Preparation process of concrete porous brick prepared from tubular pile residual slurry and waste incineration slag

A technology for waste incineration slag and residual slurry of pipe piles is applied in the field of producing concrete porous bricks by adding fly ash and stone chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048]The domestic waste incineration slag concrete porous brick made of pipe pile residual pulp is prepared from pipe pile residual slurry, domestic waste incineration slag, cement, fly ash and stone chips. Among them, the mass percentage of pipe pile slurry, domestic waste incineration slag, cement, fly ash, and stone chips accounted for by the raw materials of pipe pile slurry, domestic waste incineration slag, cement, fly ash, and stone chips is: pipe pile slurry 20%, domestic waste incineration slag 28%, cement 0.8%, fly ash 15%, stone chips 36.2%.

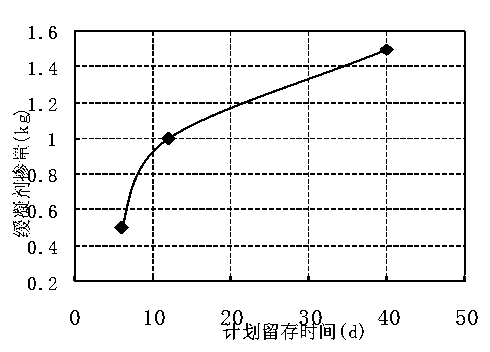

[0049] The residual slurry of pipe piles is provided by the adjacent pipe pile factory. The remaining slurry of pipe piles is mixed with sugar retarder half an hour after going offline. The ambient temperature was 15 o c. Before adding the retarder, adjust the concentration of the residual slurry of the pipe pile to 10%, and then add 0.8kg retarder to the 1T residual slurry. The amount of the retarder needs to be used up w...

Embodiment 2

[0068] The domestic waste incineration slag concrete porous brick made of pipe pile residual pulp is prepared from pipe pile residual slurry, domestic waste incineration slag, cement, fly ash and stone chips. Among them, the mass percentage of pipe pile slurry, domestic waste incineration slag, cement, fly ash, and stone chips accounted for by the raw materials of pipe pile slurry, domestic waste incineration slag, cement, fly ash, and stone chips is: pipe pile slurry 15%, domestic waste incineration slag 27%, cement 0.5%, fly ash 12.5%, stone chips 45%.

[0069] The residual slurry of pipe piles is provided by the adjacent pipe pile factory. The remaining slurry of pipe piles is mixed with sugar retarder half an hour after going offline. The ambient temperature was 30 o c. Before adding the retarder, adjust the concentration of the remaining slurry of the pipe pile to 10%, and then add 1.2kg of retarder to the 1T of the remaining slurry. The amount of the retarder needs to...

Embodiment 3

[0088] The domestic waste incineration slag concrete porous brick made of pipe pile residual pulp is prepared from pipe pile residual slurry, domestic waste incineration slag, cement, fly ash and stone chips. Among them, the mass percentage of pipe pile slurry, domestic waste incineration slag, cement, fly ash, and stone chips accounted for by the raw materials of pipe pile slurry, domestic waste incineration slag, cement, fly ash, and stone chips is: pipe pile slurry 19%, domestic waste incineration slag 35%, cement 1%, fly ash 10%, stone chips 35%.

[0089] The residual slurry of pipe piles is provided by the adjacent pipe pile factory. The remaining slurry of pipe piles is mixed with sugar retarder half an hour after going offline. The ambient temperature was 6 o c. Before adding the retarder, adjust the concentration of the residual slurry of the pipe pile to 10%, and then add 0.5kg retarder to the 1T residual slurry. The amount of the retarder needs to be used up withi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com