Pretensioned prestressed concrete quadrilateral pile and production method thereof

A quadrilateral and concrete technology, which is applied to sheet pile walls, structural elements, building components, etc., can solve the problems of weak seam welding of main reinforcement and stirrups, easy damage to the joint of the pile body, and reducing the use area of steel reinforcement. Achieve the effect of good mechanical properties of the pile body, good integrity of the pile body, and improved bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The invention will be further described below in conjunction with the description of the accompanying drawings and specific embodiments:

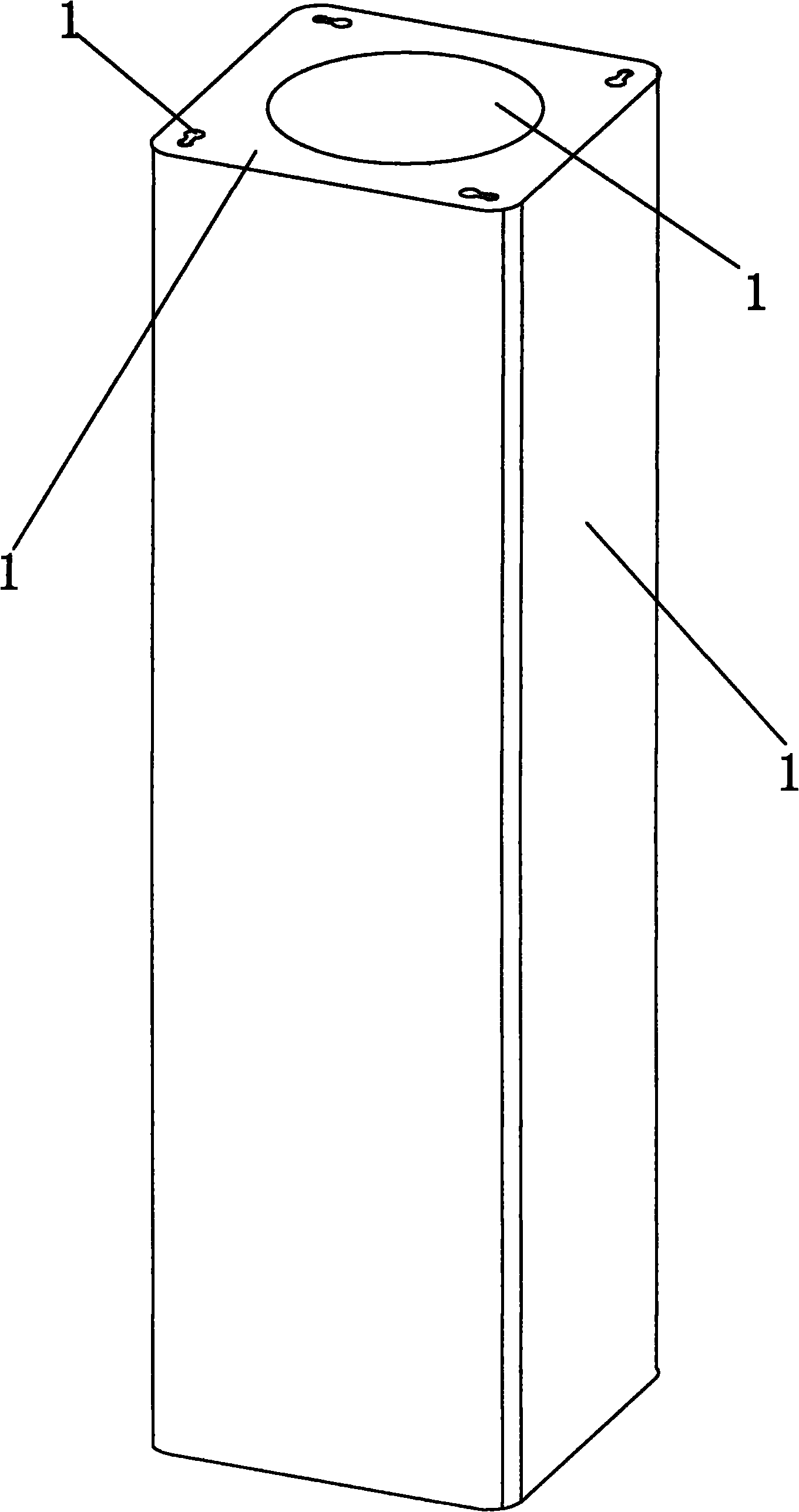

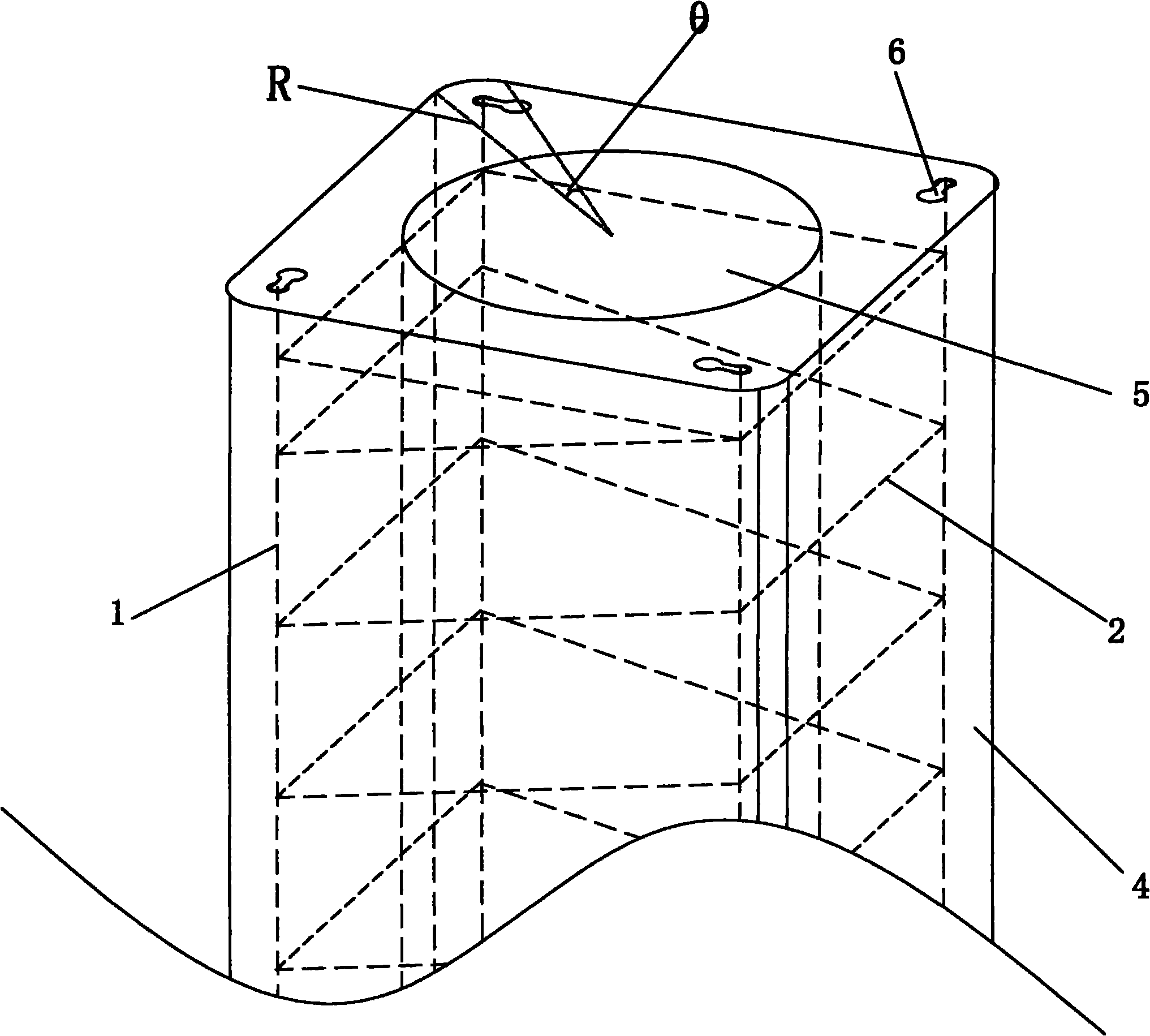

[0044] Such as figure 1 and 9 A pre-tensioned prestressed concrete quadrilateral pile shown includes a plurality of main steel bars 1, and spiral steel bars 2 are welded on the main steel bars 1, and the heads 11 of the main steel bars 1 are larger than the main steel bars 1. Diameter, quadrangular end plates 3 are respectively connected to the two ends of the main steel bar 1, and concrete is poured outside the steel cage frame composed of the main steel bar 1 and the spiral steel bar 2, and the concrete and the steel bar cage are combined into one The quadrilateral pile body 4 is provided with a central circular hole 5 running through the entire quadrilateral pile body 4 at the center of the quadrilateral pile body 4 .

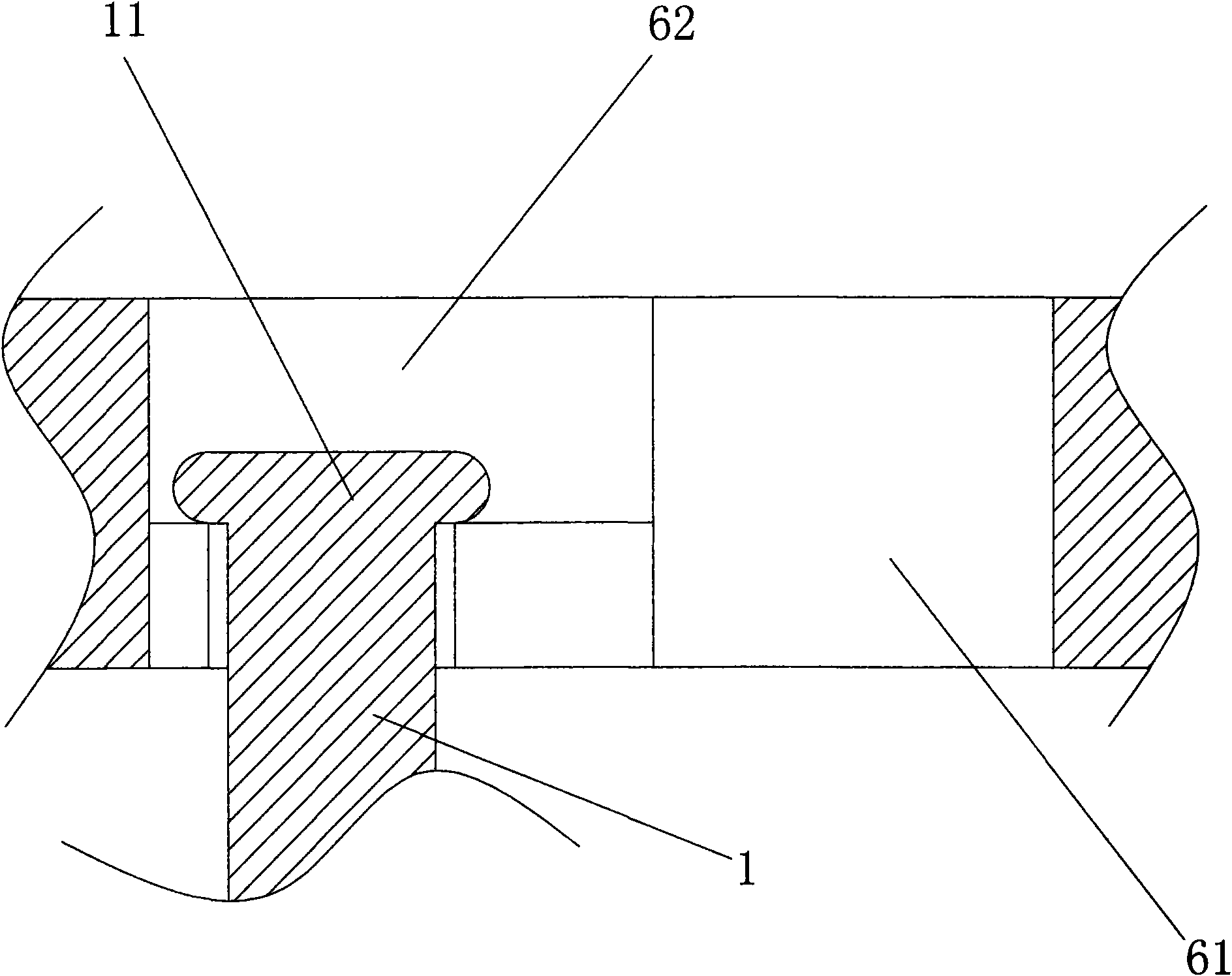

[0045] In the present invention, a plurality of combination holes 6 are provided on the quadrangular end plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com