Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Improve the bearing capacity of single pile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

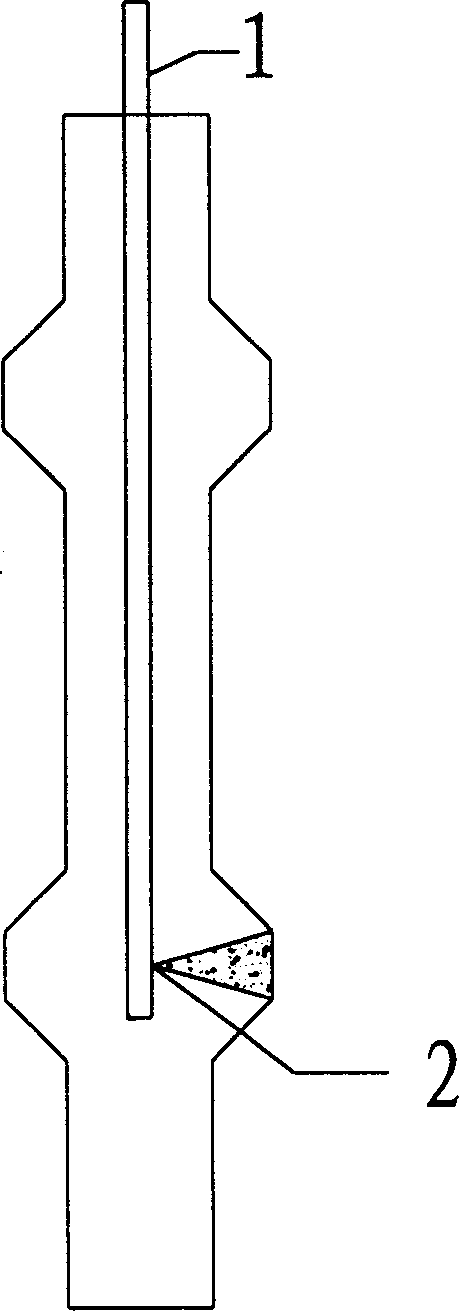

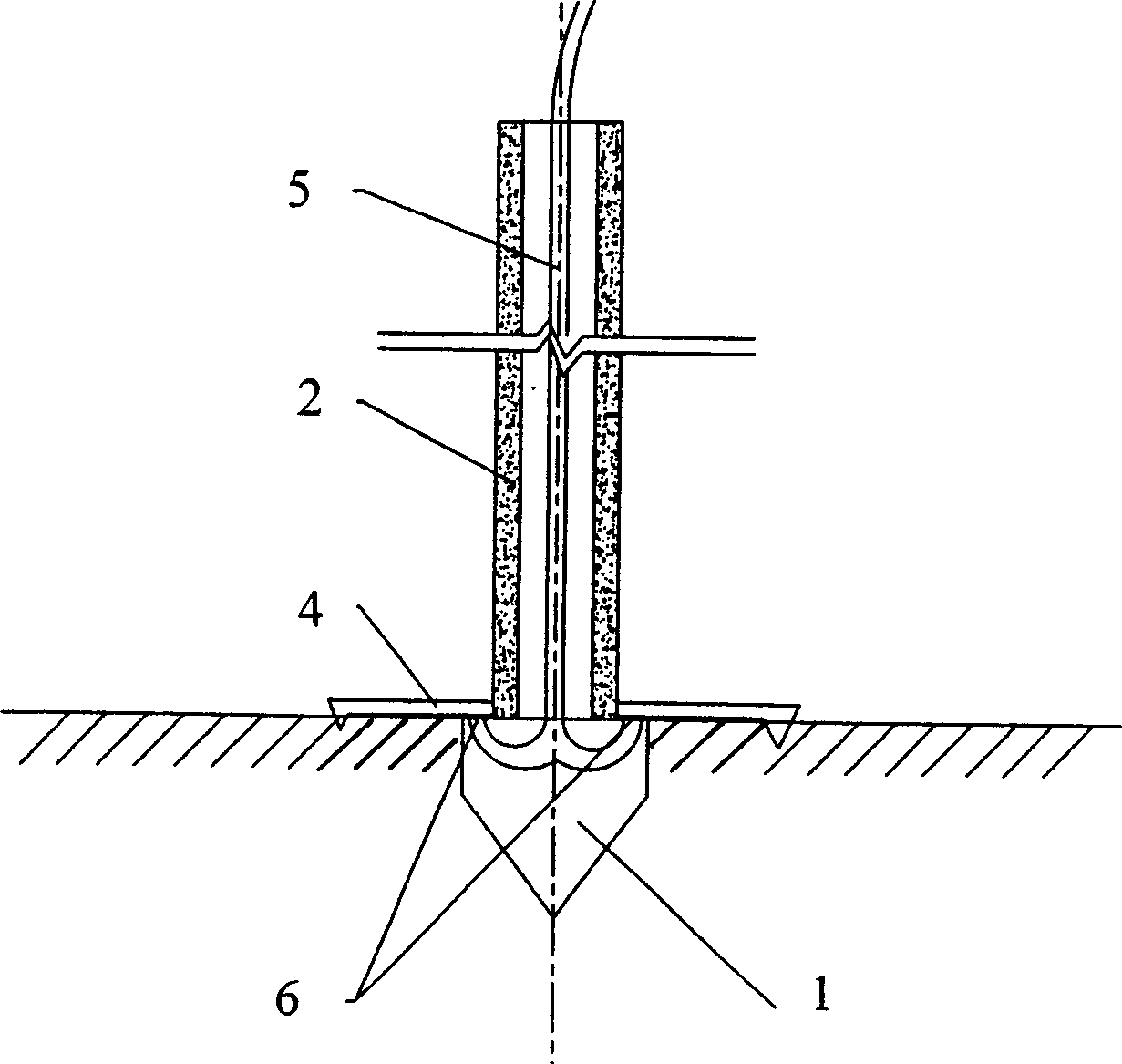

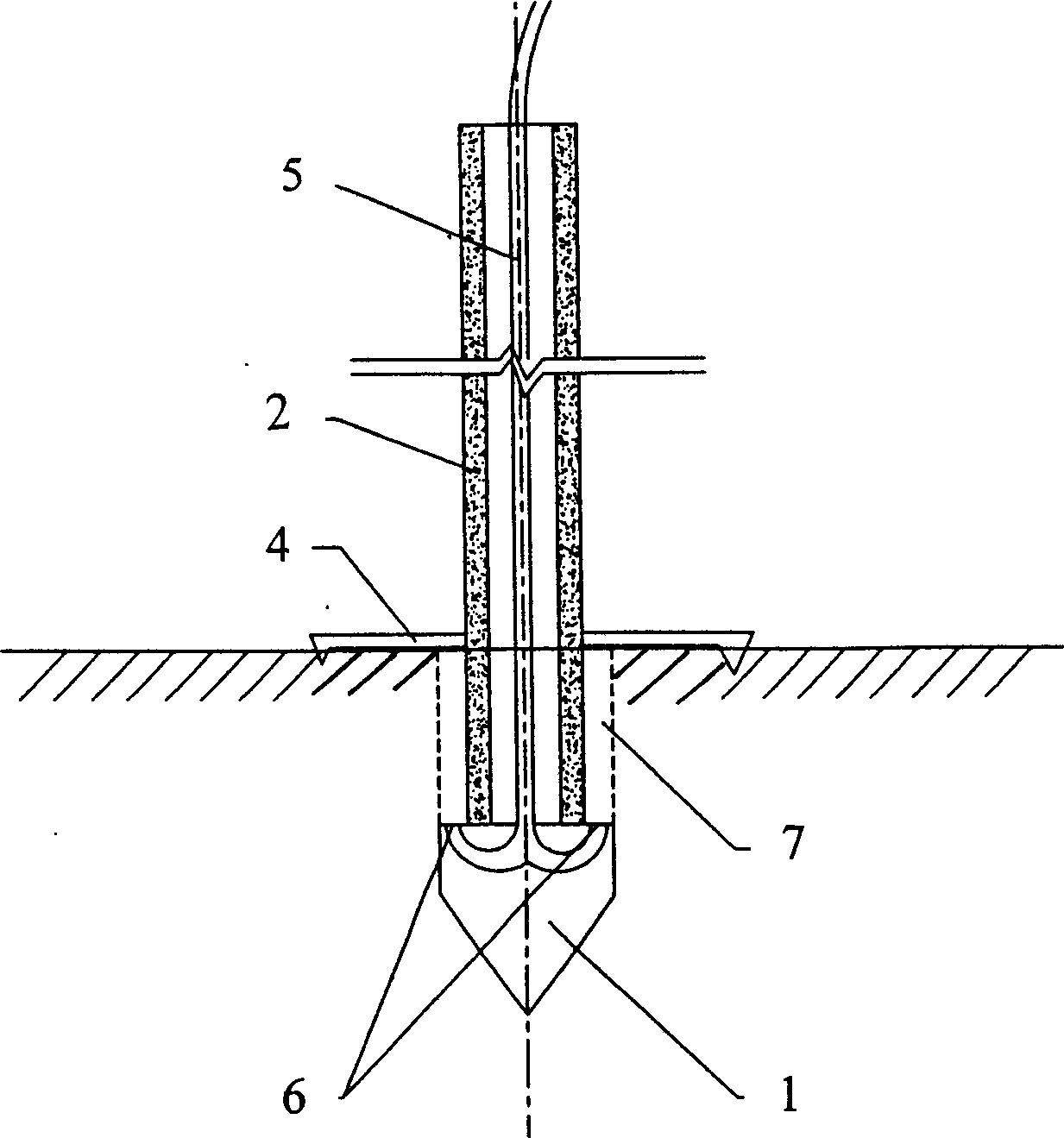

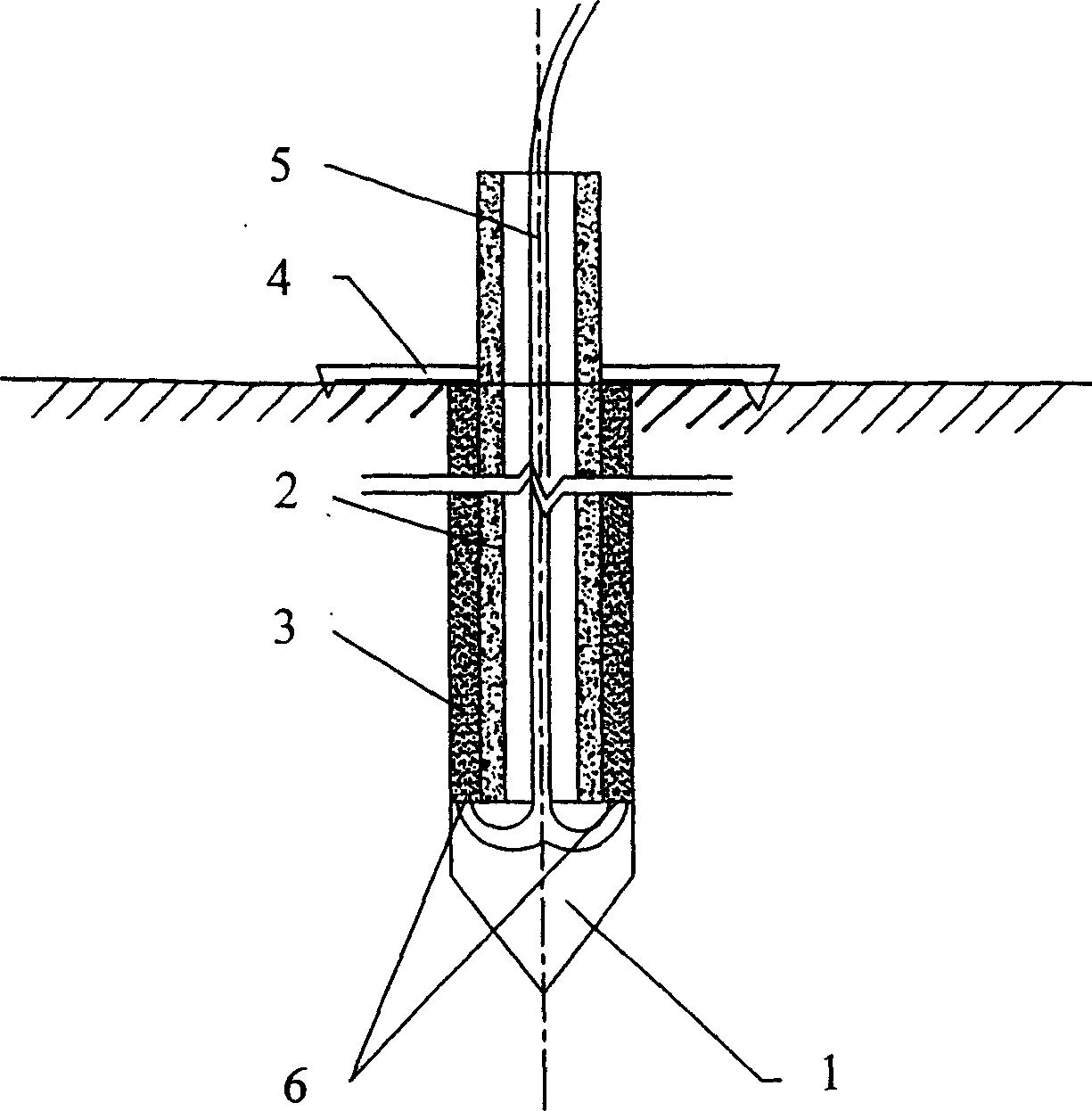

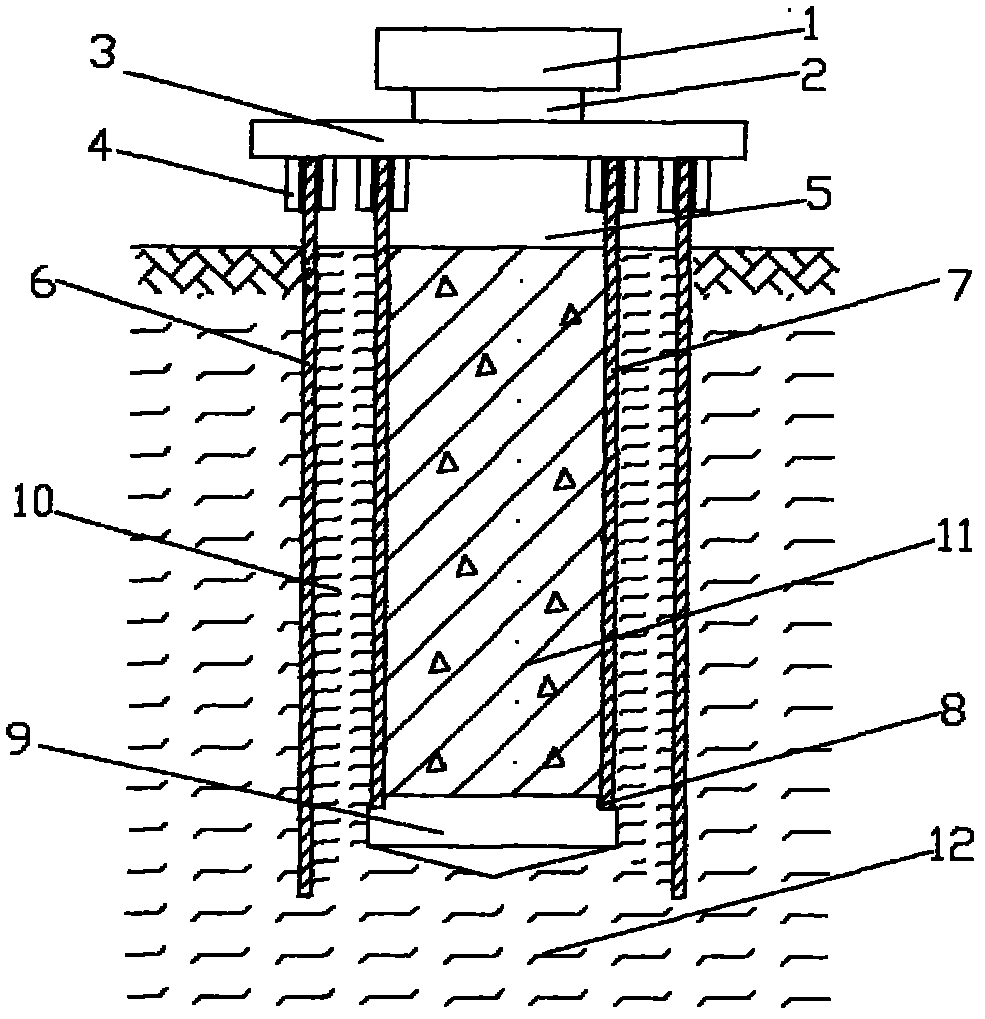

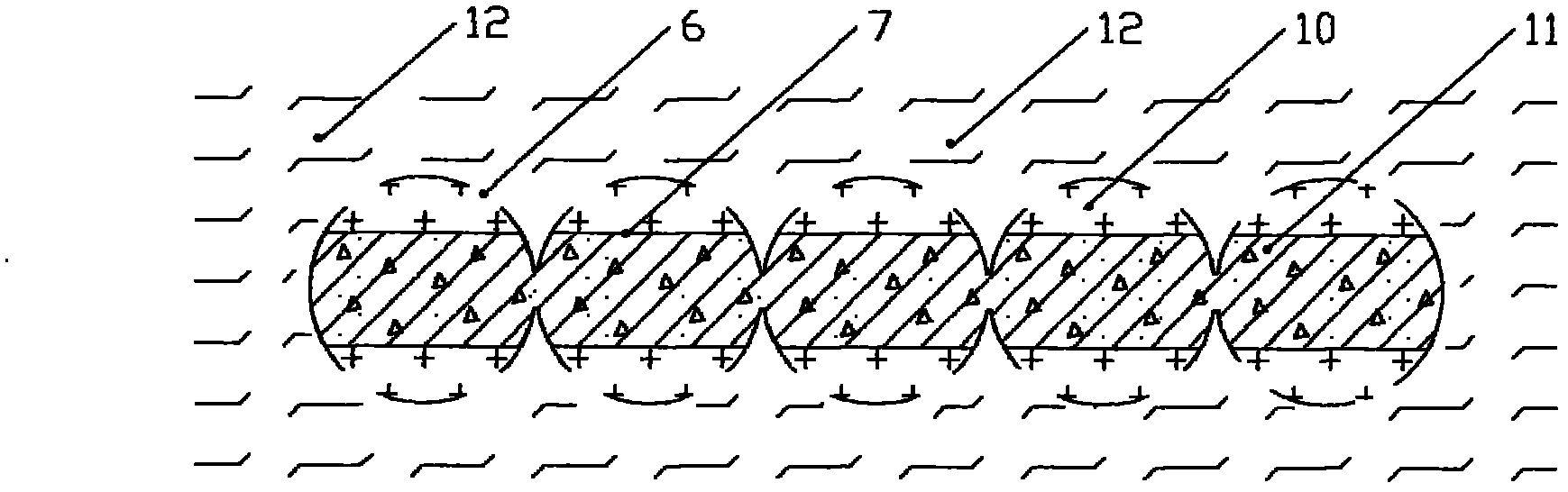

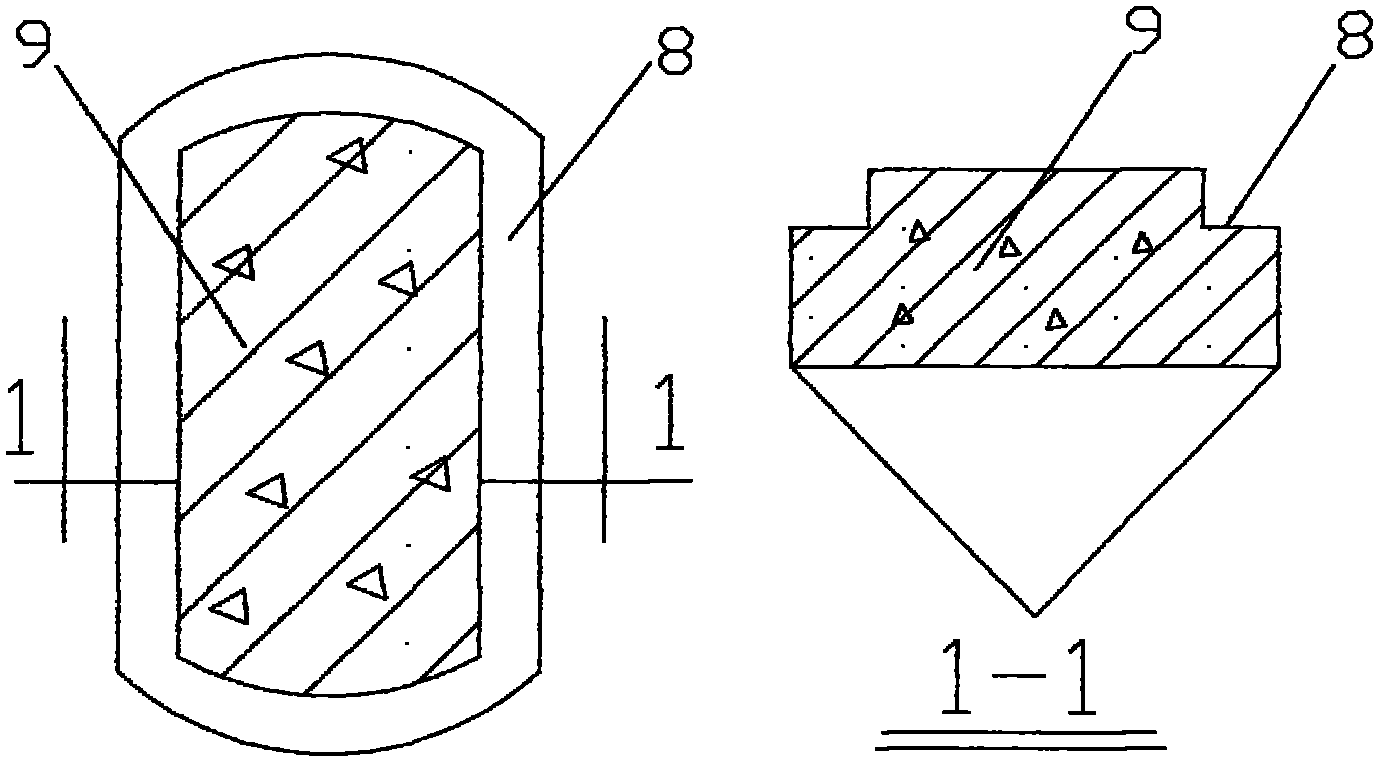

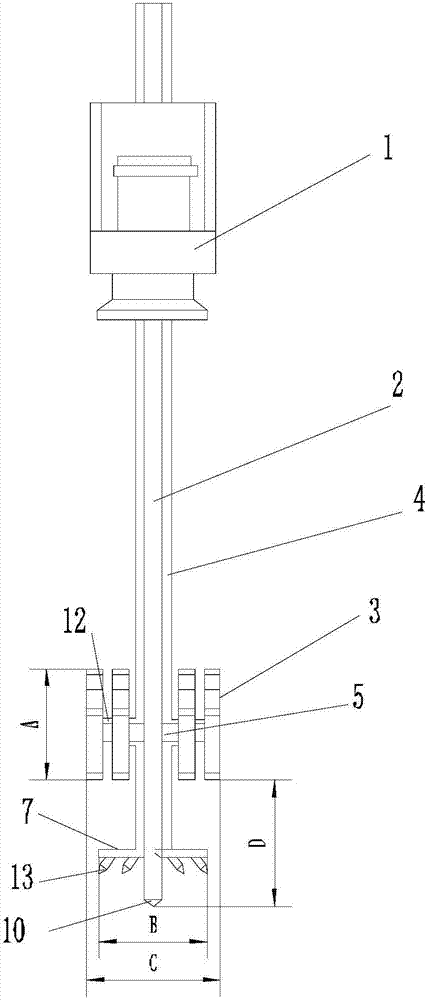

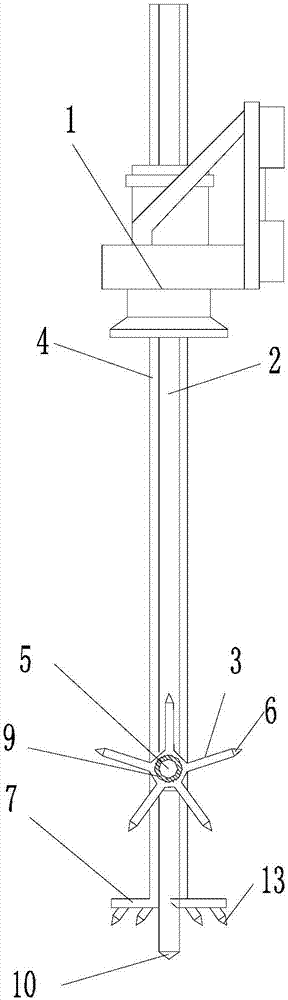

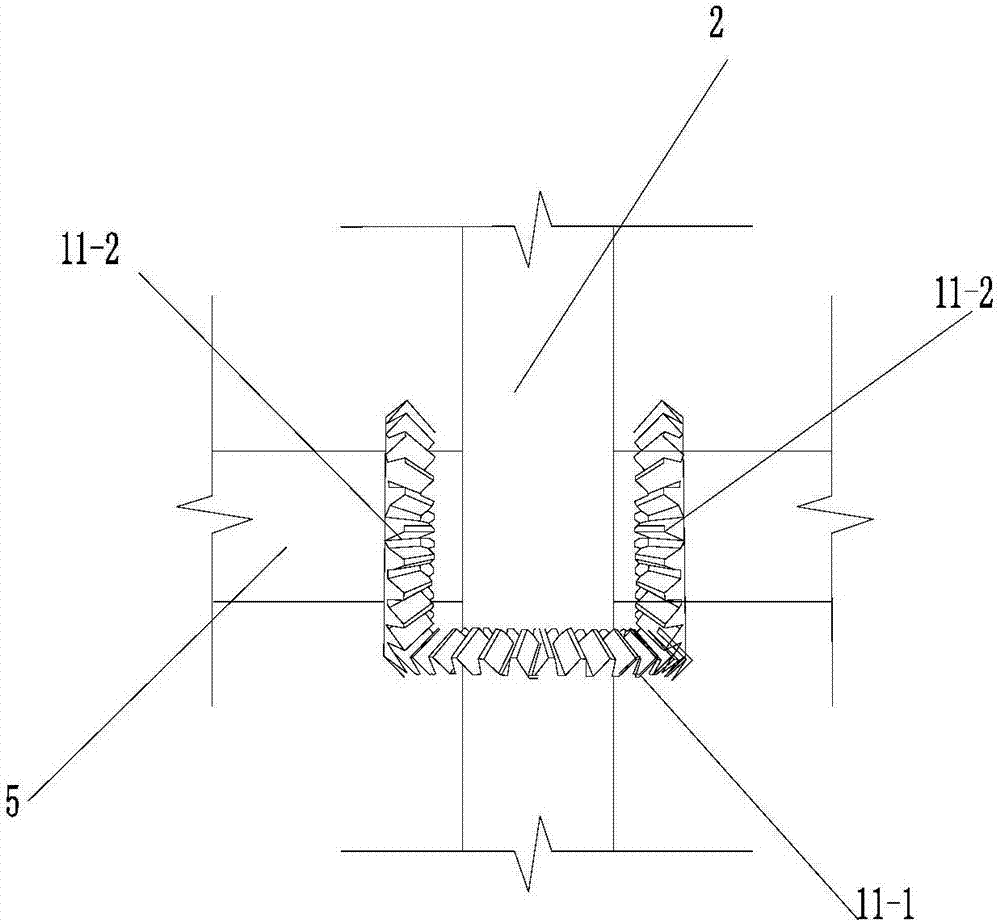

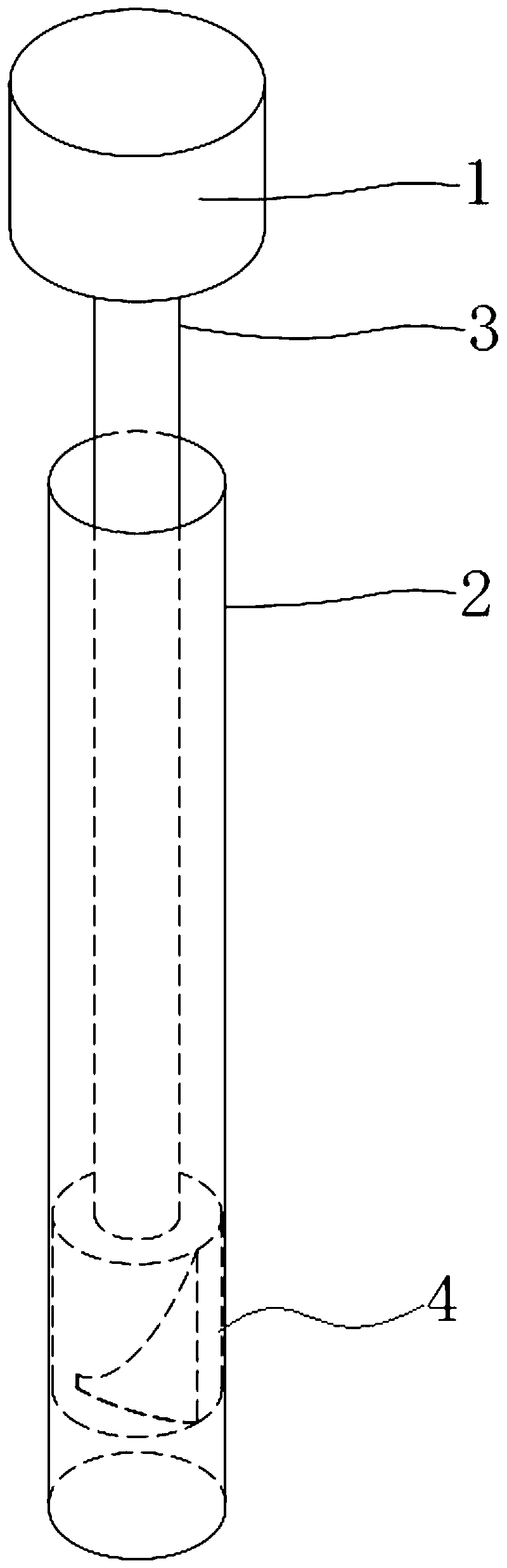

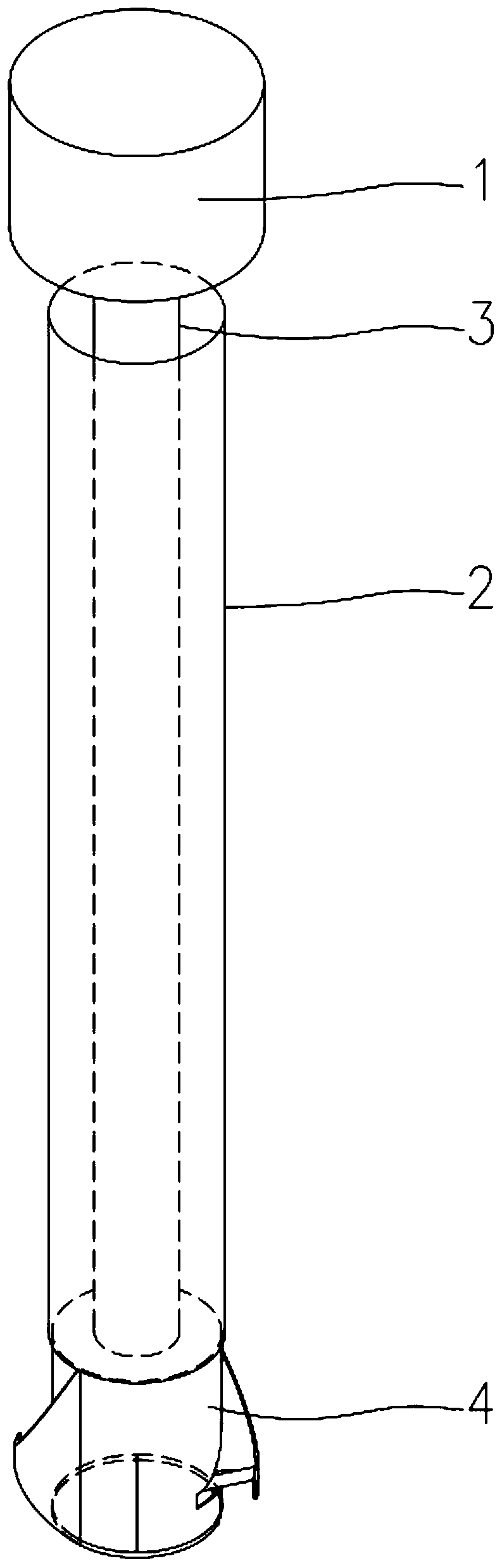

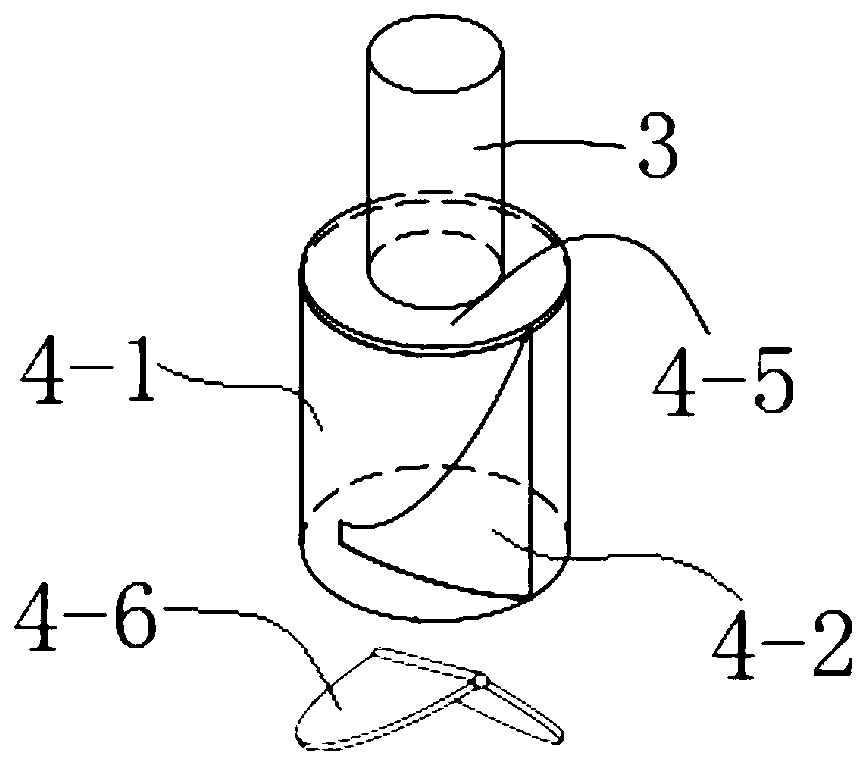

Post-grouting construction method for long helical bore grouting pile and its grouting device

ActiveCN101054799AIncrease stiffnessReduce settlementBulkheads/pilesBearing capacityBuilding construction

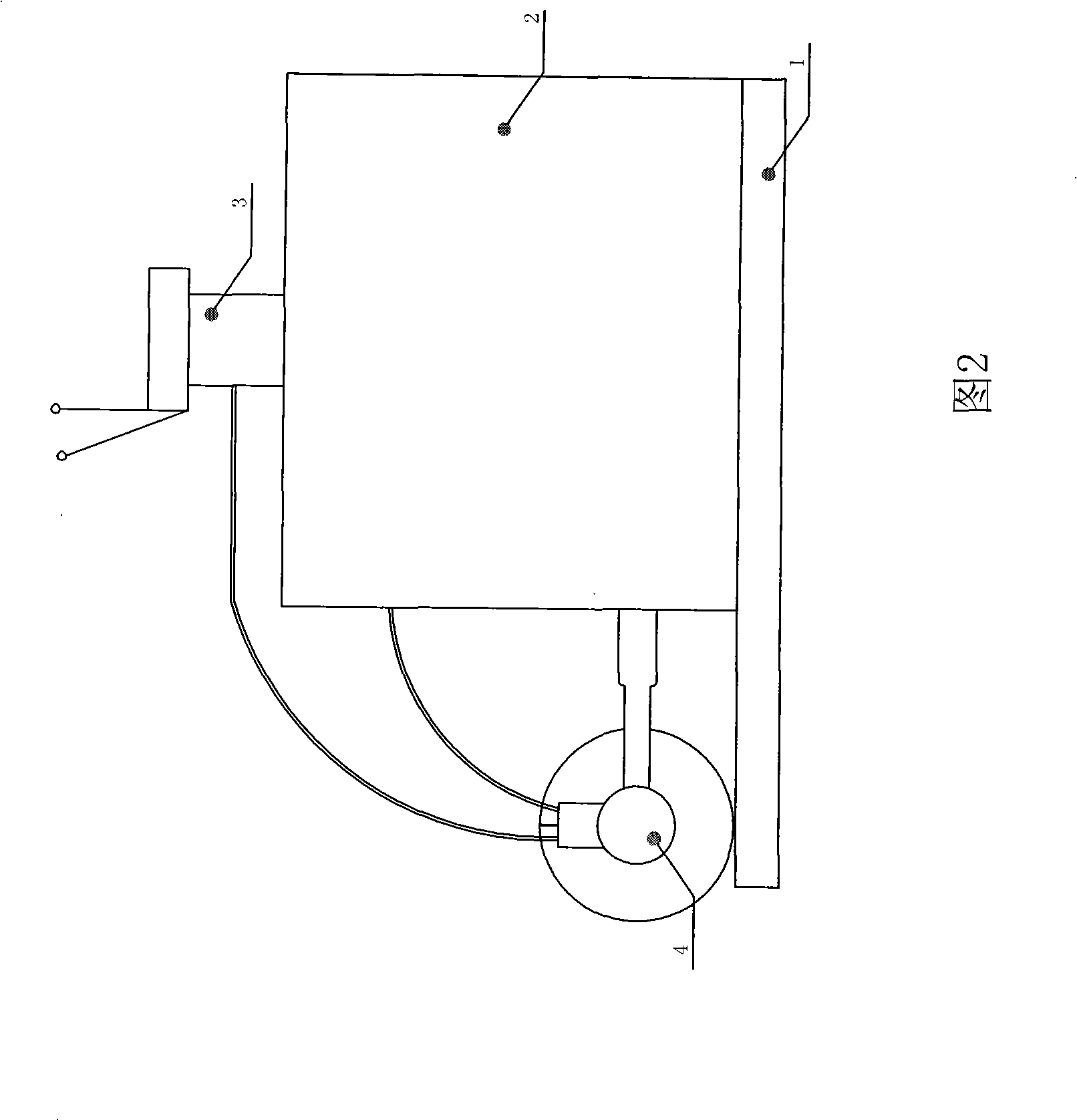

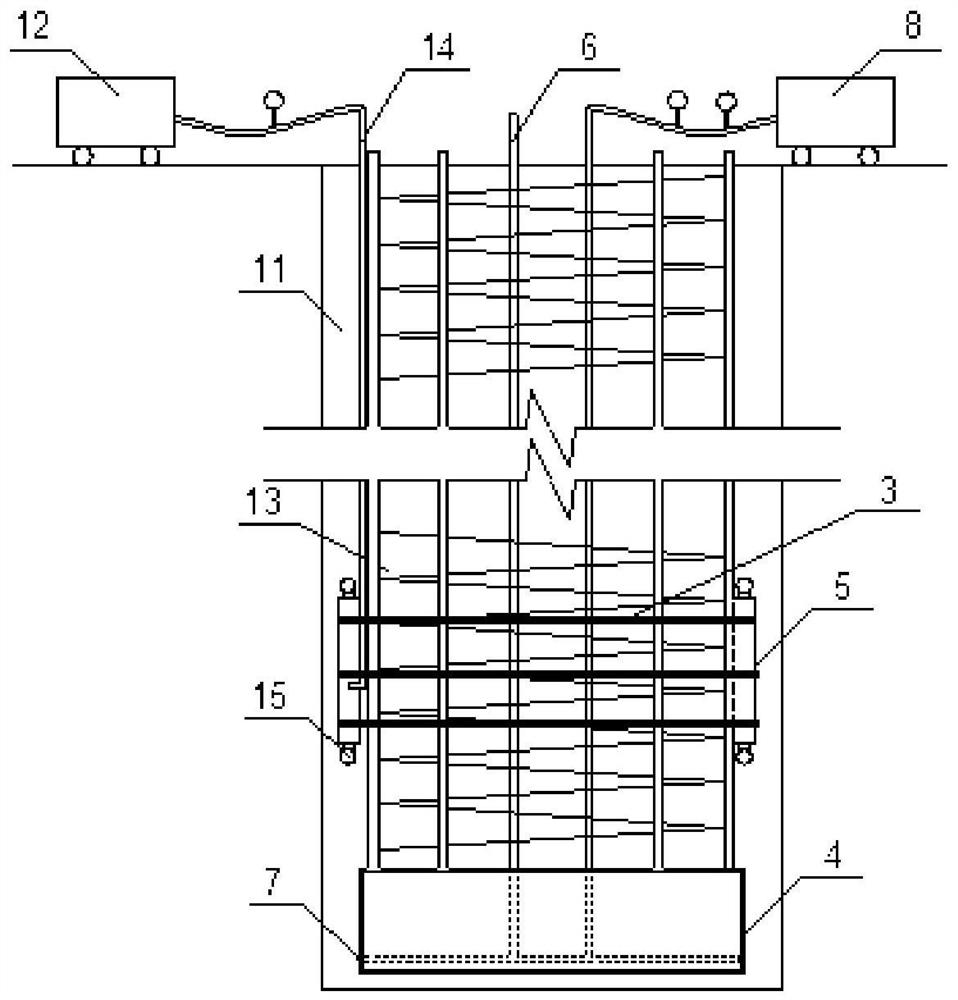

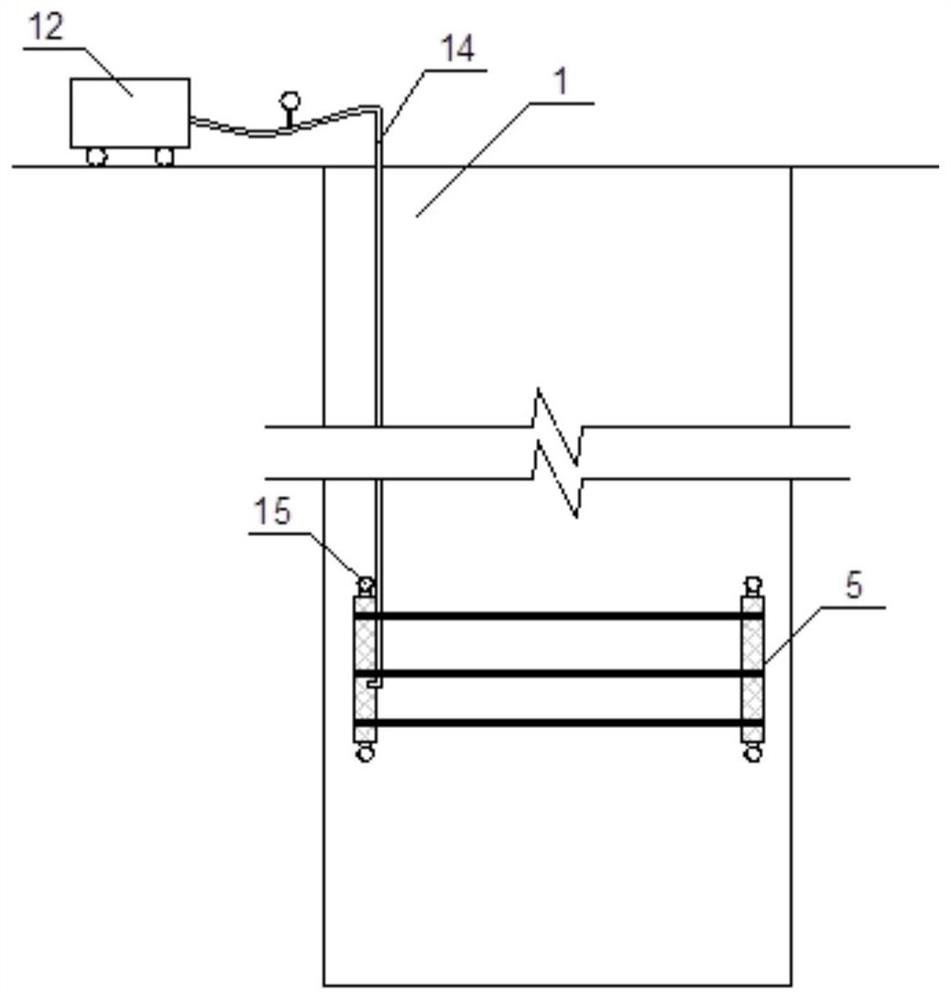

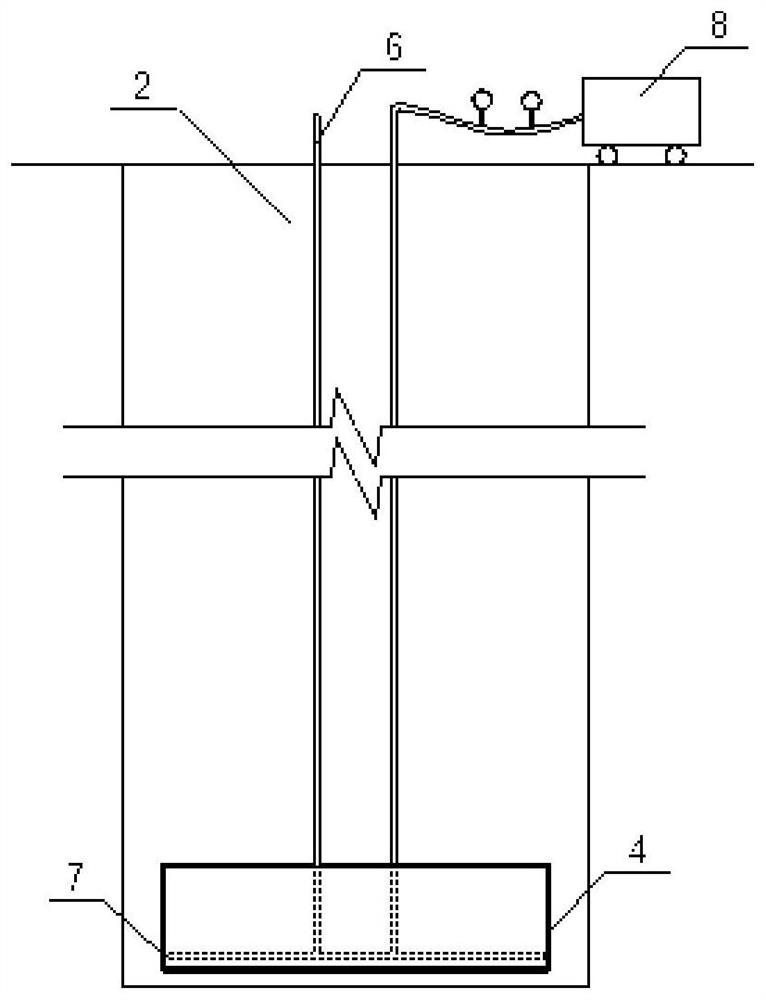

A long auger hole grouted pile post-grouting processing method and the postposition grouting device, which has the following step: firstly, the postposition grouting device is made; then, the long earth auger is used to drill; the plain concrete is pumped into the hole of the pile; after pouring the concrete on the pile stem, the grouting device is hung up and disposed above the pile stem before the cement is initially set; the hammer of the grouting device is started, and the postposition grouting device is immersed into the pile stem to the design elevation under the action of the exciting force and the leading of the guide member; the hammer is vibrating while being lifted and the hammer is drawn, then the hammer is closed, to set the postposition grouting device in the pile stem; after the pile stem concrete pouring is completed and the cement is finally set, the grouting is processed by the pile toe grouting pipe and the pile side grouting pipe, to make the soil mass in some distance around the pile toe and the pile cycle being reinforced. The invention greatly advances the bearing capacity of pile, reduces the engineering quality hidden danger of the long auger hole grouted pile and the amount of pile compared with the traditional technology, lowers the basic engineering invest.

Owner:JIAN YAN FOUND ENG

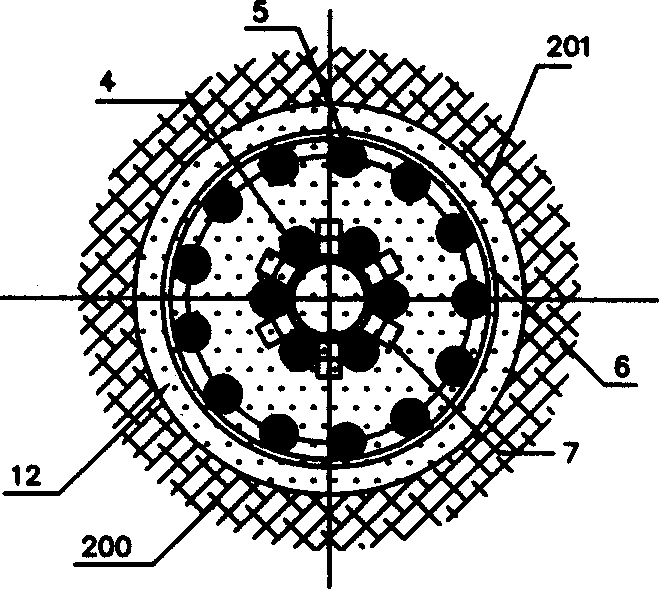

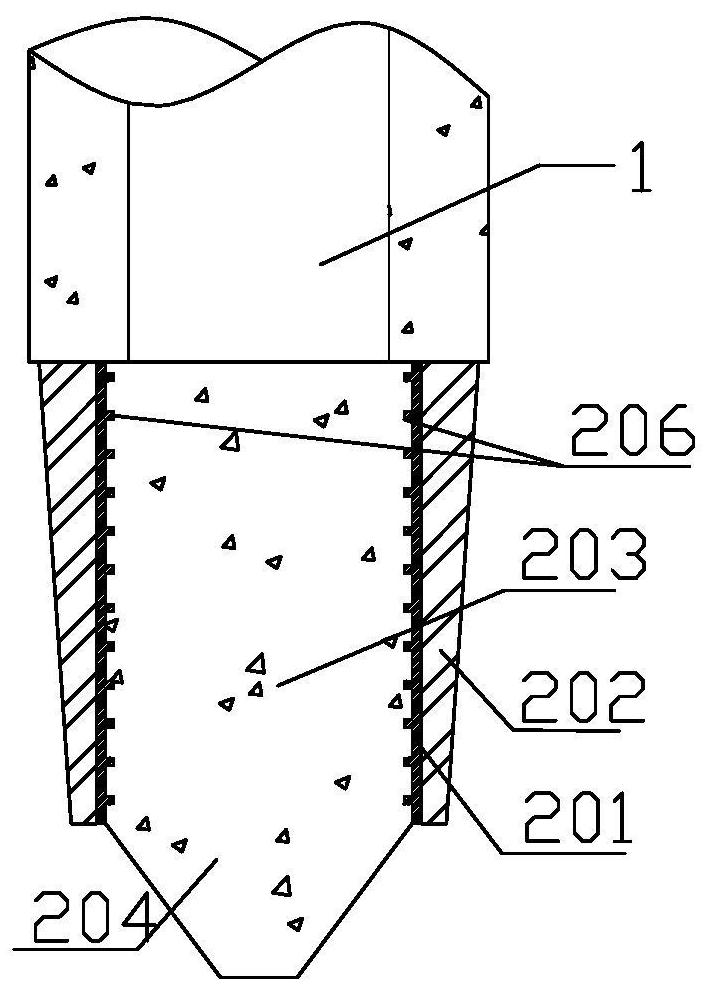

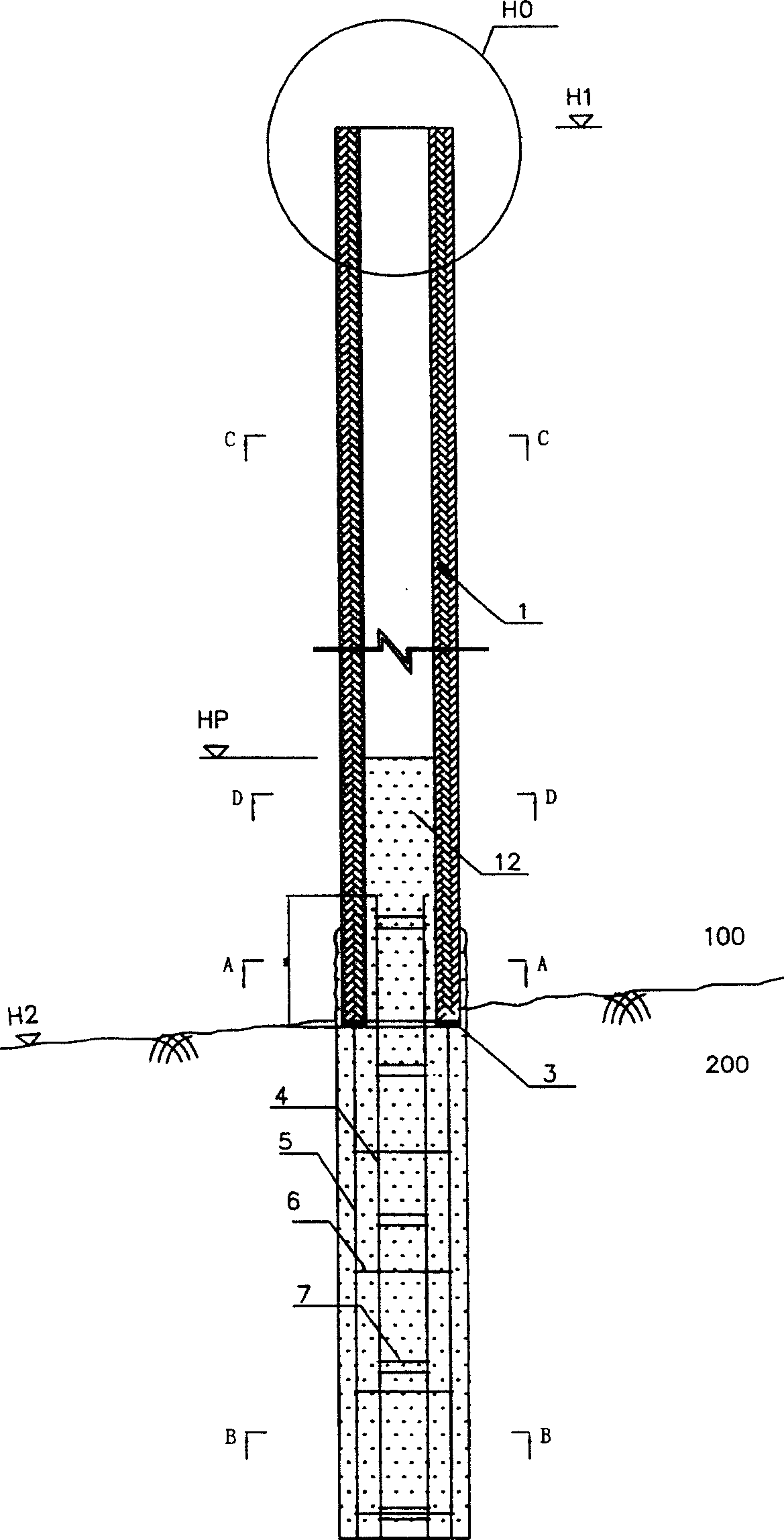

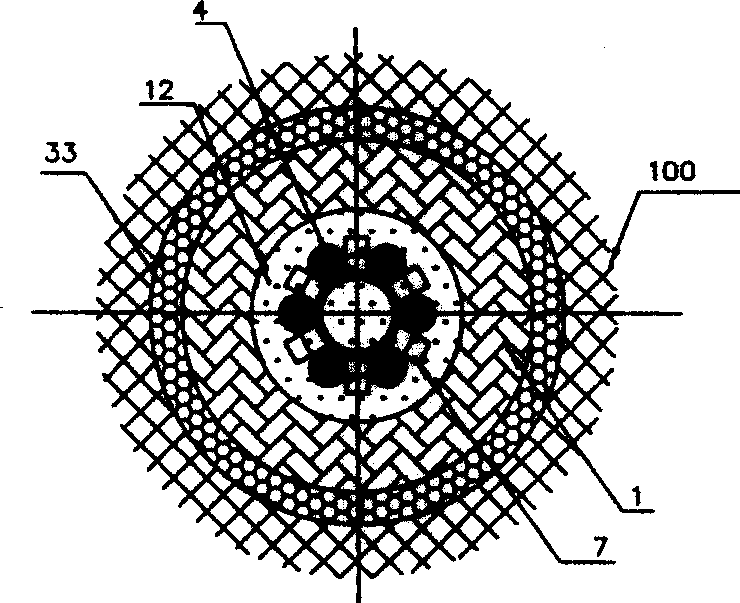

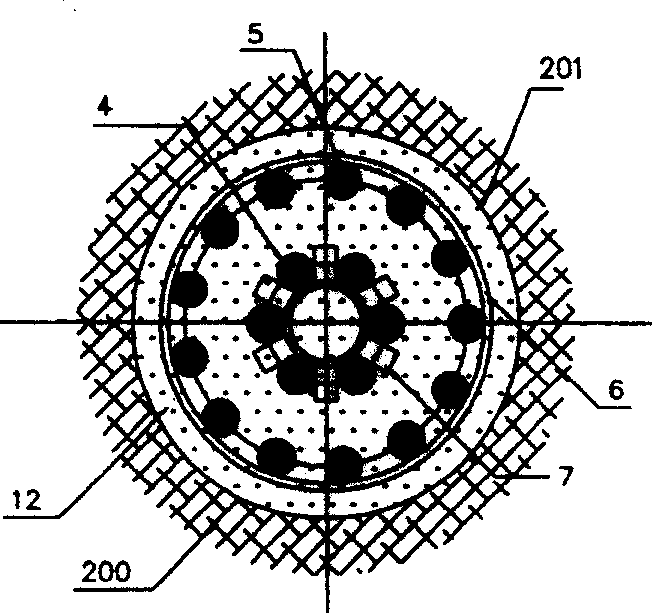

Rock engaged combined pile and its construction method

The rock engaged combined pile includes pile section inside soil layer and pile section inside rock formation combined together and includes also stuffing. The pile section inside soil layer may be prefabricated reinforced concrete pipe or steel pipe with grouted stuffing or steel pipe pile with outer coating stuffing. The pile section inside rock formation may be steel cage, steel member or prefabricated reinforced concrete member or their combination filled with stuffing. The pile section inside rock formation has its load diffused to deep rock formation via the combination of the stuffing to rock hole wall. Owing to the large contact area of the stuffing, the pile of the present invention can provide large anchoring force.

Owner:LIJI ENG

Microorganism soil-reinforcement cement fly-ash gravel (CFG) pile composite foundation and construction method

ActiveCN105386433AHigh strengthImprove bearing capacityBulkheads/pilesSoil preservationMicroorganismAggregate (composite)

The invention discloses a microorganism soil-reinforcement cement fly-ash gravel (CFG) pile composite foundation and a construction method. The construction method comprises the steps that a, a pile pipe is pressed into a foundation; b, microorganism bacterium liquid is injected into the pile pipe at the same time, and the microorganism bacterium liquid is made to diffuse towards the foundation around the pile pipe; c, the microorganism bacterium liquid is pumped out, and a cementing solution is injected into the pile pipe and made to diffuse to the foundation around the pile pipe and reacts with the microorganism bacterium liquid to generate calcium carbonate crystals, and incompact sandy soil or floury soil is cemented; d, the step b and the step c are executed repeatedly till the soil around the pile pipe meets the reinforcement requirement; e, pipe-drawing pile formation is conducted while cement-ash stabilized aggregates are poured; and f, a bed course is laid, so that the CFG pile composite foundation is formed. According to the microorganism soil-reinforcement CFG pile, the soil around the pile pipe is reinforced through calcium carbonate generated through reaction between the microorganism bacterium liquid and the cementing solution, so that the strength of the soil around the pile pipe is improved, and the quality problems of necking, pile breakage, soil carrying and the like in the pile forming process are solved; in addition, a reinforced soil body can be combined with a pile for bearing, and the bearing capacity of the single pile is effectively improved.

Owner:NANJING FORESTRY UNIV

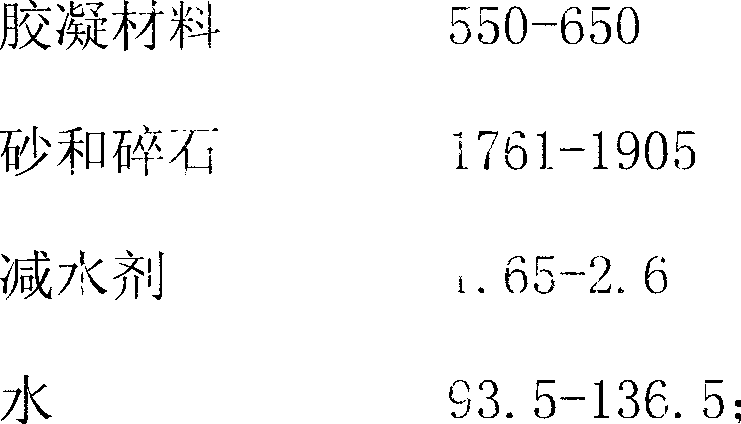

Non-autoclaved prestressed high-strength centrifuge pipe pile and preparation method thereof

ActiveCN103030342BImprove protectionReduce energy consumptionShaping reinforcementsBulkheads/pilesLow speedPre stress

The invention discloses a non-autoclaved prestressed high-strength centrifuge pipe pile and a preparation method thereof. The concrete used by the pipe pile comprises the following components in parts by weight: 550-650 parts of cement, 1761-1905 parts of sand and gravel, 1.65-2.6 parts of water reducing agent and 93.5-136.5 parts of water. The cement comprises the following components in percentage by weight: 70-90% of cement, 5-20% of microbead and 5-10% of silica fume. The method for preparing the pipe pile comprises the following steps:: A. proportionally adding water, sand, gravel and water reducing agent into cement to prepare concrete; B. distributing the concrete in a steel mold, closing the mold, stretching, and centrifugally forming a prestressed concrete pipe pile on a centrifugal machine, wherein the centrifugal forming technique comprises four stages, including low speed, medium speed, medium high speed and high speed; and C. carrying out primary atmospheric steam curing or water curing on the centrifugally formed prestressed concrete pipe pile while controlling the constant temperature at 75-95 DEG C, and naturally standing for 7 days. The strength level of the concrete satisfies C105 strength requirements.

Owner:GUANGDONG SANHE PILE CO LTD

Section bar inserting and high-pressure rotary jetting method for forming pile with expanded plates in sink area

InactiveCN1844588AReduce occupancyImprove vertical bearing capacityBulkheads/pilesLand resourcesEconomic benefits

The invention discloses a method for molding the high-pressure rotational spray expansion post in sink area. Wherein, forming a trapezium expansion disc on the post formed by rotational spraying slurry injection according to the segment pressure or the injection time; inserting section steel as anti-drawing material into the post. The invention can increase the upright bearing ability and improve the horizontal bearing ability; especially at the interface of soil, it can eliminate the effect of horizontal displacement, with lower cost, short time, easy construction, lower soil occupied and saved land resource. The invention can be used to strengthen the foundation in large distortion condition, to reduce cost and improve economic benefit, with wider application.

Owner:CHINA UNIV OF MINING & TECH

Bottom-grouting-enlarged small-diameter prestressed tubular pile composite foundation construction method

The invention discloses a bottom-grouting-enlarged small-diameter prestressed tubular pile composite foundation construction method for processing a small-area / narrow-range deep mucky soil or soft clay foundation, which is characterized in that: by utilizing the high bearing capacity and pile-bottom concrete reinforced and enlarged ends of bottom-grouting-enlarged small-diameter prestressed tubular piles, the bottom-grouting-enlarged small-diameter prestressed tubular piles effectively reduce diameters of pile bodies of the conventional prestressed tubular piles, reduce the buried depths of the pile bodies, and are arranged in a plane at a proper pile spacing to achieve micro shallow and dense pile group effect and achieve shallow soft field soil composite foundation reinforcement effect. The method has the advantages that: on bottom-grouting-enlarged small-diameter prestressed tubular pile composite foundation, the small-diameter prestressed tubular piles are used to compact the surrounding soil to transfer load, and grouting and reinforcement of pile bottoms are performed to improve the end bearing capacity, so that a shallow pile-based composite foundation is formed. Compared with a normal large-area soft soil foundation composite foundation processing method and a prestressed tubular pile foundation method, the method has the characteristics of simple process, high construction speed, miniature construction equipment, material saving and low cost.

Owner:HOHAI UNIV

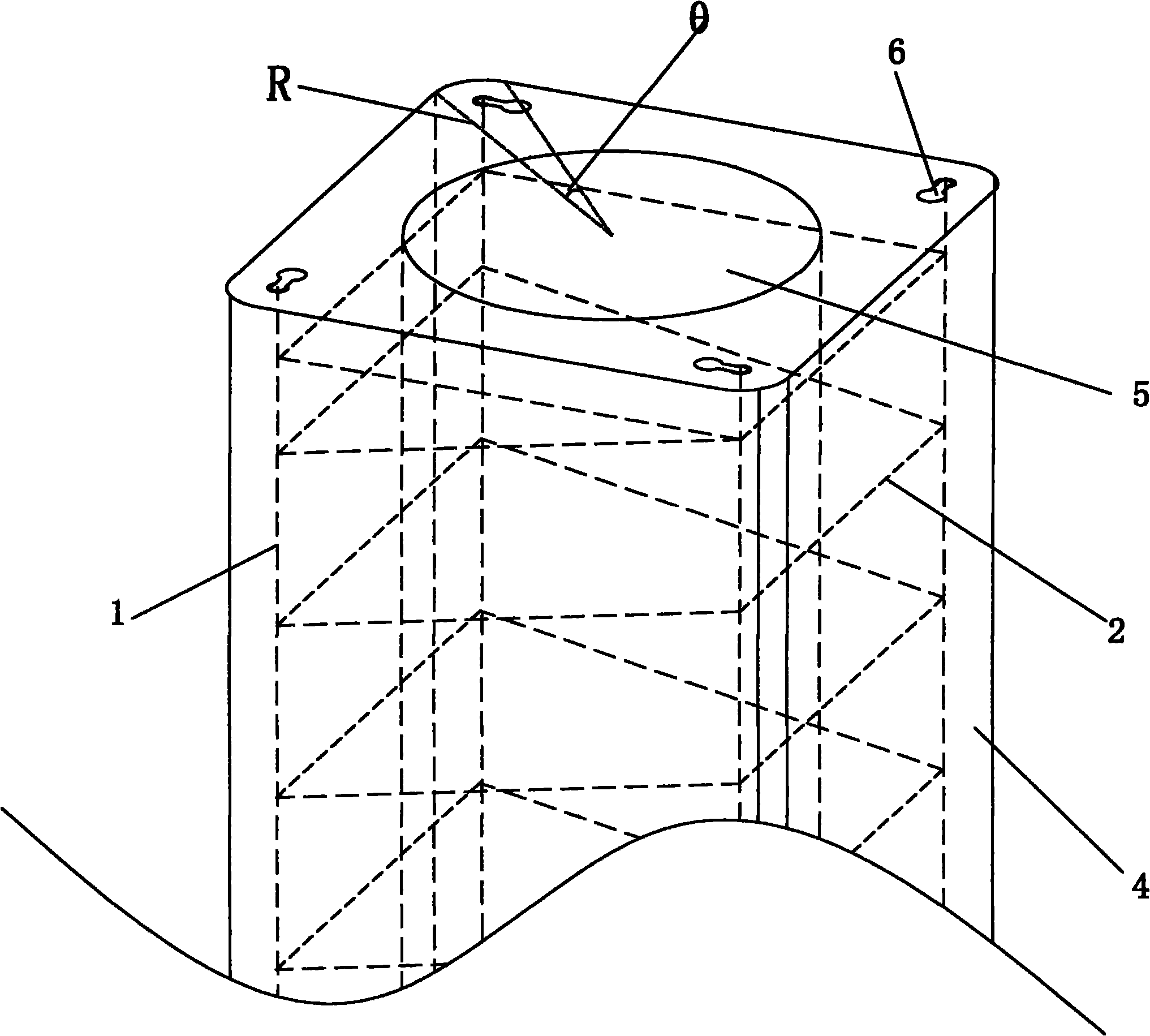

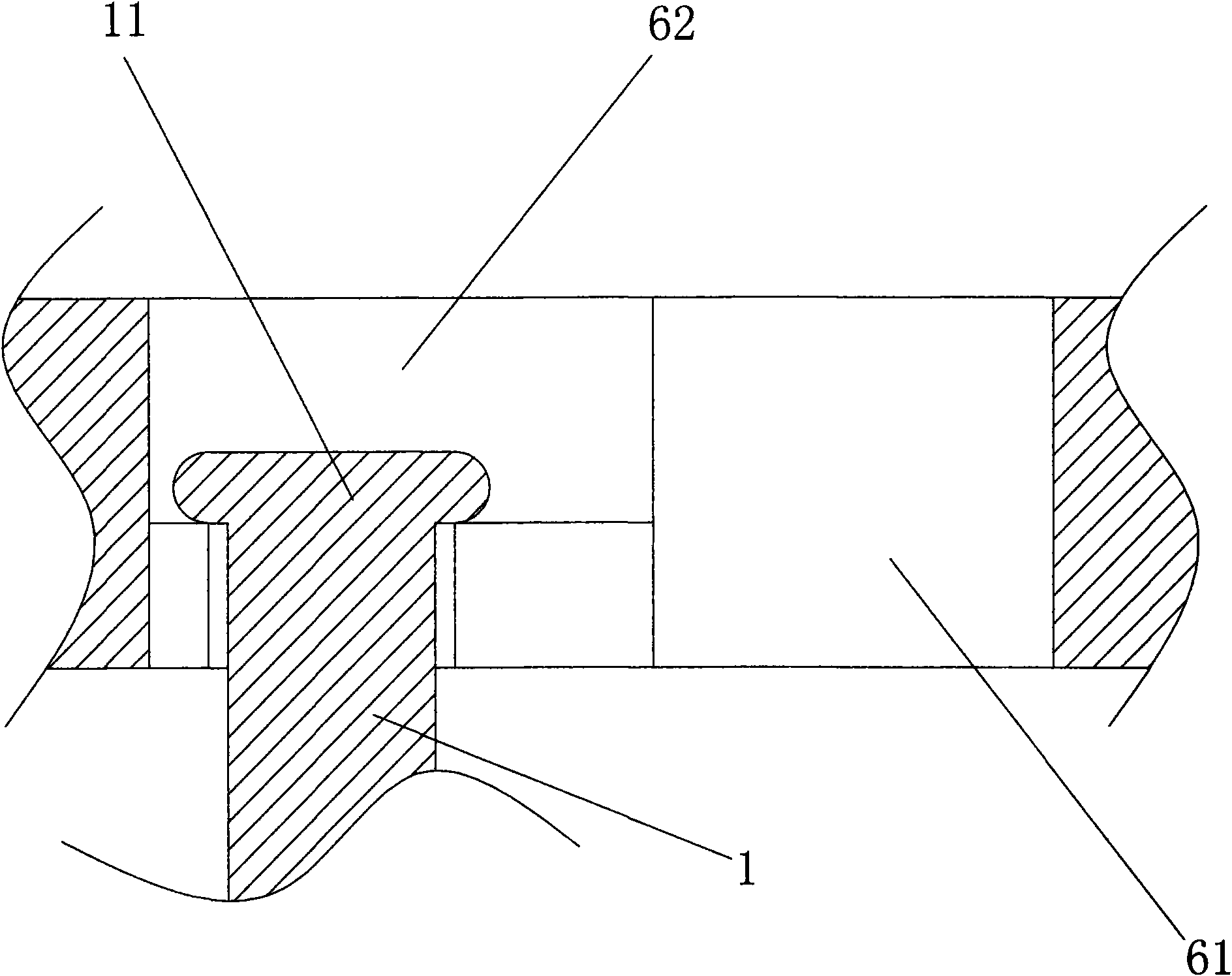

Pretensioned prestressed concrete quadrilateral pile and production method thereof

InactiveCN101914913AImprove compactnessRaise the intensity levelCeramic shaping apparatusBuilding reinforcementsPre stressRebar

The invention discloses a pretensioned prestressed concrete quadrilateral pile, which is characterized by comprising a plurality of main reinforcements, wherein the main reinforcements are welded with spiral reinforcements; the heads of the main reinforcements are greater than the diameters of the main reinforcements; both ends of the main reinforcements are connected with quadrilateral end plates respectively; concrete is poured outside a reinforcement cage frame consisting of the main reinforcements and the spiral reinforcements; the concrete is combined with the reinforcement cage frame into an integral quadrilateral pile body; and the center of the quadrilateral pile body is provided with a central round hole passing through the whole quadrilateral pile body. Aiming to overcome the deficiencies in the prior art, the invention provides the pretensioned prestressed concrete quadrilateral pile which has the advantages of high molding quality, high bearing capacity of a single pile, damage resistance during use of the reinforcement frameworks, high bending resistance bearing capacity, high shearing resistance, convenient stacking, and difficult damage during hoisting, transporting and transferring the pile. The invention also aims to provide a production method of the pretensioned prestressed concrete quadrilateral pile.

Owner:句容长江建材有限公司

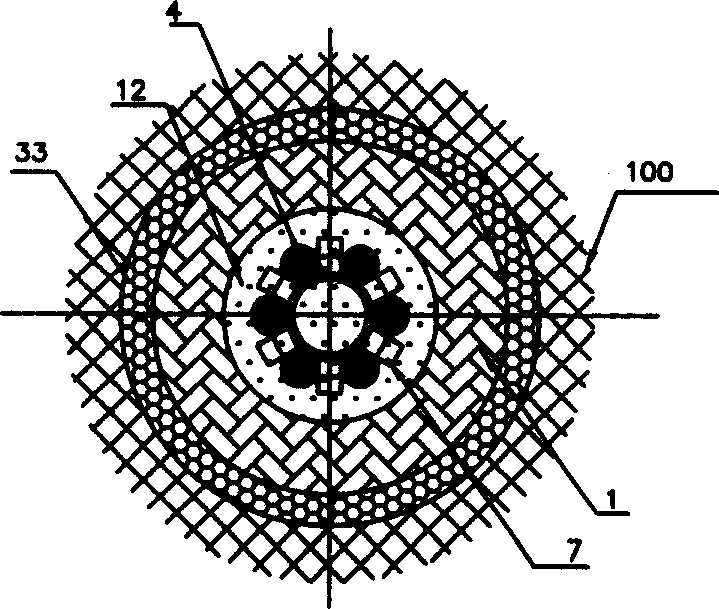

Method for construction of large head expanding combined pile

InactiveCN1793524AIncrease side frictionPlay the role of expanding the holeBulkheads/pilesGuide tubeBearing capacity

The invention discloses a big-end expansion composite pile construction method. The hole enlarging big end pile squeezes earth body to form annular pile hole around the core pile in pile sinking. Before it closes, the filling is topping up by filling guide tube to form loop type outer pack pile. The big end pile is enlarged hole to increase end bearing of core pile. The outer pack pile can increase its lateral friction resistance to increase bearing. The construction is convenient. And the pile forming quality is reliable. The composite pile can greatly increase bearing, and reduce cost. It can be applied to various constructions of drawing resistant, loading pile foundation, composite foundation, deep foundation pit supporting and anti-seep.

Owner:雷玉华

Steel pipe pile

InactiveCN102031776ADoes not affect productionDoes not affect pile sinkingBulkheads/pilesBearing capacitySteel plates

The invention discloses a steel pipe pile. A plurality of paths of stiffened steel plates are welded on the surface outside the wall of the steel pipe pile along the axial direction and are arranged on the periphery outside the wall of the steel pipe pile at equal distance. The invention provides the steel pipe pile with simple structure and lower cost. By using the invention, under the condition without increasing the pipe length and the diameter, the bearing capacity of a single pipe is improved, the production and the pile driving of the steel pipe pile cannot be influenced and the increment of materials is extremely limited.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

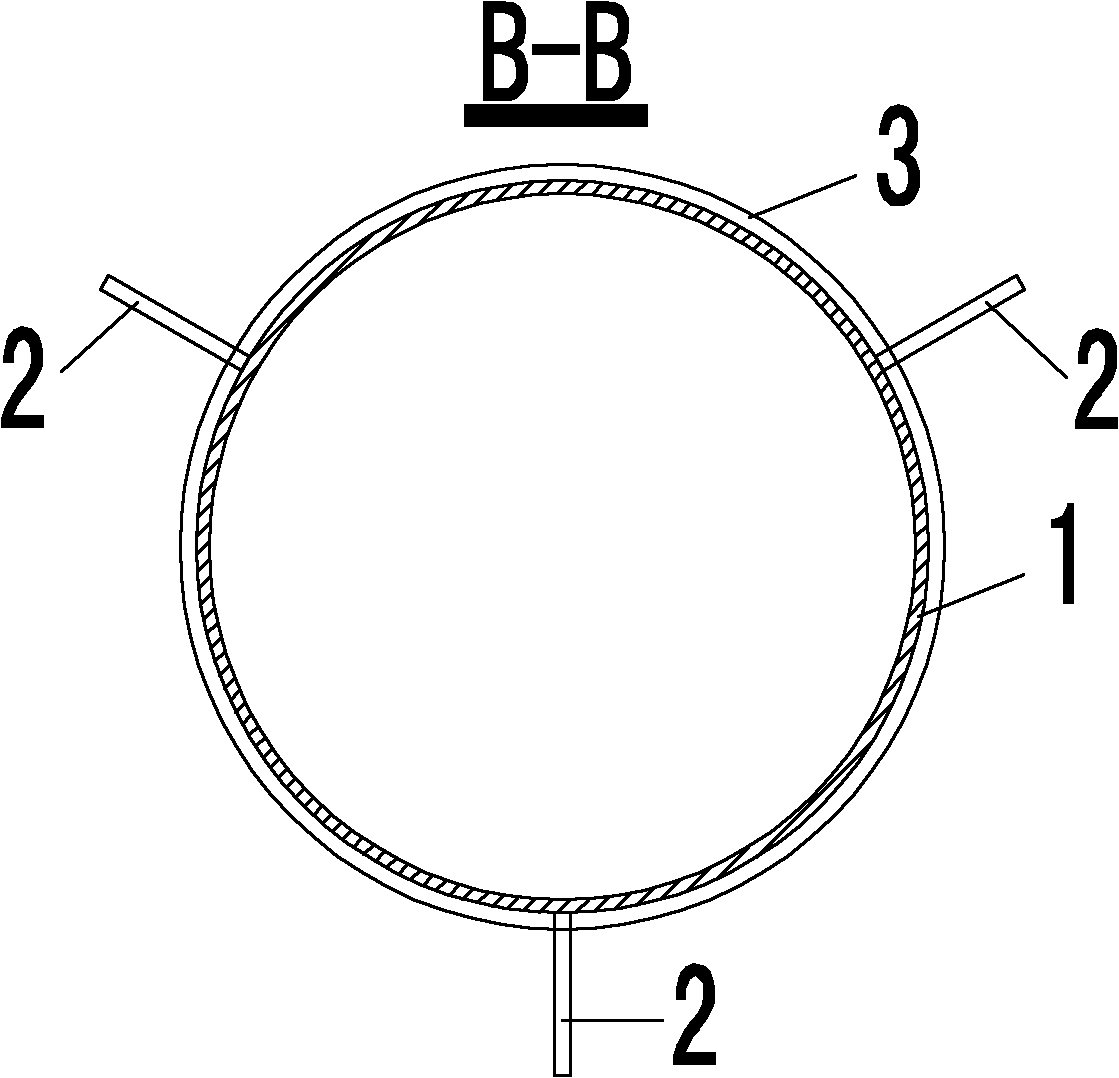

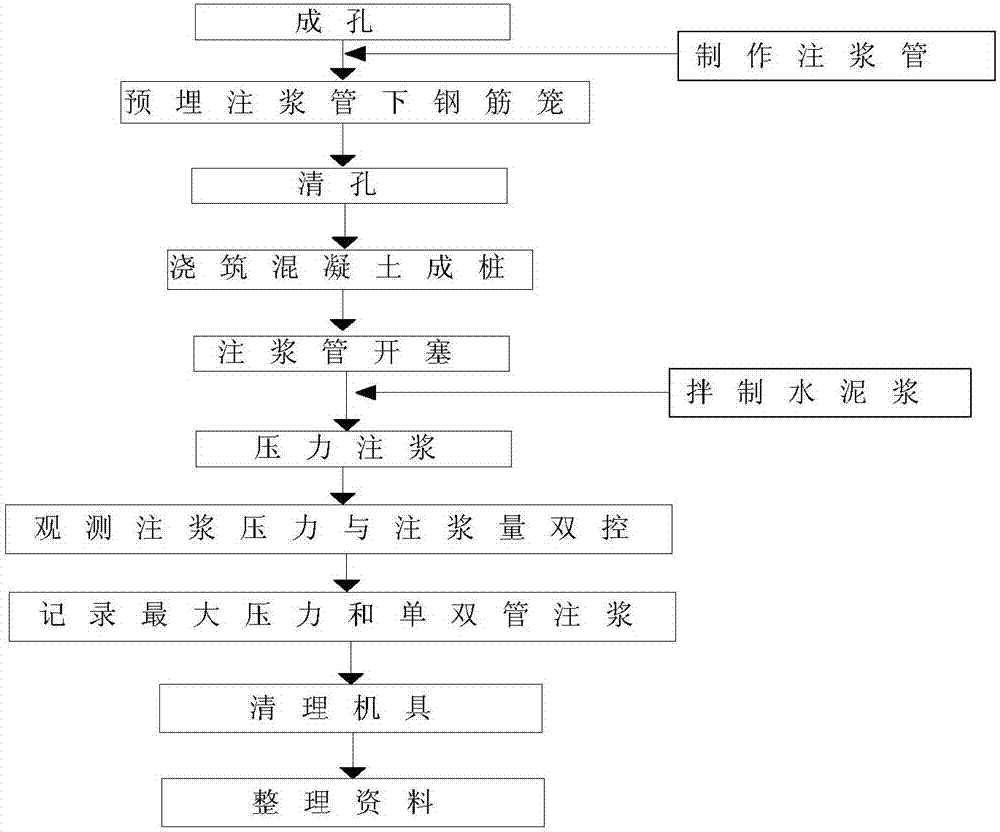

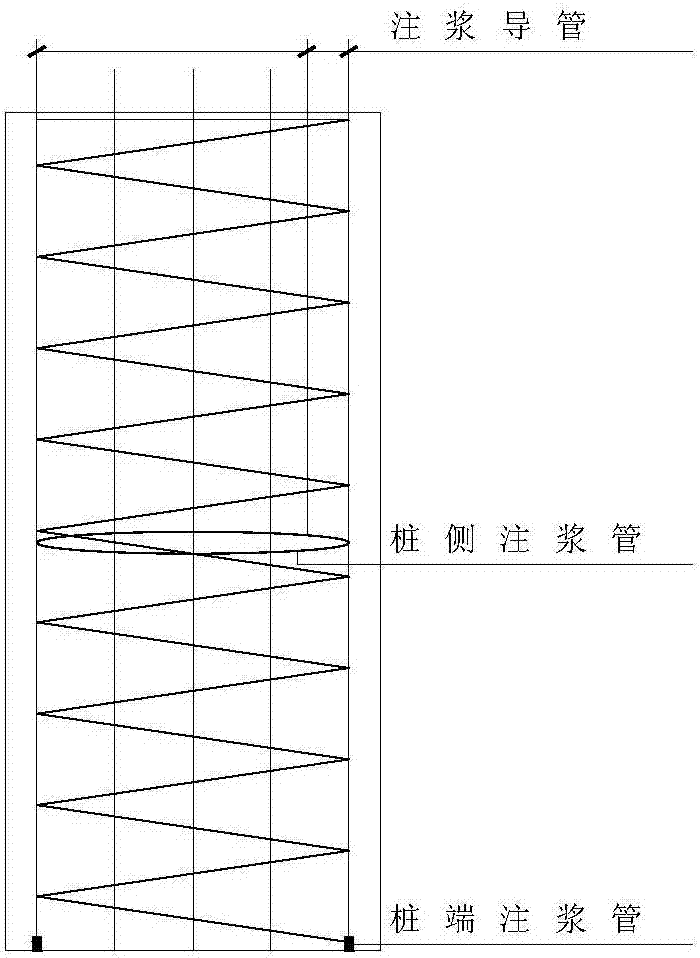

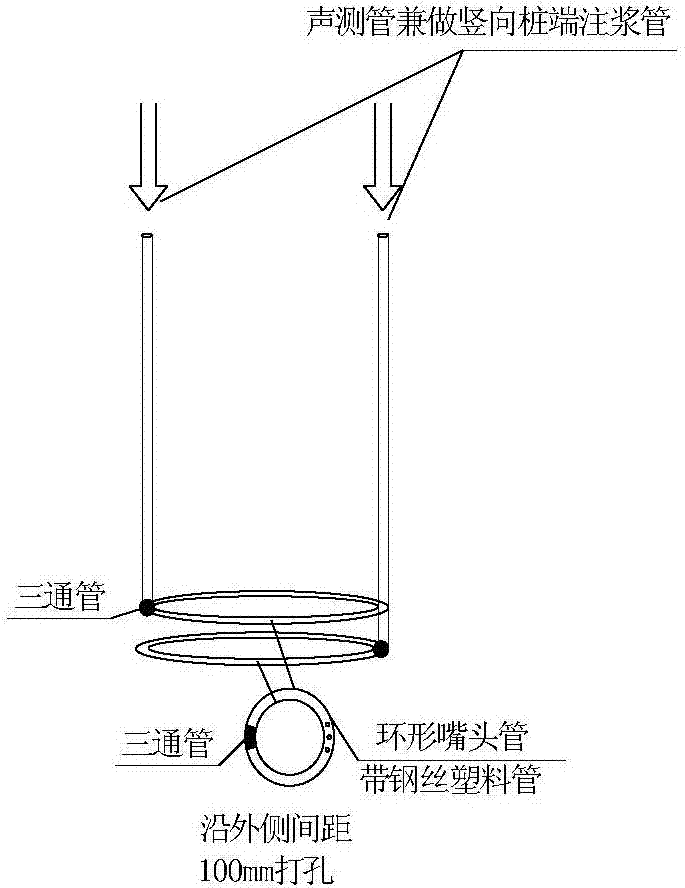

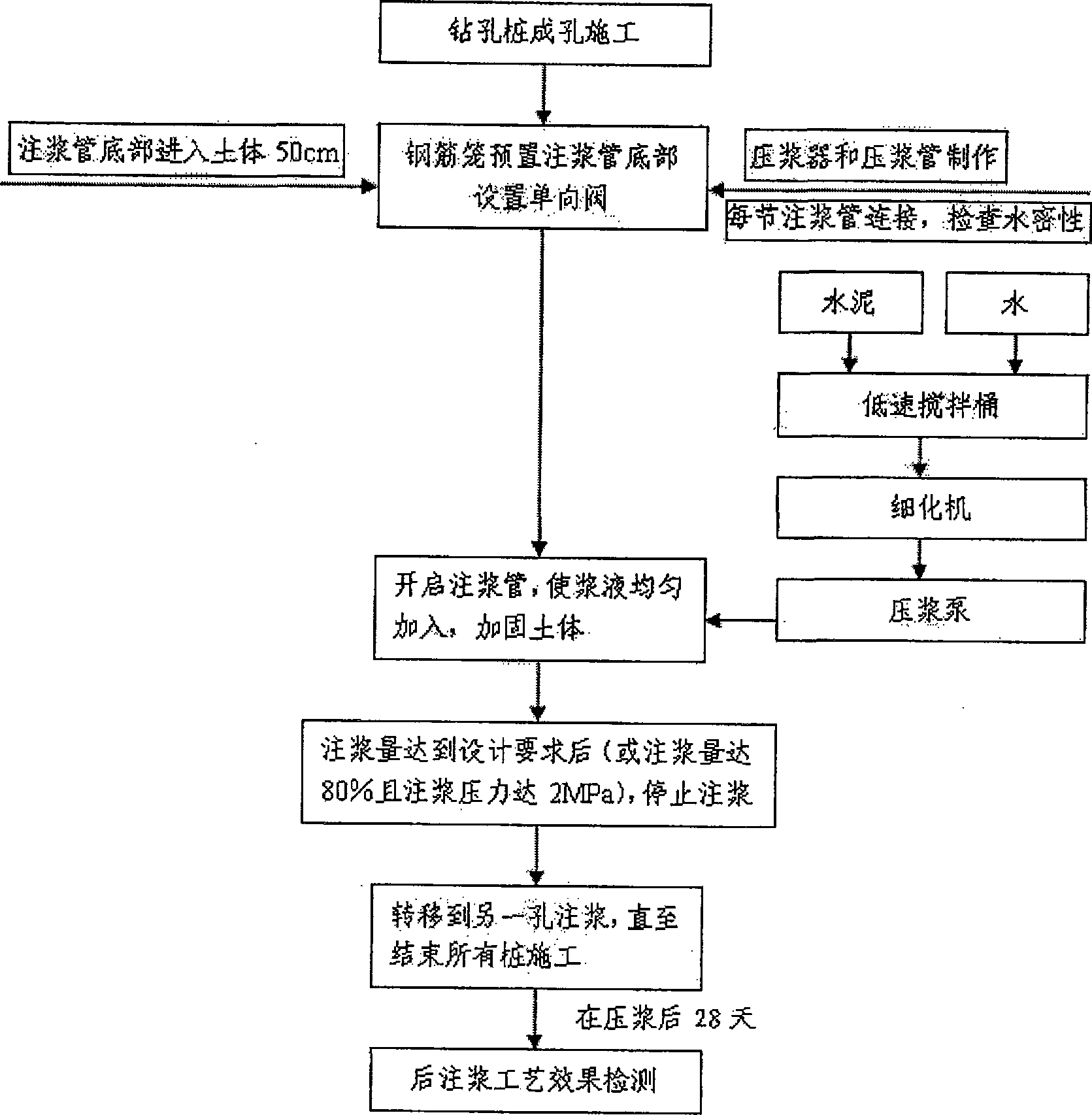

Post-grouting construction method of bridge cast-in-place pile

InactiveCN107513995AHigh structural reliabilityElimination of hidden dangers of mud skinBulkheads/pilesStructural reliabilityPipe water

The invention discloses a post-grouting construction method of a bridge cast-in-place pile. The method comprises the following steps of (1) grouting nozzle manufacturing, (2) grouting pipe installing, (3) grouting pipe water testing and (4) pump-in test and pump-in plug opening. The method has the advantages that the structural reliability of the pile bearing capacity is improved, the method can be used as an effective remedial measure for a cast-in-place pile with quality defect, a grouting pipe can be piled in the pile-forming side for grouting to improve the single-pile bearing capacity, the single-pile bearing capacity of the drilled grouting pile can be improved, and the settlement of pile foundation can be controlled effectively.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

Strengthening soft clay foundation for draining pine piles and construction method of strengthening soft clay foundation

ActiveCN105220680AIncreased undrained shear strengthImprove bearing capacityBulkheads/pilesSoil preservationGeotextileSoft clay

The invention discloses a strengthening soft clay foundation for draining pine piles and a construction method of the strengthening soft clay foundation. A plurality of rows of draining pine piles are pressed into the soft clay foundation. Pine piles are used as core materials of the draining pine piles. Geofabric or geotextile is used for wrapping and serves as a draining structural layer. A horizontal draining sand cushion is arranged on the surface of the soft clay foundation. According to the strengthening soft clay foundation for the draining pine piles and the construction method of the strengthening soft clay foundation, the draining pine piles integrate the draining function and the strengthening function, are particularly suitable for strengthening processing of soft clay foundations of small and medium-sized hydraulic structures and are also suitable for primary strengthening processing of super-soft dredger fill and peat soil foundations, and the draining pine piles can be pulled out to be repeatedly used according to processing timeliness.

Owner:EAST CHINA UNIV OF TECH

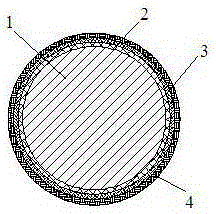

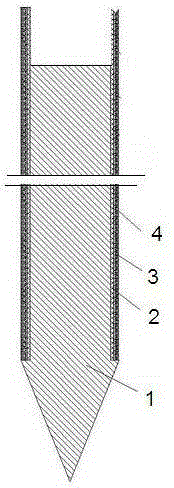

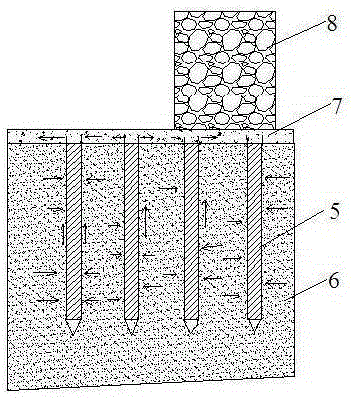

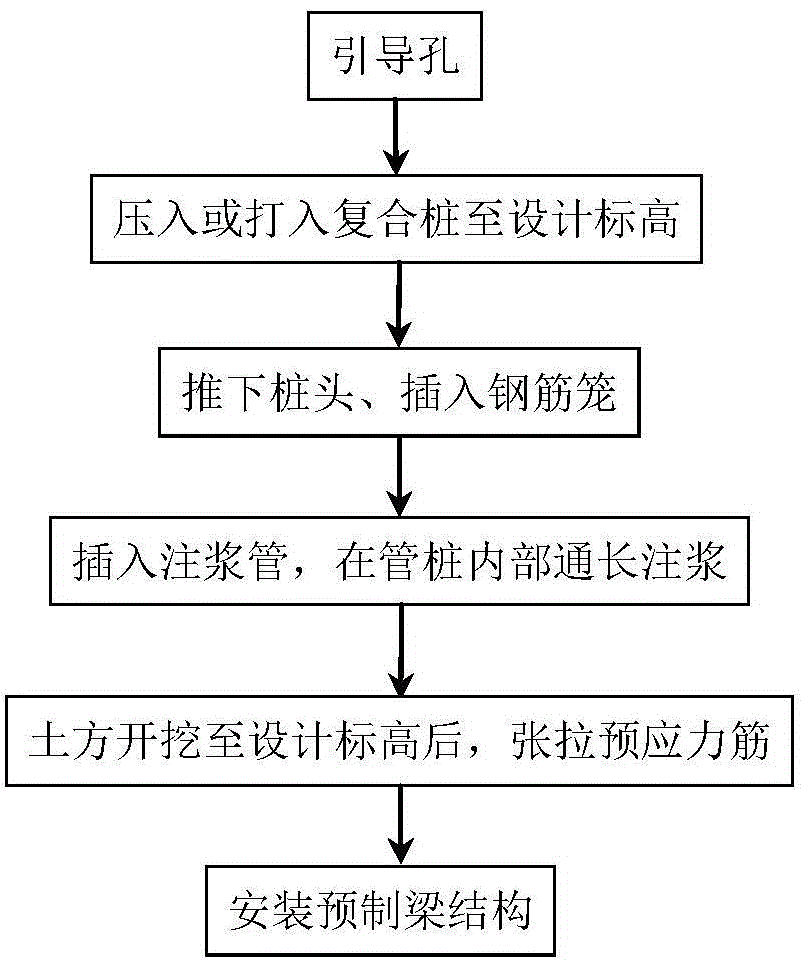

Composite pile structure serving as main structure stand column and construction method thereof

The invention discloses a composite pile structure serving as a main structure stand column and a construction method of the composite pile structure. The composite pile structure comprises a precast pile with brackets, wherein the precast pile is in a sectioned type, a pile head is arranged at the pile bottom of the precast pile, one bracket is arranged on the pile top of the precast pile, a through hole is formed in the center of the precast pile, a reinforcement cage is arranged in the through hole, and the through hole in the center of the precast pile is filled with grouting materials; the composite pile structure is used as the main structure stand column in the later period, the underground portion of the sectioned precast pile is wrapped by the grouting materials, a prestressed pipeline is arranged in the wall of the sectioned precast pile, prestressed reinforcing steel is arranged in the prestressed pipeline, and grouting holes are formed in the wall of the precast pile, and communicated with the through hole in the center of the precast pile. The composite pile structure has the advantages that the technological process such as mud wall protection is omitted, so that the construction cycle is shortened; the composite pile structure can serve as a stress component of a main structure, a load-bearing member does not need to be built again, the cost is saved, and pile formation quality is good; the composite pile structure can effectively solve the problem that hole collapse, hole shrinkage, pile breakage and sandwiching of a cast-in-situ bored pile happen in the construction process, and pile formation quality is guaranteed.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

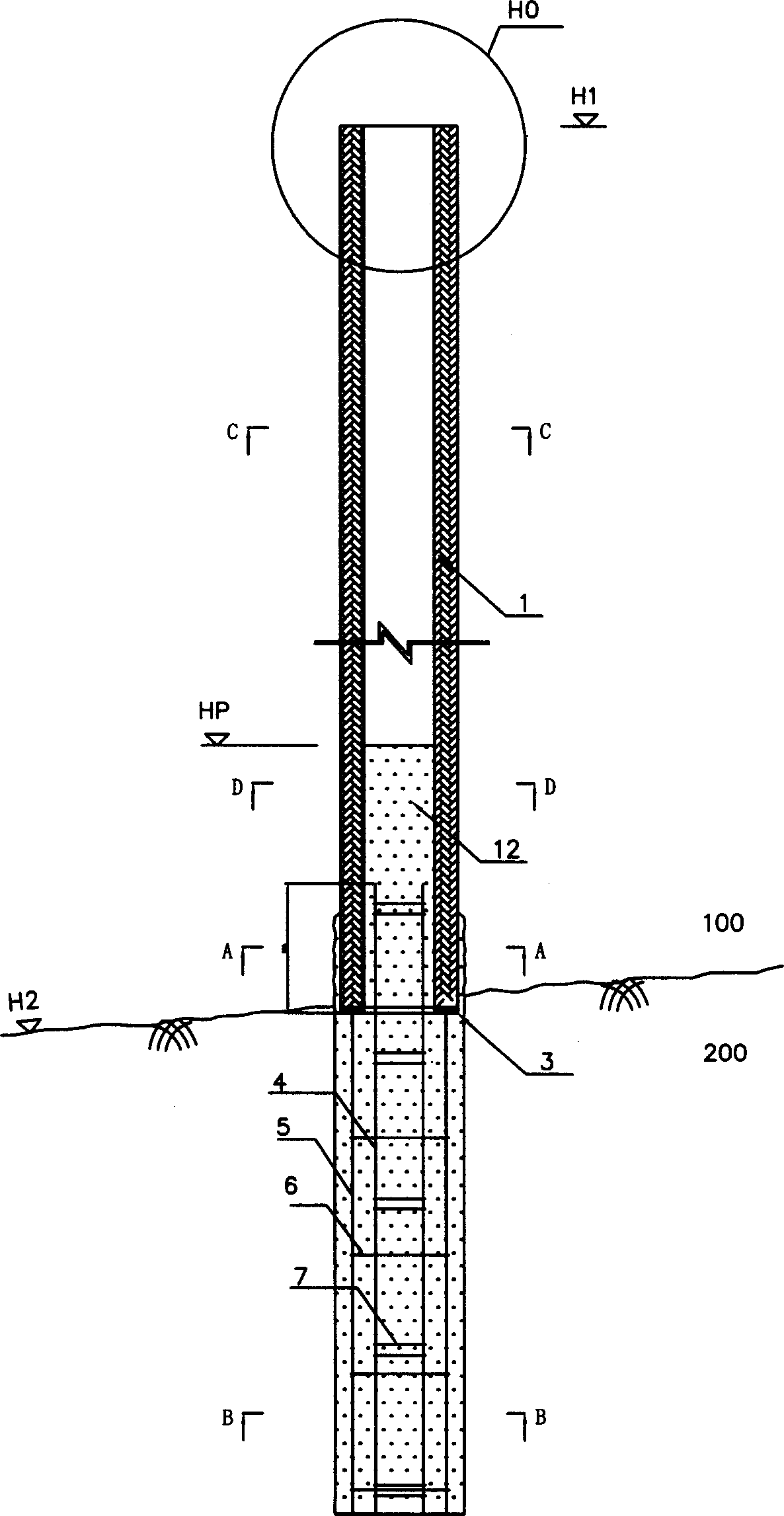

Rock-socketed hollow precast pile and rock-socketed construction method using precast pile

The invention provides a rock-socketed hollow precast pile and a rock-socketed construction method using the precast pile. The precast pile comprises a hollow pile body and a rock-socketed pile tip. The rock-socketed pile tip comprises a steel pipe pile joint section and a big-end-up circular-truncated-cone-shaped pile tip prefabricated by concrete, the steel pipe pile joint section comprises a thin-wall steel pipe, core filling concrete filled in the thin-wall steel pipe and a plurality of stiffening plates welded to the outer wall of the thin-wall steel pipe, and the core filling concrete and the circular-truncated-cone-shaped pile tip are integrally formed in a pouring mode. When rock-socketed construction is carried out, firstly, pile sinking equipment is adopted for sinking a precastpile till drilling footage is difficult, then, a rock core drilling machine is adopted for drilling or crushing plain concrete filling cores at the pile tip part and a hard soil layer and a rock stratum below the pile tip part from the hollow part of a pile body of the hollow precast pile to the designed pile bottom elevation, and a rock-socketed section pile hole is formed; and finally, the forcetransmission framework is put in, cementing materials are injected, and construction of the hollow precast rock-socketed pile is completed.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

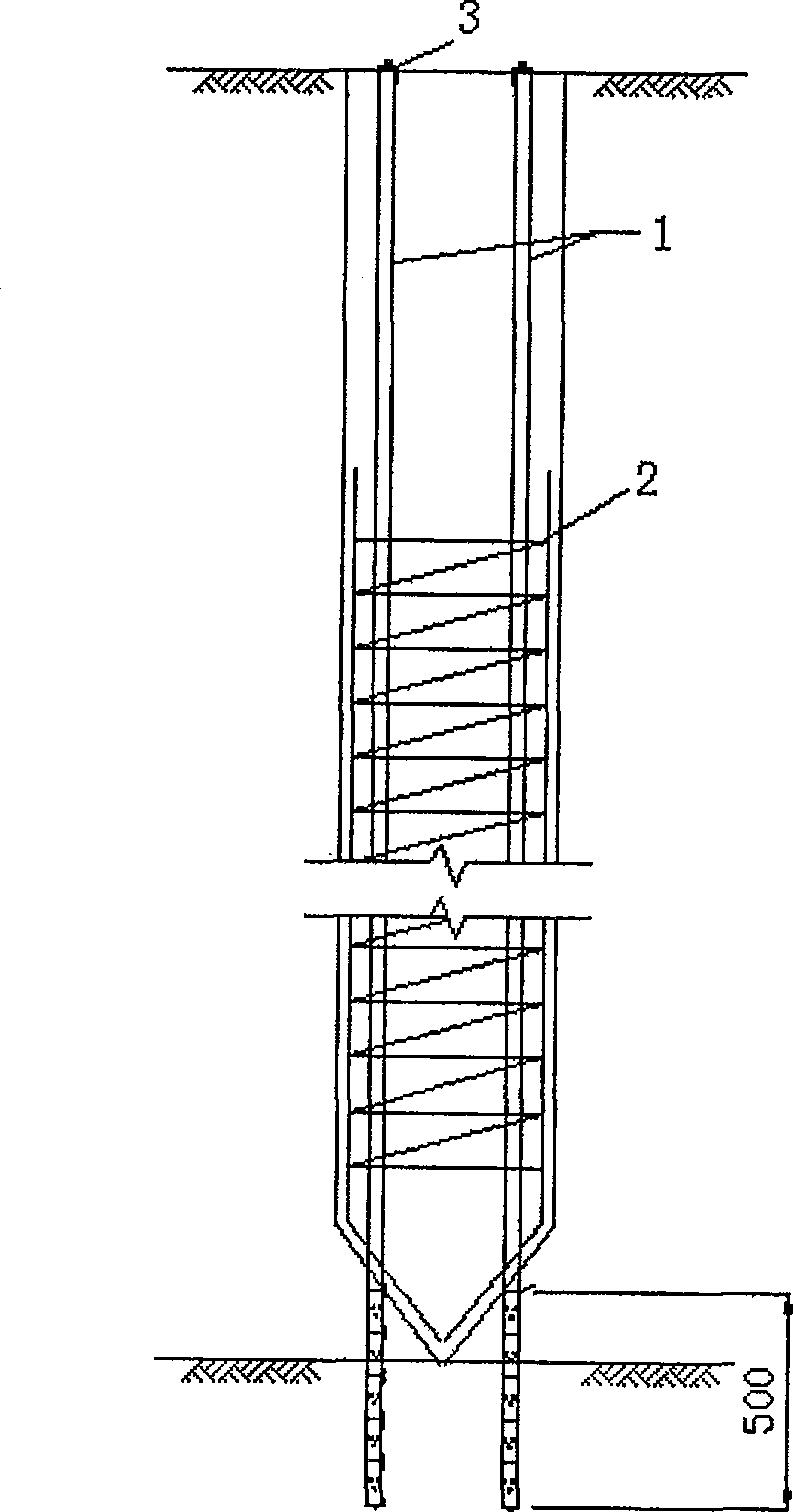

Drilling grout pile end follow-up grouting construction method

The invention relates to a post-grouting construction method for ends of bored cast-in-place piles, in specific to steps as follows: (1) Grouting depth determination and grouting device maunfaucturing; (2) Grout fluid configuration; (3) Grouting. Kernel devices for the invented post-grouting construction method, such as grouting pipelines and etc, are characterized in simple structure and convenient execution; the method can take duplicated reinforcement effects for pile-earth boundary around pile bodies and pile ends in both physical reinforcement and chemical reinforcement; the solidified sludge can take the effect of diameter expansion for the pile ends, so as to change properties of bearing stratums; meanwhile, upwelled grout fluid can solidify the sludge skin around piles, in order to take effects in increasing pile side friction resistance. Since the invented method can well resolves defects in construction of boundaries between cast-in-place piles and earth; unit pile bearing capacity of cast-in-place piles adopting the pile end post-grouting construction method, in soft earth area like Shanghai, is fundamentally improved by 20 percent to 30 percent higher than that of routine cast-in-place piles, and several examples can even reach 70 percent extremely.

Owner:SHANGHAI FOUND ENG GRP

Pile and soil concreted and integrated composite pile and construction method thereof

InactiveCN105484230AImprove weaknessOptimizing the distribution of carrying capacityBulkheads/pilesSoil preservationHigh strength concreteStress distribution

The invention discloses a pile and soil concreted and integrated composite pile and a construction method thereof. The pile and soil concreted and integrated composite pile comprises a peripheral compact soil layer. The compact soil layer is filled with in-site soil and a granular material and curing agent concreted body. The concreted body is integrally provided with a reinforced concrete pile, wherein the reinforced concrete pile and the concreted body are concreted into a whole. According to the pile and soil concreted and integrated composite pile and the construction method thereof, a frequently-used flexible granular material pile, a semi-rigid cemented soil pile, a rigid high-strength concrete pile are constructed in a compositing manner, the composite pile with the complementary strengthening and synergetic bearing functions is formed, the defect of a single pile method is overcome, and the beneficial effects of the single pile method are maintained, quality is reliable, construction is easy and convenient, manufacturing cost is low, the strength, rigidity and density are high, and the pile body size is large, so that the single-pile bearing capacity of the composite pile is high, meanwhile the weak state of soil among piles is improved greatly, and pile and soil bearing capacity distribution and pile body stress distribution are optimized; and the pile and soil concreted and integrated composite pile can be used as a vertical reinforcement body in a composite foundation as well as a single rigid pile with the compression resistance, pulling resistance, leveling resistance and corrosion resistance functions, can be used for foundation pit supporting and diaphragm wall engineering and has the wide application prospects.

Owner:邓亚光

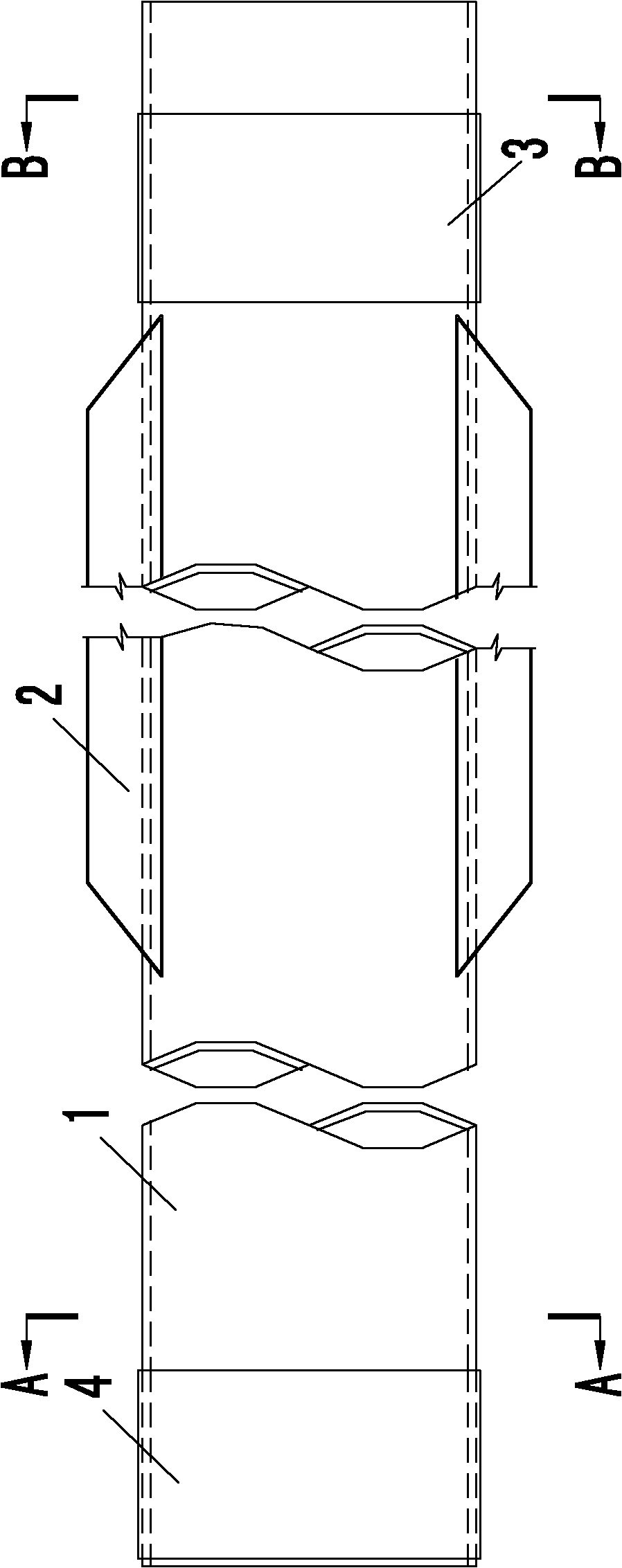

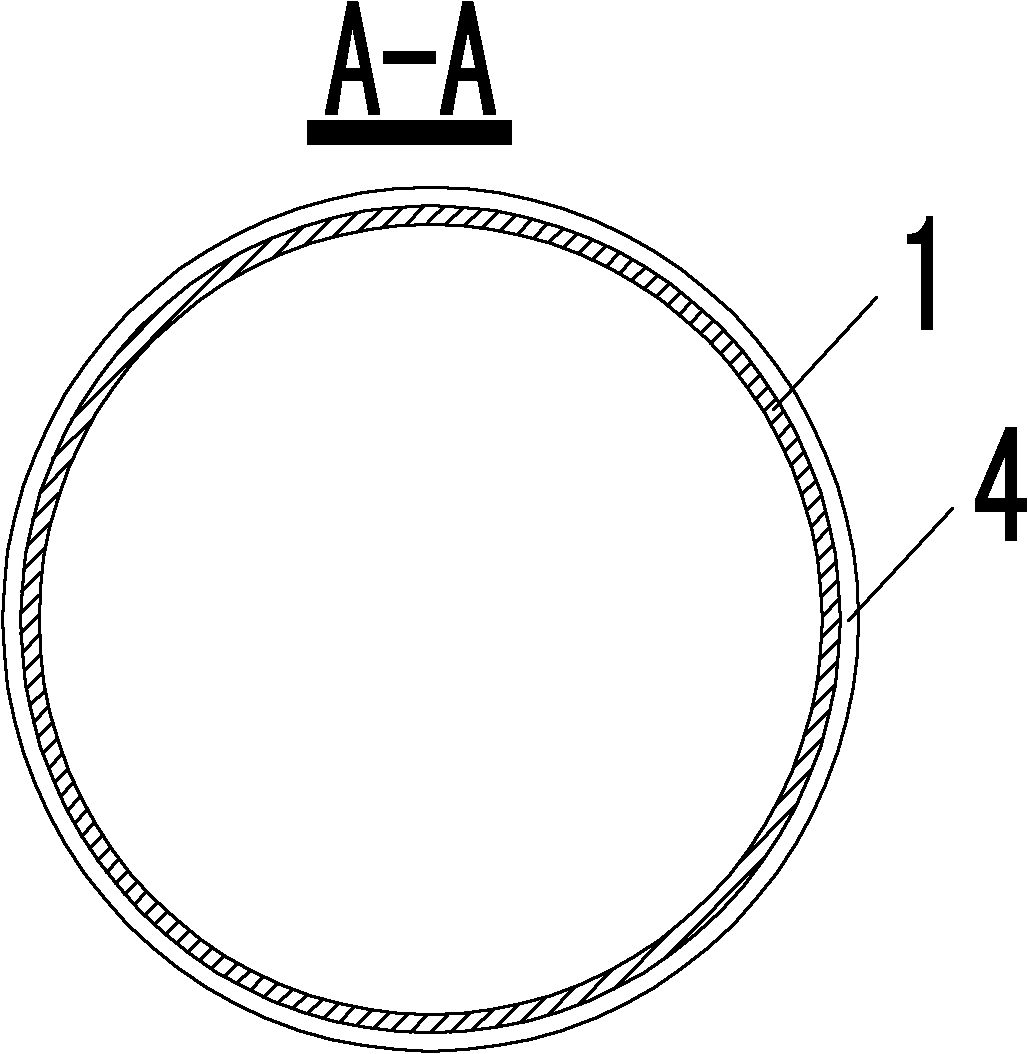

Pile mould for PCC pile and construction method for overlong PCC pile

The invention discloses a pile mould for a PCC pile and a construction method for an overlong PCC pile. The pile mould consists of a feeding section, one or more segments of intermediate sections and a pile tip section which are connected sequentially; the connection among the sections can be disassembled; and inner pipes of the sections at connecting ends are longer than outer pipes, the inner pipes are connected directly at a connecting position, and the outer pipes are connected by outer pipe connecting sections. The construction method for the overlong PCC pile comprises the following steps: firstly, sinking the pile tip section of the pile mould in foundation soil, and then sinking one or more segments of intermediate sections in the foundation soil until the sunk pile mould reaches a designed pile length; and after concrete is poured, pulling out the pile mould in a subsection mode. The construction method overcomes the restriction to the length of the PCC pile, and the pile length of the PCC pile for construction is increased greatly through the connection of the pile mould of each section so as to implement the construction of the overlong PCC pile. The pile mould can adapt to requirements of different pile lengths due to the detachable pile mould, and is convenient to transport; and the sections of the pile mould are simple in connection and convenient in operation.

Owner:HOHAI UNIV

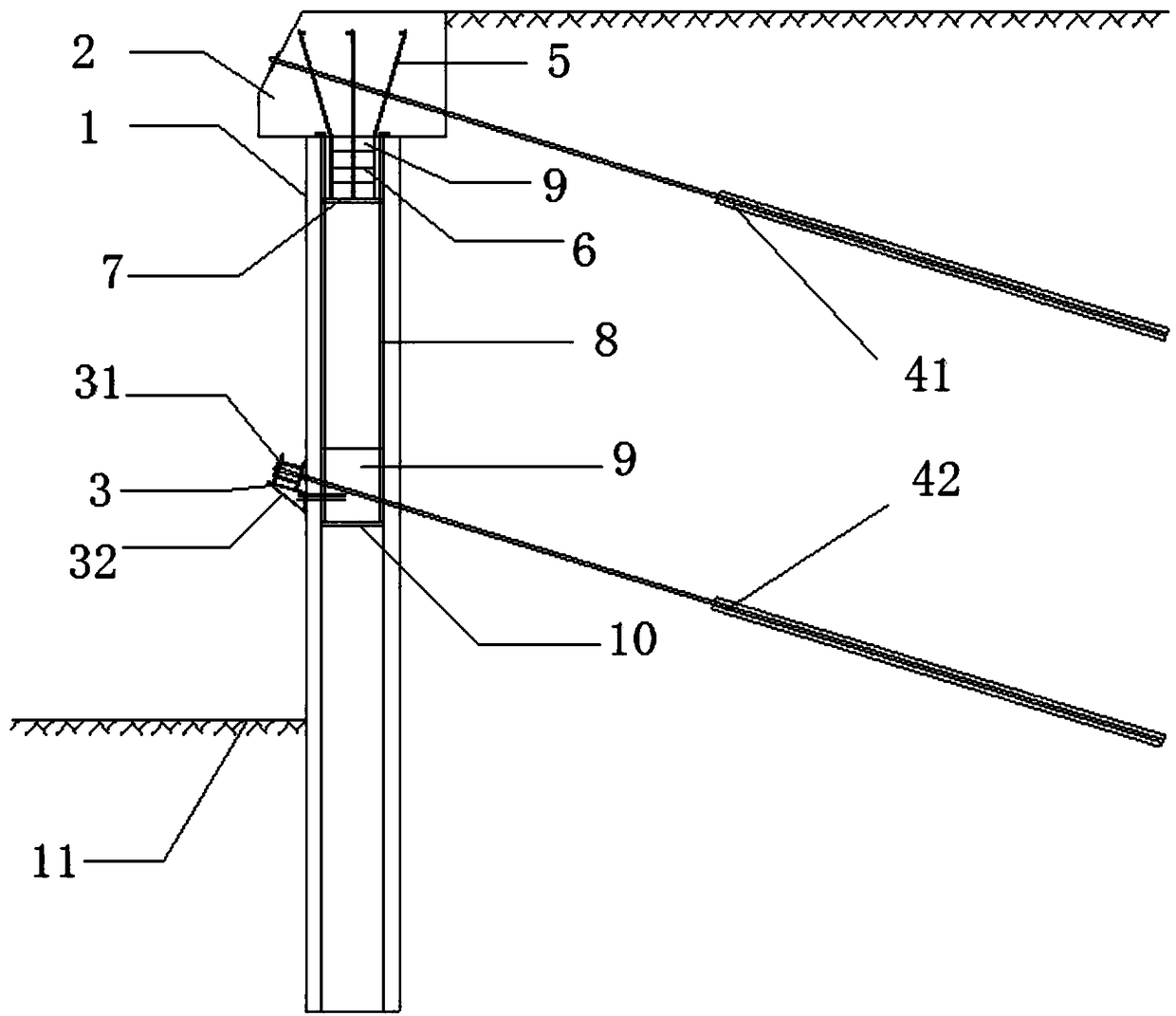

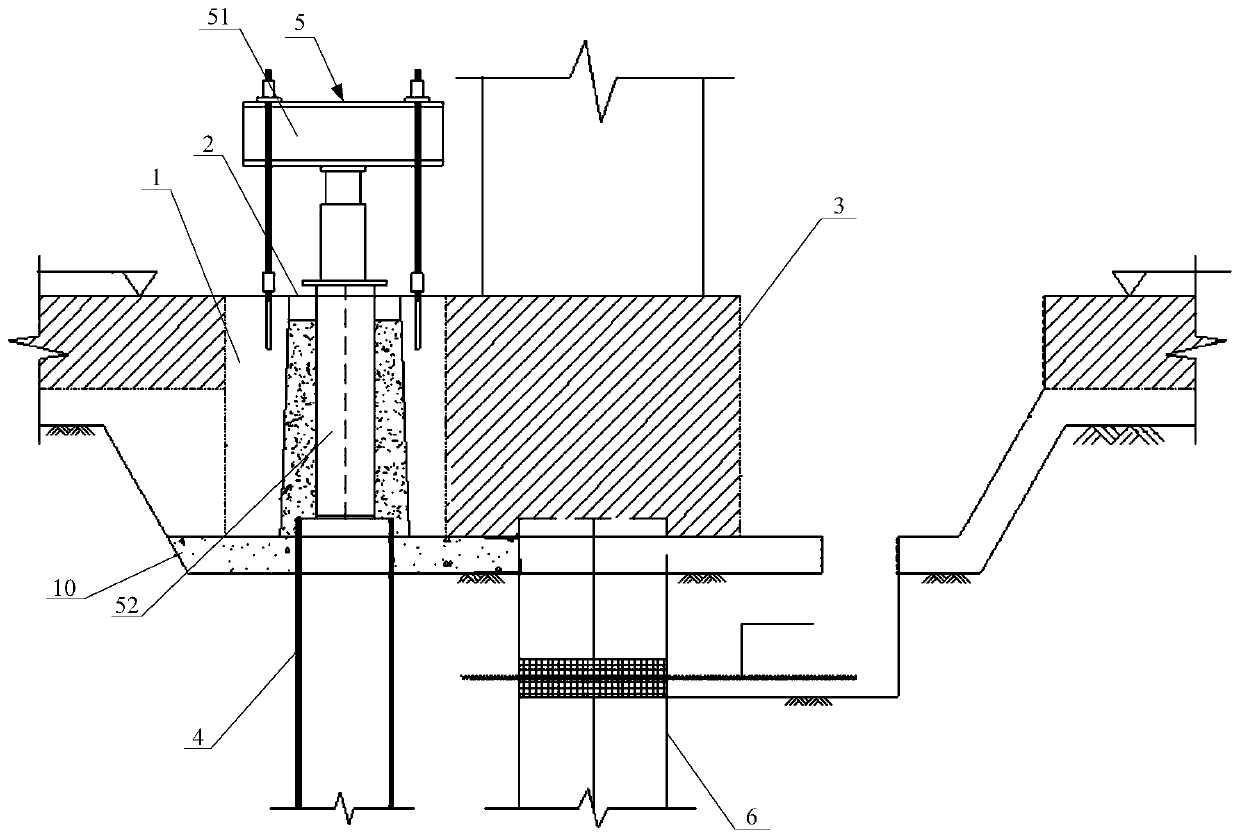

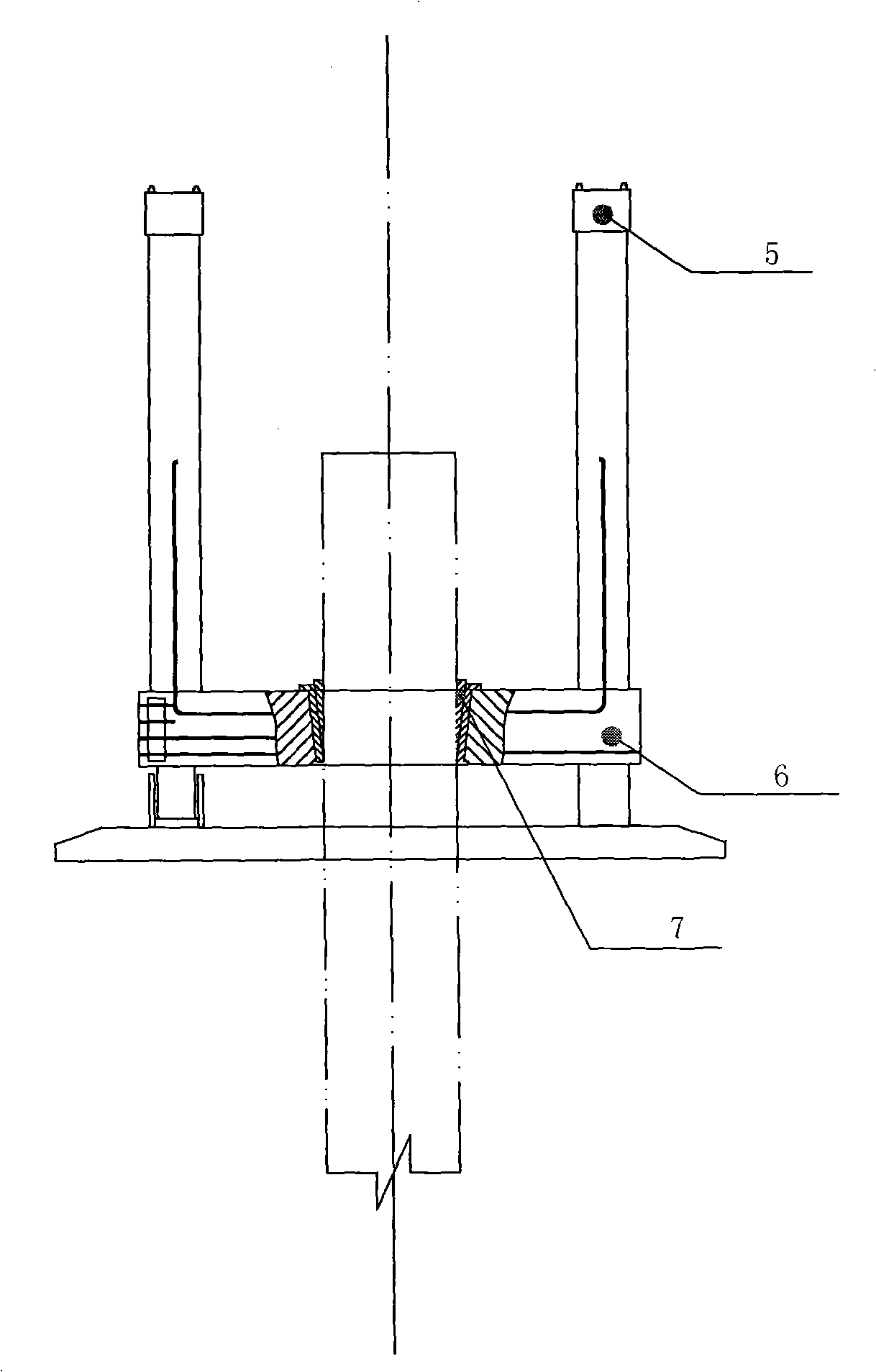

Construction method for row composite piling wall and special hole forming machine

ActiveCN102808406AImprove waterproof performanceAvoid pollutionBulkheads/pilesReinforced concreteArchitectural engineering

The invention discloses a construction method for a soft foundation cast-in-place reinforced concrete row composite piling wall and a special hole forming machine. The special hole forming machine comprises a medium-high frequency vibration hammer, a special clamp device, multiple groups of outer steel pile casings, multiple groups of inner steel pile casings, a reinforced concrete sealing pile tip or multiple steel valve pile tips and a steel hinge chain joint. According to the project for the soft foundation cast-in-place reinforced concrete row composite piling wall provided by the invention, except the single-pile bearing capacity is improved, the integrated sideslip displacement prevention capacity and the waterproof action of a composite foundation are reinforced. According to the project, the construction cost can be reduced by more than 20%, the construction soil discharge quantity is reduced by 50%, the pollution of secondary dredging transportation is avoided, and construction at different weak soil layers and complicated fields can be adapted.

Owner:北京楷泰建设工程有限公司

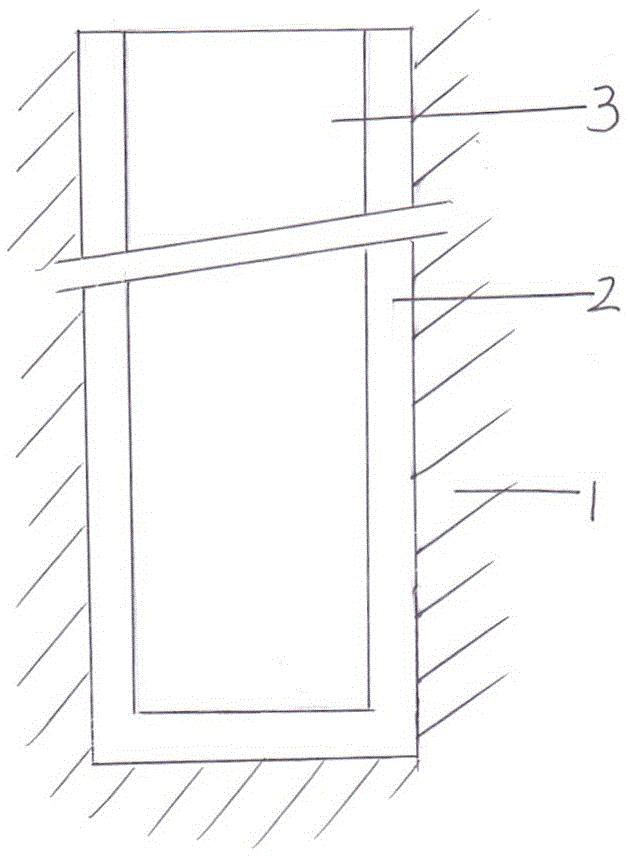

Anti-deformation supporting structure of foundation pit and construction method thereof

PendingCN108360534AImprove stabilityControl deformationExcavationsBulkheads/pilesPre stressBuilding energy

The invention discloses an anti-deformation supporting structure of a foundation pit and a construction method thereof. The anti-deformation supporting structure comprises a plurality of pre-stressedconcrete pipe piles vertically and parallelly arranged around the foundation pit, wherein the pile tops of the two adjacent pre-stressed concrete pipe piles are connected through crown beams; first supporting plates are fixed in the tops of the pre-stressed concrete pipe piles in the radial direction, a plurality of main steel bars are fixed on the first supporting plates through fill core concrete, all the main steel bars are arranged in a circle evenly around the inner walls of the pre-stressed concrete pipe piles, and the main steel bars are connected into a whole through stirrups; each main steel bar is formed by connecting a vertical section and an inclined section, wherein each vertical section is fixed inside each pre-stressed concrete pipe pile and each inclined section is fixed inside each crown beam; and the inclined sections incline toward the outer sides of the pile walls of the pre-stressed concrete pipe piles, and bend inward at the top ends of the pre-stressed concrete pipe piles. The anti-deformation supporting structure can meet the stability requirement of foundation pit deformation in the case of reducing building energy consumption and the use of building materials, the noise and pollution to the environment produced by construction machinery are very little, and construction is green and environment-friendly.

Owner:广西建工集团土木工程有限公司

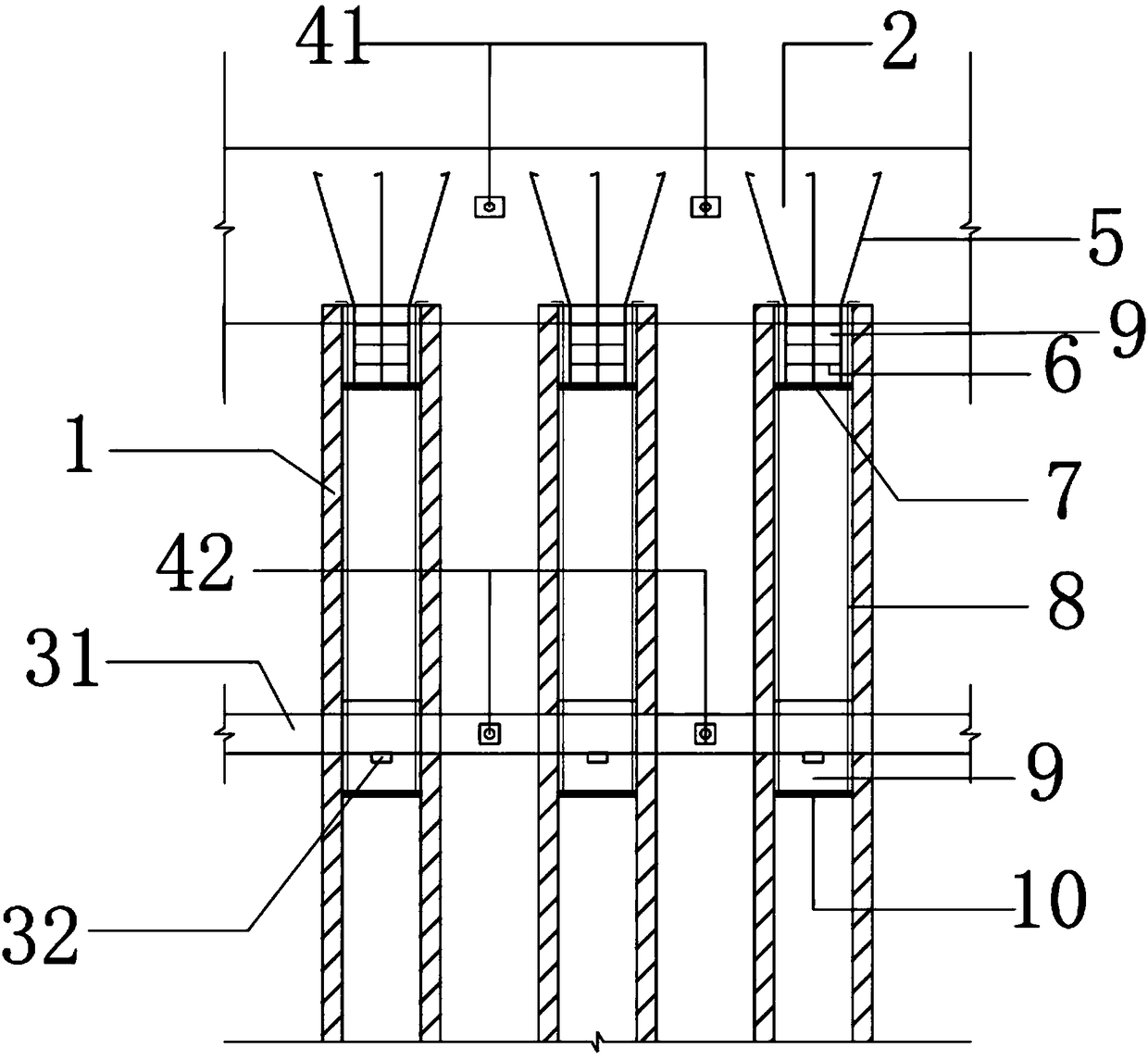

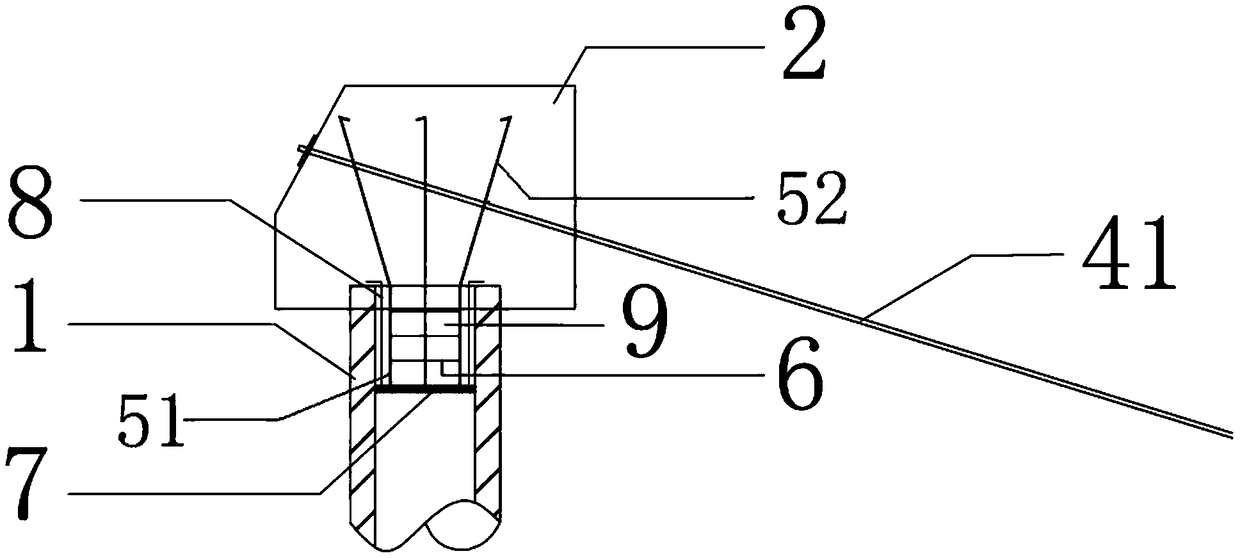

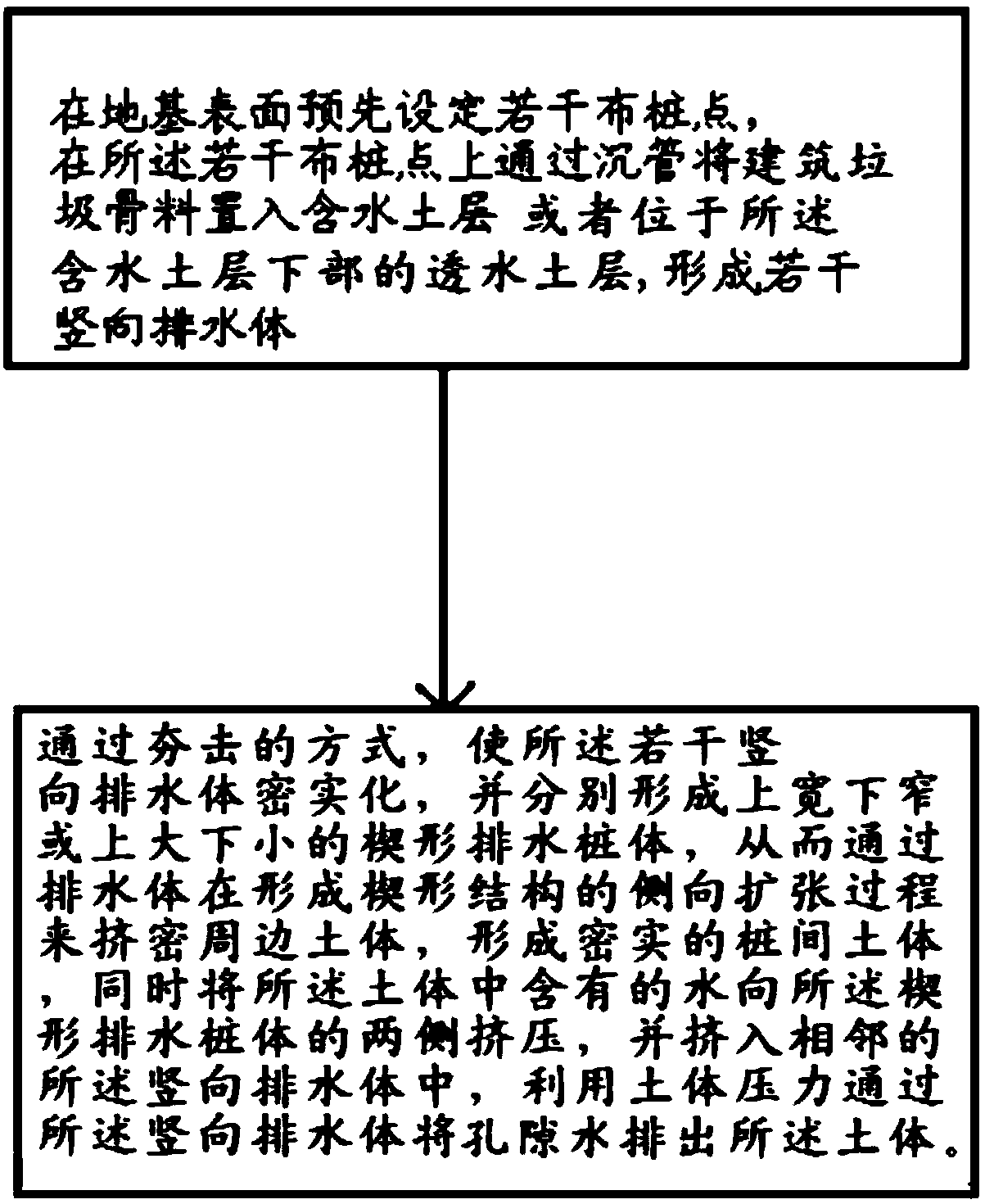

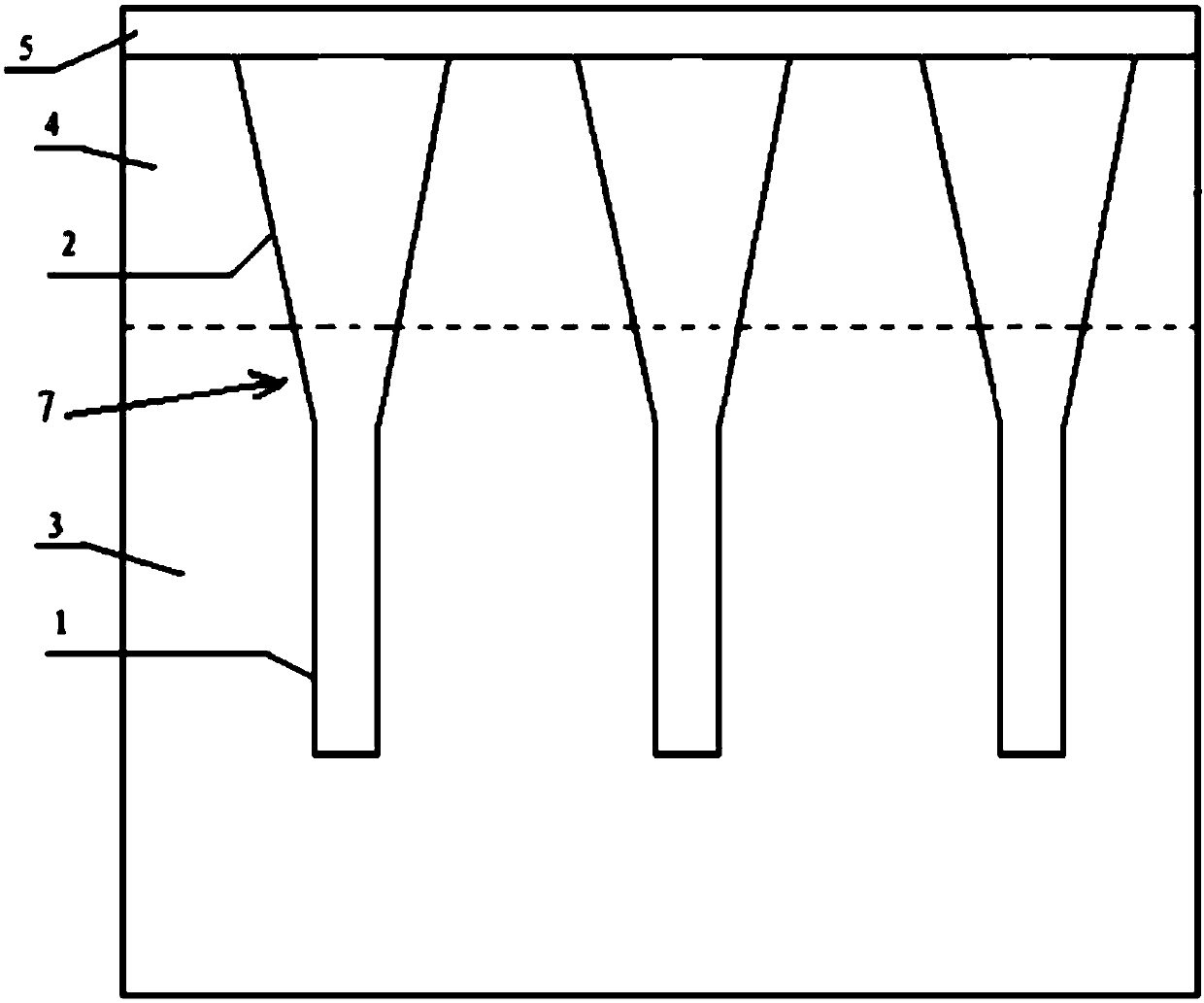

Double consolidated foundation treatment method using construction waste aggregate and composite foundation

InactiveCN108677919AReduce moisture contentImprove bearing capacityBulkheads/pilesSoil preservationEngineeringImmersed tube

The present invention provides a double consolidated foundation treatment method using construction waste aggregate. The double consolidated foundation treatment method using construction waste aggregate comprises the following steps: a. pre-setting a number of pile points on the surface of the foundation, and placing the aggregate into the aquifer or the permeable layer at the lower part of the aquifer through a immersed tube at a plurality of pile points to form a plurality of vertical drainage bodies; b. compacting a plurality of vertical drainage bodies through the way of tamping, and forming a wedge-shaped drainage pile body with wide-top and narrow-bottom or big-top and small-bottom respectively, thereby compacting the periphery soil body by the lateral expansion process of the drainage body forming the wedge-shaped structure, and forming a dense pile-to-pile soil body, at the same time, the water contained in the soil is squeezed to both sides of the wedge-shaped drainage pile body and squeezed into the adjacent vertical drainage body, the pore water is discharged from the soil through the vertical drainage body by the compressive stress of the soil. According to the doubleconsolidated foundation treatment method using construction waste aggregate, the water content of the soil can be greatly reduced in the soft soil with large water content, so as to achieve the characteristics of high bearing capacity, short construction period and low cost. The invention further provides a composite foundation.

Owner:JIANGXI JIYE SCI & TECH

High-polymer gravel permeable rigid pile and its construction technique

InactiveCN108035344AImprove the bearing capacity of single pileShorten the consolidation timeBulkheads/pilesEngineeringHigh polymer

The invention discloses a high-polymer gravel permeable rigid pile and its construction technique. The construction technique includes steps of stirring certain graded gravel grains with a high-molecular polymer at a certain ratio according to the design requirement; after stirring evenly, pouring in a pile hole; gluing the gravel grains to be a whole body by means of the high-molecular polymer.;through proper compaction and vibration, forming a rigid pile while reserving a part of gap between the gravel grains; forming a vesicular structure and arranging reverse filter layers at the outsideand the bottom part of the pile body. The high-polymer gravel permeable rigid pile is simple in construction technique, controllable in quality, short in construction term and low in cost.

Owner:HOHAI UNIV

Novel high-strength concrete for prefabricated reinforced concrete hollow square piles

InactiveCN105347743AImprove the bearing capacity of single pileHigh strengthHigh strength concreteSuperplasticizer

The invention discloses novel high-strength concrete for prefabricated reinforced concrete hollow square piles. The high-strength concrete is composed of the following raw materials in parts by weight: 3 parts of basalt fibers, 2 parts of steel fibers, 4 parts of glass fibers, 100 parts of cement, 90 parts of fly ash, 900 parts of gravels with the particle size of 10-15 mm, 200 parts of gravels with the particle size of 15-20 mm, 800 parts of sand, 130 parts of water, 1.5 parts of an amino-sulfonate high-efficiency water reducing agent, 10 parts of bentonite, 0.5 part of a super plasticizer, 1 part of an air entraining agent, 0.1 part of a defoaming agent, 0.2 part of a rosin soap, 0.05 part of a tackifier, and 0.3 part of calcium stearate. The novel high-strength concrete for the prefabricated reinforced concrete hollow square piles can significantly improve single-pile bearing capacity of the square piles, has the strength improved by 50% or more compared with concrete of the prior art, and can be specially used for the prefabricated reinforced concrete hollow square piles.

Owner:JIANGSU XINGSHA CONSTR ENG GRP

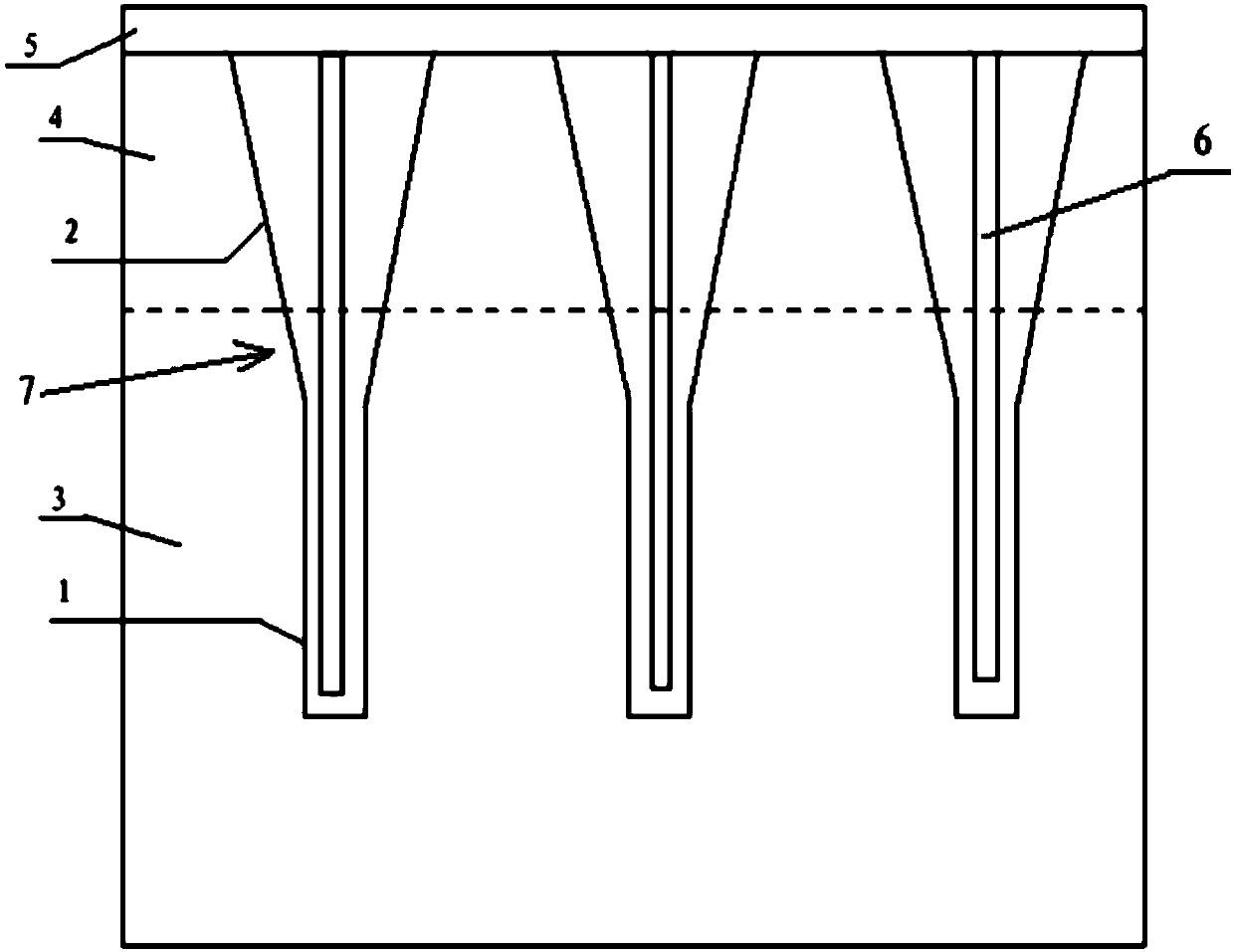

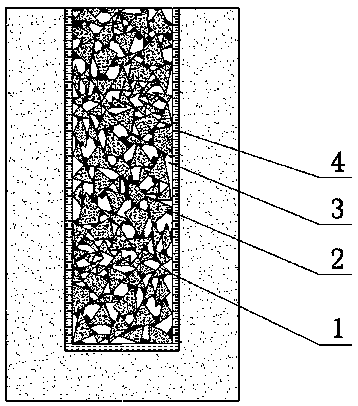

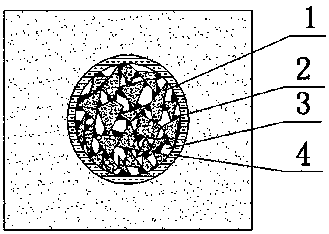

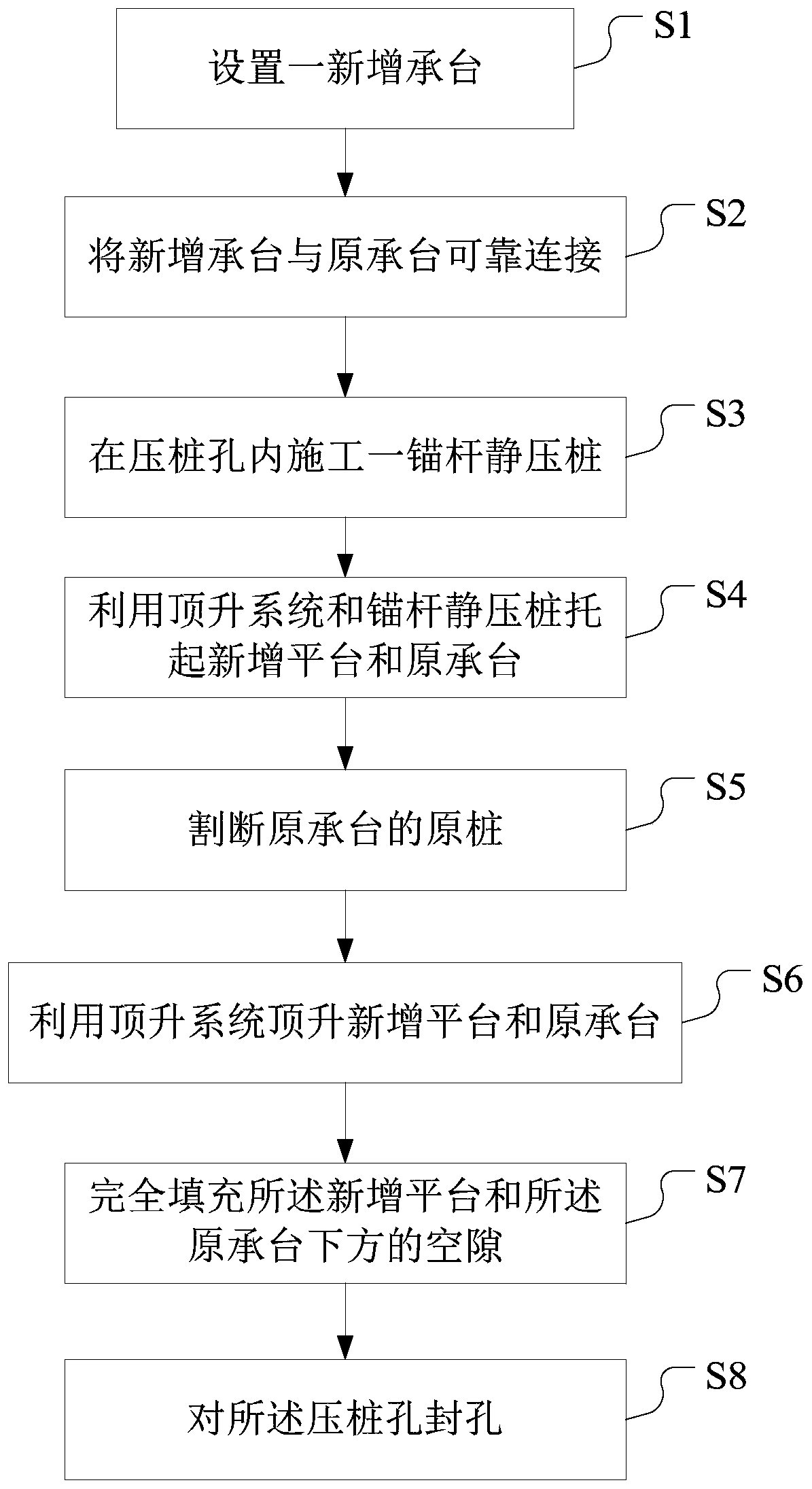

Method for jacking rectification of building

InactiveCN111411650AImprove the bearing capacity of single pileLarge jacking forceFoundation repairBulkheads/pilesRock boltArchitectural engineering

The invention provides a method for jacking rectification of a building. The method includes the following steps that S1, a newly added bearing platform is arranged, the newly added bearing platform reserves a pile pressing hole; S2, the newly added bearing platform is reliably connected with an original bearing platform; S3, an anchor rod static pressure pile is constructed in the pile pressing hole; S4, the newly added platform and the original bearing platform are supported by a jacking system and the anchor rod static pressure pile; S5, an original pile of the original bearing platform iscut off; S6, the newly added platform and the original bearing platform are jacked by the jacking system; S7, a gap below the newly added platform and the original bearing platform is fully filled; and S8, the pile pressing hole is sealed. According to the method for jacking rectification of the building, the damage to the building caused by jacking is reduced, damage to an original structure of the building is not required, and the safety is relatively high.

Owner:SHANGHAI CHANGKAI GEOTECHN ENG

Vertical cement mixing pile forming device and forming construction method

The invention discloses a vertical cement mixing pile forming device and a forming construction method. The forming device comprises a vertical driving rod, a driving device, a vertical outer sleeve sleeving the outer side of the vertical driving rod and a mixing device installed on the lower portion of the vertical driving rod. The outer sleeve is connected with a cement paste pumping device. The mixing device comprises two horizontal driving rods and two groups of mixing impellers which are symmetrically arranged and perform vertical mixing synchronously. The forming construction method comprises a first step of construction preparation, a second step of cement mixing pile construction: a step 201 of drill-down mixing and spouting; a step 202 of lifting mixing and spouting; and a step 203 of pile body forming. The vertical cement mixing pile forming device is reasonable in design, simple and convenient to construct and good in using effect; in the cement mixing pile forming process, the vertical cement mixing pile forming device is favorable for drill-down mixing feeding of a vertical cement mixing pile device, the section of a pile body of a formed cement mixing pile is rectangular, the construction is simple and convenient, and the single cement mixing pile formed by construction has higher bearing capacity.

Owner:SHAANXI ZHUANGXIN CONSTR ENG

Construction method of prestressed pipe pile with vertical water discharge grooves

InactiveCN102392445AIncrease stiffnessImprove the bearing capacity of single pileBulkheads/pilesWater dischargePre stress

The invention particularly relates to a construction method of a prestressed pipe pile with vertical water discharge grooves, and is used for solving the problems in the traditional construction of the prestressed pipe pile, such as sedimentation, bearing capability reduction and pollution to the construction field. The construction method comprises the following steps of a. uniformly distributing water discharge grooves on external circumference of the prestressed pipe pile, and arranging a V-shaped groove between two adjacent water discharge grooves, wherein the V-shaped groove is communicated with the two adjacent water discharge grooves; b. installing a water accumulation protection drum with an opening at the bottom at the insertion position of the prestressed pipe pile, wherein a water guide pipe communicated with the water accumulation protection drum is arranged on sidewall of the water accumulation protection drum and a control valve is arranged on the water guide pipe; c. inserting the prestressed pipe pile along the opening of the water accumulation protection drum, wherein pore water enters the water discharge grooves under the action of pressure, the pore water in the water discharge grooves rises and is discharged through the water guide pipe; and d. installing the water accumulation protection drum to the insertion position of next prestressed pipe pile. The construction method has reasonable and reliable structure design, not only can reduce insertion resistance to improve construction progress rate, but also has good effect of inhibiting sedimentation after construction, and has the advantages of simpleness in structure and easiness in implementation and control.

Owner:CHINA RAILWAY 17 BUREAU GRP NO 6 ENG

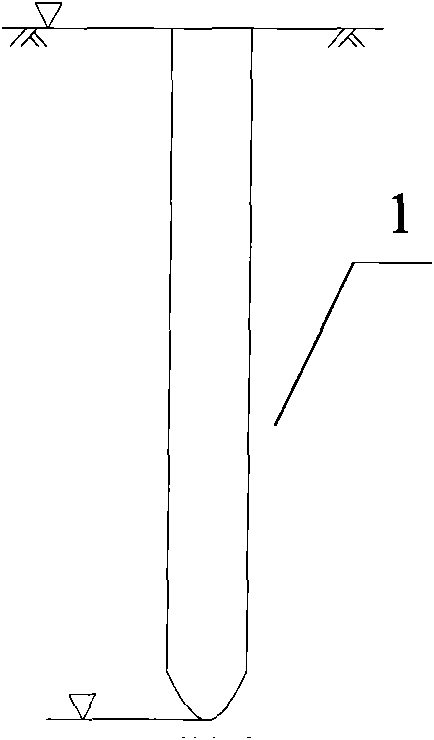

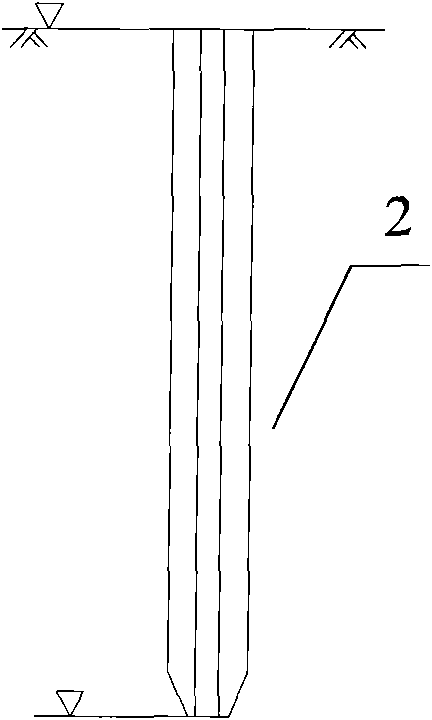

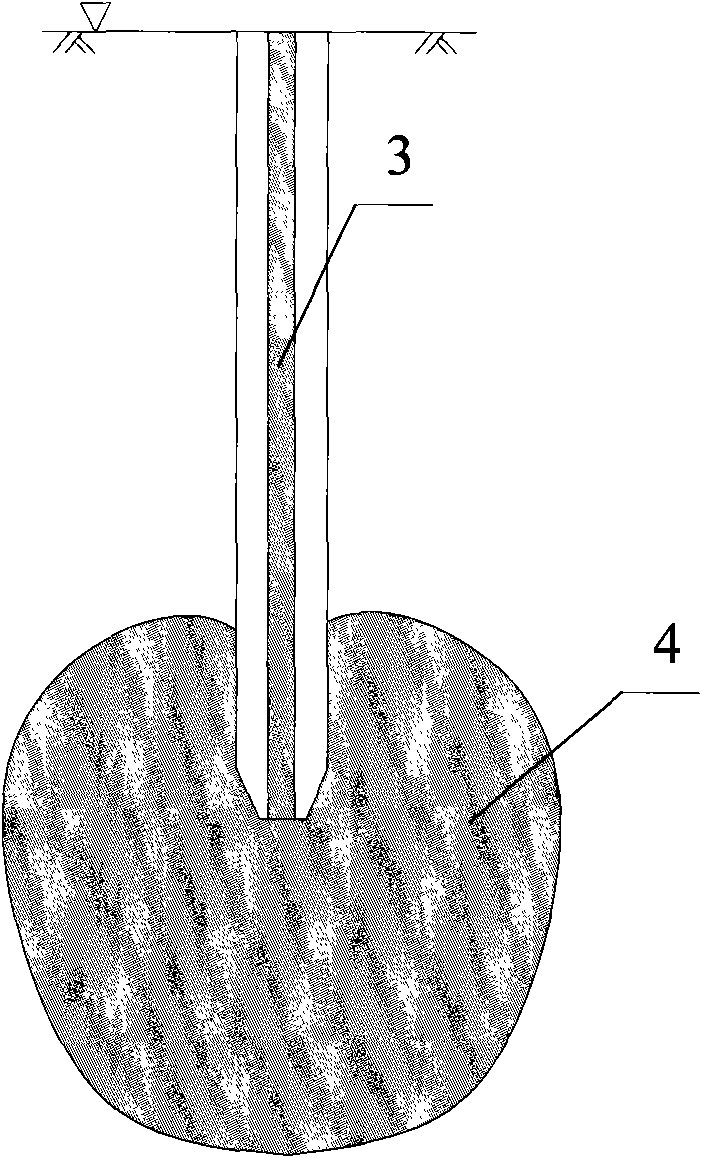

Mechanical pile forming device for base-expanded poured foundation pile and pile forming method thereof

The invention relates to a mechanical pile forming device for a base-expanded poured foundation pile and a pile forming method thereof. The mechanical pile forming device for the base-expanded pouredfoundation pile comprises a powered rotating head providing power for a rotary shaft, a rotating transmission shaft connected below the powered rotating head, a steel pipe protective casing installedon the outer side of the rotating transmission shaft in a sleeving manner and a bottom-expanding drill bit connected to an end of the rotating transmission shaft. The mechanical pile forming method comprises the steps that hole drilling operation of a pile body A of the foundation pile is conducted; the bottom-expanding drill bit goes deep into the hole bottom along the interior of the steel pipeprotective casing, and hole expanding operation is conducted; a pre-lashed pile body steel bar reinforcement cage is fed from top to bottom along the interior of the steel pipe protective casing; foundation pile concrete is poured, and meanwhile, the steel pipe protective casing is elevated; and base-expanded poured foundation pile construction is conducted, and the base-expanded end B of the base-expanded poured foundation pile is formed below the pile body A of the foundation pile. The mechanical pile forming device for the base-expanded poured foundation pile has the advantages that the influence of underground water on pile forming is obstructed, the pile forming quality of the base-expanded poured foundation pile is improved, the foundation construction cost of projects is lowered, and construction efficiency is high.

Owner:范茂丰 +1

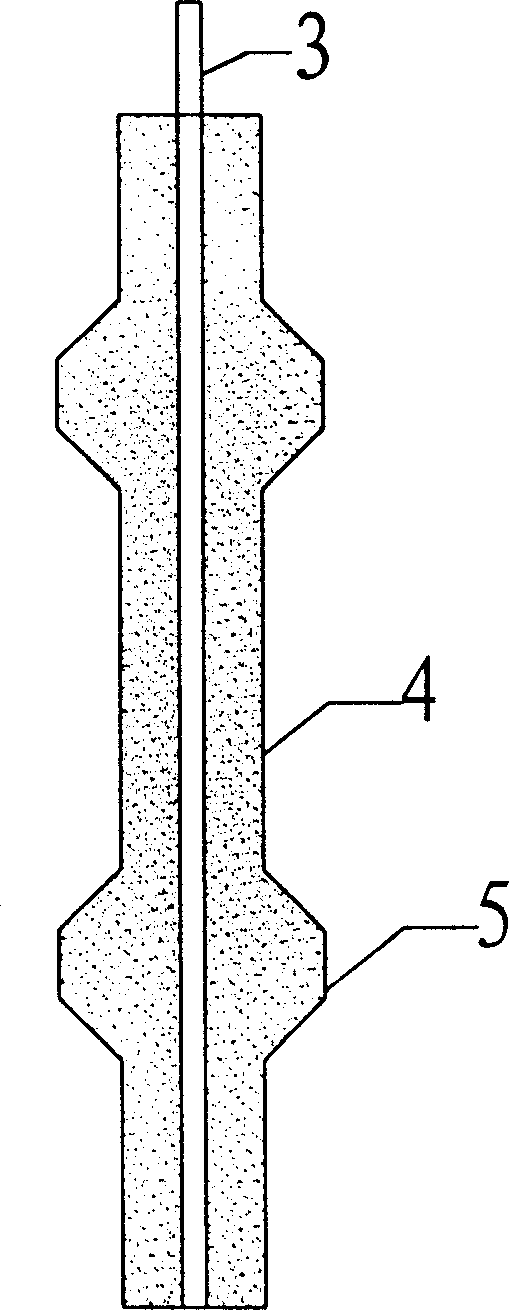

Preset stiff core rammed concrete pile and its construction method

InactiveCN1322204CImprove the bearing capacity of single pileImprove bearing capacityBulkheads/pilesReinforced concreteSoil cement

The present invention discloses a preset stiff core rammed soil-cement pile and its construction method. It includes rammed soil-cement pile, and in the pile body interior of rammed soil-cement pile a stiff core pile is set, and the pile length of said stiff core pile is greater than or equal to 2 / 3 of the preset stiff core rammed soil-cement pile length. The material of pile body of stiff core pile is plain concrete or reinforced concrete. Said invention also provides the steps of said construction method.

Owner:TIANJIN UNIV

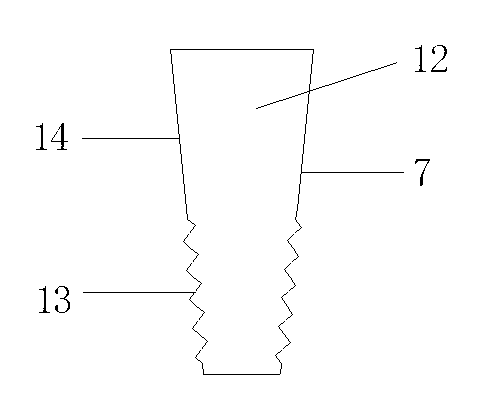

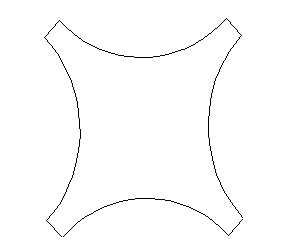

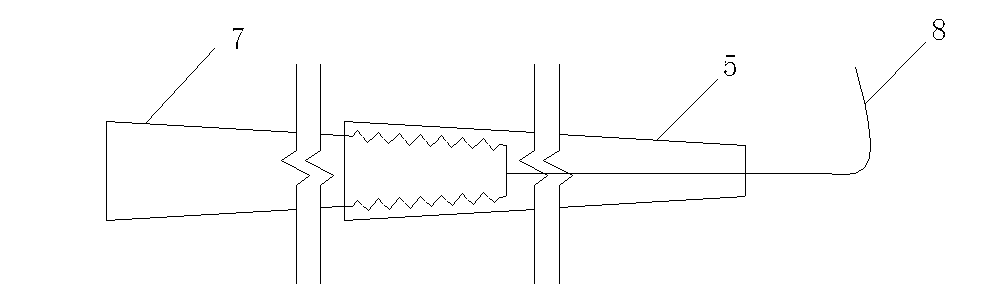

Cast-in-place X-shaped tapered pile with threaded end and construction method of tapered pile

InactiveCN102839654AReduce dosageLarge specific surface areaBulkheads/pilesOperabilityUltimate tensile strength

The invention provides a cast-in-place X-shaped tapered pile with a threaded end, which comprises a plastic casing and a pile body filled in a cavity of the plastic casing. The cross section of the pile body is X-shaped. The sectional area of the pile body is decreased gradually from the top down, and the pile body is in an inverted cone shape longitudinally. A threaded casing wall is arranged at the lower end of a casing wall of the plastic casing. The invention further provides a construction method of the cast-in-place X-shaped tapered pile with the threaded end. With the adoption of the cast-in-place X-shaped tapered pile with the threaded end, the usage of concrete is saved obviously, the unit material strength utilization ratio is increased, positive frictional resistance on the side of the pile is increased significantly, and the effect of negative frictional resistance on a pile foundation is eliminated to a greater extent. Furthermore, the construction process is simple, the operability is high, the construction indentation efficiency is high, and the bearing capacity of a single pile is high.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Construction method drive type major diameter steel pipe pore-creating filling pile

InactiveCN101324066ASafe and reliable structureImprove the bearing capacity of single pileBulkheads/pilesSteel tubeRebar

The invention relates to the field of building construction, in particular to a construction method used for punching-typed large-diameter steel pipe hole-forming pouring piles, comprising the steps as follows: step 1: hole forming: the large steel pipe with the external diameter of 800-2000mm is adopted for hole-forming; step 2: reinforced cages-arranging: the reinforced cages are arranged inside the large steel pipes; step 3: pouring: concrete is poured into the hole of the reinforced cage after the installation is complete, simultaneously, the hole-forming large steel pipe is pulled out and the pile is formed. The pouring pipe construction method of the invention can replace the construction of manpower excavating pile and the mechanical hole-forming slurry wall-protection pouring pipe with large diameter, and has the obvious advantages of safe structure, greatly improving the bearing capability of single pile, environmental protection in-situ, safe construction, reducing the construction links and saving the engineering cost, etc., compared with the traditional mechanical boring pouring and manpower excavation pouring pipes.

Owner:DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

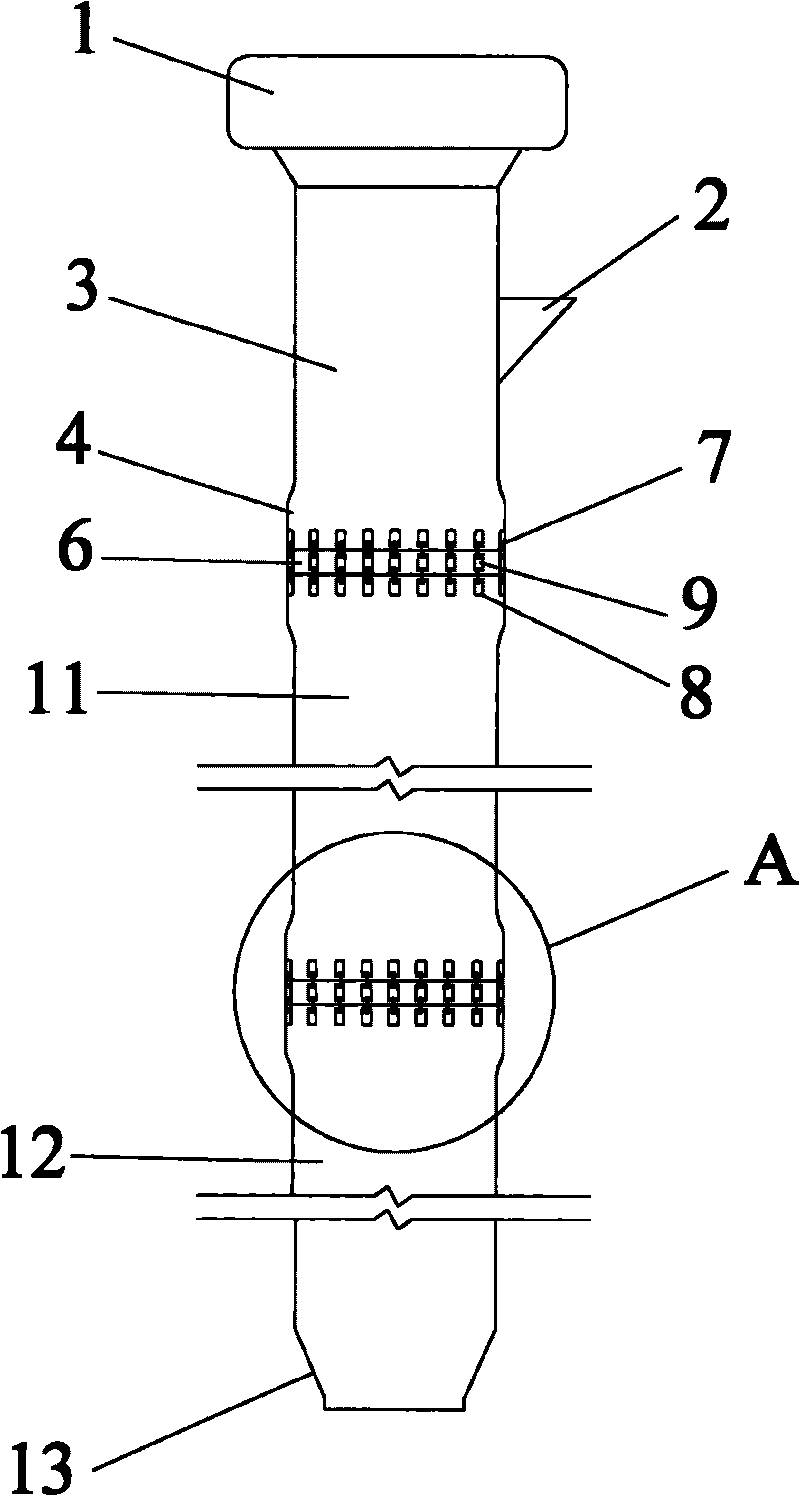

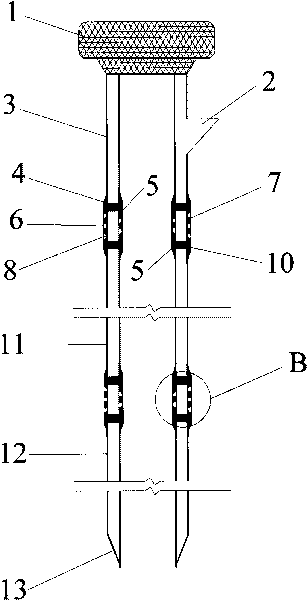

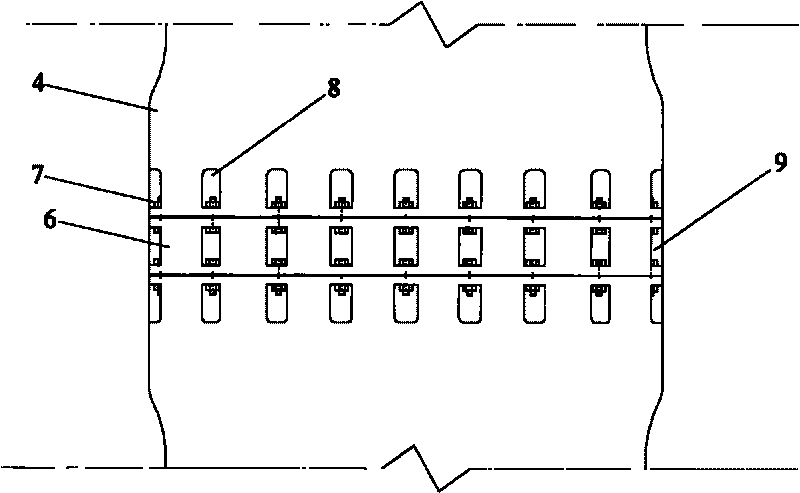

System for grouting pile side sealing and pile tip extrusion grouting of cast-in-place pile and construction method thereof

The invention relates to a cast-in-place pile side slurry sealing and pile end extrusion grouting system and a construction method thereof.The cast-in-place pile side slurry sealing and pile end extrusion grouting system comprises a pile side slurry sealing device and a pile end extrusion grouting device, and the pile side slurry sealing device is arranged on the outer side face of a reinforcement cage of a cast-in-place pile; the upper end face of the pile end extrusion grouting device is fixedly connected with the bottom end of the reinforcement cage, the lower end face of the pile end extrusion grouting device abuts against pile bottom sediment in the sinking process of the reinforcement cage, and the pile bottom sediment is axially and downwards pushed, compacted and compacted through the pile end extrusion grouting device; the pile side slurry sealing device forms a pile side slurry sealing section on the outer side of the reinforcement cage after slurry jacking, high-pressure grouting is conducted on the pile end of the cast-in-place pile and the pile side range below the pile side slurry sealing section through the pile end extrusion grouting device, and grouting reinforcing layers are formed on the pile bottom face and the pile side face. The method has the advantages that the construction process is simple, the flowing direction and the diffusion range of grout injected into the pile end and the pile side can be quantitatively and controllably controlled, then the single-pile bearing capacity of the cast-in-place pile can be greatly improved, and the settlement amount of a foundation pile is reduced.

Owner:浙江坤德创新岩土工程有限公司

Rock engaged combined pile and its construction method

Owner:LIJI ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com