High-efficiency and energy-saving concrete synergistic agent and preparation method thereof

A concrete synergist, high-efficiency and energy-saving technology, applied in the field of concrete, can solve the problems of high price, insufficient cement benefit and cost, and achieve the effect of reducing cement consumption, improving work performance, and increasing strength level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of UFD polymer copolymer:

[0040] 1) Weigh 50g of urea and 50g of deionized water, add the weighed urea and water into a 250ml three-neck bottle in turn, start stirring, adjust the stirring speed to 150rpm, after the urea is completely dissolved, weigh 10.5g of alkaline solution (alkaline solution is mixed by 4.5g ammonia water (mass fraction 28%) and 4.5g liquid caustic soda (mass fraction 40% sodium hydroxide) by mass ratio 1:1), and alkaline solution is slowly added in the there-necked flask, During this period, the stirring is not stopped, and the temperature of the water bath is raised to 50°C;

[0041] 2) Weigh 110g of 37% formaldehyde solution (the formaldehyde mass fraction in the formaldehyde solution is 37%, containing 5% methanol, and the balance is water), and when the temperature of the solution in the there-necked bottle is at 50°C, use 150ml of constant drop to dissolve The formaldehyde solution was added to the reaction system, and the drop...

Embodiment 2

[0046] First, add 5 kg of sodium tripolyphosphate into 33 kg of water and stir quickly. After it is completely dissolved, add 7 kg of sodium gluconate into it, stir and dissolve, and then add 25 kg of UFD polymer copolymer. Stir and mix, and finally add 15 kg of glycerin and 15 kg of polycarboxylic acid mother liquor into it and stir evenly to obtain a high-efficiency and energy-saving concrete synergist.

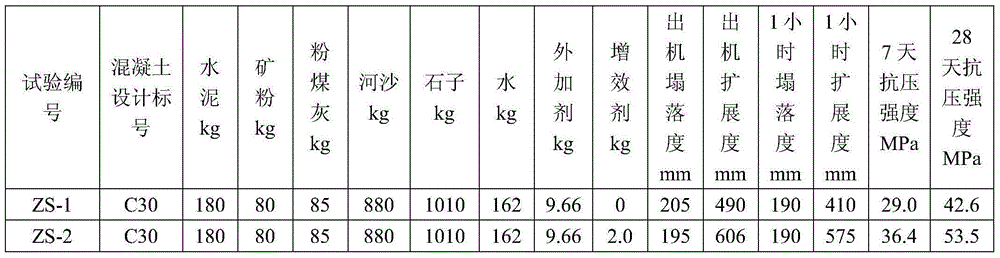

[0047]The weight percentage of the concrete synergist added in the concrete is 0.6% of the total mass of the cementitious material. Prepare relevant raw materials according to the design mix ratio of C30 concrete strength grade. Based on the mix ratio of concrete without adding synergist, add this synergist according to 0.6% of the total amount of cementitious materials. The amount of cement per kilogram is used as a comparison sample, and the test is carried out according to the "GB_T50107-2010 Concrete Strength Inspection and Evaluation Standard". The concrete test result...

Embodiment 3

[0057] First, add 3 kg of sodium tripolyphosphate into 65 kg of water and stir quickly. After it is completely dissolved, add 2 kg of sodium gluconate into it, stir and dissolve, and then add 10 kg of UFD polymer copolymer into it. Stir and mix, and finally add 10 kg of glycerin and 10 kg of polycarboxylic acid mother liquor into it and stir evenly to obtain a high-efficiency and energy-saving concrete synergist.

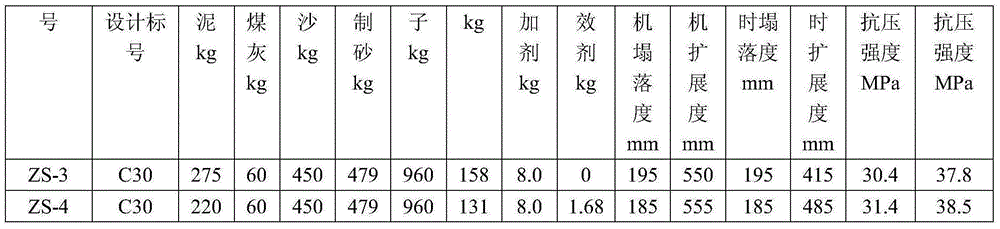

[0058] The weight percentage of the concrete synergist added in the concrete is 0.6% of the total mass of the cementitious material. Prepare relevant raw materials according to the design mix ratio of C30 concrete strength grade. Based on the mix ratio of concrete without adding synergist, add this synergist according to 0.6% of the total amount of cementitious materials. The amount of cement per kilogram is used as a comparison sample, and the test is carried out according to the "GB_T50107-2010 Concrete Strength Inspection and Evaluation Standard". The concrete te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com