Polishing method based on self-excited oscillation and force rheology composite effect of polishing solution

A technology of self-excited oscillation and polishing fluid, which is applied in the field of ultra-precision machining to achieve the effects of improved removal efficiency, high-efficiency polishing, and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

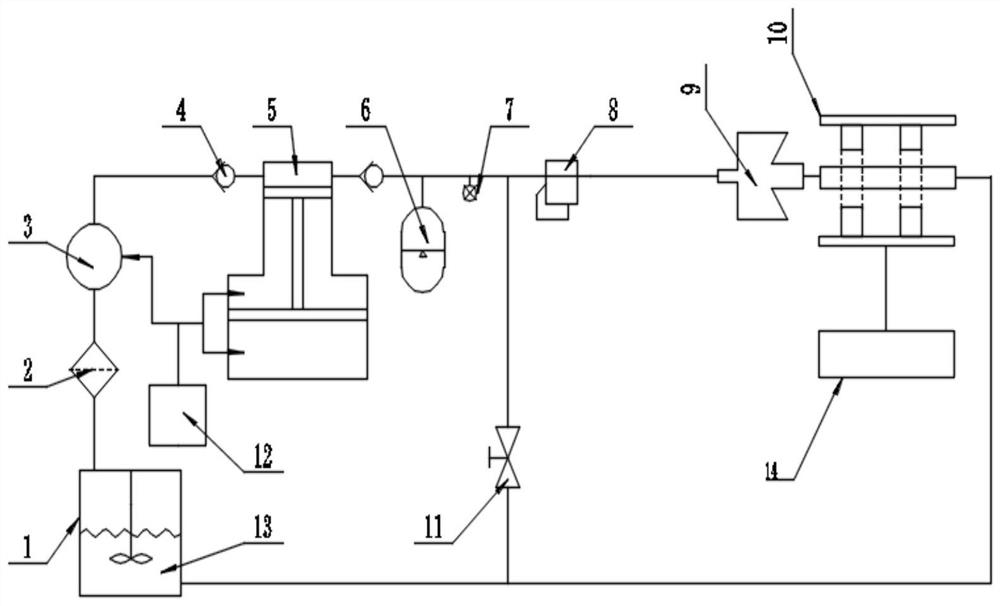

[0038] The present invention is used for processing the workpiece of aspect ratio pipeline surface, and this embodiment uses figure 1 The polishing device shown is realized, and the processing steps are as follows:

[0039] 1) The workpiece is installed in the workpiece holder 10, and the outlet of the workpiece holder 10 is connected with the self-excited oscillation device 9, and the other end of the workpiece holder 10 is connected with the polishing liquid barrel 1 through a high-pressure pipe, and the workpiece holder 10 is connected with The motor 14 is connected by a reciprocating mechanism;

[0040]2) preparing a mechano-rheological polishing solution with shear thickening properties, and placing the polishing solution in the polishing solution barrel 1;

[0041] 3) Connect the diaphragm pump 3 and the polishing solution bucket 1 through an ordinary water pipe, and add a filter 2 between the two in order to prevent impurities from wearing out the entire system;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com