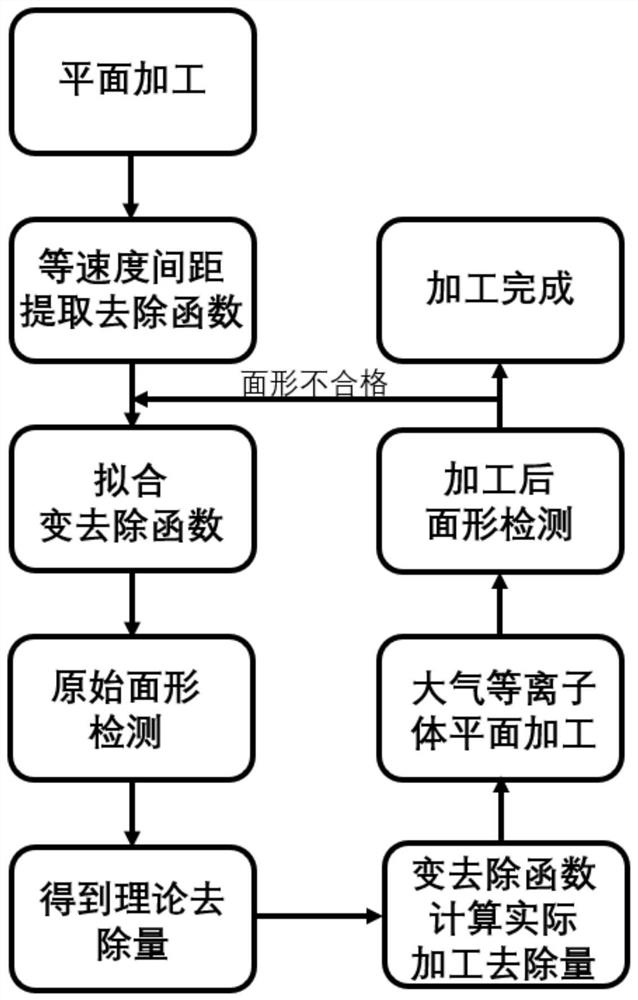

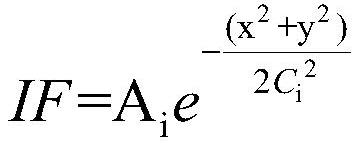

[0027] The method of the invention provides a novel atmospheric plasma processing method, which introduces a single removal function as a variable into the convolution operation, so that the atmospheric plasma processing can achieve higher processing precision.

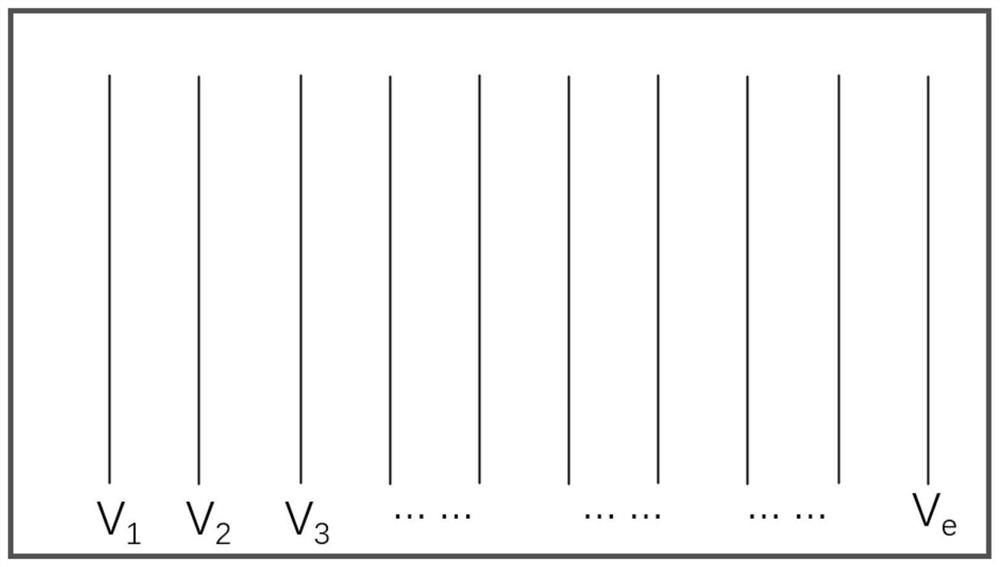

[0028] The new processing method will be clearly and systematically explained in conjunction with the atmospheric plasma processing device diagram below, and its method steps are:

[0029] Step 1: Place the experimental piece with the same specifications as the fused silica element to be processed on the processing platform of the atmospheric plasma equipment, perform precise tool setting on the workpiece, turn on the atmospheric plasma RF power supply on the sacrificial piece, and pass through the air inlet hole Into H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com