Preparation method for antistatic cement-based self-levelling surface-layer mortar

A cement-based, flat layer technology, applied in the production of self-leveling flat layer mortar, can solve the problems of endangering personal safety, poor electrical conductivity, explosion and fire, and achieve the effects of resource saving, smooth surface and improved comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

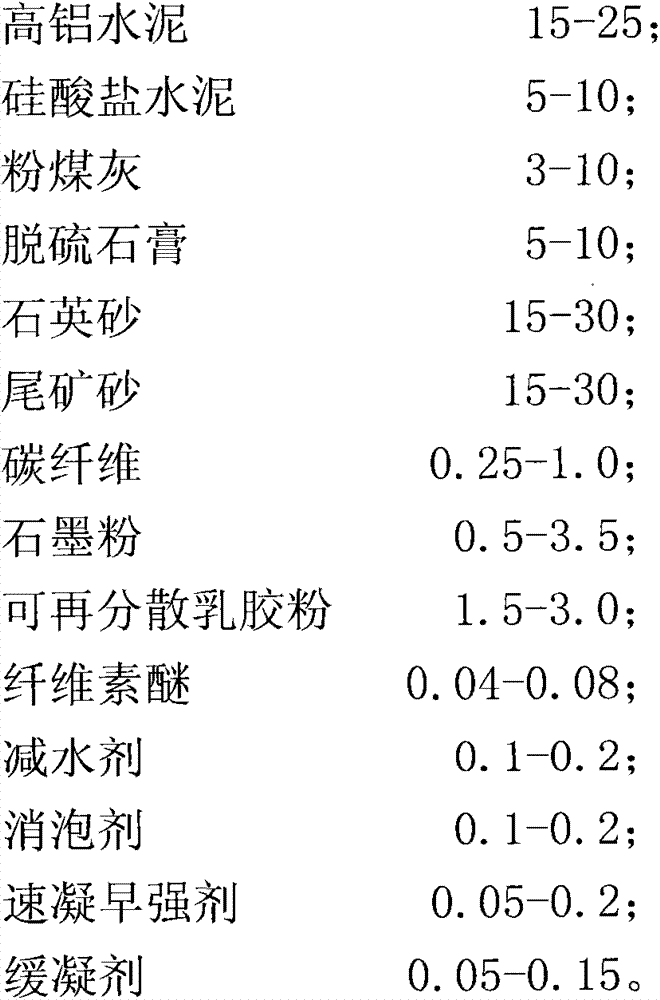

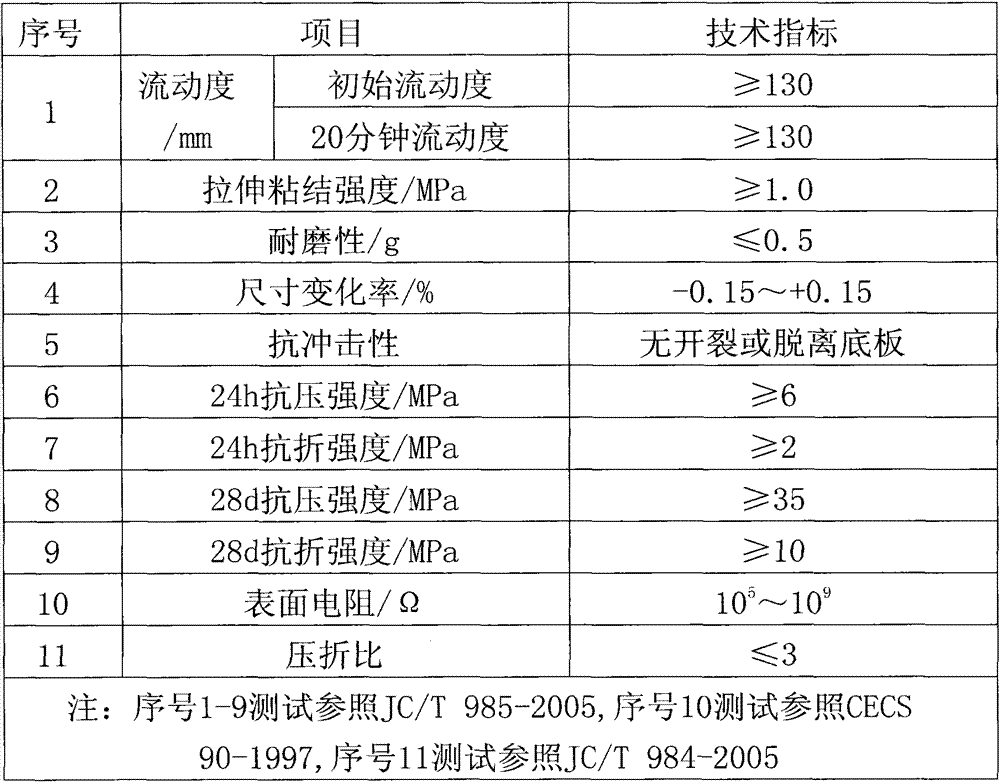

Method used

Image

Examples

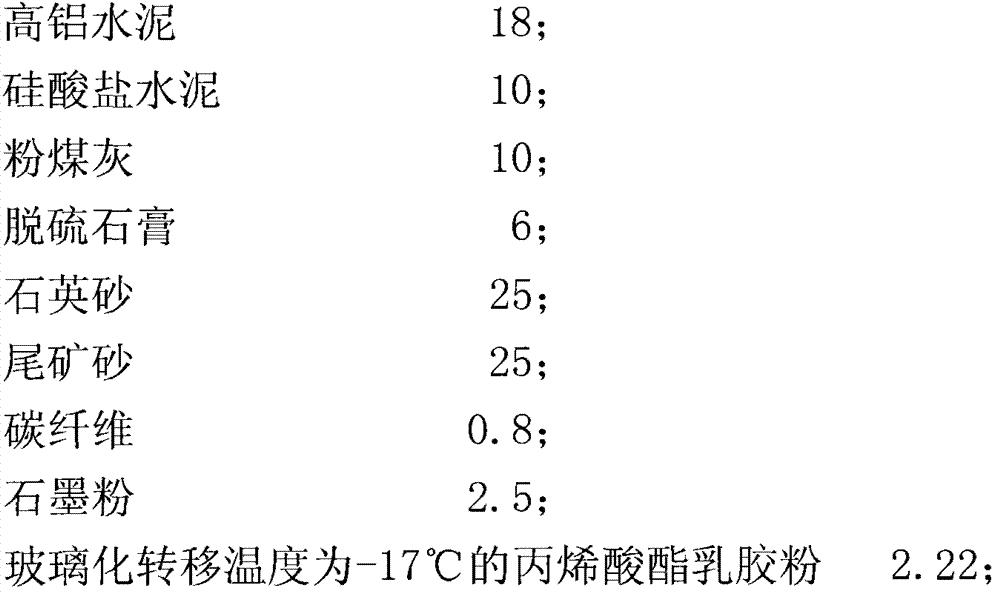

Embodiment 1

[0033] The specific embodiment that realizes the preparation method of a kind of antistatic cement-based self-leveling flat layer mortar of the present invention is:

[0034] 1. First, select raw materials:

[0035] High alumina cement: CA50-G6 type;

[0036] Portland cement: Portland cement, strength grade 42.5;

[0037] Fly ash: Class I;

[0038] Desulfurization gypsum: the content of calcium sulfate dihydrate is >93% and the mesh number is 200;

[0039] Quartz sand: mesh number 50-100, mud content ≤ 1%, moisture content ≤ 0.5%;

[0040] Tailing sand: mesh number 50-100, mud content ≤ 1%, moisture content ≤ 0.5%;

[0041] Carbon fiber: polyacrylonitrile-based carbon fiber with a length of 3mm;

[0042] Graphite powder: 500 mesh flake graphite powder with carbon content ≥ 99%;

[0043] Redispersible latex powder: acrylate latex powder with a glass transition temperature of -17°C;

[0044] Cellulose ether; hydroxypropyl methylcellulose ether with a viscosity of 1000mPa·...

Embodiment 2

[0058] The specific embodiment that realizes the preparation method of a kind of antistatic cement-based self-leveling flat layer mortar of the present invention is:

[0059] 1. First, select raw materials:

[0060] High alumina cement: CA50-G6 type;

[0061] Portland cement: Portland cement, strength grade 42.5;

[0062] Fly ash: Class I;

[0063] Desulfurization gypsum: the content of calcium sulfate dihydrate is >93% and the mesh number is 200;

[0064] Quartz sand: mesh number 50-100, mud content ≤ 1%, moisture content ≤ 0.5%;

[0065] Tailing sand: mesh number 50-100, mud content ≤ 1%, moisture content ≤ 0.5%;

[0066]Carbon fiber: polyacrylonitrile-based carbon fiber with a length of 5mm;

[0067] Graphite powder: 500 mesh flake graphite powder with carbon content ≥ 99%;

[0068] Redispersible latex powder: vinyl acetate latex powder with a glass transition temperature of -10°C;

[0069] Cellulose ether; hydroxypropyl methylcellulose ether with a viscosity of 1000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com